1915-07-01 Marmon 41, Info Book, 1534-B wm

Instruction Manual for my 1915 Marmon 41 Club Roadster that my Grandfather bought new 1915. I still drive it today,

Instruction Manual for my 1915 Marmon 41 Club Roadster that my Grandfather bought new 1915. I still drive it today,

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

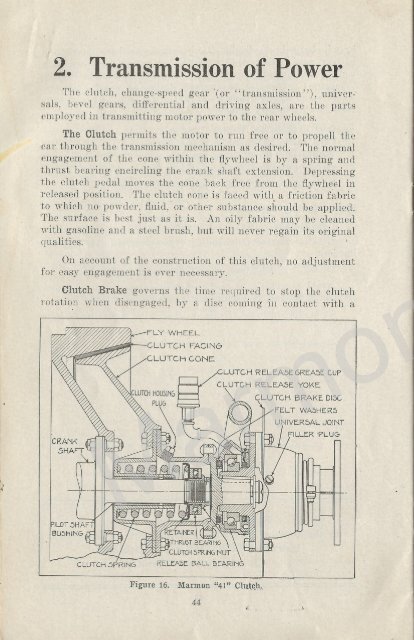

2. Transmission of Power<br />

The clutch, change-speed gear (or "transmission"), univer-.<br />

sals, bevel gears, differential and driving axles, are the parts<br />

employed in transmitting motor power to the rear wheels.<br />

The Clutch permits the motor to run free or to propell the<br />

ear through the transmission mechanism as desired. The normal<br />

engagement of the cone within the flywheel is by a spring and<br />

thrust bearing encircling the crank shaft extension. Depressing<br />

the clutch pedal moves the cone back free from the flywheel in<br />

released position. The clutch cone is faced with a friction fabric<br />

to which no powder, fluid, or other substance should be applied.<br />

The surface is best just as it is. An oily fabric may be cleaned<br />

with gasoline and a steel brush, but will never regain its original<br />

qualities.<br />

On account of the construction of this clutch, no adjustment<br />

for easy engagement is ever necessary.<br />

Clutch Brake governs the time required to stop the clutch<br />

rotation when disengaged, by a disc coming in contact with a<br />

CRANK<br />

SHAFT<br />

PILOT SHAFT<br />

BUSHING<br />

WO 10 V.<br />

CLUTCH SPRING<br />

FLY WHEEL<br />

CLUTCH FACING<br />

CLUTCH CONE<br />

LUTCH HOUSING<br />

PLUG<br />

"/„Afie<br />

Or' ETAINER <strong>41</strong>1111<br />

:1E4 THRUST BEARING<br />

CLUTCH SPRING NUT<br />

CLUTCH RELEASE GREASE CUP<br />

CLUTCH RELEASE YOKE<br />

sNvx""<br />

RELEASE BALL BEARING<br />

Figure 16. <strong>Marmon</strong> "<strong>41</strong>" Chtikh<br />

44<br />

LUTCH BRAKE DISC<br />

FELT WASHERS<br />

UN IVER5AL JOINT<br />

FILLER 'PLUG<br />

leather pad. If it is necessary to shift gears very rapidly in order<br />

to prevent clashing, the clutch brake stud may be moved back,<br />

giving a less severe action. If the clutch tends to "spin," delaying<br />

shifts without clashing, the pad may be "set up" in the same<br />

way.<br />

If it is found necessary to disassemble the clutch, proceed as<br />

follows:<br />

First remove the clutch pedal quill. In disassembling simply<br />

disconnect the circle of bolts on the rear flange at the transmission,<br />

also those on the flange of the Spicer joint, and this will permit<br />

you to remove the slip joint as a whole. Next disconnect the<br />

circle of bolts about the clutch cone and move back and out the<br />

throwout portion of the clutch as a unit. Both of these assemblies<br />

may readily be disassembled after removing, if necessary.<br />

The nut on the pilot shaft may now be removed and the<br />

thrust bearing and spring taken out, after which the clutch cone<br />

can be lifted back and out.<br />

Change-Speed Gear or "Transmission"<br />

A characteristic of the gasoline motor is that it, produces<br />

much greater power at the higher speeds than at low speeds. Too<br />

heavy a load at a low motor speed will cause it to stop or "stall"<br />

when the same load at a high motor speed will be carried easily.<br />

The change speed gear. by increasing the ratio of motor speed to<br />

wheel speed, increases the effective power for starting, hard pulling,<br />

hill clinibing, etc. It also provides for the very slow running<br />

and reversing.<br />

•<br />

The main drive gear is carried on a shaft which turns with the motor<br />

when the clutch is engaged. This gear is always in Mesh with a larger gear<br />

on the counter shaft below. The counter shaft extends rearward and carries<br />

three other gears of varying size. Above the countershaft is a squared shaft<br />

continuing the direction of the main drive gear shaft, but free to move independent<br />

of it. This squared shaft carries two gears with squared holes which<br />

must turn with the shaft but which may slide forward and back upon it.<br />

The large sliding gear. is for low and reverse speeds and the smaller gear for<br />

intermediate and high. "Neutral" is shifting lever position when both these<br />

gears are riding free in the space between their respective engaged. positions.<br />

When the operator throws the lever into low speed position a finger forces the<br />

larger gear to slide into mesh with a small gear on the countershaft. The<br />

square drive shaft then revolves much more slowly than the motor, giving<br />

great power but•little speed to the rear wheels. intermediate speed causes<br />

the other gear to mesh with a larger countershaft gear, giving more speed.<br />

For high speed, this gear slides forward, engaging a clutch on the main drive<br />

gear direct, thus Making the drive shafts virtually into one continuous shaft.<br />

For reverse, the large sliding gear is made to engage a small idler gear, which'<br />

meshes with the countershaft instead of directly on the Countershaft gear,<br />

thus changing its direction.<br />

It will be seen that the whole drive system from motor to wheels, from a<br />

control standpoint, is in three independent sections, with the two joints between<br />

them at the cliitch and gear case respectively. The center section must<br />

<strong>Marmon</strong><strong>41</strong>.com<br />

45