HPXdrive - Kinshofer

HPXdrive - Kinshofer

HPXdrive - Kinshofer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

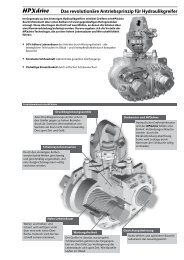

<strong>HPXdrive</strong><br />

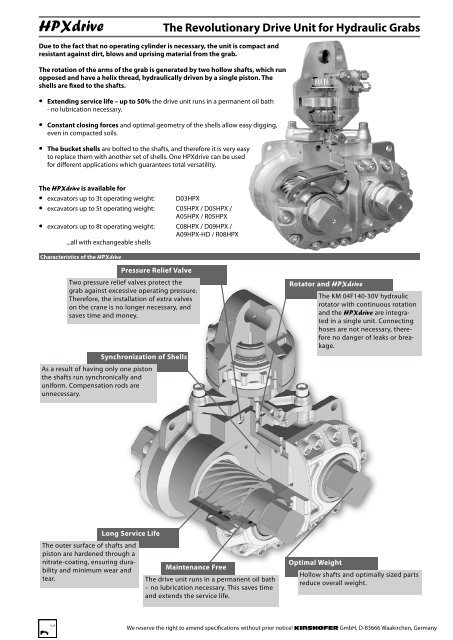

Due to the fact that no operating cylinder is necessary, the unit is compact and<br />

resistant against dirt, blows and uprising material from the grab.<br />

The Revolutionary Drive Unit for Hydraulic Grabs<br />

The rotation of the arms of the grab is generated by two hollow shafts, which run<br />

opposed and have a helix thread, hydraulically driven by a single piston. The<br />

shells are fixed to the shafts.<br />

l Extending service life – up to 50% the drive unit runs in a permanent oil bath<br />

- no lubrication necessary.<br />

l Constant closing forces and optimal geometry of the shells allow easy digging,<br />

even in compacted soils.<br />

l The bucket shells are bolted to the shafts, and therefore it is very easy<br />

to replace them with another set of shells. One <strong>HPXdrive</strong> can be used<br />

for different applications which guarantees total versatility.<br />

The <strong>HPXdrive</strong> is available for<br />

l excavators up to 3t operating weight: D03HPX<br />

l excavators up to 5t operating weight: C05HPX / D05HPX /<br />

A05HPX / R05HPX<br />

l excavators up to 8t operating weight: C08HPX / D09HPX /<br />

A09HPX-HD / R08HPX<br />

...all with exchangeable shells<br />

Characteristics of the <strong>HPXdrive</strong><br />

Pressure Relief Valve<br />

Two pressure relief valves protect the<br />

grab against excessive operating pressure.<br />

Therefore, the installation of extra valves<br />

on the crane is no longer necessary, and<br />

saves time and money.<br />

Synchronization of Shells<br />

As a result of having only one piston<br />

the shafts run synchronically and<br />

uniform. Compensation rods are<br />

unnecessary.<br />

Long Service Life<br />

The outer surface of shafts and<br />

piston are hardened through a<br />

nitrate-coating, ensuring durability<br />

and minimum wear and<br />

tear.<br />

Maintenance Free<br />

The drive unit runs in a permanent oil bath<br />

– no lubrication necessary. This saves time<br />

and extends the service life.<br />

Rotator and <strong>HPXdrive</strong><br />

Optimal Weight<br />

The KM 04F140-30V hydraulic<br />

rotator with continuous rotation<br />

and the <strong>HPXdrive</strong> are integrated<br />

in a single unit. Connecting<br />

hoses are not necessary, therefore<br />

no danger of leaks or breakage.<br />

Hollow shafts and optimally sized parts<br />

reduce overall weight.<br />

We reserve the right to amend specifications without prior notice! KINSHOFER GmbH, D-83666 Waakirchen, Germany

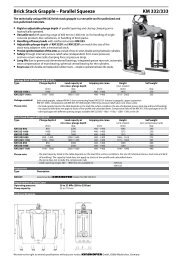

Exchangeable Shells<br />

The bucket shells of the <strong>HPXdrive</strong> are bolted to the shafts, and therefore it is very easy to replace them with another set of<br />

shells. Different types of shells for different applications can be refitted onto the driving unit, e.g. clamshell bucket, rock<br />

grab, timber grab, hay and forestry grab and multi purpose clamshell. Other types of shells are available on request.<br />

The interchangeable shells are delivered with an exchange aid that guarantees that the <strong>HPXdrive</strong> can be positioned with ease.<br />

