Adelaide Editorial Design : Australian Enviroblast

Editorial design for Australian Enviroblast in Adelaide by Cadogan and Hall. Suitable for distribution in print and online for content marketing purposes.

Editorial design for Australian Enviroblast in Adelaide by Cadogan and Hall. Suitable for distribution in print and online for content marketing purposes.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AEB<br />

AUSTRALIAN ENVIROBLAST PTY LTD<br />

Wet Abrasive<br />

Blasting Services<br />

WET ABRASIVE<br />

BLASTING SERVICES<br />

www.australianenviroblast.com.au

<strong>Australian</strong> <strong>Enviroblast</strong> Pty Ltd<br />

info@australianenviroblast.com.au<br />

www.australianenviroblast.com.au<br />

tel: 0458 455668

who we are<br />

<strong>Australian</strong> <strong>Enviroblast</strong> was<br />

founded in 2009 by Mark<br />

Chiappin with the aim of<br />

introducing environmentallyfriendly<br />

abrasive blasting<br />

services to Australia.<br />

where we are<br />

Our fleet of mobile equipment<br />

means that we are able to carry<br />

out on-site abrasive blasting and<br />

industrial coating on both largeand<br />

small-scale jobs throughout<br />

the <strong>Adelaide</strong> metropolitan area,<br />

as well as regional and country<br />

South Australia<br />

At <strong>Australian</strong> <strong>Enviroblast</strong>,<br />

we use the Quill Falcon<br />

Kwikblast® Dustless Blasting<br />

System, an environmentally<br />

friendly cleaning system<br />

noted for its power, efficiency<br />

and ability to remove a wide<br />

range of coatings, corrosion<br />

and residues from all types<br />

of structures, locations and<br />

equipment, leaving surfaces<br />

completely clean and<br />

contaminant free.<br />

<strong>Australian</strong> <strong>Enviroblast</strong> is<br />

licensed by the Environmental<br />

Protection Agency and<br />

adheres to its high standards<br />

of environmental safety with<br />

regards to air quality, noise,<br />

water quality and waste<br />

management.<br />

www.australianenviroblast.com.au

marine<br />

Using the Quill Falcon Kwikblast® System,<br />

abrasive blasting is able to successfully<br />

remove all of the following from boat hulls<br />

and decking, and marine machinery and<br />

structures:<br />

oil • grease • corrosion • soluble salts<br />

(chloride and sulphates) • chemicals • old<br />

coatings • algae • barnacles • grime and dirt<br />

www.australianenviroblast.com.au<br />

Marine vessels are naturally<br />

subject to a build up of algae<br />

and barnacles, grime and<br />

dirt, bilge-oil film and blisters<br />

after an extended time in<br />

the water. These and other<br />

unwanted additions to the<br />

hull can eventually cause so<br />

much drag that they affect a<br />

boat’s performance.<br />

Removing these types of<br />

growth and contaminants by<br />

hand is not only incredibly<br />

laborious, but it can also<br />

cause damage to the<br />

surface, particularly on a<br />

fibreglass hull. Doing so, it<br />

is easy to scratch or even<br />

gouge the gelcoat, which<br />

can lead to blisters and<br />

fractures.<br />

The difficulty of stripping a<br />

boat hull also means that it<br />

can be tempting simply to<br />

apply a fresh coat of antifouling<br />

paint over the hull<br />

without stripping it right<br />

back beforehand. As well as<br />

hiding and then eventually<br />

exacerbating problems,<br />

this also means that boat<br />

performance is affected as<br />

a result of the rough bottom<br />

and the excess weight<br />

produced by too many<br />

layers of paint.<br />

Wet abrasive blasting<br />

is extremely gentle and<br />

effective at removing<br />

unnecessary and harmful<br />

paint layers and other build<br />

ups in such a way as to<br />

maximise boat performance,<br />

without requiring enormous<br />

amounts of time and<br />

intensive labour. This means<br />

that there is more time<br />

available for anti-fouling<br />

paint and protective coatings<br />

to be applied thoroughly<br />

without increasing your<br />

downtime and maintenance<br />

costs, which will in turn have<br />

the effect of adding years to<br />

a vessel’s lifespan.

