michenfelder elektrotechnik

michenfelder elektrotechnik

michenfelder elektrotechnik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MICOMP UNI type G-MC<br />

(alternative type G-91)<br />

the moisture control<br />

system for mixer coolers<br />

�<br />

�<br />

�<br />

�<br />

�<br />

MICOMP UNI<br />

The fully automatic moisture control system for<br />

type G-MC/G-91/G-FBK<br />

mixer coolers and fluidised bed coolers<br />

When you make a decision,<br />

choose the market leader!<br />

Over 500 mixer coolers throughout the world have been fitted<br />

with Michenfelder systems. Well-known manufacturers of<br />

mixer coolers have regularly placed their trust in them over the<br />

past number of years<br />

Only by measuring in the cooler, is a high-precision, reliable<br />

output moisture content guaranteed. Initial temperature and<br />

moisture fluctuations are successfully compensated for in<br />

every phase of production<br />

Freely adjustable moisture value, moisture display in % H 2O directly (type G-MC)<br />

Versatile software and hardware expansion options available (type G-MC)<br />

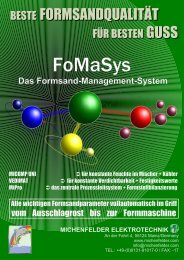

Practical expansion of the FoMaSys moulding sand management system<br />

MICOMP UNI type G-FBK<br />

the moisture control system for fluidised bed coolers<br />

Fluidised bed and/or vibration cooler users are familiar with the problem of serious output moisture fluctuations.<br />

Moisture control that is purely temperature-dependent is not a suitable solution. There are too many situations<br />

that you cannot control. For example, no water is added to cold, dry sand and what’s worse, the exhaust system<br />

also extracts the loose character-forming superfines (the typical “Monday problem”). The sand becomes<br />

inhomogeneous. Cold and unpoured sand is not identified either. The sand becomes too wet, resulting in<br />

problems<br />

.<br />

on the conveyor belt, in bunkers and in bucket elevators. For fear of over-wetting, there is a temptation<br />

to operate at a too dry level from the fluidised bed cooler, with all the problems this entails for subsequent<br />

conditioning. If you choose the leading technology in the form of the MICOMP UNI type G-FBK, you will get<br />

constant moisture at the fluidised bed cooler outlet at every phase of production. The interaction of precision<br />

measurement technology (moisture probes and temperature gauges) and optimum water addition (valve and<br />

nozzle kits) will be the major factor in your success.<br />

� Reference projects are proof of success and cost-effectiveness<br />

� Achievable precision of ±0.1 -0.2% H 2O (in the 1 st standard deviation)<br />

� Freely adjustable moisture value, moisture display in % H 2O directly<br />

� Versatile software and hardware expansion options<br />

� Practical expansion of the FoMaSys moulding sand management system<br />

FoMaSys-Module<br />

FoMaSys-Modul<br />

Michenfelder Elektrotechnik GmbH & Co. KG<br />

info@<strong>michenfelder</strong>.com | www.<strong>michenfelder</strong>.com<br />

AUTOMATIC MOISTURE CONTROL SYSTEM FOR COOLERS