Package: exchangeable shells, bolt-on teeth (for clamshell buckets), exchanging support<br />

We reserve the right to amend specifications without prior notice! KINSHOFER GmbH, D-83666 Waakirchen, Germany<br />

<strong>HPXdrive</strong><br />

Type Operating Width Volume Number of Self weight Load<br />

weight<br />

teeth<br />

capacity<br />

(t) (mm) (litre) (kg) (kg)<br />

Exchangeable Shells for Clamshell Bucket<br />

C05HPX-40S 3 - 5 400 115 4 110 3000<br />

C05HPX-45S 3 - 5 450 130 4 125 3000<br />

C05HPX-50S 3 - 5 500 140 4 130 3000<br />

C05HPX-60S 3 - 5 600 170 6 145 3000<br />

C05HPX-80S 3 - 5 800 230 6 170 3000<br />

C08HPX-40S 5 - 8 400 145 4 120 3000<br />

C08HPX-45S 5 - 8 450 160 4 135 3000<br />

C08HPX-50S 5 - 8 500 180 4 140 3000<br />

C08HPX-60S 5 - 8 600 220 6 160 3000<br />

C08HPX-80S 5 - 8 800 300 6 180 3000<br />

Exchangeable Shells for Demolition and Sorting Grab<br />

D03HPX-40S 3 400 60 - 100 1000<br />

D05HPX-50S 3 - 5 500 100 - 135 1000<br />

D08HPX-60S 5 - 8 600 150 - 160 1000<br />

D09HPX-60S 5 - 9 600 150 - 160 1000<br />

Exchangeable Shells for Multi Purpose Grab<br />

A05HPX-50S 3 - 5 500 100 3 140 1000<br />

A09HPX-60S 5 - 9 600 200 5 210 2500<br />

Exchangeable Shells for Rock Grab<br />

R05HPX-0,16S 3 - 5 400 0,16 m 2 - 95 1000<br />

R08HPX-0,16S 5 - 8 400 0,16 m 2 - 100 1000<br />

Please note: The driving unit <strong>HPXdrive</strong> Standard can only be used in combination with KINSHOFER-rotator and KINSHOFER-shells.

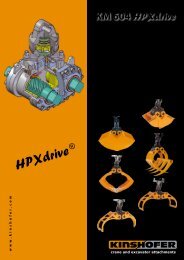

Due to the fact that no operating cylinder is necessary, the unit is compact<br />

and resistant against dirt, blows and uprising material from the grab.<br />

The rotation of the arms of the grab is generated by two shafts,<br />

which run opposed and have a helix thread, hydraulically<br />

driven by a single piston. The shells are fixed to the shafts.<br />

l Extending service life – up to 50% the drive unit runs in a<br />

permanent oil bath - no lubrication necessary.<br />

l Constant closing forces and optimal geometry of the shells<br />

allow easy digging, even in compacted soils.<br />

l The bucket shells are bolted to the shafts, and therefore<br />

it is very easy to replace them with another set of shells.<br />

One <strong>HPXdrive</strong> can be used for different applications which<br />

guarantees total versatility.<br />

The <strong>HPXdrive</strong> is available for<br />

l excavators up to 18t operating weight: D18HPX HD<br />

Characteristics of the <strong>HPXdrive</strong><br />

Synchronization of the Shells<br />

Counterbalance Valve<br />

The counterbalance valve grants the function<br />

„Close“ and sustains the clamping force, if the<br />

hydraulic pressure drops or fails. It protects the<br />

drive from overstressing caused by external forces.<br />

As a result of having only<br />

one piston the shafts run<br />

synchronically and uniform.<br />

Compensation rods are<br />

unnecessary.<br />

Long Service Life<br />

The outer surface of shafts and<br />

piston are hardened through a<br />

nitrate-coating, ensuring durability<br />

and minimum wear and tear.<br />

Rotator and <strong>HPXdrive</strong><br />

The flat hydraulic rotator with<br />

continuous rotation by means<br />

of two motors and the <strong>HPXdrive</strong><br />

are integrated in a single unit.<br />

Eco-friendly: Connecting hoses<br />

are not necessary, therefore no<br />

danger of leaks or breakage.<br />

Maintenance Free<br />

The drive unit runs in a permanent oil bath<br />

– no lubrication necessary. This saves time<br />

and extends the service life.<br />

We reserve the right to amend specifications without prior notice! KINSHOFER GmbH, D-83666 Waakirchen, Germany