- Page 1 and 2: ABRASIVE PRODUCT SOLUTIONS FOR THE

- Page 3 and 4: Machine index Right Angle/Vertical

- Page 5 and 6: Catalog navigation J What are the L

- Page 7 and 8: a technology leader FOCUSED ON INNO

- Page 9 and 10: Depressed center wheels Material/Ap

- Page 11 and 12: Depressed center wheels MACHINE USE

- Page 13 and 14: Depressed center wheels MACHINE USE

- Page 15 and 16: Depressed center wheels MACHINE USE

- Page 17 and 18: Depressed center wheels MACHINE USE

- Page 19 and 20: Small Diameter Reinforced Cut-off M

- Page 21 and 22: Small Diameter Reinforced xxx cut-o

- Page 23 and 24: Small Diameter Reinforced cut-off M

- Page 25 and 26: High-Speed Reinforced Cut-off MACHI

- Page 27 and 28: Rail Reinforced cut-off Category De

- Page 29 and 30: Chop Saw Reinforced Cut-off Categor

- Page 31: Chop Saw Reinforced Cut-off MACHINE

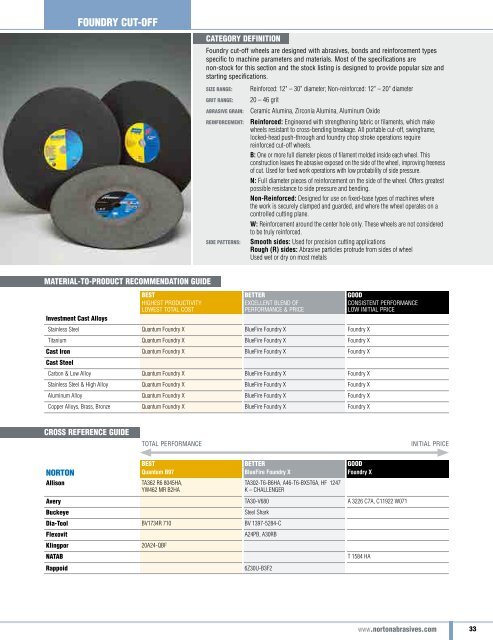

- Page 35 and 36: Toolroom Cut-off Category Definitio

- Page 37 and 38: Metallurgical Non-reinforced xxx Cu

- Page 39 and 40: Portable Snagging Wheels, Cones, an

- Page 41 and 42: Floorstand and Swingframe Snagging

- Page 43 and 44: Bench and Pedestal Wheels Category

- Page 45 and 46: Bench and Pedestal Wheels MACHINES

- Page 47 and 48: Mounted Points MACHINES USED Center

- Page 49 and 50: Mounted Points MACHINES USED Availa

- Page 51 and 52: Sharpening Stones Category Definiti

- Page 53 and 54: Sharpening Stones MACHINE USED Benc

- Page 55 and 56: Sharpening Stones MACHINE USED Wate

- Page 57 and 58: Sharpening Stones MACHINE USED Shar

- Page 59 and 60: Sharpening Stones Abrasive Files co

- Page 61 and 62: Sharpening Stones MACHINE USED Abra

- Page 63 and 64: Sharpening Stones MACHINE USED Spec

- Page 65 and 66: Rubbing Bricks MACHINES USED Catego

- Page 67 and 68: the brightest product solutions fro

- Page 69 and 70: Fiber discs MACHINES USED Featured

- Page 71 and 72: Fiber discs MACHINES USED Availabil

- Page 73 and 74: Fiber discs MACHINES USED Fiber Dis

- Page 75 and 76: Flap discs Material-to-product reco

- Page 77 and 78: Flap Discs MACHINE USED Availabilit

- Page 79 and 80: Flap discs MACHINE USED Availabilit

- Page 81 and 82: Paper xxxDiscs Category definition

- Page 83 and 84:

Featured products Paper Discs Heavy

- Page 85 and 86:

Paper Discs MACHINES USED Availabil

- Page 87 and 88:

Featured products Paper Discs MACHI

- Page 89 and 90:

Paper Discs MACHINES USED Availabil

- Page 91 and 92:

Paper Disc Accessories MACHINES USE

- Page 93 and 94:

