Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7-11 April 2014<br />

Exhibitor Profiles<br />

Allied Rainbow Asia Ltd<br />

China<br />

A05<br />

Allied Rainbow Asia Ltd works in<br />

the capacity of a sourcing agent for<br />

customers, for their requirements of<br />

pipes (in stainless steel, carbon steel,<br />

nickel alloys, copper alloys, etc) and<br />

relevant equipment.<br />

The company sources the desired<br />

material only through reputed and PEDcertified<br />

mills, from countries in Europe,<br />

Japan, USA, India, China and Korea,<br />

among others. Its QC team and logistic<br />

team supervise and manage the material<br />

at various stages. The company also<br />

welcomes third party inspections.<br />

Apart from sourcing, the company<br />

has an EPC division for value-added<br />

products and services for various<br />

projects. Services include coated pipes.<br />

info@alliedrainbow.com<br />

www.alliedrainbow.com<br />

Bercellesi Berinox<br />

Italy<br />

1A35<br />

Bercellesi Berinox is an independent<br />

stainless steel fittings manufacturer,<br />

offering a large range of pressed and<br />

welded connection fittings in austenitic<br />

and austenic-ferritic (Duplex) grades.<br />

Based in Italy, the company has<br />

manufacturing facilities near Milan and<br />

Parma.<br />

With a full range of elbows, collars, caps,<br />

concentric and eccentric reducers, tees<br />

and reducing tees, from 12 to 1,219mm,<br />

in ISO, metric, SMS, DIN, BS, EN and<br />

imperial sizes and standards, Bercellesi<br />

Berinox inventories more than 3,000<br />

references.<br />

Elbows, tees and reducers are produced<br />

from pipe, and collars and end caps are<br />

produced from plate, all with a cold<br />

forming method. Production is robotised<br />

and automated on the most popular<br />

sizes. The variety and number of the<br />

sizes produced also allows the fittings<br />

to be widely used in various industries,<br />

including water treatment, food and<br />

dairy, brewery, chemical plants, paper<br />

and pulp, and biofuel plants.<br />

The company has been ISO 9001<br />

certified since 1995, with extension to<br />

Annex I, Sect. 4.3 of PED 97/23/EC<br />

since 2009. For more than 60 years<br />

Bercellesi Berinox has been supplying<br />

its fittings throughout Europe, in more<br />

than 35 countries, developing long-term<br />

business relationships with most of the<br />

large European stockists.<br />

info@berinox.com<br />

www.berinox.com<br />

Bewo Cutting Systems BV<br />

The Netherlands<br />

6E42<br />

For more than 75 years, Bewo Cutting<br />

Systems has been concentrating on<br />

perfecting tube cutting. The company<br />

invents, develops and implements<br />

intelligent solutions for each individual<br />

customer.<br />

The technology behind Bewo machinery<br />

makes the cutting more accurate, more<br />

reliable, safer, cleaner and more efficient.<br />

For instance, all Bewo machines cut<br />

upwards. The major benefits of cutting<br />

upwards are less noise, increased safety<br />

due to the enclosed blade, and easy<br />

access to the clamping jaws. Cutting<br />

upwards also realises a reduction in<br />

chip contamination, leading to fewer<br />

scratches on the material.<br />

All Bewo cutting machines are equipped<br />

with hydraulic proportional saw feed,<br />

resulting in improved saw blade life and<br />

faster cutting. In addition, innovative<br />

technology is behind how the saw blade<br />

is positioned in relation to the tubes.<br />

The position of the saw blade allows<br />

square and rectangular tubes to be cut<br />

diagonally. When cutting diagonally, the<br />

saw blade does not start cutting in the<br />

centre of the material.<br />

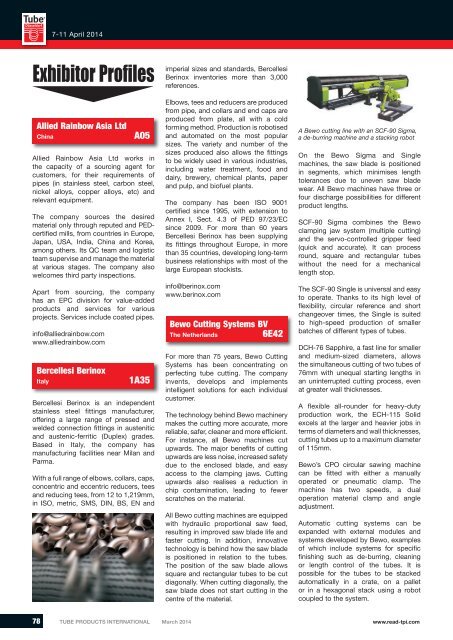

A Bewo cutting line with an SCF-90 Sigma,<br />

a de-burring machine and a stacking robot<br />

On the Bewo Sigma and Single<br />

machines, the saw blade is positioned<br />

in segments, which minimises length<br />

tolerances due to uneven saw blade<br />

wear. All Bewo machines have three or<br />

four discharge possibilities for different<br />

product lengths.<br />

SCF-90 Sigma combines the Bewo<br />

clamping jaw system (multiple cutting)<br />

and the servo-controlled gripper feed<br />

(quick and accurate). It can process<br />

round, square and rectangular tubes<br />

without the need for a mechanical<br />

length stop.<br />

The SCF-90 Single is universal and easy<br />

to operate. Thanks to its high level of<br />

flexibility, circular reference and short<br />

changeover times, the Single is suited<br />

to high-speed production of smaller<br />

batches of different types of tubes.<br />

DCH-76 Sapphire, a fast line for smaller<br />

and medium-sized diameters, allows<br />

the simultaneous cutting of two tubes of<br />

76mm with unequal starting lengths in<br />

an uninterrupted cutting process, even<br />

at greater wall thicknesses.<br />

A flexible all-rounder for heavy-duty<br />

production work, the ECH-115 Solid<br />

excels at the larger and heavier jobs in<br />

terms of diameters and wall thicknesses,<br />

cutting tubes up to a maximum diameter<br />

of 115mm.<br />

Bewo’s CPO circular sawing machine<br />

can be fitted with either a manually<br />

operated or pneumatic clamp. The<br />

machine has two speeds, a dual<br />

operation material clamp and angle<br />

adjustment.<br />

Automatic cutting systems can be<br />

expanded with external modules and<br />

systems developed by Bewo, examples<br />

of which include systems for specific<br />

finishing such as de-burring, cleaning<br />

or length control of the tubes. It is<br />

possible for the tubes to be stacked<br />

automatically in a crate, on a pallet<br />

or in a hexagonal stack using a robot<br />

coupled to the system.<br />

78 TUBE PRODUCTS <strong>INTERNATIONAL</strong> March 2014 www.read-tpi.com