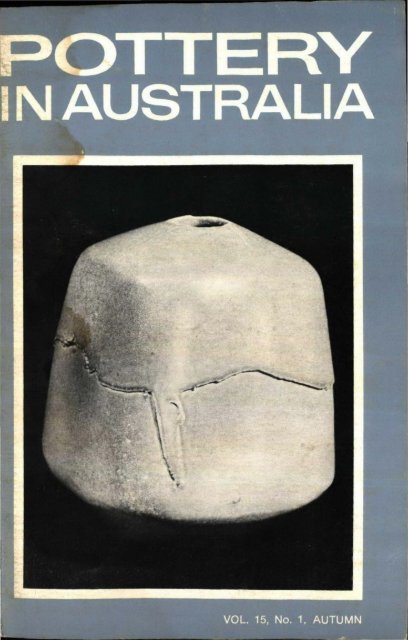

Pottery In Australia Vol 15 No 1 Autumn 1976

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

COVER: Lollis by Hiroe Swen, Pastoral Gallery, 1975, 26 cm x 19 cm.<br />

Ligbt turquoise, 1285· C., electric kiln.<br />

EDITORIAL COMMIITEE<br />

Editor Margot Staples<br />

President Beryl Barton<br />

Adele Salmon Janet Mansfield<br />

Shirley Moule Derek Smith<br />

Margaret Tuckson<br />

Business Manager Barbara Austin<br />

State Correspondents<br />

Connie Drldan (Vic)<br />

Jean Robins (WA)<br />

Ron Rowe (SA)<br />

Margaret McNaught (Old)<br />

Penny Smith (Tas)<br />

PI.ue .ddr.,s all corr .. "ondence to<br />

The Editor 0' "<strong>Pottery</strong> <strong>In</strong> Australle"<br />

48 Burton Street, OerllnghufSt, N.S.W. 2010<br />

re/ephone: 31-3<strong>15</strong>1<br />

<strong>No</strong>tice to Subscribers<br />

POllery in <strong>Australia</strong> is published twice annually, in Spring and <strong>Autumn</strong>. Tbe annual subscription<br />

is $A4, $US6, UK £Stg.2.50, Canada $6, including postage. Renewal notices will be sent<br />

when due. These are stamped "Subscriptions now due". <strong>No</strong> further issues will be forwarded<br />

until new subscription is received. New subscription application form printed at the back of<br />

the magazine to help NEW subscribers. When forwarding subscriptions, if not using printed<br />

form, please advise name, full address and date, in BLOCK LEITERS. State which issue required<br />

when commencing subscription. Please address all correspondence to:<br />

The Editor, 48 Burton Street, Darlinghurst, 20 I O.<br />

AU material published in POl/ery in A ustralia is the copyright of the Potters' Society of <strong>Australia</strong>.<br />

Requests for permission to reprint must be made to the Editor.<br />

<strong>No</strong> responsibility is accepted by Pol/ery in A ustralia for tbe content of articles nor for claims<br />

made by advertisers.<br />

Advertising Rates: Full page $65<br />

Half page $35<br />

One third page $25<br />

Plus block and setting costs<br />

Articles and photographs for inclusion in<br />

POltery in <strong>Australia</strong> should reach the Editor<br />

by <strong>15</strong>th March for tbe <strong>Autumn</strong> issue and<br />

<strong>15</strong>th August for tbe Spring issue, for selection<br />

by the Editorial Committee.

POTTERY<br />

I N AUSTRALIA<br />

PUBLISHED BY THE POTTERS' SOCIETY OF AUSTRALIA<br />

VOL. <strong>15</strong> <strong>No</strong>. 1 <strong>1976</strong><br />

Two Dollars<br />

CONTENTS<br />

Editor visits Ch ina p. 2<br />

An <strong>Australia</strong>n Potter looks at New Ch ina's<br />

Ceramics Ivan McMeekin p. 3<br />

The Potteries of Shihwan Dennis O'Hoy p. 7<br />

Wares of Yching Margot Staples p. <strong>15</strong><br />

Bryan Newman in <strong>Australia</strong> Janet Mansfield p. 18<br />

Thoroughly Modern Milling (Part One)<br />

Stephen Harrison p. 23<br />

A Day in Izcuchaca May Davis p. 30<br />

The Use of the Computer for Ceramic Glaze<br />

Calculation H. J. McWhinnie p. 31<br />

Recent Work p. 35<br />

" Qu inja" Trevor Woods p. 43<br />

Hydraulically Operated Potters' Wheel<br />

Janet Barriskill p. 47<br />

West <strong>Australia</strong>n Clay Body Test Michael Kusnik p. 51<br />

<strong>In</strong>sulation, Refractories and Kiln Design<br />

Maxwell J. Murray p. 52<br />

Half a Year Onwards-A Brief Review of<br />

the Potters' Society of <strong>Australia</strong> . p. 66<br />

Book Reviews p. 67<br />

Exhibition Reviews p. 68<br />

Exhibitions and Competitions p. 73<br />

News p. 75

EDITOR VISITS CHINA<br />

<strong>In</strong> September 1975 ten <strong>Australia</strong>n potters visited China as the guests of the<br />

