You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

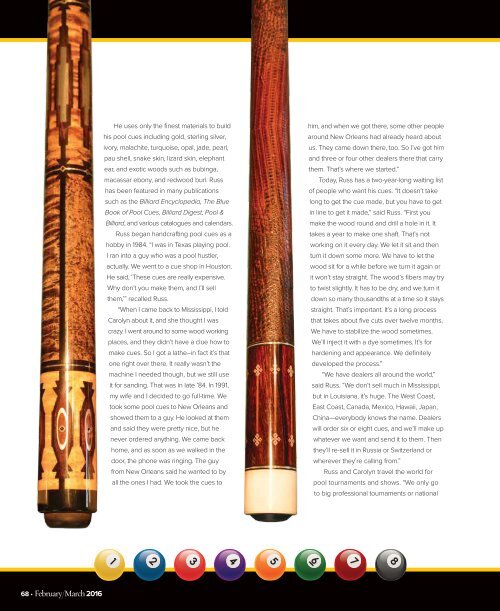

He uses only the finest materials to build<br />

his pool cues including gold, sterling silver,<br />

ivory, malachite, turquoise, opal, jade, pearl,<br />

pau shell, snake skin, lizard skin, elephant<br />

ear, and exotic woods such as bubinga,<br />

macassar ebony, and redwood burl. Russ<br />

has been featured in many publications<br />

such as the Billiard Encyclopedia, The Blue<br />

Book of Pool Cues, Billiard Digest, Pool &<br />

Billiard, and various catalogues and calendars.<br />

Russ began handcrafting pool cues as a<br />

hobby in 1984. “I was in Texas playing pool.<br />

I ran into a guy who was a pool hustler,<br />

actually. We went to a cue shop in Houston.<br />

He said, ‘These cues are really expensive.<br />

Why don’t you make them, and I’ll sell<br />

them,’” recalled Russ.<br />

“When I came back to Mississippi, I told<br />

Carolyn about it, and she thought I was<br />

crazy. I went around to some wood working<br />

places, and they didn’t have a clue how to<br />

make cues. So I got a lathe–in fact it’s that<br />

one right over there. It really wasn’t the<br />

machine I needed though, but we still use<br />

it for sanding. That was in late ’84. In 1991,<br />

my wife and I decided to go full-time. We<br />

took some pool cues to New Orleans and<br />

showed them to a guy. He looked at them<br />

and said they were pretty nice, but he<br />

never ordered anything. We came back<br />

home, and as soon as we walked in the<br />

door, the phone was ringing. The guy<br />

from New Orleans said he wanted to by<br />

all the ones I had. We took the cues to<br />

him, and when we got there, some other people<br />

around New Orleans had already heard about<br />

us. They came down there, too. So I’ve got him<br />

and three or four other dealers there that carry<br />

them. That’s where we started.”<br />

Today, Russ has a two-year-long waiting list<br />

of people who want his cues. “It doesn’t take<br />

long to get the cue made, but you have to get<br />

in line to get it made,” said Russ. “First you<br />

make the wood round and drill a hole in it. It<br />

takes a year to make one shaft. That’s not<br />

working on it every day. We let it sit and then<br />

turn it down some more. We have to let the<br />

wood sit for a while before we turn it again or<br />

it won’t stay straight. The wood’s fibers may try<br />

to twist slightly. It has to be dry, and we turn it<br />

down so many thousandths at a time so it stays<br />

straight. That’s important. It’s a long process<br />

that takes about five cuts over twelve months.<br />

We have to stabilize the wood sometimes.<br />

We’ll inject it with a dye sometimes. It’s for<br />

hardening and appearance. We definitely<br />

developed the process.”<br />

“We have dealers all around the world,”<br />

said Russ. “We don’t sell much in Mississippi,<br />

but in Louisiana, it’s huge. The West Coast,<br />

East Coast, Canada, Mexico, Hawaii, Japan,<br />

China—everybody knows the name. Dealers<br />

will order six or eight cues, and we’ll make up<br />

whatever we want and send it to them. Then<br />

they’ll re-sell it in Russia or Switzerland or<br />

wherever they’re calling from.”<br />

Russ and Carolyn travel the world for<br />

pool tournaments and shows. “We only go<br />

to big professional tournaments or national<br />

68 • <strong>February</strong>/<strong>March</strong> <strong>2016</strong>