WNIP Mar Apr 19.2 Digital

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

<strong>19.2</strong><br />

W GENERATION microScan3: microScan3: A OF NEW SAFETY GENERATION LASER OF A SAFETY NEW SCANNERS.<br />

LASER GENERATIO<br />

appens when SICK, the market leader What happens for safety when SICK, sensors, the market brings leader for together safety What sensors, its happens brings comprehensive together its comprehensive when knowledge,<br />

SICK, the marke<br />

ive experience, and cumulative innovative extensive experience, strength and cumulative in a new innovative safety strength extensive laser in scanner? a new safety laser experience, The scanner? answer The is answer easy: is and easy: cumulativ<br />

roScan3 – setting a new standard the for microScan3 the safety – setting and a new productivity standard for the of safety the your and microScan3 productivity applications. of your applications. Every – single Every setting single detail detail a new stan<br />

en carefully thought out to provide has the been best carefully possible thought out solution to provide the for best your has possible requirements solution been for your carefully where requirements the where protection thought the out to pro<br />

hines and systems is concerned. Innovative of machines and scan systems technology, is concerned. Innovative rugged of scan design, machines technology, intelligent rugged design, and connectivity, intelligent systems connectivity, and and is concern<br />

e operation are characteristics that intuitive can't operation fail to are impress characteristics at that fi rst can't glance fail intuitive to impress and will at fi rst keep glance operation and on will inspiring keep on inspiring are you time you characteristics<br />

time<br />

e again. We think that’s intelligent. and www.sick.com/microScan3<br />

time again. We think that’s intelligent. www.sick.com/microScan3 and time again. We think that’s intell

2<br />

<strong>19.2</strong><br />

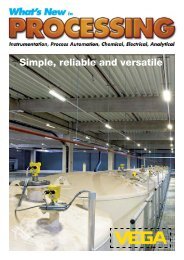

The ultimate for<br />

small tanks!<br />

The future is 80 GHz: a new generation<br />

of radar level sensors<br />

When it comes to contactless level measurement of liquids in<br />

small containers, smaller is better. With the smallest antenna of<br />

its kind, VEGAPULS 64 is simply the greatest! With its excellent<br />

focusing and insensitivity to condensation or buildup, this new<br />

radar sensor is truly exceptional. Simply world-class!<br />

www.vega.com/radar

_en.indd 1 Anzeige_microScan3_A4_4c_201510_en.indd 1 1 18.02.2016 18.02.2016 17:37:46<br />

18.02.2016 17:37:46<br />

1<br />

19.1<br />

3<br />

On the Cover...<br />

<strong>19.2</strong><br />

A new age couldn’t get off<br />

to a safer start<br />

n3: A NEW GENERATION microScan3: microScan3: A OF NEW SAFETY GENERATION LASER OF A SAFETY NEW SCANNERS.<br />

LASER GENERATION OF SAFETY LASER SCANNERS.<br />

What happens when SICK, the market leader What happens for safety when SICK, sensors, the market brings leader for together safety What sensors, its happens brings comprehensive together its comprehensive when knowledge,<br />

SICK, the market leader for safety sensors, brings together its comprehensive knowledge,<br />

extensive experience, and cumulative innovative extensive experience, strength and cumulative in a new innovative safety strength extensive laser in scanner? a new safety laser experience, The scanner? answer The is answer easy: is and easy: cumulative innovative strength in a new safety laser scanner? The answer is easy:<br />

the microScan3 – setting a new standard the for microScan3 the safety – setting and a new productivity standard for the of safety the your and microScan3 productivity applications. of your applications. Every – single Every setting single detail detail a new standard for the safety and productivity of your applications. Every single detail<br />

has been carefully thought out to provide has the been best carefully possible thought out solution to provide the for best your has possible requirements solution been for your carefully where requirements the where protection thought the out to provide the best possible solution for your requirements where the protection<br />

of machines and systems is concerned. Innovative of machines and scan systems technology, is concerned. Innovative rugged of scan design, machines technology, intelligent rugged design, and connectivity, intelligent systems connectivity, and and is concerned. Innovative scan technology, rugged design, intelligent connectivity, and<br />

intuitive operation are characteristics that intuitive can't operation fail to are impress characteristics at that fi rst can't glance fail intuitive to impress and will at fi rst keep glance operation and on will inspiring keep on inspiring are you time you characteristics time<br />

that can't fail to impress at fi rst glance and will keep on inspiring you time<br />

and time again. We think that’s intelligent. and www.sick.com/microScan3<br />

time again. We think that’s intelligent. www.sick.com/microScan3 and time again. We think that’s intelligent. www.sick.com/microScan3<br />