Ministry of Light <strong>In</strong>dustry. We spent a month touring the pottery and porcelain<br />

centres and were able as well to see ivory carving, silk weaving and embroidery,<br />

inlay and fan-making. We visited museums and took part in a number of seminars<br />

with Chinese craftsmen and technicians.<br />

One of the tasks of the museums, as the Chinese see it, is to illustrate how<br />

the past may serve the present. <strong>In</strong> the great porcelain centre of Chingdechen the<br />

museum is deliberately used as a place of inspiration for local designers. The<br />

Shanghai museum which was established in 1952 displays archeological finds.<br />

Since the Cultural Revolution in the late sixties, archeological studies have been<br />

vIgorously pursued.<br />

<strong>In</strong> the early fifties, the small craft workshops became collectives, and many<br />

new factories were established. Conditions for craftsmen in the new workplaces<br />

became healthier and more comfortable. <strong>In</strong> the factories we visited the excellent<br />

lighting and pleasant surroundings impressed us all. Continuing efforts are being<br />

made to eliminate hand work by resort to machines. Perhaps many traditional<br />

techniques will be lost because of this. However, 1 believe that there is a policy<br />

of preserving knowledge of traditional techniques so that the past will continue to<br />

serve in the development of new products.<br />

The information contained in the three articles in this issue on the potteries<br />

of China sets out information which warrants the attention of our readers.<br />

2

AN AUSTRALIAN POnER LOOKS AT<br />

NEW CHINA'S CERAMICS<br />

Ivan McMeekin<br />

<strong>In</strong> the twenty-six years that have elapsed since the 1946-1949 Liberation War the<br />

main part of Chinese industry has changed over from the use of traditional Chinese<br />

crafts and technology to the use of what is basically Western industrial technology.<br />

For artist-craftsmen like ourselves there were many aspects of the traditional<br />

crafts and technology of great value and interest, not only practical aspects but<br />

philosophical and aesthetic ones as well. With our great admiration of Sung<br />

achievements in mind, in a vague and illogical way we expected to find Sung<br />

techniques still extant, when probably they disappeared many centuries ago, and<br />

it seemed were nowhere to be seen in today's modern factories.<br />

At lirst this was a bitter disappointment, but gradually it became evident<br />

that some of the artistically important aspects of the traditional techniques were<br />

still there, but in a modern form that made them difficult to see. Simplicity and<br />

directness of technique can still be seen in many places. They can be seen in the<br />

selection, processing and blending of raw materials: there are still usually only<br />

two materials used in porcelain bodies, porcelain stone and kaolin. The processing<br />

and blending was done with an almost nonchalant simplicity that was staggering.<br />

They can also be seen in glaze application which is still done, using beautifully<br />

thought out methods of application to raw ware. Other important aspects were the<br />

willing commitment to a high skill level, and generally the extent of personal<br />

commitment to the work. Also that people were able to enjoy doing their work<br />

well without harassment and the greedy emphasis on speed and production that<br />

often mars the atmosphere of our own factories.<br />

The two forming methods almost universally used were the same as those<br />

used in our own industry : slip-casting and jolJeying - and in the refractories<br />

industry, pressing. Only at Yching in the tea-pot factory and large jar factory have<br />

hand forming methods survived virtually unchanged.<br />

<strong>In</strong> firing the change was not pronounced. The old climbing or bank kilns<br />

(called by the Chinese potters "dragon kilns" ) are often still there, but are disused.<br />

Their place has been taken by Western-style tunnel kilns, adapted to local conditions.<br />

One of the most astonishing sights we saw was a hand-fired coal-burning<br />

tunnel kiln for porcelain! . . . something far beyond our industrial capacity for skill,<br />

application, and reliability. The majority of tunnel kilns seen, however, were oilfired<br />

by pressurised burners, much in the same way as our own are. Reasons given<br />

for the change to tunnels were quite conclusive. <strong>In</strong> the first place the tunnel is a<br />

very much more efficient unit; secondly the firing of the "dragon kiln" was<br />

strenuous and exacting, and an adminsitration seeking to improve the working<br />

conditions of the people would naturally look for a more acceptable way of firing.<br />

Thirdly-an irrefutable argument-the supply of wood-fuel became exhausted, the<br />

last kilns to go out of service being those near canals which enabled them to get<br />

fuel from farther afield.<br />

However, I feel we should not presume that the same ugly shortcomings of<br />

our own industry will not automatically appear, because Chinese potters have<br />

adopted some of our techniques. Our own industry has been bugged by our inability<br />

to understand the activity as an ART, and by our industrial commercial values<br />

which are inimical to art in any case. We should remember that this particular art<br />

