MINUTES (DRAFT) Refrigeration Committee (REF) - ashrae

MINUTES (DRAFT) Refrigeration Committee (REF) - ashrae

MINUTES (DRAFT) Refrigeration Committee (REF) - ashrae

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MINUTES</strong> (<strong>DRAFT</strong>)<br />

<strong>Refrigeration</strong> <strong>Committee</strong> (<strong>REF</strong>)<br />

January 22, 2012<br />

The Palmer House Hotel<br />

Chicago, IL<br />

NOTE: These <strong>DRAFT</strong> minutes have not been approved and are not the official record until approved by this committee<br />

Members Present:<br />

Doug Scott, Chair<br />

Cesar Lim, Vice Chair<br />

Kent Anderson, Consultant<br />

Pradeep Bansal<br />

Jeff Berge<br />

Marc Chasserot<br />

David Hinde<br />

Todd Jekel<br />

Dan Manole<br />

Ross Montgomery, CO<br />

Andy Pearson<br />

Richard Royal<br />

Christopher Seeton<br />

Don Siller, Consultant<br />

Members Not Present:<br />

Chuck Gulledge, BOD Ex-O<br />

Ted Hansen<br />

Visitors:<br />

Bruce Badger<br />

Brian Becker<br />

Dimitrios Charalambopoulos<br />

Don Cleland<br />

Ioanna Deligkiozi<br />

John Dieckman<br />

Brian Fricke<br />

Cynthia Gage<br />

Bruce Griffith<br />

Timothy Gwyn<br />

Danny Halel<br />

Bill Harrison<br />

Georgi Kazachki<br />

Amey Majgaonkar<br />

Corey Metzger<br />

Chun-Cheng Piao<br />

Dan Pettway<br />

Doug Reindl<br />

John Sluga<br />

Eric Smith<br />

Tom Watson<br />

Tom Werkema<br />

Tom Wolgamot<br />

David Wylie<br />

Jing Zheng<br />

ASHRAE Staff:<br />

Steve Hammerling, AMORTS

Table of Contents<br />

Motions Passed……………………………………………..……………………..…………………. iii<br />

Action Items …………………………………………………………………..………………….……iii<br />

List of Attachments ………………………………………….…………….…………………………iii<br />

List of Acronyms………………………………………………………………………………….….iv<br />

1. Call to Order & Introductions…………………………..………………………………….…..…1<br />

2. Approval of Minutes ……………………………………………………………………..……..…1<br />

3. Review of Agenda Meeting ………………………………………………………………..….…1<br />

4. Chair’s Report …………………………………………………………………………………..…1<br />

5. Vice-Chair’s Report………………………………………………………………………………1<br />

6. Other Reports …………………………………………….…………………………………….…1<br />

6.1 BOD Ex-O/CO Report……………………………………………………………………………2<br />

6.2 CTTC Liaison Report…………………………………………………………………………… 2<br />

6.3 Global Refrigerants Topics…………………………………………………………………..… 2<br />

6.4 Consultant Report………………………………………………………………………………. 2<br />

6.5 <strong>Refrigeration</strong> Commissioning Special Project……………………………………………… 3<br />

6.6 Refrigerant Management Ad Hoc…………………………………………………………..… 3<br />

6.7 Refrigerants & their Responsible Use PD…………………………………………………… 3<br />

6.8 Other…………………………………………………………………………………………..….. 3<br />

7. 2011-12 MBOs………...…………………………………………………………………………...4<br />

8. Awards……………………………………………………………………………………………....5<br />

9. 2012-13 MBOs………. …………………………………………………………………………....5<br />

10. Unfinished Business………………………………………………………………………….....5<br />

11. New Business………………………………………………………………………………..….5<br />

12. Adjournment……………………………………………………………………………………...5<br />

ii

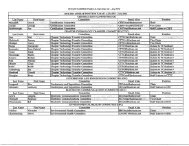

MOTIONS PASSED<br />

No. Motion<br />

the minutes from the <strong>REF</strong> Annual Meeting in Montreal be approved.<br />

1<br />

2<br />

3<br />

the Special Projects Subcommittee approve the proposed ASHRAE special project for a<br />

‘<strong>Refrigeration</strong> Commissioning Design Guide’.<br />

<strong>REF</strong> request to TC 4.3 that the final report to RP1448 be reviewed by <strong>REF</strong> before TC<br />

approval.<br />

ACTION ITEMS<br />

No. Responsibility Action Item<br />

1 Royal, Lim Work to organize possible <strong>Refrigeration</strong> Reception for Dallas<br />

2<br />

3<br />

4<br />

5<br />

meeting (Winter 2013)<br />

Lim, Scott, Staff Review MOP, Reference Manual to define and list <strong>REF</strong><br />

subcommittees, roles and responsibilities.<br />

Scott, Siller, Anderson Consider drafting a strategic goal related to refrigeration for<br />

incorporation into ASHRAE Strategic Plan<br />

Siller Develop list of refrigeration related CTTC resources to summarize<br />

what is complete and available and what tasks they need assistance<br />

from <strong>REF</strong><br />

Staff Send UNEP and TRP-1634 presentations to <strong>REF</strong> and interested<br />

parties.<br />

6 Staff Send final report of Refrigerant Management Plan Ad Hoc to <strong>REF</strong><br />

and interested parties when approved by Technology Council.<br />

7 Seeton Attend TC 4.3 meeting to communicate <strong>REF</strong> issues with draft final<br />

report to RP-1448<br />

8 Staff Email Vaughn, TC 4.3 chair, and RP-1448 PMS chair to request<br />

<strong>REF</strong> review of draft final report before they consider approval.<br />

9 Royal Develop orientation materials, summary document and list of<br />

contacts for refrigeration tours to post on <strong>REF</strong> webpage.<br />

10 Pearson/Scott Organize conference call to follow up on refrigeration survey<br />

proposals<br />

LIST OF ATTACHMENTS<br />

No. Attachment<br />

1 ASHRAE Strategic Plan<br />

2 PEAC update<br />

3 Global Refrigerants Topics<br />

4 UNEP 1634 presentation<br />

5 <strong>Refrigeration</strong> Commissioning Design Guide - Special Project Submission<br />

6 <strong>Refrigeration</strong> Management Plan Ad Hoc final report<br />

7 2011-12 MBOs<br />

8 Refrigerant Survey presentation<br />

iii

LIST OF ACRONYMS<br />

AMORTS Assistant Manager of Research and Technical Services<br />

BOD Board of Directors<br />

CNV Chair Not Voting<br />

CO Coordinating Officer<br />

CTTC Chapter Technology Transfer <strong>Committee</strong><br />

EX-O Ex-Officio<br />

H&A Honors and Awards <strong>Committee</strong><br />

IIAR International Institute of Ammonia <strong>Refrigeration</strong><br />

MOP Manual of Procedures<br />

NIST National Institute of Standards and Technology<br />

PAOE Presidential Award of Excellence<br />

PD Position Document<br />

PEAC President Elect Advisory <strong>Committee</strong><br />

PES Project Evaluation Subcommittee<br />

<strong>REF</strong> <strong>Refrigeration</strong> <strong>Committee</strong><br />

ROB Rules of the Board<br />

RP Research Project<br />

SAC Student Activities <strong>Committee</strong><br />

TC Technical <strong>Committee</strong><br />

TRP Tentative Research Project<br />

UNEP United Nations Environment Programme<br />

YEA Young Engineers in ASHRAE<br />

iv

1. CALL TO ORDER & INTRODUCTIONS<br />

Chair Doug Scott called the meeting to order at 8:00 AM and welcomed all in attendance.<br />

2. APPROVAL OF <strong>MINUTES</strong><br />

It was moved (PB) and seconded (CL) that,<br />

(1) the minutes from the <strong>REF</strong> Annual Meeting in Montreal be approved.<br />

MOTION (1) PASSED: 10-0-0, CNV<br />

3. REVIEW OF AGENDA<br />

Scott referred to agenda sent prior to meeting noting he’d try to accommodate schedules as<br />

the meeting moved along. Reindl asked to discuss Research Project (RP)-1448 when most<br />

appropriate.<br />

4. CHAIR’S REPORT<br />

Motions from Past Meetings Requiring Higher Body Approval<br />

� Montreal #2 to allow <strong>REF</strong> to review draft final report of the Refrigerant Management Plan<br />

ad hoc before Technology Council considered approval was approved. <strong>REF</strong> discussed<br />

the report via conference call an offered guidance to the ad hoc which was since<br />

considered and included in report.<br />

� Montreal #4 to approve changes to <strong>REF</strong> MOP was approved by Technology Council<br />