<strong>Mar</strong>/<strong>Apr</strong> 2016<br />

Volume <strong>19.2</strong><br />

Editor<br />

Debbie Scott<br />

debbiewnip@mweb.co.za<br />

Graphic Designer /Sub-editor<br />

Melissa Scheepers<br />

melz_designz1@yahoo.com<br />

Advertising Sales Manager<br />

Roxanne Bredenkamp<br />

roxannewnip@mweb.co.za<br />

Published by<br />

What’s New in Publishing cc<br />

ck 2000/037639/23<br />

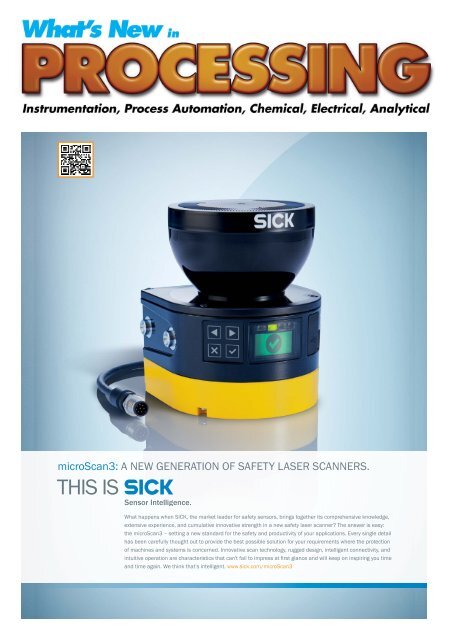

microScan3 safety laser scanner from SICK<br />

With the microScan3, SICK is starting<br />

a new generation of safety laser<br />

scanners. microScan3 reliably protects<br />

hazardous areas, accesses, and hazardous<br />

points. Every detail has been reexamined.<br />

The result? A new benchmark for safety<br />

laser scanners, individual safety, as well as<br />

productivity.<br />

safeHDDMTM scanning technology<br />

is yet another innovative development.<br />

It combines a compact design and a<br />

wide scanning range in one device. Even<br />

under the most challenging of conditions,<br />

the patented measurement principle<br />

maintains clear sight and enables<br />

remarkable performance data. It has a<br />

scanning angle of 275 degrees and the<br />

protective field has a scanning range of 5.5<br />

meters. Thanks to standardized interfaces,<br />

its smart connectivity saves costs during<br />

cabling. Using the new Safety Designer<br />

software, microScan3 can be intuitively<br />

configured and comfortably put into<br />

operation. It also indicates its operational<br />

status clearly via the multicolored display.<br />

microScan3 – safe in different<br />

situations<br />

microScan3’s rugged design makes it<br />

perfectly suited for use in harsh industrial<br />

day-to-day work. Thanks to its resilience<br />

and reliability, microScan3 increases<br />

productivity. It has a wide range of<br />

applications: It protects hazardous areas<br />

at loading and unloading stations, multisided<br />

accesses to machines and material<br />

gates, machines in harsh environments,<br />

as well as hazardous points. What’s<br />

more, microScan3 also ensures presence<br />

detection to prevent machines from<br />

being restarted without authorization.<br />

microScan3 is also very flexible and<br />

adaptable, which means that protecting<br />

hazardous areas doesn’t require any<br />

changes to work processes.<br />

microScan3 ensures employee safety:<br />

Not only does it save lives, it also supports<br />

work ergonomics.<br />

SICK is one of the world’s leading<br />

manufacturers of sensors and sensor<br />

solutions for industrial applications.<br />

Founded in 1946 by Dr. Erwin Sick, the<br />

company is headquartered in the German<br />

town of Waldkirch, in the Breisgau region<br />

near the city of Freiburg. It is a technology<br />

and market leader, maintaining a global<br />

presence with more than 50 subsidiaries<br />

and equity investments as well as<br />

numerous agencies.<br />

Duncan Venter<br />

Tel. (011) 472-3733<br />

www.sickautomation.co.za<br />

duncan.venter@sickautomation.co.za<br />

PO Box 2214<br />

Primrose 1416<br />

South Africa<br />

Tel: 0861 PROCES (776 237)<br />

Fax: 086 723 5321<br />

Printed by: Raptor Print<br />

Views expressed in this publication do not<br />

necessarily reflect the opinions of the publisher.<br />

Copyright reserved on all material<br />

FREE ENTRANCE!<br />

WINDHOEK - 10 MAY 2016<br />

WALVIS BAY - 12 MAY 2016<br />

VANDERBIJLPARK - 20 OCTOBER 2016<br />

To book a stand<br />

contact Roxanne<br />

roxannewnip@mweb.co.za<br />

or 0861 776 237<br />

See You There!<br />

Register online: www.whatsnewinprocessing.co.za

4<br />

Next generation hand-held oscilloscope<br />

<strong>19.2</strong><br />

After 17 years of leading the<br />

20MHz and 40MHz hand-held<br />

industrial oscilloscope category,<br />

Fluke models 123, 124 and 125<br />

ScopeMeter Test Tools are being<br />

replaced by new models 123B,<br />

124B and 125B.<br />

The compact ScopeMeter®<br />

120B Series, is the rugged<br />

oscilloscope solution for industrial<br />

electrical and electro-mechanical<br />

equipment troubleshooting<br />

and maintenance applications.<br />

It’s an integrated test tool, with<br />

oscilloscope, multimeter and highspeed<br />

recorder in one instrument.<br />

The ScopeMeter 120BSeries also<br />

integrates with Fluke Connect®<br />

mobile app and FlukeView® for<br />

ScopeMeter software to enable<br />

further collaboration, data analysis<br />

and archiving of critical test<br />

information.<br />

The 120B Series Industrial<br />

ScopeMeter Test Tools include<br />

innovative functions specifically<br />

designed to aid technicians’<br />

troubleshooting. Waveforms<br />

can be displayed with Connect<br />

and View. Fluke’s IntellaSet<br />

technology triggers and setsup<br />

technology and allows for<br />

automatically view related<br />

numerical measurements, all<br />

without the need to make manual<br />

measurement adjustments. With<br />

Recorder Event Detect capabilities,<br />

elusive intermittent events are<br />

captured on repetitive waveforms<br />

up to 4 kHz and logged for easy<br />

viewing and analysis.<br />

Other features of the Fluke<br />

120B ScopeMeter:<br />

• Dual-input digital<br />

oscilloscope and multimeter<br />

• 40 MHz or 20 MHz oscilloscope<br />

bandwidth<br />

• Two 5,000-count true-rms<br />

digital multimeters<br />

• Dual-input waveform<br />

and meter reading recorder for<br />

trending data over extended<br />

periods<br />

sales@comtest.co.za<br />

Batching with load cells<br />

The first task in preparing a<br />

concrete mixture, is batching<br />

raw materials. Batching means<br />

collecting raw materials,<br />

either by using methods of<br />

weighing, checking volume or<br />

by a combination of the two.<br />

During batching, there are<br />

certain permissible tolerances<br />

that are typically part of project<br />

specifications and/or noted in the<br />

“NPCA Quality Control Manual for<br />

Precast Concrete Plants”. A load<br />

cell, together with a read-out,<br />

is used to accurately weigh the<br />

correct amounts, giving you a<br />

desired mixing pattern (referred<br />

to as the mix design), which<br />

assists in mixing the concrete in<br />

the desired consistency.<br />

Cementitious materials are<br />

usually stored in hoppers/silos,<br />

with the material is loaded into<br />

the hopper either by means of a<br />

screw drive (or auger), a pneumatic<br />

system, or a gravity feed chute,<br />

loading from above. As an aside,<br />

it is important to make sure that<br />

should an auger be used, the item<br />

is specifically designed for use<br />

with cement. Retrofitting old<br />

grain augers, is not advisable, as<br />

this can lead to excessive wear and<br />

less that optimum performance.<br />

Lastly, physical inspections of<br />

the silo should be done routinely.<br />

By using load cells to weigh the<br />

content of the hopper, an accurate<br />

measurement can be done of<br />

the contents of the hopper/silo,<br />

and maintenance issues, such as<br />

water leaks or holes, can easily<br />

be detected (the weight of the<br />

content will change).<br />

Water is batched by either<br />

volume or weight. Flow meters<br />

are used as a measuring device to<br />

quantify the volume of water that<br />

passes through the valve. One<br />

concern with this method is that<br />

flow meters cannot distinguish<br />

between air and water. Leaky<br />

valves also allow water to dribble<br />

through when closed. Considering<br />

the importance of the watercementitious<br />

ratio, it is advisable to<br />

rather use load cells, as measuring<br />

weight rather than flow, is a<br />

much more accurate method of<br />

quantifying the amount of water<br />

used.<br />

Admixtures are typically<br />

batched by volume through a<br />

dispenser. Usually an admixture<br />

supplier, will provide the dispenser<br />

at no cost to the producer. It<br />

is recommended that you<br />

investigate this option. Dispensers<br />

reduce the likelihood of improper<br />

dosing. Be sure to introduce<br />

admixtures into the concrete mix in<br />

accordance with the manufacturer’<br />

recommendations.<br />

Aggregates are batched most<br />

commonly by weight. Whether<br />

in a hopper, on weigh belts, in or<br />

directly from storage bins, load<br />

cells are used to measure the<br />

weight of the material. The most<br />

common method used is weigh<br />

belts. However, “weigh belt” is<br />

a misnomer. A true “weigh belt”<br />

weighs while it is moving. In most<br />

batch plants, Live Bottom-Weigh<br />

Hoppers (LBWHs) are used. An<br />

LBWH’s belt is stationery while<br />

weighing aggregates. This type of<br />

belt may be started under load to<br />

move the weighed aggregates to<br />

a transfer belt, hopper or skip hoist.<br />

Overall, accuracy in all of the<br />

above processes can be improved<br />

by installing load cells. By weighing<br />

each component, an accurate<br />

measurement is done of the<br />

batched material, and a desired<br />

consistency can be achieved in a<br />

continuous time-saving method.<br />

glen@loadtech.co.za

5<br />

<strong>19.2</strong><br />

Using wireless here and there is one thing.<br />

But using it across my entire operation?<br />

IT’S<br />

There’s no one I could trust to do that.<br />

IMPOSSIBLE<br />

See more, do more and be more profitable with the most trusted partner in wireless — Emerson.<br />

Emerson is your proven partner with Smart Wireless in more customer sites and with more operating<br />

hours than anyone else in the process industry. Smart Wireless has the widest range of technologies<br />

to expand your vision into more places across your operations. And its self-organising mesh network<br />

delivers the highest reliability available. It is simply the most intelligent, secure and cost-effective<br />

operation-wide wireless option available. See how Smart Wireless can empower your bottom line<br />

at www.EmersonProcess.com/SmartWireless or e-mail mea.marcom@Emerson.com<br />

The Emerson logo is a trademark and a service mark of Emerson Electric Co. © 2016 Emerson Electric Co.

