assets

1OQRNnt

1OQRNnt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

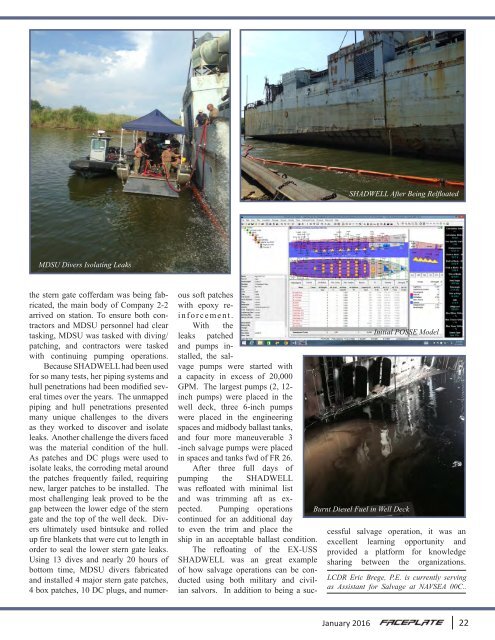

SHADWELL After Being Relfloated<br />

MDSU Divers Isolating Leaks<br />

the stern gate cofferdam was being fabricated,<br />

the main body of Company 2-2<br />

arrived on station. To ensure both contractors<br />

and MDSU personnel had clear<br />

tasking, MDSU was tasked with diving/<br />

patching, and contractors were tasked<br />

with continuing pumping operations.<br />

Because SHADWELL had been used<br />

for so many tests, her piping systems and<br />

hull penetrations had been modified several<br />

times over the years. The unmapped<br />

piping and hull penetrations presented<br />

many unique challenges to the divers<br />

as they worked to discover and isolate<br />

leaks. Another challenge the divers faced<br />

was the material condition of the hull.<br />

As patches and DC plugs were used to<br />

isolate leaks, the corroding metal around<br />

the patches frequently failed, requiring<br />

new, larger patches to be installed. The<br />

most challenging leak proved to be the<br />

gap between the lower edge of the stern<br />

gate and the top of the well deck. Divers<br />

ultimately used bintsuke and rolled<br />

up fire blankets that were cut to length in<br />

order to seal the lower stern gate leaks.<br />

Using 13 dives and nearly 20 hours of<br />

bottom time, MDSU divers fabricated<br />

and installed 4 major stern gate patches,<br />

4 box patches, 10 DC plugs, and numer-<br />

Initial POSSE Model<br />

Burnt Diesel Fuel in Well Deck<br />

ous soft patches<br />

with epoxy reinforcement.<br />

With the<br />

leaks patched<br />

and pumps installed,<br />

the salvage<br />

pumps were started with<br />

a capacity in excess of 20,000<br />

GPM. The largest pumps (2, 12-<br />

inch pumps) were placed in the<br />

well deck, three 6-inch pumps<br />

were placed in the engineering<br />

spaces and midbody ballast tanks,<br />

and four more maneuverable 3<br />

-inch salvage pumps were placed<br />

in spaces and tanks fwd of FR 26.<br />

After three full days of<br />

pumping the SHADWELL<br />

was refloated with minimal list<br />

and was trimming aft as expected.<br />

Pumping operations<br />

continued for an additional day<br />

to even the trim and place the<br />

ship in an acceptable ballast condition.<br />

The refloating of the EX-USS<br />

SHADWELL was an great example<br />

of how salvage operations can be conducted<br />

using both military and civilian<br />

salvors. In addition to being a successful<br />

salvage operation, it was an<br />

excellent learning opportunity and<br />

provided a platform for knowledge<br />

sharing between the organizations.<br />

LCDR Eric Brege, P.E. is currently serving<br />

as Assistant for Salvage at NAVSEA 00C..<br />

January 2016 22