� No motions from Aug. 29 th conference call.<br />

Scott reported that he spoke with ASHRAE meetings department on reinstituting a<br />

refrigeration reception. This reception was similar to the Welcome Party but was<br />

discontinued for fiscal reasons. The cost in Chicago would’ve been $200/person. <strong>REF</strong><br />

needs to plan 1+ years in advance so <strong>REF</strong> could work towards a reception in Dallas. Gage<br />

suggested this reception could be a good recruiting tool for TC’s and for Young Engineers in<br />

ASHRAE (YEA) members. Funding from Technology Council may be more readily available<br />

now and commercial sponsorship may be an option worth pursuing. Royal and Lim agreed<br />

to pursue effort for <strong>Refrigeration</strong> reception for Dallas (Action Item 1).<br />

5. VICE-CHAIR’S REPORT<br />

Fiscal Report<br />

Lim reported there was a deficit for <strong>REF</strong> primarily due to committee travel. Draft budget for<br />

next year increases to cover this. No other issues to report.<br />

Rules of the Board (ROB) and Manual of Procedures (MOP)<br />

No changes were made to the <strong>REF</strong> ROB. The updated MOP is posted at<br />

www.<strong>ashrae</strong>.org/society-groups/committees/refrigeration-committee.<br />

Lim agreed to review the latest MOP and develop a list of subcommittees with associated<br />

tasks and responsibilities. Lim will lead effort with help from staff and past <strong>REF</strong> chairs<br />

(Action Item 2).<br />

Reference Manual<br />

The <strong>REF</strong> reference manual was updated in June. <strong>REF</strong> may wish to review again once MOP<br />

changes discussed earlier are made.<br />

1

6. OTHER REPORTS<br />

6.1 BOD EX-O/CO Report<br />

Montgomery thanked <strong>REF</strong> members for their time and efforts over the last few months. He<br />

referred to a Technology Council Management by Objective (MBO) to work with <strong>REF</strong> to<br />

increase activities and presence in refrigeration and refrigerant activities. Montgomery asked<br />

<strong>REF</strong> what help they may need to accomplish this objective and expand their role in<br />

ASHRAE. Montgomery continued to encourage <strong>REF</strong> to consider a strategic goal related to<br />

refrigeration for incorporation into ASHRAE Strategic Plan (Attachment 1). Scott, Siller,<br />

Anderson would continue to look into drafting a refrigeration related goal (Action Item 3).<br />

Werkema gave a presentation developed for Presidential Elect Advisory <strong>Committee</strong> (PEAC)<br />

(Attachment 2) on the state of the society, highlighting recent achievements and strategies.<br />

6.2 Chapter Technology Transfer <strong>Committee</strong> (CTTC) Liaison Report<br />

Siller met with CTTC Friday as consultant for <strong>REF</strong>. Siller and CTTC chair Metzger<br />

highlighted a few of the major refrigeration related issues:<br />

� New R in ASHRAE award developed last year. Points are expansion of Presidential Award<br />

of Excellence (PAOE) points. Will be presented to Honors and Awards (H&A) committee<br />

at this meeting as Society level award.<br />

� Some comments on the difficulty relating to refrigeration program here in Chicago as<br />

many were on high-tech issues or on refrigerants. More attendees would benefit from<br />

more basic or prepackaged programs.<br />

� Much interest on CTTC in the Tentative Research Project (TRP)-1634 guide, Refrigerants<br />

Position Document (PD), and ASHRAE/NIST Refrigerants Conference.<br />

� There is a need to emphasize posting <strong>REF</strong> activities on <strong>REF</strong> webpage,<br />

www.<strong>ashrae</strong>.org/society-groups/committees/refrigeration-committee.<br />

� CTTC is still looking to receive information from <strong>REF</strong> on hosting a successful refrigeration<br />

related chapter meeting. Lim and Siller had helped to start this effort with a two pager of<br />

tips but something more comprehensive can be completed and posted.<br />

� Siller noted there is currently one vacancy in the distinguished lecturer program<br />

Siller was asked to develop a list of refrigeration related CTTC resources to summarize what<br />

is complete and available and on what tasks they need assistance from <strong>REF</strong> (Action Item<br />

4).<br />

6.3 Global Refrigerants Topics<br />

Werkema made a presentation on Global Refrigerants Topics (Attachment 3) focusing on<br />

various worldwide climate change initiatives and related activities.<br />

6.4 Consultant Report (Anderson)<br />

Anderson report that TRP-1634, Guide for Sustainable Refrigerated Facilities and<br />

<strong>Refrigeration</strong> Systems, was released for bid in fall. Three bids were received and considered<br />

by project evaluation subcommittee (PES) but no bidder selected at this time. The PES will<br />

prepare follow up questions for bidders to address for re-evaluation. UNEP is a potential cofunder<br />

and has placed the project on their agenda for a funding decision in April 2012.<br />

Werkema gave a brief presentation related to UNEP and the proposed TRP-1634<br />

(Attachment 4).<br />

2

Staff was asked to send UNEP and TRP-1634 presentation to all in attendance (Action<br />

Item 5).<br />

Planning continues for the ASHRAE/NIST Refrigerants Conference. The conference is<br />

planned for October 29-30, 2012 at NIST headquarters in Gaithersburg, Maryland.<br />

6.5 <strong>Refrigeration</strong> Commissioning Special Project<br />

It is moved (CS) and seconded (RR) that,<br />

2. <strong>REF</strong> recommends the Special Projects Subcommittee approve the proposed ASHRAE<br />

special project for a ‘<strong>Refrigeration</strong> Commissioning Design Guide’.<br />

BACKGROUND: The special project submittal form is included as Attachment 5.<br />

MOTION (2) PASSED: 10-0-0, CNV<br />

Royal noted that Wal-Mart is doing some work that may be supportive to this effort. Royal<br />

agreed to chair the Special Project committee. Technical <strong>Committee</strong>s (TC) 10.1, 10.5, and<br />

10.7 have reviewed this proposal and support this effort.<br />

Smith noted the IIAR is publishing a commissioning standard for ammonia systems that may<br />

be a resource to this Special Project committee as well.<br />

6.6 Refrigerant Management Ad Hoc<br />

Scott summarized the <strong>REF</strong> conference call last fall and subsequent discussions. A draft of<br />

the report (Attachment 6) will be submitted to Technology Council at this meeting. Staff<br />

agreed to send final report of Refrigerant Management Ad Hoc to <strong>REF</strong> when approved by<br />

Technology Council (Action Item 6).<br />

6.7 Refrigerants and their Responsible Use PD<br />

Gage and Pearson noted the Refrigerants and their Responsible Use PD was approved by<br />

the PD committee. It will be considered for approval by Technology Council and the BOD at<br />

this meeting.<br />

6.8 Other<br />

Reindl discussed a draft final report on RP-1448, Ventilation Requirements for Refrigerating<br />

Machinery Rooms. This is a TC 4.3 project which looks to evaluate the basis for the<br />

ventilation equation in ASHRAE Standard 15 and drafts a change request to Standard 15.<br />

Reindl summarized what he noted were flaws in the report. The project monitoring<br />

subcommittee (PMS) and TC meet Tuesday to review and possible approve report. Reindl<br />

wishes <strong>REF</strong> to review and comment to make changes before this report is published and<br />

made available for reference and download.<br />

It is moved (CS) and seconded (RR) that,<br />

3. <strong>REF</strong> request to TC 4.3 that the final report to RP1448 be reviewed by <strong>REF</strong> before TC<br />

approval.<br />

BACKGROUND: <strong>REF</strong> discussed the draft final report and has concerns with various<br />

methods and conclusions. <strong>REF</strong> wishes to review and provide comments to TC by February<br />

7 th .<br />

3

MOTION (3) PASSED: 10-0-0, CNV<br />

Reindl and Seeton agreed to attend TC 4.3 meeting to voice these concerns (Action Item<br />

7). Staff would email Mike Vaughn, TC 4.3 chair, and RP-1448 PMS chair to request <strong>REF</strong><br />

review of draft final report before they consider approval (Action Item 8).<br />

7. 2011-12 MBOs<br />

Scott will present status report on MBOs (Attachment 7) to the Operations Subcommittee of<br />