6<br />

Shielded SACC connectors with fast connection technology<br />

<strong>19.2</strong><br />

The ability to efficiently<br />

commission field devices<br />

reduces start-up costs and<br />

schedule risk for large projects.<br />

The line of Rosemount 8800<br />

Vortex flowmeters now offers<br />

HART® Protocol Revision 7, which<br />

allows for easier identification<br />

in the field, commissioning, and<br />

configuration.<br />

Making it easier to commission<br />

and start up a facility accelerates the<br />

return on customers’ investment.<br />

The extension of HART 7 to these<br />

vortex flowmeters simultaneously<br />

adds functionality and improves<br />

usability.<br />

Properly identifying devices<br />

both in the field and in the control<br />

room takes the guesswork out<br />

of whether or not the correct<br />

device is being configured or<br />

commissioned. The Locate Device<br />

feature of HART 7 displays a<br />

visible code on the device’s LCD<br />

screen which allows for quick field<br />

identification.<br />

Once connected to the<br />

device, or while viewing from the<br />

control room, Long Tag allows<br />

for a detailed device name to<br />

be viewed or loaded into the<br />

flowmeter. Long Tag support<br />

increases the character limit from<br />

the current eight character tag to<br />

32 characters, allowing the user to<br />

create more accurate descriptions<br />

necessary to track down each<br />

unique device.<br />

HART 7 also offers greater<br />

flexibility for device configuration.<br />

For the most up to date process<br />

information, HART 7 delivers<br />

expanded burst mode capabilities<br />

to allow the vortex meter to burst<br />

up to 8 variables and to trigger<br />

messages based on process events.<br />

In addition to the latest<br />

HART 7 features, the 8800 Vortex<br />

flowmeter now provides Sensor<br />

Signal Strength as a display and<br />

output variable. This allows for<br />

continuous health monitoring of<br />

the flow sensor both at the device<br />

and remotely as a HART variable.<br />

michael.eksteen@<br />

emerson.com<br />

Compact vortex flowmeter for low viscosity liquids<br />

The compact, cost-effective<br />

vortex flowmeter Model<br />

DVZ, is used for measuring and<br />

monitoring smaller and mediumsized<br />

flow of low viscosity, waterlike<br />

liquids in pipes. This device<br />

has impressed in numerous series<br />

applications due to its reliability<br />

and response time. It functions<br />

without any mechanical moving<br />

parts, using the vortex principle,<br />

where a sharp-edged object,<br />

the Karman vortex-generator, is<br />

installed within the flow duct,<br />

making it virtually maintenancefree.<br />

This is a considerable<br />

advantage over devices based<br />

on the variable area or impeller<br />

principle. Vortices are created<br />

behind the object whose<br />

frequency is proportional to the<br />

velocity of flow of the liquid. The<br />

flow volume can be determined<br />

with a high degree of accuracy by<br />

measuring the vortex frequency.<br />

The result is a very high linearity<br />

over the whole measuring range<br />

(0.5-4.5...10-100l/min) with an<br />

accuracy of +2.5% of full scale.<br />

Unlike calorimetric flow<br />

measurement, its measuring<br />

principle works irrespective of<br />

the temperature and without<br />

time delay and can thus also be<br />

used in time-critical applications.<br />

The measurement process<br />

is suitable for practically all<br />

liquids with a viscosity similar<br />

to water - irrespective of the<br />

pressure, temperature, density<br />

and electrical conductivity of<br />

the medium. Due to its specific<br />

operating principle, Kobold’s DVZ<br />

flowmeter is especially suitable for<br />

measuring aggressive, corrosive or<br />

saline solutions. It can also be used<br />

for ultrapure media.<br />

The DVZ series covers<br />

measuring ranges up to100l/<br />

min with its different versions.<br />

The devices can optionally be<br />

equipped with a fixed or rotatable<br />

connection. Depending on the<br />

version, a switch output (1 A/30<br />

Vdc), a frequency output (open<br />

collector, PNP) or an analogue<br />

output (4-20mA) are also available.<br />

In addition, a programmable<br />

compact electronics system is<br />

available that includes a digital<br />

display, a switch output and an<br />

analogue output. Dosing and<br />

metering electronics are currently<br />

being developed.<br />

The Kobold DVZ vortex<br />

flowmeter typically finds<br />

application in the areas of coolant<br />

monitoring of lasers, welding<br />

robots or induction heating<br />

systems for:<br />

• Monitoring the flow of low<br />

viscosity liquids<br />

• Measuring of aggressive,<br />

high-purity or salty solutions<br />

• Unsuitable for abrasive<br />

media or media containing a large<br />

proportion of fibers<br />

sales@instrotech.co.za<br />

New patch cable with OM1 bevel<br />

The new Zipcord patch cables<br />

for fiber-optic-based data<br />

cabling are available in custom<br />

cable lengths with different<br />

combinations of the LC-Duplex,<br />

SC-Duplex, ST and FSMA<br />

plug-in connectors and offer<br />

excellent optical and mechanical<br />

transmission characteristics.<br />

Featuring protection class IP<br />

20, the patch cables are suitable for<br />

transmission rates up to 10 Gbps<br />

in protected indoor applications<br />

such as data centers or office<br />

cabling. The insertion loss of the<br />

patch cables are less than 0.3 dB – a<br />

superb value – with over 35 dB for<br />

return loss, in compliance with IEC<br />

61300-3.<br />

The Zipcord patch cables are<br />

designed according to the OM1<br />

fiber category (62.5/125 µm)<br />

and fulfill fire safety regulations<br />

according to UL OFNR and<br />

LSZH. The complete article as a<br />

preassembled cabling solution is<br />

UL-listed.<br />

seanh@phoenixcontact.co.za

7<br />

<strong>19.2</strong><br />

Remote sensor telemetry<br />

system monitors temperatures<br />

from anywhere in the world<br />

sensors. Inputs are selectable 0-20<br />

mA, 4–20 mA, 0-5 V, 0-10 V or digital<br />

On/Off. Optional relay outputs<br />

rated at 30 VDC, 2 A are available<br />

for connection directly to alarm<br />

hardware.<br />

The PyroNet GSM remote sensor<br />

telemetry system can monitor<br />

temperatures from anywhere in<br />

the world. Measurements can<br />

be taken at regular intervals and<br />

transmitted to the internet via<br />

the GSM cellular phone network<br />

using the PyroNet GSM’s built-in<br />

SIM card.<br />

The unit transmits readings<br />

from up to 4 devices with analogue<br />

inputs such as the PyroCouple and<br />

PyroMini infrared temperature<br />

A choice of battery-powered,<br />

solar-powered or 6-24 V DC<br />

powered versions can be supplied<br />

for indoor or outdoor use.<br />

Calex’s hosted web interface,<br />

PyroNet GSMView ensures data<br />

is hosted securely and access is<br />

included standard in the monthly<br />

subscription. Users can export<br />

measurement data to be used in<br />

a spreadsheet, and configure the<br />

system to send email or SMS alarms,<br />

for temperature alerts or loss of<br />

communication (for example, due<br />

to power failure).<br />

info@asstech.co.za<br />

A bull’s eye in quality.<br />

New PV connectors with crimp<br />

connection<br />

Paperless recorder – Every<br />

measurement counts!<br />

Introducing new photovoltaic<br />

connectors with crimp<br />

connection. The DC connectors<br />

from the Sunclix product range<br />

are particularly suitable for<br />

mechanical assembly and simplify<br />

the cabling of photovoltaic<br />

systems.<br />

The connectors with IP68<br />

protection are designed for<br />

currents up to 30 A and voltages<br />

up to 1500 V (IEC) or 1000 V (UL).<br />

The contacts and high-quality<br />

materials ensure durability<br />

under harsh weather conditions.<br />

Thanks to the user-friendly<br />

combination of crimp connection<br />

and the Sunclix pin connector<br />

pattern, the connectors meet the<br />

high requirements for process<br />

efficiency and safe cabling.<br />

seanh@phoenixcontact.co.za<br />

Ecograph T RSG35<br />

Versatile and economical<br />

• Up to 12 inputs<br />

• Internal memory 128 MB<br />

• Ethernet, RS232/RS485, USB,<br />

Modbus RTU/TCP Slave<br />

• Safe and complete recording<br />

and visualization of all process<br />

sequences<br />

Ecograph T RSG35<br />

Price/piece in R<br />

Version for panel mounting 1–3 4–10 11–35<br />

4 × univ. input, Ethernet + USB R15180 R14573 R14117<br />

4 × univ. input, Modbus +<br />

RS232/485 + Ethernet + USB<br />

R18800 R18048 R17484<br />

Mathematics package, 4 ×<br />

universal input, Ethernet + USB<br />

R19280 R18509 R17930<br />

Math. package, 4×univ. input, Modbus<br />

+ RS232/485 + Ethernet + USB<br />

R22900 R21984 R21297<br />

*Refer to website for sales and supply conditions.<br />

R14117 *<br />

11–35 pcs.<br />

For technical details and applications visit:<br />

www.za.endress.com/e-direct<br />

Tel: 0861 363 737 (0861 endres)<br />

24 hr Helpline: 082 443 4214<br />

Service Hotline:<br />

0861 347 378 (0861 ehserv)<br />

info@za.endress.com<br />

www.za.endress.com

8<br />

<strong>19.2</strong><br />

Butterfly valves for efficient flow control<br />

Desponia centric butterfly valves with<br />

an elastomer liner, are designed for safe<br />

and reliable regulation of liquids and<br />

gases in diverse industries.<br />

Compact butterfly valves, with<br />

good flow characteristics and<br />

