LA Safety Catalogue - Issue 6

LA Safety Supplies provide high quality, competitively priced, corporate clothing, workwear, safety boots and shoes, non-safety footwear, janitorial supplies, weather wear, specialist clothing solutions, personal protective equipment, custom embroidery and printing.

LA Safety Supplies provide high quality, competitively priced, corporate clothing, workwear, safety boots and shoes, non-safety footwear, janitorial supplies, weather wear, specialist clothing solutions, personal protective equipment, custom embroidery and printing.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

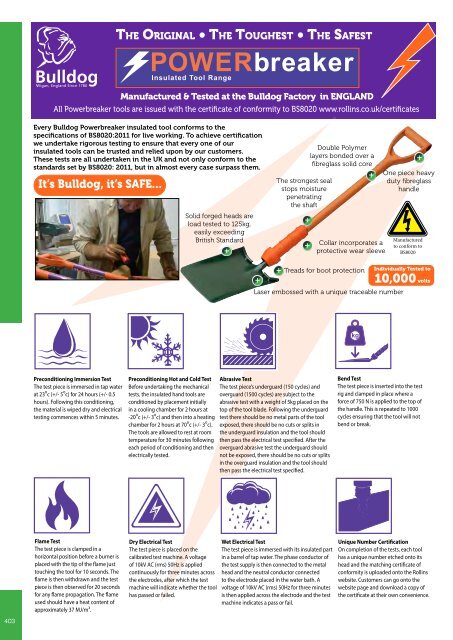

The Original • The Toughest • The Safest<br />

Manufactured & Tested at the Bulldog Factory in ENG<strong>LA</strong>ND<br />

All Powerbreaker tools are issued with the certificate of conformity to BS8020 www.rollins.co.uk/certificates<br />