Technology Council.<br />

Royal noted he made some contacts to look into tours of Wal-Mart facilities for chapter tours.<br />

A list of contacts with a list of facilities that could be toured could be made available to<br />

chapters. Jekel suggested a script, possible photos, or other orientation materials to tour<br />

attendees ahead of time to get them up to speed to better participate on tour. Royal agreed to<br />

draft these tour orientation materials as well as a list for the ASHRAE website with points of<br />

contact for various facilities (Action Item 9).<br />

Jekel noted he had a draft of write-up on refrigeration as a career but noted a review and<br />

enhancement by a professor or someone that works with students is warranted. Gage<br />

suggested approaching YEA to see if we can give them the presentation to distribute or post<br />

on student page. Local refrigeration members may be able to give presentation at chapter<br />

meetings. This presentation could target high school students also and focus on the<br />

environmental issues.<br />

Berge reported on discussions related to a refrigeration element to the Student Design<br />

Competition. The idea is for the winner to turn design into a project to actually build. There<br />

may be a $5k grant available for this. Berge will continue to work with Student Activities<br />

<strong>Committee</strong> (SAC) on the matter. Gage asked how <strong>REF</strong> stay involved with the award<br />

suggesting <strong>REF</strong> may want to invite winners to <strong>REF</strong> meeting to discuss their project.<br />

<strong>Refrigeration</strong> Survey<br />

<strong>REF</strong> conducted a survey of ASHRAE membership to gain feedback on how/if ASHRAE<br />

refrigeration products and services meet their professional needs. Survey collects 500+<br />

responses. <strong>REF</strong> held a conference call in September to help think about actions going<br />

forward. Pearson presented a summary of responses and gap analysis (Attachment 8) to<br />

determine additional refrigeration products and services needed by ASHRAE members.<br />

Highlights from the presentation include the following potential proposals:<br />

• Collate a <strong>REF</strong> seminar DVD from previous meetings<br />

• Run a <strong>REF</strong> basics seminar<br />

– Once?<br />

– Once a year?<br />

– More often?<br />

• Sponsored DVD<br />

• Teaching webinars on /refrigeration page<br />

• Handbook update – long term plan<br />

• Joint publication with other organisations<br />

• Co-membership<br />

• Current list of refrigeration speakers<br />

4

Pearson/Scott would organize conference calls to follow up on these proposals (Action Item<br />

10).<br />

8. AWARDS<br />

George Briley Award Presentation<br />

The 4 th annual George C. Briley Award for the best refrigeration-related article published in<br />

the ASHRAE Journal was presented to Mr. Amey Majgaonkar at the <strong>Refrigeration</strong><br />

<strong>Committee</strong> meeting for his article ‘Controlling Corrosion in Marine <strong>Refrigeration</strong> Systems’.<br />

Milt Garland & Comfort Cooling Awards<br />

Nominations for the Milt Garland and Comfort Cooling Awards are due May 1. Staff reported<br />

a notice was published in Insights and the E-Newsletter. One nomination for the Milt Garland<br />

Award has been received already.<br />

9. 2012-13 MBOs<br />

Lim has drafted MBOs for 2012-13 Society Year. He will send draft to <strong>REF</strong> for review and<br />

comment before finalizing for Annual Meeting.<br />

10. UNFINISHED BUSINESS<br />

(none)<br />

11. NEW BUSINESS<br />

The next <strong>REF</strong> meeting will be the ASHRAE Annual meeting in San Antonio, Texas on<br />

Sunday June 24, 2012. Staff will help to schedule interim conference calls targeted for April<br />

6 and May 25 th .<br />

12. ADJOURNMENT<br />

Scott thanked all for their attendance today and for their participation throughout the year.<br />

The <strong>Refrigeration</strong> <strong>Committee</strong> meeting was adjourned at approximately 12:05 PM.<br />

5

<strong>REF</strong> Minutes 12.W – Attachment 1<br />

ASHRAE Strategic Plan<br />

Approved by Board of Directors March 20, 2006<br />

Edited April 3, 2006<br />

Strategies numbered June 25, 2006<br />

Strategies in Direction 4 amended June 24, 2007<br />

Directions, Rationale and Strategies amended June 26, 2011

Direction 1<br />

Direction 1 ASHRAE will be a leader in advancing sustainable design, construction, and operations for<br />

new and existing built environments.<br />

Rationale<br />

1. Building sustainability effort is critical to our global environment and society.<br />

2. Leading the building sustainability effort is both competitively essential for ASHRAE members<br />

and will motivate the next generation of leaders in the field.<br />

3. ASHRAE and its membership have unique building performance expertise that sets them apart<br />

from others.<br />

4. The focus on energy efficient buildings continues to increase as energy costs rise, fossil fuel<br />

sources are depleted, and environmental impacts increase.<br />

5. In general, building operation and maintenance account for 60-80% of total cost of ownership,<br />

and building performance typically decreases after the first year of operation.<br />

6. Tools are needed to help owners operate and renew buildings in a sustainable manner thereby<br />

reducing their impact on the environment.<br />

Strategies<br />

1.1 Working with others, lead the development of integrated design, construction, and operations and<br />

maintenance guidance that includes improved energy efficiency, indoor environmental quality,<br />

water use reduction, and other key parameters for high performing and sustainable buildings.<br />

1.2 Lead and influence research, publications, education and certification for systems and equipment to<br />

be used in high-performing buildings.<br />

1.3 Develop metrics and rating systems to certify performance of buildings for improved energy and<br />

water efficiency, indoor environmental quality and other key parameters.<br />

1.4 Promote the use of life-cycle-cost analysis to encourage sustainable building construction,<br />

operation, and renewal.<br />

1.5 Lead the development and implementation of advanced operations for buildings which should<br />

include designing for maintainability (including building control systems) training, guidance, and<br />

tools for building operators.<br />

1.6 Streamline internal processes to accelerate effective technology transfer.<br />

1.7 Promote improved refrigeration system design, construction and operating efficiency.<br />

<strong>REF</strong> Minutes 12.W – Attachment 1<br />

1.8 Accelerate the use of state-of-the-art working fluid technologies to reduce environmental<br />

impacts.

Direction 2<br />

Direction 2 ASHRAE will be a world class provider of education and certification programs.<br />

Rationale<br />

1. Education is an ongoing need of ASHRAE members and the industry and provides an opportunity for<br />

membership growth.<br />

2. Membership and industry surveys show that there is a demand for ASHRAE certification programs.<br />

3. ASHRAE has the expertise and the credibility to design and deliver education and certification<br />

programs.<br />

4. Rapidly changing technology and issues such as sustainability, energy cost, and indoor<br />

environmental quality and security have created heightened expectations for timely delivery of diverse<br />

education content for life-long learning.<br />

Strategies<br />

2.1 Provide accessible on-demand education and distance learning to members and other<br />

customers.<br />

2.2 Expand ASHRAE’s education and certification delivery infrastructure and make it self-supporting.<br />

2.3 Develop a marketing strategy for certification programs within the building and energy systems<br />

industry.<br />

2.4 Create educational and train-the-trainer programs that can be offered by ASHRAE chapters.<br />

2.5 Partner with organizations around the world that have expertise in the development and delivery<br />

of education and certification programs.<br />

2.6 Promote the ASHRAE Learning Institute brand and the value of life-long learning.<br />

<strong>REF</strong> Minutes 12.W – Attachment 1<br />

2.7 Develop programs about career opportunities and work with other interested organizations that<br />

sponsor or support K-12 programs to promote career fields in our industry.<br />

2.8 Develop and promote educational programs and materials that support documents produced<br />

through ASHRAE's Standards Development and Special Publications process.<br />

2.9 Develop and encourage the use of ASHRAE documents in curricula on sustainable building and<br />

energy systems used by universities and technical schools.