low maintenance requirements,<br />

are important components in<br />

this extensive range of valves for<br />

industrial flow control.<br />

An advantage of using quarter<br />

turn butterfly valves rather than<br />

any other type of valve, is the<br />

simple, wafer shaped design, with<br />

fewer parts, for easy repair and<br />

minimal maintenance.<br />

Although butterfly valves<br />

and ball valves are both quarter<br />

turn, the benefit of butterfly<br />

valves is when they are actuated<br />

pneumatically, they open and<br />

close very quickly. The rotational<br />

disc in butterfly valves is lighter<br />

than a ball and these valves require<br />

less structural support than a ball<br />

valve of the same diameter.<br />

Unlike a ball valve, the disc of<br />

butterfly valves is always present<br />

in the passageway within the<br />

flow. This means a pressure drop is<br />

induced in the flow, regardless of<br />

the position of the valve. Ball valves<br />

should only be used for isolation,<br />

whereas butterfly valves can be<br />

safely used for isolation and control<br />

of flow.<br />

Desponia centric butterfly<br />

valves (DN 25 -1600) with an<br />

elastomer liner, are designed<br />

for safe and reliable regulation<br />

of liquids and gases in diverse<br />

industries. This range has a<br />

maximum working pressure of 16<br />

bar and an operating temperature<br />

range of between -20˚C and<br />

+140˚C according to the material.<br />

Bianca centric butterfly<br />

valves (DN 32 -900) with an on/<br />

off and control service, have a<br />

durable plastomer liner suitable<br />

for aggressive and corrosive<br />

fluids. These high performance<br />

valves have a 16 bar maximum<br />

working pressure and an operating<br />

temperature range of between<br />

-20˚C and +200˚C depending on<br />

working conditions.<br />

Special ATEX valves in this<br />

range are suitable for use in<br />

explosive atmospheres.<br />

Other valves available in the<br />

range include seated, knife and<br />

wedge gate valves, as well as ball<br />

type check valves, thermoplastic,<br />

diaphragm, pinch and angle seat<br />

valves.<br />

This range is suitable for<br />

reliable performance in diverse<br />

industries, including mining,<br />

refining, power generation, iron<br />

and steel, materials handling, food<br />

and beverage, pharmaceutical,<br />

paper and pulp, chemical, sugar<br />

and automotive.<br />

wayneh@bmgworld.net<br />

Bianca centric butterfly valves have<br />

a durable plastomer liner suitable for<br />

aggressive and corrosive fluids.<br />

High-frequency radar level technology on the rise<br />

New radar level sensor VEGAPULS 64<br />

for liquids: The smallest antenna is<br />

no bigger than a 1 Euro coin, so that<br />

the new measuring instrument is an<br />

ideal solution for installation in small<br />

containers.<br />

VEGAPULS 64, the world’s first<br />

radar level sensor for liquids,<br />

operating at a frequency of 80<br />

GHz, has instigated a radical new<br />

era in radar level measurement<br />

technology.<br />

Eighteen months ago a<br />

new sensor for the continuous<br />

measurement of bulk solids,<br />

VEGAPULS 69, was introduced<br />

with great success. This sensor<br />

also operates with a transmission<br />

frequency 3 times higher than the<br />

widely used 26 GHz frequency.<br />

The market has shown that this<br />

technology is the thing of the<br />

future – since the market launch,<br />

over 10,000 VEGAPULS 69 level<br />

sensors have already been<br />

installed. These instruments have<br />

proven their worth, especially<br />

on media with poor reflective<br />

properties, in production shafts<br />

up to 120 m deep, or in silos with<br />

numerous internal installations<br />

that generate strong false echoes.<br />

VEGAPULS 64 for liquid<br />

applications will follow this<br />

leap, also setting a milestone in<br />

measurement technology with<br />

its high dynamics and superior<br />

focusing. Media with poor<br />

reflective properties, i.e. low<br />

dielectric constant, can now be<br />

measured significantly better<br />

than with previous radar sensors.<br />

Thanks to the vastly better<br />

focusing, the beam simply passes<br />

by internal tank installations or<br />

buildup. Interfering signals, which<br />

previously had to be filtered out<br />

with false signal suppression,<br />

now play hardly any role in the<br />

measurement process.<br />

Moreover, it is now possible<br />

to use a much smaller antenna.<br />

Today there are process fittings<br />

with an antenna diameter of<br />

only ¾”. The new technology also<br />

allows precise measurement of<br />

the level very close to the tank<br />

bottom. This opens up new<br />

perspectives in determining<br />

the level in small containers<br />

used in the pharmaceutical and<br />

biotech industries, as well as<br />

determining the amount of fuel left<br />

at the bottom of large fuel tanks.<br />

Measurement accuracy is +/-2 mm,<br />

even with a working range up to 30<br />

m.<br />

The great success of bulk<br />

solids radar sensor VEGAPULS 69<br />

and the current market launch<br />

of VEGAPULS 64 for liquids are<br />

setting the agenda for the future<br />

technological development of<br />

radar level measurement.<br />

chantal.groom@vega.com<br />

Radar level sensor VEGAPULS 69 for<br />

bulk solids: Reliable level measurement<br />

for an extremely wide application<br />

spectrum.

9<br />

High pressure resistant sensors in M12 barrel<br />

Introducing<br />

high-pressure<br />

inductive sensors in an M12<br />

housing to keep up with advanced<br />

manufacturing technologies<br />

and the continuously shrinking<br />

sizes of applications. Previously<br />

available in an M18 housing, the<br />

introduction of the M12 highpressure<br />

sensor series allows the<br />

manufacturer to meet customers’<br />

evolving needs. The new offering<br />

is available in two lengths, 78 mm<br />

and 56 mm.<br />

Customers, particularly with<br />

hydraulics applications, need<br />

a more compact high-pressure<br />

sensing solution. The M12 highpressure<br />

sensor provides an ideal<br />

solution for these applications<br />

without sacrificing any<br />

performance.<br />

The high-pressure M12<br />

<strong>19.2</strong><br />

sensor series utilizes a robust<br />

stainless steel housing, suitable<br />

to withstand static or dynamic<br />

pressure up to 500 bar. The sensors<br />

offer a sensing range of 1.5 mm<br />

and carry an IP68 rating, allowing<br />

them to withstand demanding<br />

environments.<br />

brandon.topham@<br />

retautomation.com<br />

New agencies<br />

for Instrotech’s<br />

T&M division<br />

Instrotech, distributor and<br />

manufacturer of a large range of<br />

process control instrumentation<br />

and specialised systems, has<br />

merged TIA ONLINE, to form the<br />

Instrotech’s Test & Measurement<br />

division, and represents the<br />

following agencies:<br />

• RYCOM INSTRUMENTS -<br />

services the global utility, telecom,<br />

pipeline and underground<br />

construction industries<br />

• TIME ELECTRONICS - designs<br />

and manufactures precision test<br />

instruments and high performance<br />

calibration equipment<br />

• SCOPE T&M - designs and<br />

develops test and measurement<br />

products for the electromagnetic<br />

induction environment of EHV &<br />

UHV substations<br />

• KEHUI - Shandong Kehui<br />

Power Automation develops,<br />

produces and sells power cable<br />

fault monitoring equipment,<br />

power distribution automation<br />

equipment, railway power<br />

automation and switched<br />

reluctance motor drive systems<br />

• SEAWARD - provides total<br />

test solutions to enable companies<br />

and organisations to comply<br />

with the demands of all types<br />

of electrical safety legislation<br />

including portable appliance<br />

testing, installation, medical, and<br />

machinery testing.<br />

sales@instrotech.co.za<br />

Introducing the Velocio ACE &<br />

Branch range of Micro PLC’s<br />

• Easy to use intuitive development interface<br />

• Low-cost<br />

• Smallest footprint of any PLC: 63.5mm x 63.5mm x 15mm<br />

• Warnings and Errors are presented in real time<br />

• Subroutines: Break projects up into manageable chunks,<br />

and allow program reuse.<br />

• Wired and deployed in minutes. Ace PLCs come with small,<br />

high quality spring-cage capture connectors.<br />

TEMP-TEK<br />

(011) 465-8066<br />

www.temptek.co.za

Power solutions offer reliability and continuity of service<br />

New non-intrusive temperature solution<br />

Uninterruptible power supply (UPS)<br />

units<br />

Power solutions ensure<br />

protection of electrical<br />

equipment and continuity of<br />

service during planned and<br />

unexpected power outages.<br />

These modular systems<br />

include certified low emission<br />

(CLE) cast resin transformers,<br />

busbar trunkings, enclosures<br />

for power switchgear and<br />

controlgear assemblies, as<br />

well as uninterruptible power<br />

supply (UPS) units. An important<br />

advantage of selecting Legrand<br />

components for efficient, safe and<br />

Safety laser scanner<br />

flexible power distribution, is the<br />

immediate integration between<br />

the company’s busbar trunking<br />

systems, cast resin transformers<br />

and XL³ cabinets.<br />

CONTROL VALVE TEST<br />

STABILITY TEST<br />

Measuring the stability of the Control Valve by comparing a stabile input<br />

signal and air supply pressure against the output signal and valve position.<br />