Wet abrasive blasting can be used to clean the<br />

hulls of fibreglass, aluminium, metal and timber<br />

yachts and boats, and it effectively removes:<br />

• rust<br />

• paint<br />

• bitumen<br />

• mill scale<br />

• old coatings<br />

• chlorides<br />

• soluble salts<br />

• surface contaminants<br />

removing old coatings, paint and contaminants<br />

If a marine vessel is painted or a coating is applied before contaminants are<br />

removed, the coating is likely to fail because it does not adhere to the surface<br />

effectively. In addition, contaminants can draw moisture through the coating<br />

which causes blistering, detachment and can also accelerate corrosion.<br />

Wet abrasive blasting removes all types of coatings, corrosion and residues<br />

from marine vessel surfaces, meaning that blisters that need to be repaired<br />

can be identified and surfaces can be primed so that new protective coatings<br />

can be applied in such a way as to achieve maximum bonding. However, at the<br />

same time abrasive blasting won’t remove the sealing from seams or thin the<br />

metal of a boat’s hull. Abrasive blasting is able to profile surfaces in a variety<br />

of ways so that they are ready to receive all types of industrial coatings and<br />

protective paints.<br />

www.australianenviroblast.com.au

case studies<br />

Visit our website to see case studies of our wet abrasive blasting<br />

and industrical coating work on a variety of commercial fishing<br />

boats and other vessels in <strong>Adelaide</strong>.<br />

Go to www.australianenviroblast.com.au

line marking<br />

Wet abrasive blasting using the Quill Falcon<br />

Kwikblast® System removes all types of<br />

road and pavement markings, both from the<br />

surface and from any cavities or depressions.<br />

This is done without<br />

producing fumes, smoke<br />

or excessive dust,<br />

and results in a road<br />

surface that is profiled<br />

to your specifications<br />

but remains unscorched<br />

and unscarred. This is<br />

because the Quill Falcon<br />

Kwikblast® system is<br />

a precision dustless<br />

blasting system which<br />

combines the simplicity of<br />

conventional grit blasting<br />

with the effectiveness of<br />

ultra high pressure (uhP)<br />

jetting, but without the<br />

associated hazards and<br />

complications.<br />

During the wet abrasive<br />

blasting process, abrasive<br />

material is propelled at<br />

high pressure onto the<br />

road or footpath surface<br />

and this strips away<br />

unwanted markings and<br />

substances but leaves<br />

the original surface clean<br />

and contaminant free,<br />

and there is almost no<br />

dust produced during the<br />

process.<br />

Wet abrasive blasting also<br />

cleans mould, grease,<br />

oil and other slippery<br />

deposits from roads,<br />

paths, walkways, car<br />

parks and driveways.<br />

Furthermore, concrete<br />

aggregate can be<br />

exposed by wet abrasive<br />

blasting to create nonslip<br />

surfaces, perfect for<br />

use in public spaces such<br />

as shopping centres,<br />

schools, industrial parks<br />

and commercial premises.<br />

Non-slip surfaces can<br />

be created by abrasive<br />

blasting on a variety of<br />

materials and surfaces,<br />

including concrete, tiles<br />

and pavers.<br />

www.australianenviroblast.com.au

The Quill Falcon Kwikblast® System quickly and<br />

effectively removes all types of markings from road<br />

and pavement surfaces, including:<br />

• permanent and temporary thermoplastic<br />

paint<br />

• temporary road marking tape<br />

• surface dressing emulsion<br />

• resin-based paints<br />

• anti-skid surfacing<br />

removing rubber deposits<br />

Rubber deposits are also effectively removed from road<br />

surfaces, pavements and driveways using abrasive blasting.<br />

This can be extremely important in an airport environment,<br />

for instance, where a clean and profiled surface allows for<br />

maximum braking, as well as enhancing the brightness and<br />

appearance of markings.<br />

Removing rubber deposits and burn out marks also improves<br />

the appearance of roads, curbs and car parks<br />

www.australianenviroblast.com.au

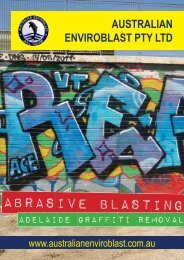

graffiti removal<br />

Graffiti removal using wet abrasive blasting<br />

means that paints and other contaminants<br />

are completely removed from the surface of<br />

brickwork, stone, metal and other materials<br />

without leaving a shadow, and the vandalised<br />

area is returned to pristine condition without<br />

any damage to the underlying surface.<br />

statues and memorials<br />

Wet abrasive blasting restores public art,<br />