Direction 3<br />

Direction 3 ASHRAE will position itself as an essential resource for optimizing the performance of<br />

building and energy systems throughout their life cycles.<br />

Rationale<br />

1. Public interest in HVAC&R related issues is growing and ASHRAE has the technical knowledge<br />

to meet this need.<br />

2. Policy makers and other stakeholders need to be aware of ASHRAE’s expertise.<br />

3. Increasing competition requires ASHRAE to distinguish itself as the leader in the field. ASHRAE<br />

needs to be recognized as the building and energy systems design and performance experts.<br />

4. The utilization of ASHRAE’s knowledge base can directly lead to gains in worker productivity and<br />

efficiency of industrial processes.<br />

5. Appropriate commissioning through the life cycle of a building promotes optimum performance.<br />

Strategies<br />

3.1 Aggressively market ASHRAE to enhance its image with the industry, policy makers, and other<br />

stakeholders through advocacy, public relations, association relations and dissemination of its<br />

products and services.<br />

3.2 Expand ASHRAE’s marketing focus to target all stakeholders in building and energy systems<br />

design and operation such as contractors, building owners, and architects.<br />

3.3 Make ASHRAE’s products and services useful, desirable, and accessible to both existing and<br />

prospective customers by strengthening and adding focus to the ASHRAE brand as a key<br />

resource.<br />

3.4 Provide tools to enable chapters to become a local focus for education and community outreach.<br />

3.5 Help ASHRAE regions and chapters provide appropriate and timely information to state and local<br />

government bodies.<br />

3.6 Establish and maintain effective relations with key government agencies so that ASHRAE is<br />

recognized as a resource for regulatory and legislative development and for program<br />

implementation.<br />

3.7 Conduct periodic market research and environmental scans to understand and act upon the<br />

needs of current and prospective members.<br />

3.8 Target selected industry media to present ASHRAE and its activities.<br />

<strong>REF</strong> Minutes 12.W – Attachment 1<br />

3.9 Promote availability of appropriate products and services to markets outside the ASHRAE<br />

membership.

Direction 4<br />

Direction 4 ASHRAE will be a global leader in the building and energy system community.<br />

Rationale<br />

1. The world has evolved from independent national economies to an interdependent global economy.<br />

2. Markets in developing countries present significant growth opportunities.<br />

3. Technology developed outside North America can enhance ASHRAE’s knowledge base.<br />

Strategies<br />

4.1 While ASHRAE’s chapter and regional structure shall be the backbone of ASHRAE’s structure<br />

globally, it shall be flexibly applied to serve our membership.<br />

4.2 ASHRAE will cooperate with organizations with shared objectives and will work to strengthen the<br />

ASHRAE Associate Society Alliance.<br />

4.3 Meetings, conferences and expositions should be held in locations that best support our<br />

members globally.<br />

4.4 The cost of membership will be balanced with the cost of providing benefits and services in<br />

different geographic regions to include adding alternatives that help increase membership<br />

globally.<br />

4.5 Publications and educational products will be priced so they are within reach of ASHRAE’s global<br />

membership but will not be priced at less than the cost of providing them.<br />

4.6 ASHRAE will develop its expertise in building and energy system technologies to embrace whole<br />

building sustainable design and be one of the most valuable resources for related publications<br />

and educational products.<br />

4.7 ASHRAE will encourage use, adaptation, and/or translation of its products in additional<br />

languages.<br />

4.8 Volunteer participation obstacles will be addressed through meeting planning and organization<br />

that is sensitive to global participation and incorporates electronic communication technologies.<br />

4.9 ASHRAE will actively support and participate in international standards development activities<br />

and will promote adoption of ASHRAE standards, or portions of standards, in standards to be<br />

used outside of North America.<br />

4.10 ASHRAE will protect its intellectual property rights.<br />

4.11 ASHRAE will provide enhanced staff support outside of North America.<br />

4.12 ASHRAE will align its business practices to better serve members globally.<br />

<strong>REF</strong> Minutes 12.W – Attachment 1<br />

4.13 The ASHRAE brand will be strengthened to reflect a global strategy that serves the needs of all<br />

members.

ASHRAE Update<br />

brought to you by PEAC<br />

Commercial Building Standards<br />

Standard 90.1-2010, Energy Standard for<br />

Buildings Except Low-Rise Residential<br />

Buildings<br />

– Recently established by U.S. Department of<br />

Energy (DOE) as the commercial building<br />

reference standard for state building energy<br />

codes.<br />

– States must certify compliance by October<br />

2013<br />

– DOE determined 18.5% less building energy<br />

use than 2007 standard<br />

– PNNL confirmed 30% less building energy use<br />

than 2004 standard<br />

Commercial/Residential<br />

Building Standards<br />

The High Performance Building Standard –<br />

189.1<br />

– 2011 standard now available<br />

ASHRAE/IES Standard 100, Energy<br />

Conservation in Existing Buildings<br />

– First publication public review could be<br />

approved in Chicago<br />

<strong>REF</strong> Minutes 12.W – Attachment 2<br />

Presidential Member Lynn G. Bellenger<br />

Lynn G. Bellenger Memorial Fund<br />

www.<strong>ashrae</strong>.org/bellenger<br />

Commercial Building Standards<br />

Standard 90.1-2013, Energy Standard for<br />

Buildings Except Low-Rise Residential<br />

Buildings<br />

– Goal 50 percent less building energy use over<br />

2004 standard<br />

– 15+ face-to-face meetings; 90+ conference<br />

calls<br />

– 40 addenda in various stages of approval;<br />

possibly 50 more to be proposed<br />

Residential Energy Standard<br />

• Draft goals being considered for ASHRAE/IES<br />

Standard 90.2, Energy-Efficient Design of Low-<br />

Rise Residential Buildings<br />

– 30% more energy efficient than the 2004 version of<br />

90.2 and IECC 2006<br />

– Technology Council appointed a Standard Advisory Panel<br />

to position 90.2 as a leadership standard<br />

– Requirements achievable to meet and enforce<br />

– To include both a prescriptive and a performance path<br />

• DOE has increased its support by means of staff<br />

and national lab analysis

What’s Your Building EQ?<br />

• As Designed Pilot launched<br />

in March 2011; pilot<br />

addresses office buildings<br />

only<br />

• Anticipated program launch<br />

in early 2012<br />

• Research project to expand<br />

building types to be rated<br />

has been proposed<br />

• BEAP and BEMP<br />

certifications now available<br />

www.buildingeq.org<br />

Technology Council<br />

• Developing Position Documents<br />

– Unvented Combustion Appliances and IAQ<br />

– Professional Aspects of Building Commissioning<br />

– Refrigerants and Their Responsible Use<br />

– Limiting Indoor Mold Growth and Managing Moisture in<br />

Building Systems<br />

– Building Safety and Security<br />

• U.S. refrigeration management plan being drafted<br />

• <strong>Refrigeration</strong> <strong>Committee</strong> compiling survey results<br />

