1915-07-01 Marmon 41, Info Book, 1534-B wm

Instruction Manual for my 1915 Marmon 41 Club Roadster that my Grandfather bought new 1915. I still drive it today,

Instruction Manual for my 1915 Marmon 41 Club Roadster that my Grandfather bought new 1915. I still drive it today,

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

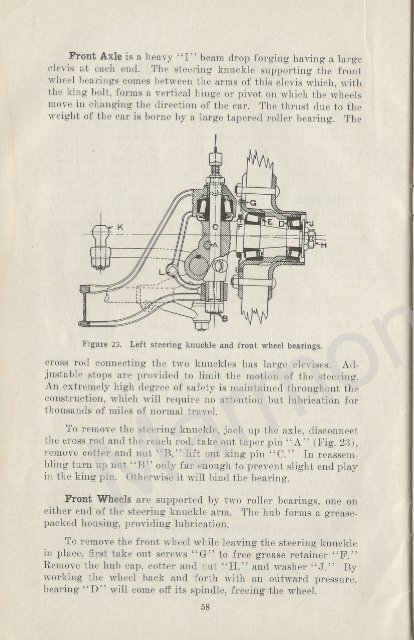

Front Axle is a heavy "I" beam drop forging having a large<br />

clevis at each end. The steering knuckle supporting the front<br />

wheel bearings comes between the arms of this clevis which, with<br />

the king bolt, forms a vertical hinge or pivot on which the wheels<br />

move in changing the direction of the car. The thrust due to the<br />

weight of the car is borne by a large tapered roller bearing. The<br />

Figure 23. Left steering knuckle and front wheel bearings.<br />

cross rod connecting the two knuckles has large devises. Adjustable<br />

stops are provided to limit the motion of the steering.<br />

An extremely high degree of safety is maintained throughout the<br />

construction, which will require no attention but lubrication for<br />

thousands of miles of normal travel.<br />

To remove the steering knuckle, jack up the axle, disconnect<br />

the cross rod and the reach rod, take out taper pin "A" (Fig. 23),<br />

remove cotter and nut "B," lift out king pin "C." In reassembling<br />

turn up nut "B" only far enough to prevent slight end play<br />

in the king pin. Otherwise it will bind the bearing.<br />

Front Wheels are supported by two roller bearings, one on<br />

either end of the steering knuckle arm. The hub forms a greasepacked<br />

housing, providing lubrication.<br />

To remove the front wheel while leaving the steering knuckle<br />

in place, first take out screws "G" to free grease retainer "F."<br />

Remove the hub cap, cotter and nut "H," and washer "J." By<br />

working the wheel back and forth with an outward pressure,<br />

bearing "D" will come off its spindle, freeing-the wheel.<br />

58<br />

Adjusting Wheel Bearings. In replacing, pack with grease<br />

and turn up nut "H" until the wheel binds, revolving the wheel a<br />

few times to take up back lash. Then relieve one-fourth turn to<br />

give 1 he bearings proper clearance. Test by seeing that the wheel<br />

runs free. With the proper adjustment by grasping opposite<br />

spokes in a vertical line and pushing on one and pulling on the<br />

other, play will be barely perceptible. When you have the adjustment<br />

just right lock the nut and replace cap.<br />

Rear System,<br />

The rear axle housing construction<br />

follows the <strong>Marmon</strong><br />

precedent, having two pressed<br />

steel sections welded together.<br />

It performs the important function<br />

of supporting the load on<br />

the rear wheels, carrying the<br />

driving members (bevel gears,<br />

differential and axle shaft) in a<br />

bath of grease, and also carries<br />

the brakes. It is made up as a<br />

complete 'unit with these parts,<br />

and may be removed if desired<br />

by disconnecting the torque bar,<br />

the flange at the rear universal,<br />

brake rods, shock absorbers, rebound<br />

straps and springs. Further<br />

disassembling of driving<br />

units, adjustment of brakes or<br />

wheel bearings may now be done<br />

as directed elsewhere.<br />

, N451""<br />

*pa<br />

Torque Bar,<br />

As power from the motor<br />

tends to make the rear wheels<br />

Figure 24. Vertical section through<br />

revolve, the axle housing naturally<br />

tends to revolve in the<br />

wheel bearings.<br />

rear wheel. Showing brakes and<br />

opposite direction. The long<br />

"torque" arm takes care of this "torque," or tendency to revolve.<br />

It does not take any driving or side sway stress, as these<br />

are efficiently cared for by the springs, as described on page 56.<br />

A long pin or swivel at the rear end joins the torque bar to the<br />

axle housing, rigidly for vertical or rotary motion, but flexible<br />

sidewise. The ball which terminates the forward end of the<br />

torque bar is carried in a vertical tube which contains cups above<br />

and below held against the ball by powerful coil springs. This<br />

<strong>Marmon</strong><strong>41</strong>.com<br />

59