The microScan3 introduces<br />

a new patented innovation<br />

in scanning technology -<br />

safeHDDM . The safeHDDM <br />

delivers XL³ cabinets unrivalled and enclosures measurement<br />

results by filtering and analysing<br />

numerous single pulses at more<br />

than one hundred times the<br />

sampling A.T. TECHNICAL rate of traditional SERVICES & SUPPLIES safety<br />

laser scanners.<br />

During Online Valve time-of-flight<br />

Testing<br />

measurement, Systems the scanner emits<br />

a laser pulse beam that is reflected<br />

by the object being detected.<br />

The time taken by the beam path<br />

is analysed and the distance<br />

to the object is calculated. The<br />

microScan3 performs thousands<br />

ACCURACY TEST<br />

Measured in user defined steps, changing the input signal and measuring<br />

microScan3: A NEW GENERATION OF SAFETY LASER SCANNERS.<br />

the valve position.<br />

BENCH TEST<br />

Measuring the actual responds of the valve by automatically<br />

ramping the input signal from 0 to 100% and back, while<br />

What happens when SICK, the market leader for safety sensors, brings together its comprehensive knowledge,<br />

extensive experience, monitoring and the cumulative displacement innovative strength of the in valve a new safety laser scanner? The answer is easy:<br />

the microScan3 and – pressure setting a new in the standard actuator. for the safety and productivity of your applications. Every single detail<br />

has been carefully thought out to provide the best possible solution for your requirements where the protection<br />

of machines RESPONDS and systems is TEST concerned. Innovative scan technology, rugged design, intelligent connectivity, and<br />

intuitive operation are characteristics that can't fail to impress at fi rst glance and will keep on inspiring you time<br />

Performed to measure the valve’s ability to<br />

and time again. We think that’s intelligent. www.sick.com/microScan3<br />

follow a block shaped input signal.<br />

RESPONDS TIME<br />

Performed to measure the valve traveltime<br />

to fully open and close the valve.<br />

SEAT LEAKAGE TEST<br />

The valve seat leakage is measured and classified according to the FCI 70-2.<br />