from 500 members on products and services<br />

• Standards <strong>Committee</strong> – 62 public review drafts,<br />

106 comments received, revised online comment<br />

database complete<br />

RP Campaign<br />

Join in the success!<br />

7,000+ members support RP …<br />

Do you?<br />

<strong>REF</strong> Minutes 12.W – Attachment 2<br />

Advanced Energy Design Guides<br />

• Circulation of 30 and 50%<br />

Advanced Energy Design<br />

Guidance series is 356,000+<br />

• Available for free download<br />

• 50% K-12 School Buildings<br />

and Existing Buildings now<br />

available<br />

• Guides on 50% Mid-Big Box<br />

Retail and Hospitals<br />

buildings available in<br />

January<br />

Members Council<br />

• Record number of Technology Award submissions<br />

–37<br />

• Proposing regional members as Members Council<br />

voting members vs. director and regional chairs<br />

• Reviewed and took action on 43 Fall Chapters<br />

Regional Conference motions<br />

• Chartered the Dominican Republic Section in El<br />

Vergel, Santo Domingo, and the Tri-Cities Section<br />

in Kingsport, Tenn.<br />

• Approved name changes for<br />

– South India Chapter to Bangalore Chapter<br />

– Hyderabad Chapter to Deccan Chapter<br />

Publishing/Education Council<br />

• COMNET recognizes the Building Energy Modeling<br />

Professional (BEMP) certification program as<br />

identifying qualified energy modelers (vs. creating<br />

its own energy modeling certification program to<br />

test individuals’ ability to use COMNET software)<br />

– Commercial Energy gy Services Network ( (COMNET) ) extends<br />

and supports existing systems for assessing and rating<br />

the energy efficiency of commercial and multifamily<br />

buildings in the United States.<br />

• Thermal Comfort Tool, Version 2, predicts thermal<br />

comfort based on Standard 55-2010; allows users<br />

to fine tune comfort analysis to needs of<br />

occupants<br />

• Special certification exam administrations<br />

provided in Italy, Brazil and Argentina

Government Affairs<br />

• Washington office now staffed with state<br />

and local government affairs manager<br />

• Canadian members working to incorporate<br />

ASHRAE standards in Canadian Building<br />

Code and a d model ode National at o a Energy e gy Code<br />

• Recent issues:<br />

–CBECS funding<br />

– Energy bills<br />

Join Us<br />

• High Performance Buildings Conference, March 12-13,<br />

2012, San Diego, Calif. Also offered is ALI course,<br />

Implementing Standard 189.1, all-day seminar March<br />

11<br />

• Building Systems and Services for the 21 st Century,<br />

CIBSE/ASHRAE, April 18-19, 2012, London<br />

• Energy Modeling Conference: Tools for Designing High<br />

Performance Buildings, Oct. 1-3, 2012, Atlanta<br />

• ASHRAE/NIST Refrigerants Conference, Oct. 29-30,<br />

2012, Gaithersburg, Md.<br />

• Seventh International HVAC Cold Climate Design<br />

Conference, Nov. 12-14, 2012, Calgary, Alberta,<br />

Canada<br />

• IAQ 2013, fall 2013, Vancouver, British Columbia,<br />

Canada<br />

Breakdown of Brand<br />

Evolvement<br />

• Updated Logo—visual acknowledgement<br />

of expansion of ASHRAE expertise<br />

• New Tagline—indicates ASHRAE’s<br />

promise to the industry and the future<br />

• Departure from use of full name—alludes<br />

to ASHRAE’s growing global presence<br />

Finances and Membership<br />

• 2010-2011 budget surplus of almost<br />

$800,000<br />

• Projected 2011-12 outlook –$150,000<br />

• Membership stable with 53,000+<br />

members<br />

• 2011-12 is the largest total revenue<br />

budget in ASHRAE history<br />

• AHR Expo 2012 is largest in history<br />

A Changing Industry<br />

An Expanding Field<br />

An Evolving Environment<br />

• The building industry has experienced rapid change within<br />

the last decade, i.e., increased demand for energy efficient<br />

buildings<br />

• HVAC&R is no longer the niche industry it once was:<br />

– Integrated design examines total building<br />

– Goal of systems y have become more than heating g or<br />

cooling, but conserving energy and promoting<br />

sustainability too<br />

• Focusing solely on HVAC&R in a dynamic green building<br />

industry is no longer practical<br />

• ASHRAE has been expanding its scope to meet needs of<br />

total building for some years now, e.g.:<br />

– Commissioning<br />

– Building automation control<br />

– Indoor environmental quality<br />

– Building energy efficiency<br />

ASHRAE.org<br />

• Better navigation<br />

• Better search<br />

engine<br />

• Better tracking<br />

• All designed to help<br />

you find the<br />

information you<br />

need to support you<br />

whether in your role<br />

in the industry or<br />

ASHRAE<br />

<strong>REF</strong> Minutes 12.W – Attachment 2

<strong>Refrigeration</strong> Com.<br />

Issues Update<br />

January 23, 2012<br />

Tom Werkema<br />

Climate Change - International<br />

� 3 largest GHGs at record levels<br />

� Increasing at ever faster rate<br />

� CO 2 @ 389 PPM<br />

� CH 4 & N 2O also up<br />

� Total increase 29% since 1990<br />

Climate Change – Other Countries<br />

� Australia – new carbon tax<br />

� 18 bills introduced – lower Chamber approved 74-72<br />

� Tax $18A/MT CO2 � HFC-134a ~$32 USD/kg<br />

�� Japan new parliament has not discussed<br />

� Canada – 873 MM T above KP 2,792 MM T<br />

� Europe<br />

� EU Advocate General determines EU ET can include foreign airlines<br />

� 2012 85% free, 15% auction<br />

� 15.5% emissions reduction since 1990; economy grew by 41%<br />

� Emission trading – value below $9/MT CO2e � Peaked at almost $40/MT CO2 � Adding aviation, aluminum, ammonia production<br />

� Adding nitrous oxide, PFCs<br />

Montreal Protocol<br />

HFC Amendment<br />

� Baseline 2005-2008, GWP HFCs plus 85% GWP HCFCs<br />

� Imports/exports banned to non parties of this Amendment<br />

� 20 chemicals including 2 HFOs<br />

� Discussions continue, but decision blocked by China, India, Venezuela,<br />

BBolivia li i<br />

� Approved $400 M new funds for 2012-2014 – lowest in history<br />

Climate Change – International<br />

� Meetings concluded 36 hours late at 6 AM, Dec 11<br />

� Durban Platform – negotiate by 2015, start 2020<br />

� Includes all major emitters (China, India, US, EU)<br />

� Green Climate Fund (empty)<br />

� Climate Technology gy Center – Feb, , 2012 Germany y<br />

� HFC “enabling” Text disappeared during final day<br />

� Second phase Kyoto Protocol starting in 2013<br />

� Until 2017 or 2020<br />

� By May 1, 2012 Developed Parties submit “ambition”<br />

� 11% of total current emissions<br />

� Japan, Russia, Canada will not participate in Second Period<br />

� Leaves EU and EU wanabees, plus maybe New Zealand<br />

� Added nitrogen trifluoride to KP list<br />

US EPA – Major Activity<br />

<strong>REF</strong> Minutes 12.W – Attachment 3<br />

� Power Plants GHG Reduction – (originally nPRM 9/30/11) –<br />

released by White House 12/20/2011<br />

�Oil Refineries – 12/2011 proposal (not!), 11/2012 final<br />

� Delayed y 2011 FC GHG reporting p gfrom<br />

3/30/12 to 9/28/2012<br />

� Cars 62 mpg by 2025, trucks 44 mpg – avg 54.5 mpg<br />

� Credit for MAC revisions or substitution<br />

� SNAP<br />

�Approved three hydrocarbons for appliance, small<br />

refrigeration on 12/20/2011<br />

� 57 grams limit domestic refrigerators, 150 grams retail refrigeration<br />

� Propane, isobutane or R-441A<br />

� Includes conditions to minimize fire risk, inlcuding warning labels<br />

and disposal practices

EPA – HCFC Allowances 2012-2014<br />

HCFC-22 proposed to be allocated as follows<br />

Year – (Metric Tons) 2012 2013 2014<br />

Current Rule 40,700 35,900 31,100<br />

Proposed Max 36,200 31,400 26,300<br />

Proposed Min 25,100 20,800 16,400<br />

-Creates transition to 2015-9 & 14,100 MT HCFC-22<br />

-Comments due Feb 3, 2012; then Final Rule ??<br />

-Changes based on inventory liquidation, large retail food<br />

sector recycling, recovered-recycled amounts<br />

Montreal Protocol Executive <strong>Committee</strong><br />

� Approved ~ 60 developing country HCFC Phase-out Management Plans in<br />

2011<br />

� $326 M approved vs. original $712M request, 349 Projects<br />

� Focus on HCFC-141b phase out first, where its an option<br />

� China HPMP<br />

� DDecision i i to t provide id $265 M ffor projects j t across 7 market k t sectors t<br />

� Phase-down of foams and transition to hydrocarbons and CO 2<br />

� ICR and RAC sectors targeted with legislation and phase-downs<br />

� Mexico HPMP<br />

� Stage 1 Focus 141b foam conversions to cyclopentane and methyl formate<br />

� Possible ban on 141b by 2015<br />

� Brazil HPMP<br />

� Foam 141b targeted; transition to hydrocarbons<br />

� Quotas for import, export, and end of equipment life will be implemented<br />

� India – not approved as yet<br />

Europe<br />

<strong>REF</strong> Minutes 12.W – Attachment 3<br />

� Review of F-gas Regulation 842/2006<br />

�Commission published report end of September w/ options<br />

� Stakeholder consultations thru year end<br />

�Commission �Commission proposal for F Gas Amendment summer 2012<br />

� Submit to Parliament September 2012<br />

�Expected Outcomes<br />

� Revised regulation: implementation 2014/2015<br />

� Further HFC bans<br />

� Foam blowing, domestic refrigeration???<br />

� Possible overall phase-down and quota system, 30% reduction by<br />

2020<br />

� Base year 2005-2007?

