You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

eastern iowa farmer photo / Lowell Carlson<br />

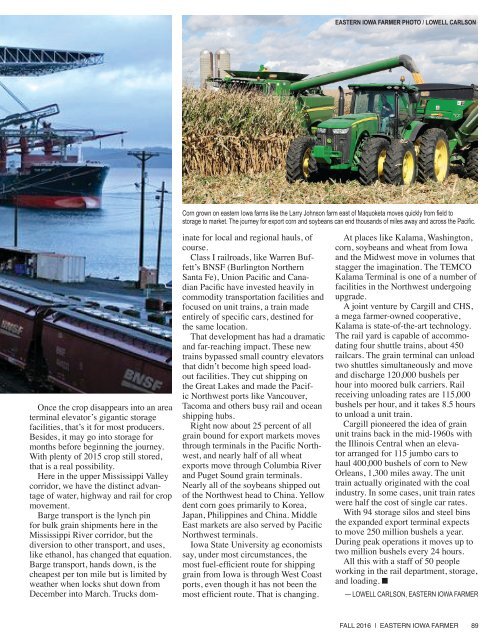

Corn grown on eastern <strong>Iowa</strong> farms like the Larry Johnson farm east of Maquoketa moves quickly from field to<br />

storage to market. The journey for export corn and soybeans can end thousands of miles away and across the Pacific.<br />

Once the crop disappears into an area<br />

terminal elevator’s gigantic storage<br />

facilities, that’s it for most producers.<br />

Besides, it may go into storage for<br />

months before beginning the journey.<br />

With plenty of 2015 crop still stored,<br />

that is a real possibility.<br />

Here in the upper Mississippi Valley<br />

corridor, we have the distinct advantage<br />

of water, highway and rail for crop<br />

movement.<br />

Barge transport is the lynch pin<br />

for bulk grain shipments here in the<br />

Mississippi River corridor, but the<br />

diversion to other transport, and uses,<br />

like ethanol, has changed that equation.<br />

Barge transport, hands down, is the<br />

cheapest per ton mile but is limited by<br />

weather when locks shut down from<br />

December into March. Trucks dominate<br />

for local and regional hauls, of<br />

course.<br />

Class I railroads, like Warren Buffett’s<br />

BNSF (Burlington Northern<br />

Santa Fe), Union Pacific and Canadian<br />

Pacific have invested heavily in<br />

commodity transportation facilities and<br />

focused on unit trains, a train made<br />

entirely of specific cars, destined for<br />

the same location.<br />

That development has had a dramatic<br />

and far-reaching impact. These new<br />

trains bypassed small country elevators<br />

that didn’t become high speed loadout<br />

facilities. They cut shipping on<br />

the Great Lakes and made the Pacific<br />

Northwest ports like Vancouver,<br />

Tacoma and others busy rail and ocean<br />

shipping hubs.<br />

Right now about 25 percent of all<br />

grain bound for export markets moves<br />

through terminals in the Pacific Northwest,<br />

and nearly half of all wheat<br />

exports move through Columbia River<br />

and Puget Sound grain terminals.<br />

Nearly all of the soybeans shipped out<br />

of the Northwest head to China. Yellow<br />

dent corn goes primarily to Korea,<br />

Japan, Philippines and China. Middle<br />

East markets are also served by Pacific<br />

Northwest terminals.<br />

<strong>Iowa</strong> State University ag economists<br />

say, under most circumstances, the<br />

most fuel-efficient route for shipping<br />

grain from <strong>Iowa</strong> is through West Coast<br />

ports, even though it has not been the<br />

most efficient route. That is changing.<br />

At places like Kalama, Washington,<br />

corn, soybeans and wheat from <strong>Iowa</strong><br />

and the Midwest move in volumes that<br />

stagger the imagination. The TEMCO<br />

Kalama Terminal is one of a number of<br />

facilities in the Northwest undergoing<br />

upgrade.<br />

A joint venture by Cargill and CHS,<br />

a mega farmer-owned cooperative,<br />

Kalama is state-of-the-art technology.<br />

The rail yard is capable of accommodating<br />

four shuttle trains, about 450<br />

railcars. The grain terminal can unload<br />

two shuttles simultaneously and move<br />

and discharge 120,000 bushels per<br />

hour into moored bulk carriers. Rail<br />

receiving unloading rates are 115,000<br />

bushels per hour, and it takes 8.5 hours<br />

to unload a unit train.<br />

Cargill pioneered the idea of grain<br />

unit trains back in the mid-1960s with<br />

the Illinois Central when an elevator<br />

arranged for 115 jumbo cars to<br />

haul 400,000 bushels of corn to New<br />

Orleans, 1,300 miles away. The unit<br />

train actually originated with the coal<br />

industry. In some cases, unit train rates<br />

were half the cost of single car rates.<br />

With 94 storage silos and steel bins<br />

the expanded export terminal expects<br />

to move 250 million bushels a year.<br />

During peak operations it moves up to<br />

two million bushels every 24 hours.<br />

All this with a staff of 50 people<br />

working in the rail department, storage,<br />

and loading. n<br />

— lowell carlson, eastern iowa farmer<br />

fall <strong>2016</strong> | <strong>Eastern</strong> <strong>Iowa</strong> <strong>Farmer</strong> 89