michenfelder elektrotechnik

michenfelder elektrotechnik

michenfelder elektrotechnik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

We can facilitate a price comparison<br />

To allow you to make a fair comparison, we have decided to expand our product range to include<br />

the low-cost moulding sand moisturising system LC. It is the alternative to competitors’ systems<br />

available in the market. The moisture probe is installed on the belt upstream of or in the used sand<br />

weighing device. This facilitates a true price comparison.<br />

Scope of delivery<br />

The LC system consists of a self-cleaning NF-SR moisture probe. The measurement generator and<br />

the processing unit are located in the separate steel-plate housing. The moisture values measured<br />

in Volt and the evaluated material temperature in oC are transmitted to the processing unit for<br />

conversion to a percentage moisture value. Forty years of experience at Michenfelder have gone<br />

into this data conversion process. The system has been designed for installation and<br />

commissioning by the customer. To facilitate this, we supply a CD ROM with commissioning report,<br />

program flow visualisation and instructions for the adjustment of the characteristic curve using the<br />

customer’s PC or laptop.<br />

Operating principle<br />

When commissioning is complete (when the calibration value curve has been drawn up), the NF-<br />

SR probe measures the initial material moisture. The integrated processing unit then calculates the<br />

volume of residual water to be added depending on the batch size. At the same time as the used<br />

sand flows into the mixer (filling process), the calculated water volume is automatically metered out<br />

to the required final moisture level that was preset.<br />

The principle of measuring moisture upstream of the mixer<br />

With regard to hardware technology and the measuring point upstream of the mixer, the LC system<br />

provides you with the same kind of solution as that offered by the competitors. If you are about to<br />

make this investment decision, you must remember that when measuring material on the belt or in<br />

the used sand bunker, in principle, only part of the volume of material in a full mixer batch can be<br />

recorded. This means that the accuracy of the initial moisture with reference to the entire batch is<br />

only an average max. of ± 0.2% H2O (in the 1st standard deviation). Depending on the clay<br />

content, this can result in variations of up to ± 5-10% in compactability at the moulding machine<br />

directly. This is common to all systems that measure moisture upstream of the mixer.<br />

Who is the LC system designed for?<br />

There are customers who, for financial or other reasons, cannot or do not wish to exploit the full<br />

potential for reducing the moulding sand related scrappage in their production system by improving<br />

moulding sand quality. In cases such as this, customers are chiefly concerned with improving sand<br />

preparation processes in the areas of mixing, moulding and casting generally. Therefore, if the<br />

primary motivation is to avoid “extreme outliers” in the area of moulding sand moisture that can<br />

frequently result in production stoppages, then the installation of the low-cost moulding sand<br />

moisturising system is a suitable alternative.<br />

Given the growing requirements in modern foundries, investments must be quickly<br />

amortised, i.e. they must pay for themselves. This is best achieved by fully exploiting all the<br />

optimisation potential provided by measurement and control technology in order to reduce<br />

scrappage in a sand preparation plant. For this, we recommend Michenfelder’s modular<br />

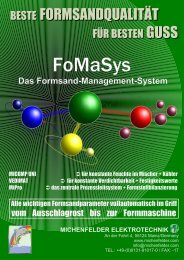

Moulding Sand Management System FoMaSys.