XtraBlatt issue 01-2016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTERNATIONAL<br />

1<br />

whole harvest all operations are done by us, from mowing<br />

to turning and tedding through to uptake with two<br />

forage wagons. We do not need a contractor, or help<br />

from neighbours.”<br />

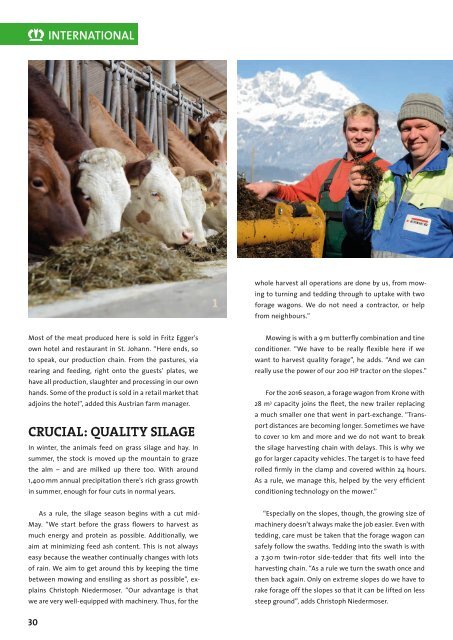

Most of the meat produced here is sold in Fritz Egger’s<br />

own hotel and restaurant in St. Johann. “Here ends, so<br />

to speak, our production chain. From the pastures, via<br />

rearing and feeding, right onto the guests’ plates, we<br />

have all production, slaughter and processing in our own<br />

hands. Some of the product is sold in a retail market that<br />

adjoins the hotel”, added this Austrian farm manager.<br />

CRUCIAL: QUALITY SILAGE<br />

In winter, the animals feed on grass silage and hay. In<br />

summer, the stock is moved up the mountain to graze<br />

the alm – and are milked up there too. With around<br />

1,400 mm annual precipitation there’s rich grass growth<br />

in summer, enough for four cuts in normal years.<br />

Mowing is with a 9 m butterfly combination and tine<br />

conditioner. “We have to be really flexible here if we<br />

want to harvest quality forage”, he adds. “And we can<br />

really use the power of our 200 HP tractor on the slopes.”<br />

For the 2<strong>01</strong>6 season, a forage wagon from Krone with<br />

28 m 3 capacity joins the fleet, the new trailer replacing<br />

a much smaller one that went in part-exchange. “Transport<br />

distances are becoming longer. Sometimes we have<br />

to cover 10 km and more and we do not want to break<br />

the silage harvesting chain with delays. This is why we<br />

go for larger capacity vehicles. The target is to have feed<br />

rolled firmly in the clamp and covered within 24 hours.<br />

As a rule, we manage this, helped by the very efficient<br />

conditioning technology on the mower.”<br />

As a rule, the silage season begins with a cut mid-<br />

May. “We start before the grass flowers to harvest as<br />

much energy and protein as possible. Additionally, we<br />

aim at minimizing feed ash content. This is not always<br />

easy because the weather continually changes with lots<br />

of rain. We aim to get around this by keeping the time<br />

between mowing and ensiling as short as possible”, explains<br />

Christoph Niedermoser. “Our advantage is that<br />

we are very well-equipped with machinery. Thus, for the<br />

“Especially on the slopes, though, the growing size of<br />

machinery doesn’t always make the job easier. Even with<br />

tedding, care must be taken that the forage wagon can<br />

safely follow the swaths. Tedding into the swath is with<br />

a 7.30 m twin-rotor side-tedder that fits well into the<br />

harvesting chain. “As a rule we turn the swath once and<br />

then back again. Only on extreme slopes do we have to<br />

rake forage off the slopes so that it can be lifted on less<br />

steep ground”, adds Christoph Niedermoser.<br />

30