Ai2SA QMS-ISO Article-R3

An Ai2SA point of view in relation to assisting a leading SI in attaining ISO certification and some lessons learnt in relation to process.

An Ai2SA point of view in relation to assisting a leading SI in attaining ISO certification and some lessons learnt in relation to process.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>ISO</strong> 9001:2008 certification: benefits & pitfalls in relation to control systems projects<br />

Architects Integrating Industry (<strong>Ai2SA</strong>) specialize in specification, design, engineering, commissioning, project<br />

and quality management of Industrial Control & Information Systems. We wish to share some more lessons<br />

learned in relation to a project where we recently assisted another one of South Africa’s leading System<br />

Integrator’s (SI) with the establishment of their <strong>ISO</strong> (International Organization for Standardization) certified<br />

Quality Management System (<strong>QMS</strong>), specifically for control systems projects. This involved developing<br />

procedure(s), works instruction(s), associated “forms” (templates) and generating projects “records” required.<br />

The main objectives (and resultant benefits) of the SI achieving <strong>ISO</strong> certification includes: 1.) improve customer<br />

satisfaction, 2.) reduce customer complaints, 3.) improve project delivery and 4.) improve recoverability all by<br />

a target percentage (%) which implies being able to track the metrics and subsequent results objectively.<br />

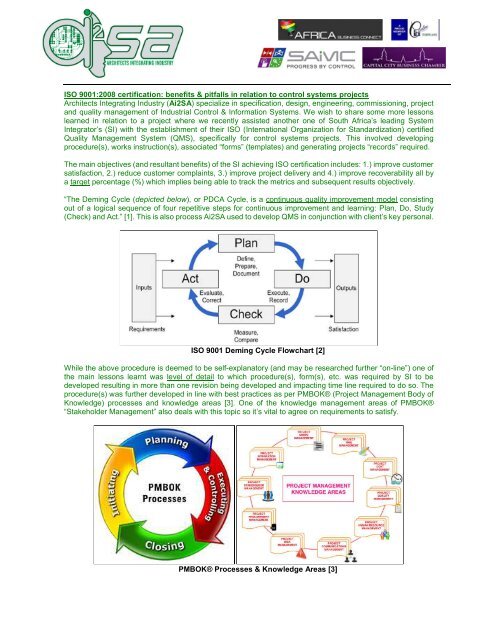

“The Deming Cycle (depicted below), or PDCA Cycle, is a continuous quality improvement model consisting<br />

out of a logical sequence of four repetitive steps for continuous improvement and learning: Plan, Do, Study<br />

(Check) and Act.” [1]. This is also process <strong>Ai2SA</strong> used to develop <strong>QMS</strong> in conjunction with client’s key personal.<br />

<strong>ISO</strong> 9001 Deming Cycle Flowchart [2]<br />

While the above procedure is deemed to be self-explanatory (and may be researched further “on-line”) one of<br />

the main lessons learnt was level of detail to which procedure(s), form(s), etc. was required by SI to be<br />

developed resulting in more than one revision being developed and impacting time line required to do so. The<br />

procedure(s) was further developed in line with best practices as per PMBOK® (Project Management Body of<br />

Knowledge) processes and knowledge areas [3]. One of the knowledge management areas of PMBOK®<br />

“Stakeholder Management” also deals with this topic so it’s vital to agree on requirements to satisfy.<br />

PMBOK® Processes & Knowledge Areas [3]

The next lesson learnt was not to enforce new procedure(s) but rather to consult with the personnel on what<br />

was already in place and to document these and to add to this based on our experience. The resultant generic<br />

projects “best practices” process is depicted below reflecting key phases, processes, hold points, etc.<br />

“Best Practices” Control Systems Projects Methodology developed by <strong>Ai2SA</strong><br />

In line with above <strong>Ai2SA</strong> as part of #SAIMC has initiated the “Professional Services” standards sub-committee<br />

and hope to upskill the industry over coming years through it by writing white papers, etc. re the subject.<br />

Yet another lesson is that not all companies document their forms to same extent which mean there may be<br />

scope to improve content of documentation over time. Subsequently <strong>Ai2SA</strong> used some of their own Intellectual<br />

Property (IP) to expedite deliverable development. Previously for projects procedure +/- 108 documents<br />

supported procedure however by optimizing procedure and forms this has now reduced to 42 forms (not all<br />

relevant for all projects). A typical form (template) which becomes a record when filled in is depicted below:<br />

Example of a form (template) developed by <strong>Ai2SA</strong>

Another lesson learnt relates to obtaining “buy in” from the team in following procedures and using forms /<br />

system developed. While this is required to retain certification, it is also important that documents serve purpose<br />

it was developed for. To assist <strong>Ai2SA</strong> developed training “modules” and provided training to respective role<br />

players and will continue with ad-hoc internal audits to ensure process is complied with. The people using<br />

system is however expected to comply with requirements of <strong>ISO</strong> fundamentals e.g. control of records / change<br />

control, etc. and is further encouraged to “own” system and to improve on it following due processes. People<br />

adapt to change at different rates and it is vital to understand this and not to force systems on people. Various<br />

studies have been done in relation to change management as is depicted in figure below also reflecting methods<br />

to support people along the process:<br />

Kubler-Ross Change Curve [4]<br />

Please feel free to contact the author should you need more information in attempting <strong>ISO</strong> certification or simply<br />

wish to increase efficiencies and returns.<br />

W: www.ai2sa.co.za / M: +27(0) 82 559 7437 (Find us on Facebook, LinkedIn, Twitter and Google+)<br />

Kind regards<br />

Petrus Klopper (Managing Director and Senior Project Manager)<br />

References/Bibliography<br />

[1] 2016, "Deming cycle, PDCA," 2016. [Online]. Available: https://www.isixsigma.com/dictionary/deming-cyclepdca/.<br />

Accessed: Dec. 15, 2016.<br />

[2] N. *, "How to get <strong>ISO</strong> 9001: 2015 certification | building <strong>ISO</strong> 9001: 2015 <strong>QMS</strong>," in Obtain <strong>ISO</strong> Certification,<br />

Bizmanualz, 2016. [Online]. Available: https://www.bizmanualz.com/obtain-iso-certification/how-to-start-youriso-9001-certification.html.<br />

Accessed: Dec. 15, 2016.<br />

[3] Project Management Institute (PMI) Processes & Knowledge Areas as interpreted further by others [Online].<br />

Available: http://www.pmi.org/pmbok-guide-standards/foundational/pmbok; http://www.mpmm.com/projectmanagement-best-practices.php.<br />

and http://www.kodyaz.com/pmp/project-management-knowledge-areasaccording-to-pmi.aspx<br />

Accessed: Jan. 7, 2017.<br />

[4] Paul Morris [Online]. Available: http://www.searchmuse.com/blog/2015/04/02/kubler-ross-change-curve.html<br />

. Accessed: Jan. 7, 2017.