Film and Foam Finishing Disc Access

- Page 95 and 96:

Cloth PSA Discs And Accessories MAC

- Page 97 and 98:

Flexible Diamond Coated Discs MACHI

- Page 99 and 100:

Quick-Change xxx Discs Material/APP

- Page 101 and 102:

Quick-Change xxx Discs MACHINE USED

- Page 103 and 104:

Quick-Change Discs MACHINE USED Nor

- Page 105 and 106:

Quick-Change Discs MACHINE USED Ava

- Page 107 and 108:

Paper Sheets & Rolls Category defin

- Page 109 and 110:

Paper Sheets & Rolls MACHINES USED

- Page 111 and 112:

Paper Sheets & Rolls MACHINES USED

- Page 113 and 114:

Paper Sheets & Rolls MACHINES USED

- Page 115 and 116:

Cloth Sheets & Rolls Availability C

- Page 117 and 118:

Abrasive Sponges Featured Products

- Page 119 and 120:

File Belts MACHINE USED Category de

- Page 121 and 122:

File Belts MACHINE USED Availabilit

- Page 123 and 124:

Portable Belts MACHINES USED Portab

- Page 125 and 126:

Featured Products Narrow Belts MACH

- Page 127 and 128:

Narrow belts MACHINE USED 1" to 6"

- Page 129 and 130:

Narrow belts MACHINES USED 2" to 10

- Page 131 and 132:

Featured products Wide Belts Norton

- Page 133 and 134:

Norax Belts MACHINE USED Category d

- Page 135 and 136:

FasTtRack Service Made-To-Order Bel

- Page 137 and 138:

Flap Wheels MACHINES USED Featured

- Page 139 and 140:

Flap Wheels MACHINES USED Mini Flap

- Page 141 and 142:

FLAP XXX WHEELS MACHINES USED Mini

- Page 143 and 144:

Flap Wheels MACHINES USED 3-1/2" -

- Page 145 and 146:

Flap Wheels MACHINES USED 10" - 16"

- Page 147 and 148:

Flap Wheels MACHINES USED Sand-O-Fl

- Page 149 and 150:

Spiral Bands MACHINE USED Availabil

- Page 151 and 152:

Cartridge Rolls, Spiral Rolls, Cone

- Page 153 and 154:

Cartridge Rolls, Spiral Rolls, Cone

- Page 155 and 156:

Cartridge Rolls, Spiral Rolls, Cone

- Page 157 and 158:

Cartridge Rolls, Spiral Rolls, xxxC

- Page 159 and 160:

Square & Cross Pads, Overlap Slotte

- Page 161 and 162:

Bore Polishers Category definition

- Page 163 and 164:

FlexDrums Category definition FlexD

- Page 165 and 166:

FlexDrums Hub Units • FlexDrum hu

- Page 167 and 168:

Coated Abrasive Basics Coated Abras

- Page 169 and 170:

Coated Abrasive Basics Coated Abras

- Page 171 and 172:

we’ve surfaced faster solutions T

- Page 173 and 174:

Non-Woven Depressed Center Discs Ap

- Page 175 and 176:

Non-Woven Standard Back-up Pad Disc

- Page 177 and 178:

Non-Woven Quick-Change Discs MACHIN

- Page 179 and 180:

Non-Woven Quick-Change Discs Featur

- Page 181 and 182:

Non-Woven Quick-Change Discs Featur

- Page 183 and 184:

Non-Woven Quick-Change Discs Featur

- Page 185 and 186:

Non-Woven Hook and Loop Discs MACHI

- Page 187 and 188:

Non-Woven Brushes Featured Products

- Page 189 and 190:

Non-Woven Hand Pads, Rolls and Spon

- Page 191 and 192:

Non-Woven unified Wheels Cross Refe

- Page 193 and 194:

Non-Woven Unified Wheels MACHINES U

- Page 195 and 196:

Non-Woven Convolute xxxWheels MACHI

- Page 197 and 198:

Non-Woven Convolute Wheels MACHINES

- Page 199 and 200:

Non-Woven Belts MACHINES USED Categ

- Page 201 and 202:

Non-Woven Flap Wheels MACHINES USED

- Page 203 and 204:

Non-Woven Flap Wheels MACHINES USED

- Page 205 and 206:

Non-Woven Abrasive Basics Getting t

- Page 207 and 208:

complementing our ABRASIVES PORTFOL

- Page 209 and 210:

Wire Brushes Featured products AND

- Page 211 and 212:

Wire Brushes MACHINES USED Featured

- Page 213 and 214:

Masking Tape Norton Premium Tan Hig

- Page 215 and 216:

your pathway TO PRECISION PERFORMAN

- Page 217 and 218:

Vitrified Wheels Vitrified Wheel Bo

- Page 219 and 220:

Vitrified Wheels Troubleshooting Gu

- Page 221 and 222:

Vitrified Wheels ID and Race Wheels

- Page 223 and 224:

Vitrified Wheels Vitrified Wheels F

- Page 225 and 226:

Vitrified Wheels Vitrified Wheels F

- Page 227 and 228:

Vitrified Wheels Vitrified Wheels F

- Page 229 and 230:

Vitrified Wheels Vitrified Wheels F

- Page 231 and 232:

Vitrified Wheels Category Definitio

- Page 233 and 234:

Surface Grinding Segments Category

- Page 235 and 236:

Cylindrical Wheels Category Definit

- Page 237 and 238:

Cylindrical Wheels Availability Tie

- Page 239 and 240:

Centerless and Feed Wheels Proper W

- Page 241 and 242:

Creepfeed Blank Stock FastTrack Ser

- Page 243 and 244:

55A Blank Stock FastTrack Service C

- Page 245 and 246:

Bonded abrasives basics How to Read

- Page 247 and 248:

our dressing tools MAKE THE PERFECT

- Page 249 and 250:

Diamond Tools Single Point Tools Ou

- Page 251 and 252:

Diamond Tools Single Point Tools co

- Page 253 and 254:

Diamond Tools Single Point Tools co

- Page 255 and 256:

Diamond Tools Toolroom Tools Norton

- Page 257 and 258:

Diamond Tools Multi-Point (Grit) To

- Page 259 and 260:

Diamond Tools Multi-Point (Grit) To

- Page 261 and 262:

Diamond Tools Blade Tools With the

- Page 263 and 264:

Included Angle on Diamond Diamond T

- Page 265 and 266:

Diamond Tools Accessories Tool hold

- Page 267 and 268:

Diamond Stationary Fliesen Tools Fu

- Page 269 and 270:

Rotary Dressing Tools Category Defi

- Page 271 and 272:

setting a new industry standard FOR

- Page 273 and 274:

Norton Diamond / cBN Stock Wheels N

- Page 275 and 276:

Norton Diamond / cBN Stock Wheels H

- Page 277 and 278:

Norton Diamond / cBN Stock Wheels A

- Page 279 and 280:

Norton Diamond / cBN Stock Wheels D

- Page 281 and 282:

Norton Diamond / cBN Stock Wheels S

- Page 283 and 284:

Norton Diamond / cBN Stock Wheels S

- Page 285 and 286:

Norton Diamond / cBN Stock Wheels S

- Page 287 and 288:

Norton B99 Express Diamond / cBN Wh

- Page 289 and 290:

CNC Diamond / cBN Wheels Diamond CN

- Page 291 and 292:

CNC Diamond / cBN Wheels cBN CNC Wh

- Page 293 and 294:

CNC Diamond / cBN Wheels Norton CNC

- Page 295 and 296:

Truing and Dressing Guide Diamond a

- Page 297 and 298:

Dressing Sticks Vitrified Dressing

- Page 299 and 300:

Electroplated Diamond and cBN Produ

- Page 301 and 302:

Electroplated Diamond and cBN Produ

- Page 303 and 304:

Electroplated Diamond and cBN Produ

- Page 305 and 306:

Electroplated Diamond and cBN Produ

- Page 307 and 308:

Electroplated Diamond and cBN Produ

- Page 309 and 310:

Electroplated Diamond and cBN Produ

- Page 311 and 312:

General Information Safety - It’s

- Page 313 and 314:

General Information Diameter of Whe

- Page 315 and 316:

General Information Get access to t