3

is theirs, and was introduced into the West only a few centuries ago. Their long<br />

experience and greater understanding of it will, I feel, lead them along a different<br />

path, and the introduction of Western technology should be seen as a stage in the<br />

revitalisation of their industry, that they and we agree had sunk to a low ebb prior<br />

to 1949. They are adapting the industry-or the art if you wish-to the new aims<br />

of an idealistic socialist structure, the aims of a people determined to take their<br />

rightful place in the human community.<br />

The Museum Collections<br />

The collections we saw had been formed since 1949, and comprised mainly<br />

excavated pieces. To the student of Chinese ceramics these collections were of the<br />

greatest interest as the often irrefutable provenance of a piece (provenance in this<br />

application meaning what it is, where, and when it was made), formed on archeological<br />

grounds, enables us to revise our ideas about the things we already know<br />

of, and, rather more interesting, a number of wares new to us in the West, or at<br />

most only slightly known, have been excavated and studied.<br />

Following in more or less chronological order are some of the discoveries<br />

that were new to me:<br />

1. There was a greater variety of wares produced in Neolithic or pre-historic<br />

times than 1 had envisaged, and, of course, the Neolithic culture co-existed with<br />

the early dynasties such as Shang. One of the most interesting early wares, almost<br />

unknown in the West, is the Blackware made in Shantung province and elsewhere<br />

in the coastal region. The collections in Shanghai, Nanking, and Peking contained<br />

examples of this ware. It is a beautifully made, burnished, black earthenware. The<br />

largest number of Neolithic wares are in the Peking Palace collection.<br />

2. There were then no major surprises until the end of the Han dynasty, that is<br />

the commencement of the period known to Western scholars as the Six Dynasties,<br />

and which is often thought of as the Chinese equivalent of our Dark Ages, a period<br />

of some four hundred years (A.D. 221 to A.D. 588) between the end of Han and<br />

(disregarding the short Sui Dynasty) the commencement of Tang. It was a<br />

confused period of unrest, but also of stimulation, change and achievement in art.<br />

It was during this period that the ware we call celadon emerged and developed.<br />

Celadons had been made in Han times, but it was only during the Six Dynasties<br />

that the ware started to disclose its unique character.<br />

These early celadons have been known in the West as Yueh celadons, Yueh<br />

being a kingdom at that time occupying what is now, in broad terms, the province<br />

of Chekiang. However, these new Chinese collections and studies make it cle

I<br />

Neolithic: black earthenware stem-cup.<br />

Ming: blue and white porcelain bowl<br />

te-chen, and 1 was astonished at the number of well-known Southern Sung wares<br />

that were made in that centre. The best of the Yingch'ing or Ch'ingpai wares it<br />

seems all came from Ching-te-chen (there were of course other centres making<br />

this ware), also several similar wares that have puzzled collectors for some time,<br />

like the ivory coloured ware in the Ting style. Chinese scholars believe that the<br />

potters who fled south at the collapse of <strong>No</strong>rthern Sung were responsible for the<br />

sudden development of Ching-te-chen as a major centre in Southern Sung times.<br />

This makes the phenomenal development of porcelain there during Ming times<br />

much easier to understand.<br />

4. An interesting little fact emerged in relation to the so-called "green Chun" ware.<br />

I had often wondered whether these pots were the result of some chance variation<br />

in firing conditions or glaze ingredients in the production of the usual blue Chun.<br />

But 1 found that this was not the case, that they were made at a place called<br />

Lin J u, some fifty miles to the west-south-west of Chun Chou. Another interesting<br />

little fact emerged in relation to Chun wares and that is that the name is pronounced<br />

like a combination of June and doin' (short for doing) , i.e., Jooen.<br />

5. It seems also that we need to revise our ideas about the <strong>No</strong>rthern celadons.<br />

A number of pieces which 1 would have described without hesitation as <strong>No</strong>rthern<br />

celadons were attributed to the Lung Ch'uan centre in Chekiang province.<br />

6. Of great interest but not necessarily a surprise were the Yuan Dynasty<br />

porcelains decorated in underglaze blue.<br />

7. Another interesting fact to emerge in relation to Ming blue and white was that<br />

many of the wares which we describe as "export wares" were also distributed on<br />

the Chinese home market. Sherds picked up in Soochow, and several pieces in the<br />

5

collections indicated this. It seems we should make a study of fMing blue and<br />

white made for the general Chinese populace of that dynasty. I feel that these<br />

would prove to be very beautiful wares, and in many ways preferable to the<br />

rather straight-laced, over-decorated Imperial wares.<br />

Comments<br />

It may be wondered why there are no examples mentioned of work by<br />

individual artist-potters making either utensils or sculptural pieces other than<br />

representational figures. The reason is simple: we saw none, and the impression I<br />

formed is that they do not exist in China.<br />

It is my own view that the individual artist-potter is a phenomenon appearing<br />

at a particular stage of industrial, economic, or cultural development. <strong>In</strong> our own<br />

case he appears towards the end of the nineteenth century after some one hundred<br />

and fifty years of ceramic industrialisation, quite largely, it seems, as a result of<br />

deep dissatisfaction with industrial pots and industrial/commercial values and<br />

concepts in general. The Chinese and Japanese ideas which Leach brought back<br />