Anzeige_microScan3_A4_4c_201510_en.indd 1 18.02.2016 17:37:46<br />

www.ventil.nl<br />

3<br />

of these single ➢ 012 pulse 345 1005 calculations<br />

admin@atts.co.za<br />

in just 30 milliseconds and in this<br />

way, safeHDDM offers a very high<br />

level of resistance to ambient light,<br />

HONEYWELL<br />

10<br />

All power solutions systems<br />

encompass the latest technology<br />

Rfor osemount energy X-well efficiency, Technology quality<br />

power is a supply, surface optimum sensing safety<br />

temperature<br />

and enhanced aesthetics. measurement<br />

solution The environmentally that eliminates friendly, the<br />

need dry type for cast thermowell resin transformers, process<br />

penetration transfer electrical when power measuring between<br />

process two different temperatures voltage in systems pipe<br />

applications. at the same This frequency, solution with<br />

provides low environmental an accurate impact. and<br />

repeatable These HV/LV internal transformers process offer<br />

temperature significant savings measurement, on electricity while<br />

eliminating costs and possible can reduce leak electricity points<br />

and consumption simplifying by specification,<br />

up to 20%<br />

installation during off-peak and maintenance.<br />

activity.<br />

Rosemount X-well Technology<br />

is available in the Rosemount<br />

648 Wireless Temperature<br />

Transmitter and Rosemount<br />

0085 Pipe Clamp Sensor<br />

Assembly. These components<br />

work together to calculate<br />

process temperature via the<br />

transmitter’s thermal conductivity<br />

algorithm. Rosemount X‐well<br />

Technology works by measuring<br />

the pipe surface temperature<br />

and ambient temperature, and<br />

combining this information with<br />

Legrand certified low emission (CLE)<br />

cast resin transformers<br />

The absence of flammable<br />

dust insulation and screen liquids, contamination. the use of<br />

self-extinguishing<br />

Rugged Design materials<br />

exempt The microScan3 of toxic gas offers emissions, a<br />

scanning reduced range noise of levels 275°, and more low<br />

than electromagnetic<br />

three-quarters of a emissions, circular<br />

area, ensure leaving enhanced no environmental<br />

blind spots<br />

when protection mounted in all on installations.<br />

the 90° corner<br />

of a machine. Standard The durability distribution of<br />

the transformers scanner is have guaranteed rated power by<br />

the between compact 100 light and metal 3 150 diecast<br />

primary housing rated which, voltage along up to with 36 kV<br />

kVA,<br />

specially and secondary designed rated electronics voltage up<br />

offers<br />

to 433<br />

an<br />

V.<br />

exceptionally high level<br />

of electromagnetic<br />

Special transformers<br />

compatibility<br />

have<br />

(EMC). The vibration resistant<br />

rated power up to 20 000 kVA,<br />

mounting bracket is equipped<br />

primary rated voltage up to 36<br />

with slide-in guide rails, enabling<br />

kVA and secondary rated voltage<br />

simple and fast mounting of the<br />

scanner.<br />

Smart Connectivity<br />

Time is always an important<br />

factor when it comes to<br />

installation and commissioning.<br />

The standardised M12 system<br />

connection facilitates simple<br />

and fast cabling, while a standard<br />

mini USB interface plug enables<br />

Laser Stroke Sensor<br />

straight-forward configuration<br />

and diagnosis, using a laptop.<br />

Once the scanner has been<br />

configured, the ➢ 011 settings 695 8000 are stored<br />

www.honeywellprocess.com<br />

in the integrated system plug. If<br />

the scanner head is damaged due<br />

to external forces and needs to be<br />

12<br />

on request.<br />

Unlike oil transformers, these<br />

an cast understanding resin units, of with the thermal reduced<br />

conductivity overall size properties dimensions, of can the be<br />

installation installed inside and process buildings piping. and do<br />

not A require major additional advantage building of<br />

Rosemount structures. This X-well means Technology optimum<br />

is flexibility accurate process in any temperature<br />

environment.<br />

measurement Because no without cooling requiring fluids are<br />

any necessary, intrusions maintenance or penetrations costs are<br />

into minimised. the process, allowing for<br />

quicker For and climate easier conditions installation these<br />

along transformers with simplified can long-term withstand<br />

maintenance. severe conditions Users do - E2 not -<br />

have environmental to design, class, size or C2 maintain - climatic<br />

thermowells. class, F1-fire-behaviour Wake Frequency class.<br />

Calculations The are transformers eliminated, as well are<br />

as enhanced time spent determining by pre-fabricated material<br />

compatibility, busbar trunking the right systems, insertion which<br />

length provide and the synergy necessary for profile. a direct<br />

connection. With Rosemount X-well<br />

Technology, These users busbar can also trunking add<br />

temperature systems, with measurement minimum points overall<br />

without dimensions, having provide to shut down flexibility a<br />

process. in all areas X-well of Technology an installation, can<br />

be including installed with confined a standard spaces. pipe<br />

clamp Aluminium procedure or copper and ordinary busbars<br />

hand and tools, cast and resin does transformers not require are a<br />

skilled equipped contractor. with various accessories<br />

to Rosemount provide maximum X-well Technology versatility<br />

for any type of power application,<br />

including areas which are<br />

subjected to high thermal stress<br />

and where equipment is sensitive<br />

to electromagnetic interferences.<br />

replaced, the new scanner head<br />

will be ready for operation as soon<br />

as it has been connected.<br />

Intuitive Operation<br />

It might be assumed that a<br />

high-performance safety laser<br />

scanner would be complex to<br />

handle and operate; however,<br />

the microScan3 incorporates<br />

a large easy-to-read colourchanging<br />

status display to show<br />

the condition of the scanner. The<br />

colour-changing Busbar trunkings display, along<br />

with pictorial<br />

Safety is<br />

status<br />

important<br />

indication,<br />

in the<br />

is<br />

backed by plain-text messages<br />

design of all components.<br />

available to scroll through, using<br />

The absence of fuel masses<br />

on-board navigation buttons.<br />

in the cast resin transformers is<br />

TEMP-TEK (PTY) LTD<br />

➢ 011 465 8066<br />

sales@temptek.co.za<br />

18.6<br />

<strong>19.2</strong><br />

combined with a low fire load<br />

typical of busbars. This feature<br />

is increases the best the of intrinsic both worlds safety as of it a<br />

provides building against an accurate the propagation process<br />

temperature of a possible fire. similar to a<br />

thermowell This fire while retardant maintaining range<br />

the is benefits tested for of a fire non-intrusive resistance<br />

surface according measurement. to DIN 4102-09 Current and EN<br />

surface 1366-3 standards. temperature sensing<br />

technology The connections only provides of high a<br />

surface power busbar measurement line elements that have can<br />

be reliable easily influenced mechanical by interlocks ambient<br />

temperature, for easy installation. while Rosemount<br />

This design<br />

X‐well eliminates Technology errors and corrects prevents for<br />

external potential conditions dangers to which infer the can<br />

process occur with temperature. conventional systems<br />

when Applications starting up the that system. can<br />

benefit There from are Rosemount other X-well critical<br />

Technology devices for optimum include protection,<br />

pipelines,<br />

high reliable velocity distribution flows, slurries, and effective heavy<br />

particulate service continuity fluids, wellheads, in the event cleanin-place<br />