65 th ExCom Meeting<br />

Bali, Indonesia<br />

November, 2011<br />

� ASHRAE – Founded in 1894<br />

◦ One of largest non profit Standards Organizations Globally<br />

◦ 52,000 Members<br />

◦ 175 Local Chapters<br />

� Over 20 Local Local Chapters in A5 Countries<br />

� Over 9,000 Members outside NA<br />

� A5 fastest growing presence<br />

◦ 50 Affiliated Technical Societies<br />

◦ 100 Standard writing Technical <strong>Committee</strong>s<br />

� Project Details<br />

◦ Strong need: no comparable Guide exists<br />

◦ Targeted Audiences include:<br />

� Facility owners, operators and servicing technicians<br />

� Contractors Contractors, design engineers and manufacturers<br />

� Policy makers and energy efficiency program designers<br />

� Educators including UNEP training seminars<br />

◦ Initially written in English<br />

◦ Some indication that Partner Societies may also fund and<br />

support UN language translations<br />

� Expected to cost $20,000<br />

� Refrigerated “Cold Chain” focus<br />

◦ Foods-Medicines<br />

◦ Food Processing, Refrigerated Warehousing, Supermarkets<br />

� A5 particular focus<br />

◦ Currently y most use HCFC-22 refrigerated g systems y<br />

� Particularly true for SMEs<br />

◦ Normal life span is 20-30 years for Warehousing<br />

� 10-15 years for Supermarkets<br />

� Proposed Financing<br />

◦ $150,000 from ASHRAE<br />

◦ $250,000 from MLF<br />

◦ $ 75,000 from technical expertise<br />

◦ UNEP support<br />

◦ 24 months th ffor completion l ti<br />

<strong>REF</strong> Minutes 12.W – Attachment 4<br />

� Project Details - Overview<br />

◦ Facility design concepts<br />

◦ Cooling loads<br />

◦ <strong>Refrigeration</strong> system technologies and choices<br />

◦ Equipment q p and control options p<br />

◦ Performance modeling & life-cycle analysis<br />

◦ Each section written from simple, key concepts to more complex<br />

methods and techniques

� Project Details - Benefits<br />

◦ Large energy savings and greenhouse gas reduction<br />

◦ 20-40% energy savings over current practices<br />

◦ Methods to evaluate refrigerant options<br />

◦ Large impact in developing countries<br />

◦ High load intensity – systems operate year round<br />

� Perishable products – must perform at all times<br />

◦ Promote advanced control strategies<br />

◦ Methods for optimized efficiency and performance monitoring<br />

◦ Performance Benchmarking metrics<br />

� Project Details – Content Outline<br />

◦ Refrigerated Facility Design and Cooling Loads<br />

◦ <strong>Refrigeration</strong> System Components and System Design<br />

◦ Controls and Control Strategies<br />

◦ Energy Modeling and Performance Analysis<br />

◦ Commissioning, Operations and Benchmarking<br />

� Project Details - Guide Considerations<br />

◦ Facility orientation, building site use, work flow<br />

◦ Building envelope – insulation, doors<br />

◦ Infiltration management<br />

◦ System design using optimization and system balances<br />

◦ Compressors, condensers, evaporators interactions<br />

◦ Control systems<br />

◦ Energy and on-site resource options<br />

◦ Water re-use and heat recovery<br />

� Project Details - Distribution<br />

◦ UNEP<br />

◦ ASHRAE’s Chapters<br />

◦ ASHRAE’s Associate Society Alliance members<br />

<strong>REF</strong> Minutes 12.W – Attachment 4

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

TO BE CONSIDERED BY SPECIAL PROJECTS SUBCOMMITTEE<br />

NOTE: Please use a separate form for each proposed project.<br />

1. Submitter Submittal Date: December 15, 2011<br />

Name/Affiliation: Jim McClendon, Wal-Mart Stores<br />

Bill Harrison, Trane Arkansas<br />

Doug Scott, VaCom Technologies<br />

Kent Anderson<br />

Contact Information: James.Mcclendon@wal-mart.com<br />

waharrison@trane.com<br />

dscott@vacomtech.com<br />

M_Kent_Anderson@att.net<br />

2. Cognizant / Sponsoring <strong>Committee</strong>(s):<br />

<strong>Refrigeration</strong> <strong>Committee</strong> (Doug Scott, Chair)<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

3. Proposed Project & Scope Overview:<br />

(If project is to develop a publication, include three things that will set this work apart from existing or<br />

competitive publications and how the publication will be useful to the intended audience.)<br />

The proposed project will develop a refrigeration commissioning design guide publication on<br />

commissioning of low and medium temperature refrigeration systems. The intent is to address the<br />

commissioning requirements for these types of systems, which are very different from the commissioning<br />

required HVAC systems, as well as design a modular approach that is consistent with how refrigeration<br />

projects are commonly designed, contracted and implemented.<br />

Thousands of refrigeration systems are installed every year in facilities ranging from convenience stores to<br />

large and sophisticated frozen food distribution centers. Many of these systems are started with a<br />

performance test consisting of “can the system maintain temperature in the case?” <strong>Refrigeration</strong> systems<br />

consume a large amount of energy and poorly commissioned systems use more energy than systems<br />

properly commissioned. No comprehensive commissioning guide for low and medium temperature<br />

refrigeration systems exists. A guide will save energy and protect the quality of food throughout the food<br />

chain served by these systems. The guide will have global reach through ASHRAE’s global membership,<br />

as well as through adoption by many large firms with global presence.<br />

Note: The CIBSE refrigeration commissioning document (CIBSE Commissioning Code R: 2002) was<br />

reviewed and it was determined that it was not a good “starting point” for the proposed effort. The CIBSE<br />

document is quite detailed in terms of start-up procedures, safety and other specific processes, whereas the<br />

publication would focus on the process of commissioning and technical procedures related to performance<br />

and efficiency.<br />

The initial Guide document will cover refrigeration commissioning in general, but will emphasize and give<br />

primary consideration to commercial and light industrial systems (e.g. retail stores, halocarbon warehouse<br />

systems, etc.) Commissioning of heavy industrial process systems, which typically use ammonia and large<br />

Special Project Submittal Form (Updated Aug 2010) Page 1

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

central compressor plants, will be addressed in a subsequent revision, likely in collaboration with other<br />

associations, e.g. IIAR, IARW and RETA.<br />

4. Intended Audience (s):<br />

(If project will result in a publication indicate what industry/specialty it is aimed at and why the why the<br />

audience would want to buy it.)<br />

The intended audience is designers, installers and owners of refrigeration systems, in the US and globally.<br />

5. Expected Project Deliverables:<br />

(Include workshops, seminars, training courses, publications, CDs, or reports. Indicate proposed/expected<br />

format for any published work.)<br />

The expected deliverable is a new publication on commissioning of low and medium commercial<br />

refrigeration systems. Follow-up seminars or workshops could also be a possible, to promote the use of<br />

the publication.<br />

The construction of commercial and industrial refrigeration systems are typically accomplished in a<br />

different manner than for HVAC systems. Only rarely is a traditional design model employed, with an<br />

architect taking responsibility for the owner over the design engineers and with a general contractor<br />

responsible for the refrigeration contractor, along with the other construction trades. More often, the owner<br />

has a prime contract with the refrigeration installer, who may be a design-build contractor supplying the<br />

equipment or may simply be the installer of equipment purchased separately by the owner. The owner<br />

often establishes detailed criteria or even designs the refrigeration systems in-house, or relies on a<br />

manufacturer or OEM (typical in many supermarket chains) or uses a design consultant with refrigeration<br />

specialization. Since much of the commercial refrigeration business is repetitive (e.g. chains), the design<br />

often evolves from one project to the next, following a general criteria or the experience of “what works”.<br />

The <strong>Refrigeration</strong> Commissioning Guide will be designed for modular use; acknowledging the varied<br />

methods of designing and contracting the refrigeration work. The Guide will be usable whether or not<br />

commissioning is incorporated at the outset of the design phase, and will be flexible and easily adopted in<br />

part or in whole, without assuming one contracting method over another. The major stages of<br />

commissioning will be defined such that an owner or contractor can adopt portions of the Guide without<br />

being required to re-design the documentation to allow logical use or achieve continuity.<br />

The proposed stages of the <strong>Refrigeration</strong> Commissioning Guide are:<br />

1. Commissioning during Planning and Design<br />

2. Commissioning during Construction<br />

3. Commissioning during Start-up<br />

4. Commissioning during the First Year<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

There are two major aspects in the Guide, which will have some overlapping considerations but will be<br />

kept separate as much as possible; the commissioning process and the technical procedures used in<br />

commissioning. The process definition will utilize the framework in ASHRAE Guideline 0, with<br />

modifications to accommodate the nature of the refrigeration contracts and implantation (as noted<br />

previously). The Guide is expected to be used frequently by design-build contractors, who would both<br />

manage the process and execute the technical procedures, so the Guide must be designed to accommodate<br />

this “self-managed” method as well as for commissioning performed by an independent third party.<br />