to England in 1920 were grafted onto this already existing movement and have<br />

influenced it profoundly. But to expect to find potters similar to our own artistpotters<br />

in a culture as different from our own as China is, and at such a different<br />

stage of its history, is at best, parochial.<br />

For over a thousand years the making of pots in China has been seen as a<br />

major art form. It still is. Chinese potters are eclectic. There have been many<br />

examples in the past of their welcoming, enjoying, and digesting foreign influences<br />

to produce a new valid and lovely idiom of their own as a result. It is my view<br />

that they are today at the start of another such cycle.<br />

To have been able to see it at first hand was an indelible experience which,<br />

hopefully, may initiate such a cycle in ourselves.<br />

Ivan McMeekin led the delegation of ten <strong>Australia</strong>n potters who visited China as<br />

guests of the Ministry oj Light <strong>In</strong>dustry in that country in September 1975. Cj.<br />

Editorial this issue.<br />

HOW TO DETECT GAS LEAKS. David Medlin, whose article "Low Cost Stoneware Kiln"<br />

appeared in <strong>Vol</strong>. 14, <strong>No</strong>.2, has sent this correction to the procedure for checking gas leaks.<br />

DO NOT USE A LIGHTED TAPER, this could be dangerous.<br />

"Propane gas is not toxic and is odourless, but . an . odorant has been added to give<br />

it a distinctive smell similar to onions. If the dIst<strong>In</strong>ctIve odour has been detected an<br />

immediate cbeck sbould be made for leaks. Brush a mixture of two parts household<br />

detergent to one part water on the suspected leak; if it bubbles, immediately turn off the<br />

Propane gas cylinder valve and tighten or repair tbe equipment.<br />

If Propane gas is leaking do not strike matches or operate any electrical appliances in<br />

the vicinity. Remove all sources of ignition and open all doors and windows. Do not attempt<br />

to relight Propane gas until all traces of odour have disappeared. Turn on again and check<br />

the suspected leak witb detergent and water.<br />

Remember Propane gas is heavier than air and will remain in open containers, cellars<br />

and confined spaces for a considerable time."<br />

6

THE POTTERIES OF SHIHWAN<br />

Dennis 0 ' oy<br />

Senior Lecturer-Ceramics, Bendigo <strong>In</strong>stitute of Technology.<br />

After some weeks in the People's Republic of China and having visited Peking<br />

and several other important centres, we travelled south to Kwangchou which was<br />

to serve as our base for visiting the local potteries and particularly those of<br />

Shihwan. Whilst at Kwangchou we also hoped to discover the tiny village from<br />

which my father and his grandfather before him, had set out for <strong>Australia</strong> last<br />

century.<br />

Better known in the western world as Canton, Kwangchou is the largest city<br />

in Kwangtung Province. It is quite heavily industrialised but thanks to its subtropical<br />

climate is plentifully endowed with parks and street-trees. By now we<br />

had become used to the crowds of people and, as in all Chinese cities, to the sea<br />

of bicycles with bells challenging the blaring horns of vehicular traffic.<br />

High on a hill well away from the noise of the city stands the impressive red<br />

Five Storey Pagoda, built in the Ming Period (1368-1644) and now a museum of<br />

Chinese ceramics. It has an excellent collection. The lower floors are used to<br />

display wares produced at the nearby pottery centre of Shih wan and the higher<br />

levels, historical wares. The Shihwan ceramic collection was obviously extensive.<br />

Outside of China the Camoes Museum in Macau houses a smaller collection of<br />

Shihwan ceramics.<br />

There are numerous small potteries around Kwangchou, particularly in or<br />

near the many villages. On a trip to Ts'ung hua, a hot spring resort some 80 km<br />

north of Kwangchou, we passed scores of kilns along the roadside. The kilns<br />

varied considerably with beehive kilns having corbelled arches, vertical doublechambered<br />

kilns and small intermittent tunnel-kilns. However, most of these kilns<br />

were used to produce bricks for local requirements and building projects. At the<br />

hot springs the distinctive lamp posts and balustrades with designs of dragons,<br />

phoenixes and plants were all ceramic. There were also ceramic rubbish receptacles<br />

glazed white, blue and green lining all the streets. All of these were Shihwan<br />

ceramic wares, and could be found even at distant Kweilin.<br />

Shlhwan<br />

Shihwan (Shekwan) is located south-west of Kwangchou on a bank of a<br />

tributary of the Sui Kiang (West River). To get there from Kwangchou one must<br />

first travel some 30 km to Fa-shan, a city of 240,000 inhabitants and then 9 km<br />

to Shihwan. On approaching Shihwan it was obvious we were near a pottery town<br />

as the extensively cultivated fields gave way to scarred low rolling hills which had<br />

been dug for centuries for ceramic materials. Rising along the crests of other hills<br />

were the long climbing kilns dominated only by the towering smoking chimneys<br />

of the potteries. The long kilns which are really tunnels, are built on slopes at an<br />

angle approaching twenty degrees, varying from the foot of the hill to the top.<br />

