You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BALL BEARING HOUSED UNITS<br />

ENGINEERING • LUBRICATION<br />

VISCOSITY INDEX<br />

The ideal oil (as far as viscosity is concerned) would be the same<br />

viscosity at all temperatures. All oils become less viscous (thin-out)<br />

when heated and more viscous (thickened) when cooled.<br />

However, oils do not vary in viscosity to the same extent. Some<br />

thicken or thin more rapidly than others.<br />

The term viscosity index, or VI, is used to rate oils according to<br />

their temperature-viscosity behavior.<br />

Oils with the highest viscosity index are more resistant to changes<br />

in viscosity with changes in temperature than lower viscosity index<br />

oils. Obviously, high viscosity-index lubricants are most suitable for<br />

bearing applications experiencing wide temperature variations.<br />

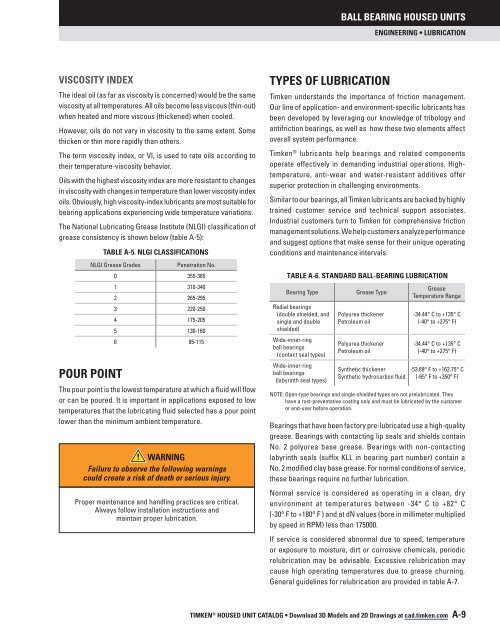

The National Lubricating Grease Institute (NLGI) classification of<br />

grease consistency is shown below (table A-5):<br />

TABLE A-5. NLGI CLASSIFICATIONS<br />

NLGI Grease Grades<br />

Penetration No.<br />

0 355-385<br />

1 310-340<br />

2 265-295<br />

3 220-250<br />

4 175-205<br />

5 130-160<br />

6 85-115<br />

POUR POINT<br />

The pour point is the lowest temperature at which a fluid will flow<br />

or can be poured. It is important in applications exposed to low<br />

temperatures that the lubricating fluid selected has a pour point<br />

lower than the minimum ambient temperature.<br />

WARNING<br />

Failure to observe the following warnings<br />

could create a risk of death or serious injury.<br />

Proper maintenance and handling practices are critical.<br />

Always follow installation instructions and<br />

maintain proper lubrication.<br />

TYPES OF LUBRICATION<br />

<strong>Timken</strong> understands the importance of friction management.<br />

Our line of application- and environment-specific lubricants has<br />

been developed by leveraging our knowledge of tribology and<br />

antifriction bearings, as well as how these two elements affect<br />

overall system performance.<br />

<strong>Timken</strong> ® lubricants help bearings and related components<br />

operate effectively in demanding industrial operations. Hightemperature,<br />

anti-wear and water-resistant additives offer<br />

superior protection in challenging environments.<br />

Similar to our bearings, all <strong>Timken</strong> lubricants are backed by highly<br />

trained customer service and technical support associates.<br />

Industrial customers turn to <strong>Timken</strong> for comprehensive friction<br />

management solutions. We help customers analyze performance<br />

and suggest options that make sense for their unique operating<br />

conditions and maintenance intervals.<br />

TABLE A-6. STANDARD BALL-BEARING LUBRICATION<br />

<strong>Bearing</strong> Type<br />

Radial bearings<br />

(double shielded, and<br />

single and double<br />

shielded)<br />

Wide-inner-ring<br />

ball bearings<br />

(contact seal types)<br />

Wide-inner-ring<br />

ball bearings<br />

(labyrinth seal types)<br />

Grease Type<br />

Polyurea thickener<br />

Petroleum oil<br />

Polyurea thickener<br />

Petroleum oil<br />

Synthetic thickener<br />

Synthetic hydrocarbon fluid<br />

Grease<br />

Temperature Range<br />

-34.44° C to +135° C<br />

(-40° to +275° F)<br />

-34.44° C to +135° C<br />

(-40° to +275° F)<br />

-53.89° F to +162.75° C<br />

(-65° F to +350° F)<br />

NOTE: Open-type bearings and single-shielded types are not prelubricated. They<br />

have a rust-preventative coating only and must be lubricated by the customer<br />

or end-user before operation.<br />

<strong>Bearing</strong>s that have been factory pre-lubricated use a high-quality<br />

grease. <strong>Bearing</strong>s with contacting lip seals and shields contain<br />

No. 2 polyurea base grease. <strong>Bearing</strong>s with non-contacting<br />

labyrinth seals (suffix KLL in bearing part number) contain a<br />

No. 2 modified clay base grease. For normal conditions of service,<br />

these bearings require no further lubrication.<br />

Normal service is considered as operating in a clean, dry<br />

environment at temperatures between -34° C to +82° C<br />

(-30° F to +180° F ) and at dN values (bore in millimeter multiplied<br />

by speed in RPM) less than 175000.<br />

If service is considered abnormal due to speed, temperature<br />

or exposure to moisture, dirt or corrosive chemicals, periodic<br />

relubrication may be advisable. Excessive relubrication may<br />

cause high operating temperatures due to grease churning.<br />

General guidelines for relubrication are provided in table A-7.<br />

TIMKEN ® HOUSED UNIT CATALOG • Download 3D Models and 2D Drawings at cad.timken.com A-9