Every Bulldog Powerbreaker insulated tool conforms to the<br />

specifications of BS8020:2011 for live working. To achieve certification<br />

we undertake rigorous testing to ensure that every one of our<br />

insulated tools can be trusted and relied upon by our customers.<br />

These tests are all undertaken in the UK and not only conform to the<br />

standards set by BS8020: 2011, but in almost every case surpass them.<br />

It’s Bulldog, it’s SAFE...<br />

The strongest seal<br />

stops moisture<br />

penetrating<br />

the shaft<br />

Double Polymer<br />

layers bonded over a<br />

fibreglass solid core<br />

One piece heavy<br />

duty fibreglass<br />

handle<br />

Powerbreaker Insulated Digging Tools<br />

PD5SM2INR<br />

Square Mouth Shovels Taper Mouth Shovels<br />

• Use for trench work,<br />

concrete mixing, tarmac &<br />

shovelling<br />

• Treaded model stops<br />

slippage in wet and<br />

muddy conditions<br />

• Sometimes preferred to the<br />

square mouth for shovelling<br />

out or backfilling trenches,<br />

concrete mixing and working<br />

tarmac<br />

• Treaded model stops<br />

slippage in wet and muddy<br />

conditions<br />

Manufactured & Tested in the UK<br />

Square Trench Shovels<br />

• Used for digging narrow<br />

trenches when laying<br />

cable and pipe<br />

• Treaded model stops<br />

slippage in wet and<br />

muddy conditions<br />

TOOLS<br />

Solid forged heads are<br />

load tested to 125kg,<br />

easily exceeding<br />

British Standard<br />

Collar incorporates a<br />

protective wear sleeve<br />

Manufactured<br />

to conform to<br />

BS8020<br />

Treads for boot protection<br />

Individually Tested to<br />

10,000 volts<br />

Laser embossed with a unique traceable number<br />

Part No Shaft Head Treaded<br />

Length<br />

T0181 28” No.2 No<br />

T0182 28” No.2 Yes<br />

Part No Shaft Head Treaded<br />

Length<br />

T0183 28” No.2 No<br />

T0184 28” No.2 Yes<br />

Part No Shaft Head Treaded<br />

Length<br />

T0185 28” 290x215 No<br />

T0186 28” 290x215 Yes<br />

Trench Fork<br />

Cable Layers<br />

Newcastle Drainers<br />

Preconditioning Immersion Test<br />

The test piece is immersed in tap water<br />

at 23 o c (+/- 5 o c) for 24 hours (+/- 0.5<br />

hours). Following this conditioning,<br />

the material is wiped dry and electrical<br />

testing commences within 5 minutes.<br />

Preconditioning Hot and Cold Test<br />

Before undertaking the mechanical<br />

tests, the insulated hand tools are<br />

conditioned by placement initially<br />

in a cooling chamber for 2 hours at<br />

-20 o c (+/- 3 o c) and then into a heating<br />

chamber for 2 hours at 70 o c (+/- 3 o c).<br />

The tools are allowed to rest at room<br />

temperature for 30 minutes following<br />

each period of conditioning and then<br />

electrically tested.<br />

kg kg kg kg<br />

Abrasive Test<br />

The test piece’s underguard (150 cycles) and<br />

overguard (1500 cycles) are subject to the<br />

abrasive test with a weight of 5kg placed on the<br />

top of the tool blade. Following the underguard<br />

test there should be no metal parts of the tool<br />

exposed, there should be no cuts or splits in<br />

the underguard insulation and the tool should<br />

kg kg kg kg<br />

then pass the electrical test specified. After the<br />

overguard abrasive test the underguard should<br />

not be exposed, there should be no cuts or splits<br />

in the overguard insulation and the tool should<br />

then pass the electrical test specified.<br />

Bend Test<br />

The test piece is inserted into the test<br />

rig and clamped in place where a<br />

force of 750 N is applied to the top of<br />

the handle. This is repeated to 1000<br />

cycles ensuring that the tool will not<br />

bend or break.<br />

• The four square prongs<br />

and chisel ponts make<br />

penetration of hard ground<br />

easier<br />

• Ideal for breaking up<br />

stubborn ground when<br />

digging clay or stone<br />

• Slightly dished blade<br />

• Ideal for breaking up<br />

stubborn ground when<br />

digging clay or stone<br />

• Treaded model stops<br />

slippage in wet and muddy<br />

conditions<br />

• For digging holes, deep narrow<br />

trenches, cable channels, pipe<br />

channels, drain channels or<br />

post holes<br />

• Treaded model stops<br />

slippage in wet and<br />

muddy conditions<br />

Flame Test<br />

The test piece is clamped in a<br />

horizontal position before a burner is<br />

placed with the tip of the flame just<br />

touching the tool for 10 seconds. The<br />

flame is then withdrawn and the test<br />

piece is then observed for 20 seconds<br />

for any flame propagation. The flame<br />

used should have a heat content of<br />

approximately 37 MJ/m³.<br />

Dry Electrical Test<br />

The test piece is placed on the<br />

calibrated test machine. A voltage<br />

of 10kV AC (rms) 50Hz is applied<br />

continuously for three minutes across<br />

the electrodes, after which the test<br />

machine will indicate whether the tool<br />

has passed or failed.<br />

Wet Electrical Test<br />

The test piece is immersed with its insulated part<br />

in a barrel of tap water. The phase conductor of<br />

the test supply is then connected to the metal<br />

head and the neutral conductor connected<br />

to the electrode placed in the water bath. A<br />

voltage of 10kV AC (rms) 50Hz for three minutes<br />

is then applied across the electrode and the test<br />

machine indicates a pass or fail.<br />

Unique Number Certification<br />

On completion of the tests, each tool<br />

has a unique number etched onto its<br />

head and the matching certificate of<br />

conformity is uploaded onto the Rollins<br />

website. Customers can go onto the<br />

website page and download a copy of<br />

the certificate at their own convenience.<br />

Part No Shaft Head Treaded<br />

Length (mm)<br />

T0187 28” 305x250 No<br />

Part No Shaft Head Treaded<br />

Length (mm)<br />

T0188 28” 280x125 No<br />

T0189 28” 280x125 Yes<br />

Part No Shaft Head Treaded<br />

Length (mm)<br />

T0190 28” 407x175 No<br />

T0191 28” 407x175 Yes<br />

403 404