The kilns are covered by tiled roofs which rise in step-like sections up the slope.<br />

The fences and walls around many houses and garden plots are made from<br />

structured piles of brown jars, pots and kiln saggars-all "wasters" from the kilns.<br />

The history of Shih wan pottery can be traced as far back to the Southern<br />

Sung Dynasty 1127-1279. The current pottery and porcelain products are<br />

extensive - ranging from articles for daily use, building materials, decorative<br />

objects using glazes, figures and animal modelling.<br />

7

Shihwan has long been noted for figure modelling, as seen in the lively,<br />

colourfully-glazed didactic temple decorations of the past. At the neighbouring city<br />

of Fo-shan, the Fo-shan Ancestral Temple is richly decorated w'th these figures.<br />

Similar examples can be seen in the temples of Hong Kong and Macau, and even<br />

at the Joss House at Breakfast Creek, Brisbane, which was built entirely with<br />

materials brought to <strong>Australia</strong> by the early immigrant Chinese pioneers.<br />

Shihwan has a population of 23,000 people, of which 8,000 are pottery<br />

workers. There are 14 pottery and porcelain factories divided into the following<br />

categories:-<br />

I. <strong>In</strong>dustrial pottery and porcelain.<br />

2. Architectural pottery and porcelain.<br />

3. Domestic, daily use pottery and porcelain.<br />

4. Art pottery and porcelain.<br />

Shihwan Art <strong>Pottery</strong> and Porcelain Factory<br />

When we arrived at our first pottery, the Shihwan Art <strong>Pottery</strong> and Porcelain<br />

Factory, we were welcomed by Comrade Chan, representing the Revolutionary<br />

Committee and the Workers. Comrade Chan explained that this was the only<br />

"Art" pottery in Shihwan, and was established by 30 families in 1952 as a cooperative<br />

with 100 workers. Prior to forming the co-operative, the families had<br />

worked on an individual basis. <strong>In</strong> 1958 the co-operative was re-organized as the<br />

Shihwan Art <strong>Pottery</strong> and Porcelain Factory, now employing 530 workers. The<br />

art pottery produces basically four types of articles:-<br />

I. Figures, contemporary motifs of soldiers and peasants, and traditional themes.<br />

2. Animals, also along traditional lines.<br />

3. Decorative glazes wares.<br />

4. Small bonsai wares.<br />

During the tour of the pottery we were particularly interested in the manufacturing<br />

stages of the figures. I n the design studio the craftsmen were modelling<br />

fine clay figures of lions, bears, roosters, figures on oxen and armed revolutionaries.<br />

After the clay models had been made, pl aster moulds, often comprising several<br />

complicated sections and pieces, were cast. The figures were then slip cast and<br />

later, upon removal from the moulds, the various parts were joined and fettled.<br />

After drying, underglaze colours and stains were painted onto the figures and the<br />

glazes applied together with additional colours where required.<br />

Away from the modelling and casting rooms, in another building taking<br />

advantage of a hill, was the wood fired dragon (lung) kiln. We entered the<br />

building through a circular doorway above a flight of steps, before coming to<br />

the long tunnel kiln stretching beyond us. The kiln was (internal) 50 metres<br />

long, 1.7 metres high and 1.6 metres wide. The pieces to be fired (in saggars) are<br />

stacked into the kiln through loading openings in the sides. The roof of the kiln<br />

had many strategically-placed small openings through which splinters of wood<br />

could be fired so the temperature could progress up the inside of the kiln at<br />

1360°C. Through years of firing the inside had developed a rich lining of ash<br />

glaze. Once in 1938 there were thirty hill kilns in Shihwan. Many of these have<br />

now disappeared to be replaced by more modern continuous oil-fired kilns, as<br />

China has developed her own oil fields.<br />

Above this dragon-kiln at the top of the hill along a flat site, was an oilfired<br />

continuous kiln measuring 16 metres long, 1.8 metres wide and 1.9 metres<br />

high. The kiln had a total of nine small firing chambers, and the glazed figures<br />

were set on small refractory trays and mechanically pushed along through the<br />

8

)<br />

Chimneys of other kilns<br />

dominate a large<br />

hill-kiln at Shihwan.<br />

A garden fence of<br />

sandy-bodied unglazed<br />

dishes (kiln wasters) .<br />

Shihwan.<br />

Glazed didactic figures<br />

at Shihwan decorate the<br />

Fo-shan Ancestral<br />

Temple.<br />

9

kiln. <strong>In</strong> another building a larger continuous oil-fired kiln was nea ing completion<br />

and would eventually replace the wood-fired one.<br />

More than 60 varieties of glazes are used at this pottery, d vided into high<br />

firing glazes over 1300°C, and low temperature glazes under l300°C: Many have<br />

