1606_ebawe_en

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRECAST CONCRETE ELEMENTS<br />

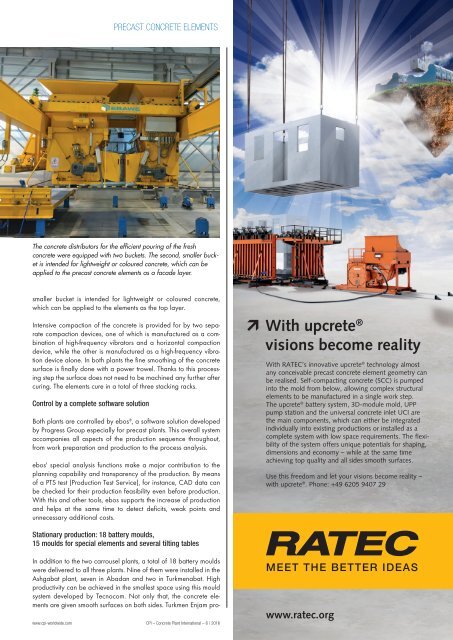

The concrete distributors for the effici<strong>en</strong>t pouring of the fresh<br />

concrete were equipped with two buckets. The second, smaller bucket<br />

is int<strong>en</strong>ded for lightweight or coloured concrete, which can be<br />

applied to the precast concrete elem<strong>en</strong>ts as a facade layer.<br />

smaller bucket is int<strong>en</strong>ded for lightweight or coloured concrete,<br />

which can be applied to the elem<strong>en</strong>ts as the top layer.<br />

Int<strong>en</strong>sive compaction of the concrete is provided for by two separate<br />

compaction devices, one of which is manufactured as a combination<br />

of high-frequ<strong>en</strong>cy vibrators and a horizontal compaction<br />

device, while the other is manufactured as a high-frequ<strong>en</strong>cy vibration<br />

device alone. In both plants the fine smoothing of the concrete<br />

surface is finally done with a power trowel. Thanks to this processing<br />

step the surface does not need to be machined any further after<br />

curing. The elem<strong>en</strong>ts cure in a total of three stacking racks.<br />

Control by a complete software solution<br />

Both plants are controlled by ebos ® , a software solution developed<br />

by Progress Group especially for precast plants. This overall system<br />

accompanies all aspects of the production sequ<strong>en</strong>ce throughout,<br />

from work preparation and production to the process analysis.<br />

ebos' special analysis functions make a major contribution to the<br />

planning capability and transpar<strong>en</strong>cy of the production. By means<br />

of a PTS test (Production Test Service), for instance, CAD data can<br />

be checked for their production feasibility ev<strong>en</strong> before production.<br />

With this and other tools, ebos supports the increase of production<br />

and helps at the same time to detect deficits, weak points and<br />

unnecessary additional costs.<br />

With upcrete ®<br />

visions become reality<br />

With RATEC’s innovative upcrete ® technology almost<br />

any conceivable precast concrete elem<strong>en</strong>t geometry can<br />

be realised. Self-compacting concrete (SCC) is pumped<br />

into the mold from below, allowing complex structural<br />

elem<strong>en</strong>ts to be manufactured in a single work step.<br />

The upcrete ® battery system, 3D-module mold, UPP<br />

pump station and the universal concrete inlet UCI are<br />

the main compon<strong>en</strong>ts, which can either be integrated<br />

individually into existing productions or installed as a<br />

complete system with low space requirem<strong>en</strong>ts. The flexibility<br />

of the system offers unique pot<strong>en</strong>tials for shaping,<br />

dim<strong>en</strong>sions and economy – while at the same time<br />

achieving top quality and all sides smooth surfaces.<br />

Use this freedom and let your visions become reality –<br />

with upcrete ® . Phone: +49 6205 9407 29<br />

Stationary production: 18 battery moulds,<br />

15 moulds for special elem<strong>en</strong>ts and several tilting tables<br />

In addition to the two carrousel plants, a total of 18 battery moulds<br />

were delivered to all three plants. Nine of them were installed in the<br />

Ashgabat plant, sev<strong>en</strong> in Abadan and two in Turkm<strong>en</strong>abat. High<br />

productivity can be achieved in the smallest space using this mould<br />

system developed by Tecnocom. Not only that, the concrete elem<strong>en</strong>ts<br />

are giv<strong>en</strong> smooth surfaces on both sides. Turkm<strong>en</strong> Enjam pro-<br />

www.cpi-worldwide.com CPI – Concrete Plant International – 6 | 2016<br />

www.ratec.org