Roba-Profile - MB Maschinenbau

Roba-Profile - MB Maschinenbau

Roba-Profile - MB Maschinenbau

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

012<br />

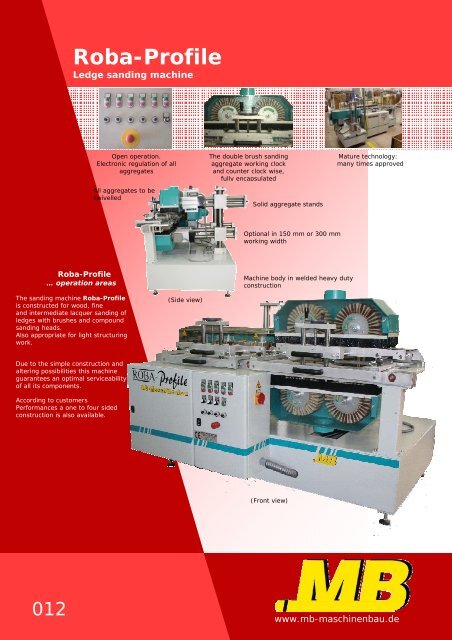

<strong>Roba</strong>-<strong>Profile</strong><br />

Ledge sanding machine<br />

<strong>Roba</strong>-<strong>Profile</strong><br />

… operation areas<br />

The sanding machine <strong>Roba</strong>-<strong>Profile</strong><br />

is constructed for wood, fine<br />

and intermediate lacquer sanding of<br />

ledges with brushes and compound<br />

sanding heads.<br />

Also appropriate for light structuring<br />

work.<br />

Due to the simple construction and<br />

altering possibilities this machine<br />

guarantees an optimal serviceability<br />

of all its components..<br />

According to customers<br />

Performances a one to four sided<br />

construction is also available.<br />

Open operation.<br />

Electronic regulation of all<br />

aggregates<br />

All aggregates to be<br />

swivelled<br />

(Side view)<br />

The double brush sanding<br />

aggregate working clock<br />

and counter clock wise,<br />

fully encapsulated<br />

Solid aggregate stands<br />

Optional in 150 mm or 300 mm<br />

working width<br />

Machine body in welded heavy duty<br />

construction<br />

(Front view)<br />

Mature technology:<br />

many times approved<br />

www.mb-maschinenbau.de

The feed system consists<br />

of gummed transport<br />

rollers.<br />

The lateral stops are<br />

ball bearing subject led<br />

and easy to adjust.<br />

All top pressure units<br />

are centrally adjustable.<br />

Machine data:<br />

<strong>Profile</strong> 211 <strong>Profile</strong> 221 <strong>Profile</strong> 222 <strong>Profile</strong> 232<br />

Machine lenght: 890 mm 890 mm 1830 mm 1830 mm<br />

Machine width: 1000 mm 1000 mm 1000 mm 1000 mm<br />

Machine height: 1400 mm 1400 mm 1400 mm 1400 mm<br />

Weight: 400 kg 450 kg 800 kg 850 kg<br />

Working width: 5 – 150 mm<br />

Working height: 850 mm – 900 mm<br />

Piece thickness: 5 - 100 mm<br />

Piece length: min 350 mm; shorter length on request<br />

Electrical power: 2,5 KW 5 KW 5 KW 7 KW<br />

Voltage: 230/400V 50 HZ 3 PH/N<br />

Machine data:<br />

<strong>Profile</strong> 233 <strong>Profile</strong> 233L <strong>Profile</strong> 243 <strong>Profile</strong> 244<br />

Machine lenght: 2720 mm 2500 mm 2720 mm 3400 mm<br />

Machine width: 1600 mm 1000 mm 1600 mm 1600 mm<br />

Machine height: 1400 mm 1400 mm 1400 mm 1400 mm<br />

Weight: 1000 kg 1000 kg 1000 kg 1350 kg<br />

Working width: 5 – 150 mm<br />

Working height: 850 mm – 900 mm<br />

Piece thickness: 5 - 100 mm<br />

Piece length: min 350 mm; shorter length on request<br />

Electrical power: 7,5KW 7KW 9,5KW 9,5KW<br />

Voltage: 230/400V 50 HZ 3 PH/N<br />

(Technical details are subject to change)<br />

Special solutions<br />

<strong>Roba</strong>-<strong>Profile</strong> with six sanding aggregates<br />

Legend:<br />

O = top<br />

U = bottom<br />

S/R = side<br />

right<br />

S/L = side left<br />

013

<strong>Roba</strong>-<strong>Profile</strong><br />

<strong>Profile</strong> sanding machine<br />

The <strong>Roba</strong> <strong>Profile</strong> sanding principle<br />

The main idea of the ROB sanding principle is the clockwise sanding followed<br />

immediately by counter clockwise sanding: Only in this way it is ensured that,<br />

independently of the wood grain structure, all upstanding „hairs“ are denibbed.<br />

The <strong>Roba</strong> <strong>Profile</strong> machine in all its configurations is build for sanding moldings<br />

found in various furniture, window and joinery companies. Solid, veneered or<br />

lacquered.<br />

In the main configuration the <strong>Roba</strong> <strong>Profile</strong> machine contains two rotational<br />

sanding heads and a pressure roll system. Set up in this way it is a solid basic<br />

layout for those customers who wish an optimized price-performance ratio.<br />

Due to the modular construction of the <strong>Roba</strong> <strong>Profile</strong> series, the machine can be<br />

configured to every customers demand. E.g. an eight head machine is able to<br />

sand profiled moldings from all four sides.<br />

Equipped with the <strong>MB</strong> Flex brush systems the machine is very easy and fast<br />

maintained and set up for a new profile.<br />

Divergently to the known systems based on sanding belts the <strong>Roba</strong> <strong>Profile</strong><br />

brush system forgive a not strictly exact setting of the aggregates.<br />

Centralized set up for the side guides and the top pressure roll devices<br />

make sure that even not experienced personnel is able to maintain such a<br />

machine. In only a couple of minutes a <strong>Roba</strong> <strong>Profile</strong> is ready to<br />

proceed.<br />

Further on this machine type is used for intermediate lacquer sanding.<br />

For that often feeds speeds up to 100 m/min. are necessary.<br />

The standard working breadth is 150mm, as an option some<br />

customers desire 300 mm.<br />

The advantages of the ROB principle summarized:<br />

1. Clockwise followed by counter clockwise sanding ensures best<br />

results.<br />

2. Pressure roll system will hold workpieces from 330 mm safely.<br />

Piece-by-piece feeding of shorter parts is also possible.<br />

3. Centralized set up for the side guides and top pressure system.<br />

4. Very easy maintenance and set up.<br />

5. Best offer for small investments.<br />

6. Infinite variable setting of the head rotations and feed speed.<br />

7. Tool free set up of the sanding aggregates.<br />

8. High feed speeds are technical possible.<br />

9. Modular construction meets every customers demand without<br />

complicating the machine.<br />

10. Abrasive configuration is freely eligible from the <strong>MB</strong> Flex system.<br />

www.mb-maschinenbau.de

Example of application<br />

Side view of the bottom and top aggregate. Here shown in the short<br />

machine version with both aggregates one upon the other<br />

Six double sanding heads set up guarantees best results<br />

Customized 500 mm working breadth version<br />

Two sanding heads set in an angle provide better<br />

edge sanding