been influenced by the Sung-

Entrance to the building<br />

housing the dragon (lullg)<br />

kiln. Shihwan AP and PF.<br />

Young boys during<br />

school vacation helping<br />

build a new continuous<br />

oil-fired tunnel-kiln,<br />

Shihwan Porcelain<br />

Factory.<br />

A countryside pottery at<br />

San Pu. The brown<br />

glazed jars have simple<br />

incised lines through the<br />

glaze.<br />

1 1

t<br />

Making the clay figure<br />

model at the Shih wan Art<br />

<strong>Pottery</strong> and Porcelain<br />

Factory.<br />

Applying underglaze colours<br />

to vitreous figures,<br />

Shihwan Art <strong>Pottery</strong> and<br />

Porcelain Factory.<br />

Selecting brown glazed<br />

spouted jars and cooking<br />

dishes, Shihwan.<br />

12

accompanied us through our stay in China as a representative of the China<br />

Travel Service.<br />

Our rout took us again through the countryside of Fo-shan and Shihwan.<br />

Further on I was struck by the similarity of the countryside to that of Victoria or<br />

N.S.W. around the Divide. There were even vast stands of familiar gum trees,<br />

the only difference being the terraced slopes and rice paddies.<br />

We had to cross several large rivers by ferry and whilst waiting for the boat<br />

at San Pu, the opportunity arose for a quick look at another village pottery. It<br />

was by the river, where all the materials and wares could be transported. Stacked<br />

around the yard were the characteristic unglazed sandy grey clay wares and<br />

common brown glazed jars and pots. Similar looking wares, together with the<br />

green glazed types mentioned earlier, although much older, can be found throughout<br />

<strong>Australia</strong> where there were Chinese settlements last century. These wares are<br />

much sought after by collectors and very high prices are paid for them. The vivid<br />

green glaze on these tiles, garden ware, ginger jars and pots are derived from the<br />

addition of metallic copper in the form of filings. The brown glaze consists of<br />

fine river-mud, rice-straw ash and some lime.<br />

We arrived at the district capital of Toi-shan from which many Chinese had<br />

left long ago for Victoria and in particular for the Bendigo gold fields. We passed<br />

yet another pottery in the town with brown glazed ovoid shaped jars stacked<br />

high. Leaving Toi-shan we eventually found my father's old village surrounded<br />

by fields and dominated by a high brick tower, typical of the fortifications used<br />

to ward off bandits or to protect the villagers during periods of strife. Passing the<br />

tower we walked along a narrow lane-way. The neat grey brick tiled houses were<br />

built close together and without much difficulty we came to the house where my<br />

father and grandfather had once lived. Grandfather had emigrated to the Bendigo<br />

Diggings during the great rushes of the 1850's, and my father left the village late<br />

last century to join him. It did not take long for the villagers to discover our<br />

arrival, and they flocked to the house to see and warmly welcome us.<br />

Two days later the train left Kwangchou Station and carried us back to the<br />

Hong Kong border. The next day a party of <strong>Australia</strong>n potters began their tour<br />

of the Chinese potteries.<br />

Errata: See <strong>Vol</strong>. 14, <strong>No</strong>. I, Page 53. Victorian Clay Body Test <strong>No</strong>. 75/ 3. Total<br />

shrinkage to 2% abs. should be 13.9% not 8.0%.<br />

Page 55, Test <strong>No</strong>. 75/ 5. Total shrinkage should be 12.8% not 1.28%.<br />

PUG GOON & BENDIGO CLAYS<br />

The Potters' Gallery, 48 Burton Street, Darlinghurst NSW 2010, tel. 31 .3<strong>15</strong>1 ,<br />

now sells BendIgo ovenware clay.<br />

13

Disused<br />

"dragon" kilo.<br />

Red Star<br />

<strong>Pottery</strong>.<br />

Leather-hard<br />

pots waiting<br />

for glaze.<br />

Cooking pots<br />

Star <strong>Pottery</strong>.<br />

drying, Red<br />

14

WARES OF YCHING<br />

Margot Staples<br />

Photographs by Kevin Crick and Doug Alexander.<br />

Among the most appealing pots produced in China today are the wares of<br />

Yching County. There in the town of Ting Shan potters have been engaged at<br />

their craft for over 2,000 years.<br />

The outstanding pottery of the area is the red, unglazed vitrified ware known<br />

in China as Tse-sa (or purple sand ware) . Modern methods of body production<br />

and firing are used for the red vitrified ware, although the shapes are formed by<br />

traditional hand methods, including press moulding. The clay, a tough material<br />

of medium plasticity and extreme fineness comes from a deposit of shale said to<br />

be found nowhere else. After digging, the clay is weathered for three months or<br />

more and is prepared by a vacuum grinding machine and then vacuum pug-mill,<br />

which is an improvement on the pan mill used previously. The finished pieces<br />

are fired in saggars for ease in kiln packing and protection from soot. They are<br />

passed through a tunnel kiln 44 metres in length with a firing time of 36 hours.<br />

The temperature reaches 1300°C and the atmosphere is oxidising.<br />

The pace of the work is constant but unhurried. The craftsmen sit comfortably<br />

in well-lit work rooms and take great pride in their skills. This is one of<br />

the few places where the potters still mark their ware with their own stamps.<br />