a mains processes, power failure. high viscosity<br />

of<br />

fluids These and harsh include processes DMX³ air in the circuit oil<br />

& breakers, gas, chemical, DMX³ refining, MCCB’s, food supply and<br />

beverage, inverters, metals isolating and switches mining and and<br />

pulp XL³ and enclosures paper industries. for sites between<br />

160 A and 6 300 A. XL³ distribution<br />

enclosures comply with every<br />

michael.eksteen@<br />

part of the standard IEC 61439<br />

emerson.com<br />

to guarantee reliability and total<br />

protection of the installation.<br />

The UPS system also ensures<br />

continuity of service, in terms of<br />

power and back up time.<br />

Optimum sizing of power<br />

The colour of the status display<br />

stages, the latest electronic<br />

is mirrored to numerous highvisibility<br />

LED’s located around the<br />

components and thorough<br />

testing of each unit, ensure<br />

rim of the scanner head, offering<br />

simple<br />

dependability<br />

diagnosis<br />

and<br />

from<br />

safety<br />

various<br />

of the<br />

angles. new system.<br />

High performance batteries<br />

The microScan3 launches<br />

and an efficient charging system<br />

SICK’s new generation of safety<br />

laser<br />

have<br />

scanners.<br />

extended<br />

The<br />

battery<br />

microScan3<br />

life by<br />

reliably<br />

up to<br />

protects<br />

50%.This<br />

hazardous<br />

UPS<br />

areas,<br />

system<br />

accesses encompasses and hazardous three ranges points, –<br />

ensuring the Modular a new series benchmark for a reliable for<br />

safety power laser supply scanners, up to the 120 safety kVA, the of<br />

individuals Conventional and productivity.<br />

series up to 10 kVA<br />

and the Line Interactive series,<br />

duncan.venter@<br />

which is a UPS system up to 3 kVA.<br />

sickautomation.co.za<br />

legrand.south-africa@legrand.co.za<br />

SOLIFLO (PTY) LTD<br />

➢ 011 792 2196<br />

sales@soliflo.co.za

11<br />

<strong>19.2</strong><br />

Tasteful water: Iron control optimised<br />

The new Liquiline System<br />

CA80FE colorimetric analyser<br />

offers precise monitoring of<br />

dissolved iron content in water<br />

and supports plant managers in<br />

complying with stipulated limit<br />

values.<br />

Drinking water not only<br />

has to be free from harmful<br />

substances and tolerable but<br />

must be aesthetically pleasing<br />

and tasteful. At concentrations<br />

commonly found in drinking<br />

water, dissolved iron is not harmful<br />

to human health. However<br />

because it impairs water taste and<br />

colour, local authorities stipulate<br />

strict containment limits for iron.<br />

Elevated iron concentrations can<br />

also lead to build-up of deposits<br />

and settling of microorganisms<br />

in distribution systems and<br />

household water supplies. This is<br />

undesirable for consumers and<br />

utilities responsible for treatment<br />

of water for industrial processes, as<br />

iron deposits can cause corrosion<br />

or encrusting of pipes, turbines<br />

and vessels leading to expensive<br />

repairs or even complete system<br />

replacement.<br />

With the Liquiline System<br />

CA80FE, waterworks and plant<br />

managers can rely on highprecision<br />

online monitoring<br />

of iron. The analyser uses the<br />

standardised ferrozine method<br />

to deliver regulation-compliant<br />

measured values and features<br />

detailed logbooks that allow<br />

comprehensive documentation<br />

of the iron values. Plant managers<br />

are well prepared for audits and<br />

can prove compliance to water<br />

authorities at any time.<br />

Saving energy in iron removal<br />

Iron removal is achieved by<br />

oxidising iron to form iron oxide<br />

hydrate which is insoluble and<br />

can be removed by filtration or<br />

sedimentation. Liquiline System<br />

CA80FE monitors the iron removal<br />

online and delivers measured<br />

values fast – helping to optimise<br />

the control of air blowers and<br />

thus save energy in the oxidation<br />

process. Fast measurements also<br />

help plant operators to detect<br />

potential process disturbances<br />

quickly and advanced diagnostics<br />

with remote access support them<br />

in prompt analysis and remedy.<br />

Low reagent consumption and<br />

optimised maintenance<br />

Liquiline System analysers<br />

are designed with highly precise<br />

dispensers for reagent and<br />

standard dosing guaranteeing<br />

reduced consumption and low<br />

operating costs. Automatic<br />

cleaning and calibration functions<br />

ensure that the analyser and its<br />

sample preparation and reagents<br />

work reliably and without manual<br />

intervention over a longer period<br />

of time. Maintenance tasks can be<br />

carried out easily and with minimal<br />

tools, reducing maintenance costs<br />

and increasing process uptime.<br />

Easy operation and integration<br />

Liquiline System shares the<br />

user-friendly operation that plant<br />

personnel already know from other<br />

online analysis parameters such as<br />

pH or chlorine - operating errors are<br />

virtually eliminated. Its integration<br />

into process control systems is also<br />

seamless via Modbus, PROFIBUS<br />

and EtherNet/IP digital fieldbuses.<br />

Additionally, Liquiline System can<br />

be easily upgraded to a measuring<br />

station by connecting up to four<br />

Memosens sensors. The analyser<br />

then adopts the transmitter<br />

functions resulting in a reduction<br />

of the investment costs in the plant.<br />

Flexible sample preparation<br />

The self-priming version<br />

of Liquiline System CA80 is the<br />

best choice for particle-free<br />

water. It is ready for operation<br />

without any additional settings.<br />

For applications where sample<br />

preparation is needed, the CAT810/<br />

CAT820 sample preparation<br />

systems are available. They are<br />

fully controlled by the analyser<br />

via Memosens communication<br />

und thus easy to commission and<br />

operate.<br />

Liquiline System CA80FE helps<br />

waterworks and plant managers<br />

keep their water treatment under<br />

control and comply with the strict<br />

regulatory limits, while making<br />

daily life easier for operators.<br />

jan.swart@za.endress.com

12<br />

New inline analyser system for edible oil and fat processing<br />

<strong>19.2</strong><br />

Introducing the OPTIQUAD-EOF<br />

4050 W for the continuous inline<br />

measurement of free fatty acids<br />

(FFA), total polar material (TPM),<br />

peroxide value (POV), moisture<br />

or dirt. The optical spectroscopic<br />

analyser system is aimed at frying<br />

and other edible oil as well as fat<br />

applications.<br />

OPTIQUAD-EOF 4050 W<br />

measures directly in the pipe:<br />

analysis is achieved via an optical<br />

window mounted in a standard<br />

VARINLINE measuring section.<br />

The readings of FFA, TPM, POV<br />

moisture or dirt are provided<br />

instantly for process control or<br />

dynamic control loops via four<br />

4...20 mA outputs. Depending on<br />

the application, measurement of<br />

anisidine value (AV) and iodine<br />

value (IV) are possible. Compared<br />

to conventional laboratory<br />

methods used to obtain these<br />

values, OPTIQUAD-EOF 4050 W<br />

reduces the need for sampling,<br />

sample transport and handling,<br />

and the associated sources of error<br />

and costs.<br />

The optical spectroscopy<br />

analyzing method allows for a<br />

wide range of use in edible oil<br />

applications, such as oil extraction,<br />

oil refinement and frying processes<br />

up to oil recycling, as well as fat<br />

processing. For example, the<br />

continuous inline measurement<br />

of FFA content in frying oil helps to<br />

minimize the addition of fresh oil:<br />

the FFA value can be kept below<br />

a defined limit whilst allowing to<br />

maintain a high level of quality. It<br />

also provides a wide measuring<br />

range, e.g. 0…98% for FFA, and<br />

an accuracy of RMSEp: ±0,03%<br />

up to ± 1% FFA, depending on the<br />

measurement range.<br />

OPTIQUAD-EOF 4050 W<br />

spectroscopic analysis system<br />

consists of the analyser unit<br />

(protection rating IP65/NEMA4X)<br />

and the operating unit, an<br />

industrial PC with touch screen<br />

display for parameterisation and<br />

automatic calibration in a stainless<br />

steel housing (IP65/NEMA4X),<br />

optionally built into a switch<br />

cabinet. It uses up to four measuring<br />

methods (transmission, scattering,<br />

fluorescence and refraction)<br />

with up to 12 wavelengths<br />

from ultraviolet to infrared.<br />

The underlying calibration is<br />

calculated automatically from<br />

reference data specific to the<br />

application. OPTIQUAD-EOF 4050<br />

W is the successor of OPTIQUAD-<br />

FFA 4050 W.<br />

j.alexander@krohne.com<br />

New relative humidity probe that hands control to the user<br />

Michell Instruments has<br />

introduced the new<br />

HygroSmart HS3 advanced<br />

interchangeable relative<br />

humidity and temperature probe.<br />

It’s 100% configurable, giving<br />

users maximum flexibility. It<br />

also allows for alterations to RH<br />

measurements, to keep step with<br />

changes or developments in the<br />

process.<br />

Users can set the zero/span<br />

range, output signals and choose<br />

from five output parameters<br />

(including dew point). All these<br />

changes and settings are made on<br />

a PC via the application software.<br />

The unit can also be ordered<br />

directly from Michell with the<br />

probes fully configured to unique,<br />

individual specifications.<br />

The new probe ensures zero<br />

process downtime by keeping<br />

maintenance to a minimum<br />

with an interchangeable sensor.<br />

When recalibration is due, the<br />

old HygroSmart HS3 sensor is<br />

simply exchanged for a new,<br />

freshly calibrated one. This simple<br />

procedure allows for the probe to<br />

remain installed, and takes only a<br />

few seconds to carry out. Using the<br />

replaceable sensor ensures that<br />

the HygroSmart HS3 probe has a<br />

low life-time cost, when compared<br />

to fully disposable probes.<br />

Alternatively, minor calibration<br />

adjustments can be easily made<br />

on any installed HS3 probe, with a<br />

5-point digital trim adjustment via<br />

the application software to ensure<br />

maximum accuracy without<br />

needing to replace the sensor.<br />

Designed for demanding<br />

industrial conditions, the<br />

HygroSmart HS3 probe features<br />

a solid corrosion-resistant body,<br />

10 bar pressure sealing and IP67<br />

pressure rating. In addition it also<br />

has an accuracy of 0.8%RH, making<br />

it among the most accurate and<br />

reliable RH probes on the market.<br />

sales@instrotech.co.za<br />

Safe AS-I input module especially for light guard applications<br />

The new safe AS-i input<br />

module is designed for the<br />

connection of electro-sensitive<br />

protective equipment (ESPE) with<br />

electronic outputs to EN 61496-<br />

1. It is particularly suited for the<br />

connection of safe inductive<br />

sensors such as GM705S. Pulse<br />

pick-ups for the display of muting<br />

functions can be connected via<br />

M12 sockets.<br />

The integrated outputs<br />

ensure the connection of two<br />

signal lamps. The tried-andtested<br />

quick mounting avoids<br />

wiring faults. The AS-i flat cable<br />

can be connected from three<br />

different directions. There is one<br />

M12 connecting socket each for<br />

the transmitter, the receiver and<br />

the two signal outputs.<br />

Fail-safe sensors with a<br />

current consumption below 200<br />