Special Project Submittal Form (Updated Aug 2010) Page 2

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

The <strong>Refrigeration</strong> Commissioning Guide will be designed to allow use by a variety of construction and<br />

contracting arrangements, including:<br />

� Design-build project by a refrigeration contractor<br />

� Owner-designed projects, installed by refrigeration contractor<br />

� Projects designed for owner by a consultant, installed by a refrigeration contractor<br />

The Guide will be developed recognizing the characteristics of the refrigeration equipment and systems<br />

which are different from most HVAC counterparts, such as:<br />

� <strong>Refrigeration</strong> systems are built of components, rather than factory-assembled packages. As such,<br />

each system is unique and performance is greatly affected by component interactions and control<br />

methods. Even in commercial refrigeration for chains, systems vary from site to site. Compressors<br />

and condensers are selected to meet the needs of various loads and application conditions, with<br />

control valves and electronic control systems often selected and applied by a different party from<br />

the provider of the major equipment.<br />

� Two factors, the purchase of equipment from multiple vendors to minimize costs and the common<br />

practice of the owner specifying a control vendor which OEMs and contractors must use, increases<br />

the challenges of integration and can contribute to poor system performance and uncertain<br />

responsibilities.<br />

� Most refrigeration components (unlike HVAC equipment) are not certified to a rating standard and<br />

generally do not even reference a test standard in the equipment catalogs, moreover the applied<br />

conditions may be significantly different that the common available rating standards. Sizing,<br />

design practice and equipment performance expectations are thus subject to significant rules-ofthumb<br />

and experience factors.<br />

� <strong>Refrigeration</strong> must perform (maintain temperatures) at all times vs. air conditioning which may be<br />

designed to meeting temperatures at a certain percentage of hours. Thus safety factors are a<br />

practical necessity, and the amount of safety factor is rarely “tested”.<br />

Stage 1 – Commissioning during Planning and Design<br />

Define methods for working with owner and design team to define owner’s requirements for<br />

commissioning:<br />

� Who will be responsible for the commissioning process and communications<br />

� Which stages does the owner want to include in commissioning<br />

� Who will be involved in commissioning tasks:<br />

o Manage activities<br />

o Establish acceptance, track variances and resolve discrepancies<br />

� Build communications process and milestones into project schedules<br />

Define the high level commissioning scope; the systems, types of measurements and activities to be<br />

included in commissioning, such as:<br />

� Verification of equipment make, model, size, features, accessories, etc.<br />

� Component and equipment performance, including capacity and/or efficiency<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

Special Project Submittal Form (Updated Aug 2010) Page 3

� Overall plant efficiency<br />

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

� Control system functionality and consistency with mechanical equipment and mechanical controls<br />

� System piping integrity, design for low leakage and leak-tightness<br />

Define the depth of specific tests and degrees of measurement expected, along with the necessary points of<br />

measurement, and additional costs of instrumentation, labor and system modifications or accommodations<br />

to allow commissioning.<br />

� System access points for instrumentation (the intent is to define this activity and describe the<br />

process, providing examples if needed, not to list the exact points of access for specific systems)<br />

� Additional temporary or permanent instruments or sensors, based on the desired degree of<br />

performance measurement, which could extend as far as installing power meters and flow meters<br />

� Pressure tests and vacuum test procedures, instrumentation and responsibilities, which may go<br />

beyond the normal construction specifications, or may simply define a witness responsibly.<br />

� Calibration methods and responsibilities.<br />

� Integration of ongoing performance monitoring capabilities.<br />

� Determine if equipment-based or system level automated fault detection and diagnostics (FDD)<br />

will be included in the project and develop/coordinate procedures for enabling and testing.<br />

The Guide will provide maximum flexibility in allowing users to adopt the process and procedures to their<br />

individual needs. The responsibilities in this Stage include informing the owner of the commissioning<br />

options available, along with costs, to assist in determining the depth and extend of commissioning<br />

procedures.<br />

Stage 2 – Commissioning during Construction<br />

The Guide will define the commissioning process during construction, including the necessary areas of<br />

responsibilities, examples or report scope and intervals, and related details. Flowcharts will be included to<br />

explain the responsibilities and communications process.<br />

The following responsibilities will be defined:<br />

� Identify all parties who have roles in meeting the commissioning goals.<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

� Communication with parties on a timely basis as engineers, individual vendors, contractors and<br />

other agents come in and out of the construction process.<br />

� Define the specific activities and technical areas to address and the key junctures or milestones to<br />

employ to avoid being “too late” to include commissioning prerequisites and also to avoid<br />

construction delays (which realistically results in the commissioning goal being bypassed). An<br />

example would be specific plan reviews for points of connection for instrumentation.<br />

� Communication with vendors before equipment arrives on site. Many of the key commissioning<br />

measures may occur at a factory or OEM which may requires that the commissioning<br />

documentation (certification potentially) be provided by the vendor. Verification by the<br />

commissioning agent may take the form of a factory acceptance test or review of documentation.<br />

The Guide will provide examples and a listing of categories which an owner may include in refrigeration<br />

commissioning. <strong>Refrigeration</strong> commissioning may be performed along with other building commissioning<br />

Special Project Submittal Form (Updated Aug 2010) Page 4

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

activities (e.g. HVAC, construction details, electrical panel thermography, etc.). The Guide will not<br />

include these elements but will be designed keeping in mind the flexibility required to be of maximum<br />

value in a variety of implementation scenarios.<br />

Stage 3 – Commissioning at Start-Up<br />

The Guide will define the commissioning process required in addition to normal equipment start-up<br />

procedures in order to achieve and confirm the owners commissioning objectives. The Guide will not<br />

attempt to define how specifically to start a refrigeration system (e.g. refrigerant and oil charging, pulldown<br />

temperatures, safety considerations, etc.), since refrigeration systems are highly varied and individual<br />

manufacturers or OEMs should provide general start-up information. The Guide will refer to other<br />

ASHRAE documents and industry resources related to safety and mechanical refrigeration systems, but<br />

will not reproduce the requirements and procedures related to refrigeration safety systems and related<br />

validation.<br />

Recommended process steps during start-up will be defined with examples, including:<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

� Training, planning and documentation prior to start-up, defining the responsibilities and milestones<br />

affecting all parties involved.<br />

� Provide options for how schedule impacts can be dealt with, in the event the commissioning goals<br />

delay the project schedule, and defining in advance the responsibility for resolution and choices.<br />

� Examples of how individual equipment and overall system performance can be measured and<br />

validated, with varying levels of cost, instrumentation and precision.<br />

Commissioning at start-up includes management of metering and instrumentation, either permanent or<br />

temporary, along with collection of data, which may be manual or electronic. In most instances a control<br />

system will be part of the refrigeration system and can be utilized as part of the commissioning technical<br />

procedures.<br />

Calibration of sensors and instruments is fundamentally important and will be described, separate from<br />

individual technical procedures. There is limited calibration of sensors and transducers in either<br />

commercial or industrial refrigeration systems, due to the large number of sensors and low cost type of<br />

sensors and control systems employed, and even the term “calibration” is generally misused in the industry.<br />

Since accurate control is a necessary to achieve expected performance and efficiency, this is an important<br />

area that will receive detailed industry-specific investigation and recommendations as part of the<br />

<strong>Refrigeration</strong> Commissioning Guide. To be effective, commissioning may require changes in the way<br />

sensors and calibration methods are viewed (and may have cost impacts).<br />

Commissioning at start-up will include discussion of how to adjust commissioning methods based on the<br />

weather at time of start-up, since refrigeration is highly affected by weather, both in terms of load and heat<br />

rejection performance. Methods to apply artificial load (if feasible) or artificially reduce load and to<br />

change control settings to test control response more realistically will be discussed generally, as well as<br />

defined in technical procedures.<br />

Technical procedures will be provided for the most common and fundamental equipment, system<br />

configurations and control features, particularly those that are commonly employed in new construction<br />

and new codes. However, the Guide will not provide a comprehensive set of procedures or attempt to be<br />

accurate for all users or system designs, and will avoid the effect of dictating system design or best<br />

practices by way of too-detailed commissioning procedures. The technical procedures will be directly<br />

usable in many instances, particularly on simple systems, and moreover will provide a template for others<br />

to develop more specific procedures. In the future additional technical procedures may be developed by<br />