Tea-pots and other useful pieces for the table are produced, as well as flowerpots,<br />

writing-sets (ink-slabs, brush-holders and water pots) , and decorative<br />

pieces. Large flat dishes are made by slabs, the base slab being pressed into a<br />

mould. Round pots such as tea-pots are first formed as cylinders made by the<br />

slab method. The cylinder is beaten into a spherical shape and placed into a<br />

mould. The final shape is produced by inserting the fingers inside and pressing<br />

the clay against the form. The finished pieces are burnished with tbin sections of<br />

buffalo born. They may be decorated by slip applied with a long tapering stick<br />

or inlaid with a clay of another colour. When the pieces are white-hard they may<br />

be carved with a diagonally cut metal tool sharpened on both sides. The ware is<br />

often brushed with water to enable a sweeping cut to be made with the tool held<br />

upright, as a brush.<br />

The Red Star <strong>Pottery</strong> nearby produces lovely cooking pots and huge slabbuilt<br />

pots for water storage, lotus growing or gold-fish raising. The latter pots<br />

are produced by team work. Slabs are beaten out and cut to the required width<br />

with a stick into which tbree sharpened blades are set at right angles. Bases are<br />

cut and placed on low wooden supports. Two workers are needed to lift the large<br />

slabs. The first is joined to the base in the usual way and its top is tapered so<br />

as to receive the succeeding slab which is slotted to fit over it. With teamwork<br />

a number of pots in different stages can be worked on at once. Tbe potters hold<br />

a wooden form inside and paddle the outside as they move around the pots, to<br />

produce shapes of such regularity as to appear to have been thrown.<br />

<strong>In</strong> this pottery as elsewhere in China attempts are made to mecbanise production<br />

and here a huge jigger is used to produce basic shapes which are<br />

finished off by hand.<br />

Many of the large pots are decorated with a dragon motif applied in clays<br />

of various colours. The pots are set outside to stiffen and when leather hard<br />

are glazed, using a long spouted container like a watering-can. The inside is<br />

<strong>15</strong>

Lining up handle and<br />

spout. The wooden tool is<br />

curved to fit tbe diameter of<br />

the flange exactly.<br />

Engraving a leather-bard<br />

flower-pot.<br />

Finisbing off a pressmoulded<br />

tea-pot.<br />

Decorating a press-moulded<br />

tea-pot.<br />

16

poured with the required amount of glaze and a pad on a long stick used to<br />

swish it over y missed spots. The outside is then glazed, the potter moving<br />

around the form as he pours because of the size of the pots.<br />

<strong>In</strong> the grounds of the Red Star <strong>Pottery</strong> the old dragon (lung) kiln still<br />

stands. Long hours of hard work were needed to fire it. Here as in many other<br />

pottery factories in China tunnel kilns are superseding these old "monsters". To<br />

the <strong>Australia</strong>n potters viewing the town from the top of the dragon kiln, it was a<br />

stirring thought, indeed, that the sherds at our feet were hundreds of years old.<br />

Slab-built pots are shaped<br />

by paddle and anvil, Red<br />

Star <strong>Pottery</strong>.<br />

Glazing leather-hard POts<br />

with an ash/ clay glaze.<br />

<strong>No</strong>te implement for catching<br />

eXcess.<br />

17

BRYAN NEWMAN IN AUSTRALIA<br />

Janet Mansfield<br />

English potter, Bryan Newman was brought to <strong>Australia</strong> by the Craft Board of<br />

the <strong>Australia</strong> Council. According to many potters here, he has been one of the<br />

most successful of the visiting craftsmen that the Board has sponsored. With<br />

workshops given in all States, potters have had every opportunity to learn<br />

practical technology and some aesthetic assessment of the ceramic art. That Bryan<br />

is an experienced teacher was obvious by the fact that he sustained his enthusiasm<br />

and good will during what must have been an exhausting programme continually<br />

working and travelling.<br />

It is obvious too that Bryan is committed to clay. He says there are jobs in<br />

the pottery to correspond to all one's moods and the facets of one's personality.<br />

Even balancing the books suits a part of his nature although Bryan admits to<br />

being the only potter he knows who can find enjoyment in book-keeping.<br />

Bryan Newman delights in paradox, he likes to keep a flexible attitude to<br />

life and enjoys nearly everything. He finds the silly and ludicrous just as meaningful<br />

as the perfect and sublime maintaining that life is as it should be, just<br />

a little bit crazy with a balance between chaos and order. What he says today,<br />

he may contradict tomorrow, happily changing his ideas and emphasis regularly.<br />