statues and memorials to their former glory<br />

without damaging the fine detail and contours<br />

or detracting from the artist’s original vision.<br />

Intricate surface designs can be cleaned<br />

without any damage, as there are no<br />

chemicals used and the process is a gentle<br />

one. Likewise, public memorials can be fully<br />

appreciated if they are clean and all writing<br />

and inscriptions is clearly visible.<br />

swimming pools<br />

Abrasive blasting is effective both in cleaning<br />

pool surrounds and creating non-slip<br />

pathways, but also for cleaning pool interiors,<br />

or stripping and restoring them in preparation<br />

for re-surfacing or re-tiling.<br />

www.australianenviroblast.com.au

estoration<br />

Abrasive blasting can be used for a variety of<br />

purposes in the restoration and renovation of<br />

all types of buildings and structures, including<br />

domestic and commercial premises as well<br />

as all types of industrial and manufacturing<br />

spaces.<br />

In <strong>Adelaide</strong>, many of our<br />

finest heritage buildings<br />

and residences are<br />

located within high-density<br />

areas, and therefore they<br />

are particularly prone to<br />

suffering from traffic and<br />

environmental pollution and<br />

degradation. Sandstone and<br />

bluestone, historically the<br />

stones used in the majority<br />

of <strong>Adelaide</strong> buildings,<br />

can become severely<br />

discoloured and this leads<br />

not only to a deterioration in<br />

appearance but also to the<br />

overall integrity of the stone<br />

as result of decay.<br />

However, wet abrasive<br />

blasting means that years<br />

of soot, grime and fumes<br />

build up can be removed<br />

quickly but without causing<br />

any damage to the surface.<br />

More gentle than sand<br />

blasting and other types of<br />

cleaning, abrasive blasting<br />

is ideal for use on softer<br />

stones like sandstone,<br />

bluestone, limestone and<br />

masonry.<br />

The Quill Falcon Kwikblast®<br />

Dustless Blasting<br />

System is economical,<br />

environmentally-friendly and<br />

non-toxic. No chemicals<br />

are used and therefore<br />

there is no negative<br />

environmental impact. Little<br />

dust is produced and so our<br />

abrasive blasting services<br />

can be employed in heritage<br />

or residential areas without<br />

the need for encapsulation<br />

or causing undue disruption.<br />

Heritage restorations of<br />

sandstone or bluestone<br />

buildings, houses and<br />

cottages naturally requires<br />

additional care and<br />

sensitivity and abrasive<br />

blasting using the Quill<br />

Falcon Dustless Blast<br />

System is the ideal solution.<br />

www.australianenviroblast.com.au

Abrasive blasting is an essential tool in a wide<br />

variety of building renovation applications. It offers<br />

a versatile, efficient, thorough but gentle cleaning<br />

process that makes it ideal in all kinds of renovation<br />

and restoration tasks.<br />

Whether stripping paint from interior and exterior<br />

walls, cleaning oil-stained driveways and car parks,<br />

removing graffiti, repairing flood or fire damage,<br />

undertaking a sensitive heritage restoration or<br />

renovating memorials or public art works, our<br />

abrasive blasting services are the ideal cleaning and<br />

preparation solution<br />

renovation, restoration or resale<br />

If you’re a homeowner, builder, house painter or property manger<br />

renovating or redecorating a home, or preparing it for sale or<br />

rental, stripping away old, existing layers of paint is vital before<br />

repainting. Abrasive blasting cleans away all residual paint<br />

layers leaving an extremely smooth, even finish that is the ideal<br />

preparation for repainting.<br />

Likewise, if your brickwork or stonework, fences and walls,<br />

driveway or outdoor living area need to be cleaned and revitalised<br />

before a resale or renting out, abrasive blasting strips away oil<br />

and mould stains, residue and corrosion, and restores all types of<br />

surfaces to pristine condition.<br />

www.australianenviroblast.com.au

photo gallery<br />

Visit our website to see photographs of our restoration work<br />

on a range of <strong>Adelaide</strong> buildings, including heritage and period<br />

properties, commercial and business premises, and a variety of<br />

homes throughout the metropolitan area and regional SA.<br />

Go to www.australianenviroblast.com.au

<strong>Australian</strong> <strong>Enviroblast</strong> Pty Ltd<br />

info@australianenviroblast.com.au<br />

www.australianenviroblast.com.au<br />

tel: 0458 455668