FAS622en_pH measurement

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

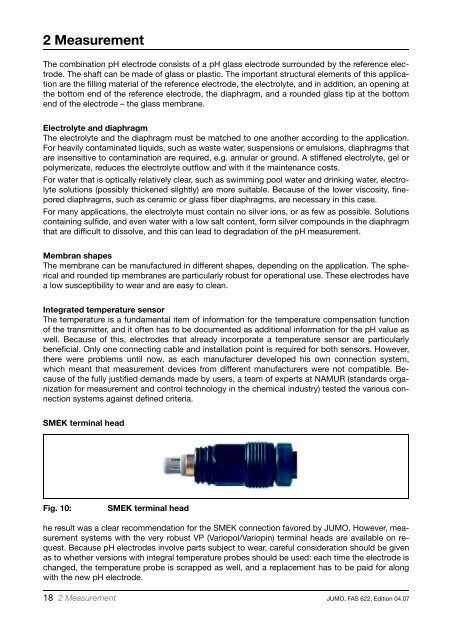

2 Measurement<br />

The combination <strong>pH</strong> electrode consists of a <strong>pH</strong> glass electrode surrounded by the reference electrode.<br />

The shaft can be made of glass or plastic. The important structural elements of this application<br />

are the filling material of the reference electrode, the electrolyte, and in addition, an opening at<br />

the bottom end of the reference electrode, the diaphragm, and a rounded glass tip at the bottom<br />

end of the electrode – the glass membrane.<br />

Electrolyte and diaphragm<br />

The electrolyte and the diaphragm must be matched to one another according to the application.<br />

For heavily contaminated liquids, such as waste water, suspensions or emulsions, diaphragms that<br />

are insensitive to contamination are required, e.g. annular or ground. A stiffened electrolyte, gel or<br />

polymerizate, reduces the electrolyte outflow and with it the maintenance costs.<br />

For water that is optically relatively clear, such as swimming pool water and drinking water, electrolyte<br />

solutions (possibly thickened slightly) are more suitable. Because of the lower viscosity, finepored<br />

diaphragms, such as ceramic or glass fiber diaphragms, are necessary in this case.<br />

For many applications, the electrolyte must contain no silver ions, or as few as possible. Solutions<br />

containing sulfide, and even water with a low salt content, form silver compounds in the diaphragm<br />

that are difficult to dissolve, and this can lead to degradation of the <strong>pH</strong> <strong>measurement</strong>.<br />

Membran shapes<br />

The membrane can be manufactured in different shapes, depending on the application. The spherical<br />

and rounded tip membranes are particularly robust for operational use. These electrodes have<br />

a low susceptibility to wear and are easy to clean.<br />

Integrated temperature sensor<br />

The temperature is a fundamental item of information for the temperature compensation function<br />

of the transmitter, and it often has to be documented as additional information for the <strong>pH</strong> value as<br />

well. Because of this, electrodes that already incorporate a temperature sensor are particularly<br />

beneficial. Only one connecting cable and installation point is required for both sensors. However,<br />

there were problems until now, as each manufacturer developed his own connection system,<br />

which meant that <strong>measurement</strong> devices from different manufacturers were not compatible. Because<br />

of the fully justified demands made by users, a team of experts at NAMUR (standards organization<br />

for <strong>measurement</strong> and control technology in the chemical industry) tested the various connection<br />

systems against defined criteria.<br />

SMEK terminal head<br />

Fig. 10:<br />

SMEK terminal head<br />

he result was a clear recommendation for the SMEK connection favored by JUMO. However, <strong>measurement</strong><br />

systems with the very robust VP (Variopol/Variopin) terminal heads are available on request.<br />

Because <strong>pH</strong> electrodes involve parts subject to wear, careful consideration should be given<br />

as to whether versions with integral temperature probes should be used: each time the electrode is<br />

changed, the temperature probe is scrapped as well, and a replacement has to be paid for along<br />

with the new <strong>pH</strong> electrode.<br />

18 2 Measurement JUMO, FAS 622, Edition 04.07