ASHRAE committees or through collaboration with other industry participants.<br />

Special Project Submittal Form (Updated Aug 2010) Page 5

Technical Procedures<br />

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

The basic technical procedures planned for the initial Guide will be sufficient basic systems and to serve as<br />

examples and will include approximately 20-25 procedures, such as:<br />

1. To be completed with committee input.<br />

Stage 4 – First Year Commissioning<br />

The Guide will define the process and general technical procedures for commissioning over the first year of<br />

operation, in order to address operation under varying weather conditions and variations in facility<br />

operation. Since refrigeration systems are significantly affected by ambient temperatures, performance can<br />

only be fully evaluated over the course of a year. In addition, retail facilities are started up prior to store<br />

opening and realistic customer traffic, and industrial facilities often require significant time to reach normal<br />

operating traffic levels.<br />

The Guide will discuss continuous commissioning and performance monitoring methods and how they may<br />

be utilized over the first year and thereafter to automate the commissioning process.<br />

6. Anticipated Project Timeline:<br />

(Include project start date, key milestones, and project completion.)<br />

The expected timeline for the project is:<br />

Document approved by cognizant committee – June 2012<br />

Bid and Award for consultant – August 2012 through October 2012<br />

Document development, peer review and editing – November 2012 through August 2013<br />

Document available for Purchase – October 2013<br />

7. Estimated Total Project Cost: $120,000<br />

Estimated Cost Breakdown:<br />

Meetings/ Travel: 4 meetings @ $10K per meeting (travel costs) = $40K<br />

May be reduced by using conference calls and meetings during ASHRAE meetings<br />

Consultants: $0K<br />

Contractors: $50K<br />

ASHRAE Staff time: Project Administration = $15K;<br />

Editing/Layout = $15K<br />

Other (please specify):<br />

Note: Work is a combination of work by committee members and other parties listed below, plus a<br />

consultant to do develop the primary document and incorporate input from other parties.<br />

8. Identified Co-Funding:<br />

(Include sources of funding and anticipated $$ from each source.)<br />

Anticipated $$ are unknown at this time.<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

Special Project Submittal Form (Updated Aug 2010) Page 6

9. Required ASHRAE Funding:<br />

(Note: Item 9 = Item 7 minus Item 8)<br />

ASHRAE portion is unknown until co-funding is secured.<br />

10. Additional Potential Co-Funding Sources:<br />

(List all that apply.)<br />

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

Industry sponsors are being solicited. Funding and/or in-kind contribution may be available from:<br />

Wal-Mart<br />

Target<br />

Food Marketing Institute (FMI)<br />

California Energy Commission (commissioning procedures may be appropriate for acceptance testing<br />

methods required for 2013 Title 24 standards)<br />

Hill-Phoenix<br />

Hussmann<br />

US DOE<br />

11. Proposed <strong>Committee</strong> Membership<br />

Chair: Richard Royal Vice Chair: TC 10.7 member (tbd)<br />

Members and/or Associations to be represented (please list):<br />

<strong>Refrigeration</strong> <strong>Committee</strong><br />

Section 10 TCs (10.1, 10.5, 10.7)<br />

GPC 0<br />

Wal-Mart – potentially Richard Royal (<strong>REF</strong> member)<br />

Target – potentially Larry Meeker (noted interest)<br />

IIAR or IARW (even though heavy industrial will be in a future version)<br />

TESCO (UK or US)<br />

Hill-Phoenix (Scott Martin or David Hinde, either representing 10.7 or <strong>REF</strong>)<br />

FMI (Rob Uhl, Safeway, member 10.7 and Standard 147 committee)<br />

Emerson – potentially Warren Beeton<br />

Source <strong>Refrigeration</strong> – Bryan Beitler<br />

Tim Gwyn – DC Engineering<br />

Refrigerant Manufacturers<br />

Others<br />

Outreach plan to form committee:<br />

Once draft is deemed acceptable for sharing, review with:<br />

Select Section 10 chairs.<br />

Identify Asia Pacific interests (contact Don Cleland, Pradeep Bansal, Cesar Lim)<br />

Contact OEMs<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

Special Project Submittal Form (Updated Aug 2010) Page 7

12. Additional information in support of proposed project:<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

Special Project Submittal Form (Updated Aug 2010) Page 8

Attachment A<br />

SUBMITTAL FORM FOR A PROPOSED SPECIAL PROJECT<br />

Required Elements for all completed projects intended for Publication prior to submittal to<br />

ASHRAE Publications Staff for final layout and editing:<br />

� Incorporation of all review comments and changes/revisions as required by reviewers (peer,<br />

cognizant, etc) and the Publisher.<br />

� Complete manuscript text (no missing chapters, sections, front or back mater) in accordance with<br />

the author’s manual.<br />

� Complete illustrations (all figures, tables, photographs, sketches) in accordance with the author’s<br />

manual where all copies are legible (rather than blurry, pixilated captures of graphics).<br />

� Complete supplementary information (including software, data, appendices, indexes) in accordance<br />

with the author’s manual.<br />

� Submission of all text, figures, tables, illustrations, and other supplementary information in file<br />

formats specified in the author’s manual or otherwise directed by the Publisher.<br />

� All necessary permissions in written form from all owners of any copyrights or trademarks in any<br />

materials or content to be included in the work complying with the requirements of the copyright or<br />

trademark owner including instructions from the copyright or trademark owner on the citations to<br />

be included in the final manuscript or publication.<br />

Additional required information for all completed projects intended for Publication:<br />

<strong>REF</strong> Minutes 12.W – Attachment 5<br />

� Key words that would be used to search for the Publication or its content on the Internet<br />

� Industry/specialty within and/or outside HVAC to which the Publication is aimed<br />

� Non-ASHRAE institutions, associations, conferences, exhibitions, or publications that are relevant<br />

to the completed Publication<br />

� Existing web sites (and associated URLs) that are relevant to the completed Publication<br />

Special Project Submittal Form (Updated Aug 2010) Page 9

<strong>REF</strong>RIGERANT<br />

MANAGEMENT PLAN<br />

Ad Hoc to Tech Council<br />

<strong>REF</strong> Minutes 12.W – Attachment 6

Project Name: Refrigerant Management Plan<br />

EXECUTIVE SUMMARY<br />

Final Report<br />

<strong>REF</strong> Minutes 12.W – Attachment 6<br />

<strong>Refrigeration</strong> and air conditioning applications are growing worldwide, as well as in the United<br />

States, since they are critical contributors to the health, comfort, and welfare of humanity.<br />

However, the use of refrigerants has consequences for the environment (e.g. ozone depletion and<br />

climate change) if the refrigerants are not properly selected and managed throughout their lifecycle.<br />

Refrigerants are created, then are either destroyed, recycled, or released to the environment.<br />

Refrigerant manufacturers, contractors, and users are frequently falsely accused of mismanagement<br />

and abuse of refrigerants; this report intends to lay the groundwork to correct and explain this often<br />

misunderstood concept, and create an awareness of what really happens in the Industry. Long term,<br />

ASHRAE’s role will be further specified by the future “RMPIC Refrigerant Management Program<br />

Implementation” committee that will be formed by Technology Council later in 2012, after this<br />

report is received. Proper cradle to grave management is necessary to minimize the environmental<br />

impact and to ensure that suitable refrigerants are used by the HVAC&R industry to meet growing<br />

demand.<br />

In the United States of America, every household has at least one refrigerator; over 90% have central<br />

A/C or heat pump systems. Nearly all passenger vehicles and commercial trucks are equipped with<br />

air-conditioning. There are over 35,000 commercial systems in supermarkets and big box stores,<br />

and, thousands of truck and bus air-conditioning and refrigeration systems on the roads. In addition,<br />

there are reefer ships, and thousands of commercial chillers and heat pumps and direct expansion<br />

units used in commercial, industrial and institutional applications. All of these applications utilize<br />

refrigerants – either synthetics such as CFCs (existing systems only), HCFCs, HFCs and HFOs or<br />

refrigerants based on naturally occurring compounds such as ammonia, hydrocarbons, and carbon<br />

dioxide.<br />

Direct refrigerant emissions are estimated by the EPA to represent about 3% of global greenhouse<br />