mA can be operated on AC507S<br />

without auxiliary voltage. The<br />

LEDs indicate the status of the<br />

inputs and outputs and the<br />

communication.<br />

The new safe AS-i input<br />

module meets the requirements<br />

up to SIL3 according to EN 62061<br />

and PL e to EN 13849-1. In the<br />

event of a fault, the integrated<br />

communication monitoring<br />

switches the signal outputs off.<br />

info.za@ifm.com

13<br />

<strong>19.2</strong><br />

Versatile, low-cost electronic transmitter with ceramic sensor<br />

The KOBOLD SEN-96 - an<br />

electronic transmitter with<br />

ceramic sensor for air, industrial,<br />

technical, gases and water and oil<br />

– is designed to be installed in gas<br />

distribution plants, on gas bottles,<br />

refrigerators, compressors,<br />

vacuum pumps and in hydraulic<br />

and high-pressure water plants.<br />

The SEN96 has proven to be<br />

very safe against overload, tolerate<br />

pressure peaks very effectively, and<br />

is ideally suited for use in hydraulic<br />

systems. Typical applications here<br />

are compressors, pump systems<br />

and cooling circuits.<br />

The handy SEN96 is connected<br />

to the process with G1/4, G1/2,<br />

1/4”NPT or 1/2”NPT threads. 23<br />

measuring ranges which run from<br />

-1...0 bar to 0...600 bar relative<br />

pressure are available.<br />

There is a choice of 4...20 mA,<br />

0...5 V, 0...10 V, 0.5...4.5 V ratiometric<br />

or 1...5 V analogue outputs for<br />

signal transmission. Fast, on the<br />

spot information of the measured<br />

pressure is made possible by<br />

the practical AUF type plug-on<br />

displays. Standard sensors have<br />

protection class IP65. The wetted<br />

parts are stainless steel, ceramic<br />

and sealing material FPM.<br />

The compact and versatile<br />

SEN-96 pressure sensor offers tried<br />

and tested measuring principles<br />

with a thick film ceramic measuring<br />

cell and features very good<br />

repeatability and great reliability.<br />

The unit is ideally suited for<br />

use in industry in general, and<br />

specifically in gas stocking or<br />

machines production, in light or<br />

heavy pneumatics industry, in<br />

the refrigeration industry, and in<br />

welding and vacuum applications.<br />

sales@instrotech.co.za<br />

TRIPLE ECCENTRIC<br />

ROTARY PROCESS VALVES<br />

ZWICK TRI-CON<br />

Zwick Tri-Con valves are<br />

successfully used for isolation, on/off,<br />

control and ESD applications for industrial<br />

and exhaust gases, hydrocarbons, chemicals,<br />

liquids and steam with process temperatures up to<br />

815C. The Tri-Con valve is used extensively on the<br />

oil & gas, chemical, petro-chemical and power generation<br />

industries.<br />

Zwick Tri-Con provides:<br />

• SIL 3 certification<br />

• Size from 2” (50mm) to 88” (2250mm)<br />

• Bi-directional operation<br />

• Zero leakage sealing<br />

• Non-rubbing - Self-centering disc<br />

• Metal-to-metal seats<br />

• Fire-safe certified sealing<br />

VEREENIGING<br />

Tel: +27 (0)11 397 2833<br />

Fax: +27 (0)11 397 4700<br />

DURBAN<br />

Tel: +27 (0)31 579 2593<br />

Fax: +27 (0)31 579 2562<br />

E-mail: sales@valve.co.za<br />

Exports: africaexports@valve.co.za

14<br />

12<br />

<strong>19.2</strong><br />

Power solutions offer reliability an<br />

New two-in-one redundant designs for gas ultrasonic flow<br />

All power solutions systems<br />

o<br />

meters offer measurement verification in fiscal applications<br />

encompass the latest technology<br />

New Daniel 3410 Series gas<br />

ultrasonic meter platform<br />

with dual-transmitters and<br />

meters in a single body provide<br />

more process insight to minimize<br />

measurement uncertainty,<br />

financial risk and operating costs.<br />

The new Daniel gas ultrasonic<br />

flow meter platform elevates its<br />

well-proven British Gas design<br />

by providing two meters and<br />

transmitters in a single body to<br />

help natural gas operators and<br />

pipelines improve reliability<br />

and efficiency. Designed to<br />

maximize capital budgets by<br />

permitting two completely<br />

independent measurements with<br />

the installation of just a single<br />

flowmeter, the new 3415 (fourpath<br />

+ one-path) and 3416 (fourpath<br />

+ two-path) gas ultrasonic<br />

flow meters combine a four-path<br />

fiscal meter with an additional<br />

check meter, while the new 3417<br />

(four-path + four-path) meter<br />

provides two fiscal meters for full<br />

redundancy and equal accuracy<br />

within one meter body. This twoin-one<br />

redundant design delivers<br />

continuous on-line verification of<br />

custody transfer measurement<br />

integrity, device health and<br />

process conditions, and improves<br />

fiscal metering confidence while<br />

ensuring regulatory compliance.<br />

Both Daniel 3415 and 3416<br />

gas ultrasonic meters measure<br />

flow using four horizontal chordal<br />

paths in addition to a reflective<br />

path dedicated to verification<br />

of the primary measurement,<br />

enabling improved metering<br />

insight, more informed<br />

decision making and simplified<br />

flow meter verification. For<br />

enhanced immunity to pipe wall<br />

contamination, the 3416 meter<br />

is equipped with an additional<br />

vertical reflective path to detect<br />

liquid or very thin layers of<br />

contamination at the bottom<br />

of the meter that otherwise<br />

remain completely hidden in a<br />

direct-path meter design. This<br />

allows reliable monitoring of<br />

process changes before they<br />

affect measurement, thus<br />

reducing calibration frequency<br />

and enabling maintenance to<br />

be condition-based instead of<br />

calendar-based.<br />

To further improve reliability<br />

and uptime in particularly<br />

demanding custody transfer<br />

applications, users can leverage<br />

the Daniel 3417 gas ultrasonic<br />

meter with its unique dual-plane<br />

power supply, optimum safety<br />

configuration that combines of OIML R137 MID Accuracy. In<br />

two independent four-path addition,<br />

and enhanced they feature<br />

aesthetics.<br />

redundant<br />

British Gas fiscal meters into one electronics The environmentally with a patented friendly,<br />

meter body. The configuration transducer dry type cast synchronization<br />

resin transformers,<br />

ensures complete measurement function transfer that electrical is unique power to Daniel between<br />

redundancy with two meters of gas two ultrasonic different voltage technology. systems<br />

equal accuracy and the ability This at function the same coordinates frequency, the with<br />

for each meter to operate acoustic low firing environmental of both meters impact.<br />

independently of the other. This to avoid These interference HV/LV transformers between offer<br />

design significantly reduces cost the significant two meters, savings allowing on electricity<br />

the<br />

for measurement stations that highest costs sampling and can reduce rate possible electricity<br />

traditionally utilize two separate and consumption providing stable by up ultrasonic<br />

to 20%<br />

meters with their associated signals<br />

during and<br />

off-peak optimal<br />

activity.<br />

low flow<br />

piping, calibrations and response for a more accurate and<br />

installations. Uninterruptible The power 3417 supply meter (UPS)<br />

is reliable measurement.<br />

ideal units<br />

for border stations that are<br />

P becoming bi-directional, storage<br />

Furthermore, all meters are<br />

ower solutions ensure<br />

applications, remote locations<br />

equipped with MeterLink, a<br />

protection of electrical<br />

such as offshore platforms or for<br />

fully automated diagnostics<br />

equipment and continuity of<br />

use on large compressor stations<br />

software package. MeterLink<br />

service during planned and<br />

or lines without a bypass.<br />

allows operators access to<br />

unexpected power outages.<br />

easy-to-interpret diagnostic<br />

Knowing These if and modular when a systems<br />

gas information, providing greater<br />

ultrasonic include meter certified has low drifted emission<br />

visibility to meter performance<br />

and (CLE) who cast is paying resin transformers,<br />

the and product quality as well as<br />

measurement busbar trunkings, shift is critically enclosures<br />

alerts that are generated when<br />

important for power to switchgear customers’ and<br />

abnormal operating conditions<br />

business. controlgear The assemblies, 3417 meter as<br />

are detected. Daniel multi-path<br />

addresses well as these uninterruptible needs because power<br />

redundant gas ultrasonic meters<br />

it can supply be used (UPS) as units. a shared An important<br />

meter provide additional measurement<br />

between<br />

advantage two<br />

of selecting contracting<br />

Legrand<br />

confidence by calculating<br />

parties for a tremendous capital<br />

corrected<br />

Legrand volume<br />

certified low<br />

rates, emission mass<br />

(CLE)<br />

and<br />

components for efficient, safe and cast resin transformers<br />

savings or for complete custody energy rates and real time AGA<br />

flexible power distribution, is the<br />

transfer backup measurement 10 speed The of absence sound. This of ensures flammable<br />

should<br />

immediate maintenance<br />

integration between<br />

be a repeatable insulation and liquids, accurate the flow use of<br />

needed. the company’s The 3415 and busbar 3416 trunking<br />

also measurement, self-extinguishing<br />

even materials<br />

when<br />

deliver systems, significant cast resin advantages, transformers<br />

process exempt conditions of toxic vary gas or emissions,<br />

differ<br />

particularly and XL³ cabinets.<br />

shale plays, by from reduced calibrated noise conditions. levels and low<br />

giving operators greater visibility electromagnetic<br />

emissions,<br />

into gas quality.<br />

ensure enhanced environmental<br />

All meters are approved michael.eksteen@<br />

protection in all installations.<br />

to the more stringent class 0.5 emerson.com Standard<br />

distribution<br />

CONTROL VALVE TEST<br />

transformers have rated power<br />

STABILITY TEST<br />

between 100 and 3 150 kVA,<br />

Measuring the stability of the Control Valve by comparing a stabile input<br />

signal and air supply pressure against the output signal and valve position.<br />

primary rated voltage up to 36 kV<br />

ACCURACY TEST<br />

and secondary rated voltage up<br />

Measured in user defined steps, changing the input signal and measuring<br />

the valve position.<br />

oxidised bearings, torn impellers both to liquids 433 V.<br />

and air, as well as in<br />

BENCH TEST<br />

or deflector Measuring deformation.<br />

the actual responds of the valve by automatically<br />

hazardous Special environments. transformers have<br />

ramping the input signal from 0 to 100% and back, while<br />

With a<br />

monitoring<br />

robust<br />

the displacement<br />

construction<br />

of the valve<br />

rated power up to 20 000 kVA,<br />

and pressure in the actuator.<br />

the EGE flow sensor is resistant primary rated voltage up to 36<br />

RESPONDS TEST<br />

Performed to measure the valve’s ability to<br />

to corrosion XL³ cabinets is ideal for use in kVA and secondary rated voltage<br />

follow a block and shaped enclosures<br />

input signal.<br />

bryant@countapulse.co.za<br />

Plug and play solution makes flow monitoring easy<br />

The compact plug and play<br />

EGE SNS 450 thermodynamic<br />

flow sensor provides ease of flow<br />

monitoring with low maintenance<br />

benefits.<br />

The innovative screwin<br />

adapter on the EGE<br />

thermodynamic flow sensor<br />