Bryan's work schedule in his own studio allows for plenty of variety. He<br />

will spend three to four months on sculptural work, using slabs and combinations<br />

of slabs and thrown forms, turning in relief to repetition throwing, making one<br />

activity an antidote to the other. He feels the shapes he makes metamorphose,<br />

subtly changing as the working time progresses. He is not pedantic about the<br />

functional aspects of his domestic ware but likes to believe that most of it does<br />

work mechanically. It is more important that a shape pleases him and if it<br />

should have a small defect, well he says, it's like accepting defects in one's<br />

friends.<br />

At home, a farm house in Somerset, Bryan works with his wife Julie who<br />

is also a professional potter and who mainly makes domestic ware. For six<br />

months of the year he employs an assistant. His pace of work is very fast using<br />

very few tools believing that they are only an extension of his body which is<br />

more responsive anyway. His record output was 607 saucers in one day and that<br />

included preparing and weighing out all the clay.<br />

Bryan uses two clay bodies. For small pieces he mixes 25% fire clay with<br />

75 % ball clay. For larger work he adds sagger clay to this mix in the proportion<br />

of one part sagger clay to two parts of the other mix. His clays are blended in a<br />

dough mixer and then stored for six weeks to mature before use. Besides being<br />

fast and efficient in his work, Bryan is also neat. He always covers ware boards<br />

with newspaper which keeps them clean and dry. His schedule of work usually<br />

involves three weeks of making and then one and a half weeks glazing to firing.<br />

Bryan normally bisque fires.<br />

'<br />

He has two kilns, one of 18 cubic feet, do ndraught, which has a David<br />

Etchel! oil burner mounted at the top. The larger kiln, not so old nor yet quite as<br />

reliable has a capacity of 55 cubic feet and is fired with two swirlamiser burners<br />

in conjunction with a I" compressor. Bryan likes to combine dry glazes with<br />

shiny areas of glaze on the one piece. For the dry glazes he uses unwashed ash<br />

with China clay. When using pigments, an amount of china clay is added to<br />

18

I<br />

BRYAN NEWMAN in the<br />

garden of Vic Greenaway's<br />

pottery.<br />

modify the colour. The glaze recipes that Bryan uses were given to all participants<br />

of his workshops.<br />

For his <strong>Australia</strong>n workshops Bryan took his students through a progressive<br />

series of throwing from bottles with stoppers and storage jars with lids to teapots,<br />

teapots as we know them and teapots only limited by one's imagination. He<br />

found that the students did not have the same technical achievement with their<br />

stoppers and spouts as they could command with the rest of their shapes. <strong>In</strong><br />

throwing, he says, potters should experiment extending their materials, making<br />

them so thin that the pot collapses totally. If the collapse is only in one part, then<br />

that is its weak point. Experimenting with really thick handles (even thick to<br />

the point of ridiculousness) as a reaction against the commercially thin handles<br />

that we have been brought up to admire, will provide us with a balance. This<br />

experiment we can apply to other combined or applied pieces such as stoppers<br />

and knobs or lugs. Varying the widths, shapes and levels of rims to alter the<br />

character of the pot, may possibly alter the potter in the trying. The rim, he<br />

says, gives the feeling of weight and section to a pot.<br />

Bryan claims having an intimate relationship with teapots. For good<br />

pouring, the holes between the pot and the spout should be large enough and<br />

numerous enough to enable the spout to be completely filled While pouring, the<br />

spout should be tapered and have a sharp end. His use of the tapered piercer, a<br />

tool for making holes from Podmores caused a run on a Sydney potters' supplier,<br />

19

the only source in <strong>Australia</strong>. Bryan constructed many different teapots during<br />

the workshop including the upside down or Christmas Pudding version, one<br />

cylindrical one with severely turned lines, a barrel, a bottle angled at 60° and a<br />

bowl and disc teapot. Some of these combined several different thrown sections<br />

and Bryan has previously made them by combining twelve or more pieces. Some<br />

bandIes were puJled, Bryan dips the clay length into the water instead of his<br />

band and so has no dribbles of water running to his elbows; some handles were<br />

thrown discs, turned and then cut to the desired length.<br />

Thrown plates, bowls and bottles were demonstrated during the workshop<br />

and Bryan used string to tie freshly thrown bowls and bottles to form lobed<br />

divisions in each piece. Bryan altered the tension of the string to create sharp or<br />

slow curves and also suggested using string soaked in slip or pigment for<br />

heightening the lobed effect.<br />

Bryan doesn't draw his work first, rather lets it all happen in the clay. With<br />

a visual idea in mind he uses ceramic techniques to make a statement. Such a<br />

statement is then the start. Tbis particularly applies to his slab pieces when the<br />

form of a stickle back fish, an Edwardian high rise building or a boat shape<br />

intrigues him enough to explore the form in clay. <strong>In</strong>spiration comes from life in<br />

Bryan's case, from his past, from bow he sees the future and how these influence<br />

his life at tbe present. He does go to museums but spends more time looking at<br />

the paintings and sculptures than the pots. He often goes to the Horniman<br />

Museum in South London to see their good collection of masks and musical<br />

instruments. Bryan usually works on several slab pieces at one time enabling him<br />

to "home in" on an idea. Often his first statement he feels is a little stilted. He<br />

relies on the last piece of clay applied to each work to unify and balance the<br />

whole.<br />

Slabs are cut from a large block of clay with the use of a wire and sticks.<br />

The sticks are notched at intervals of i-inch, i-inch and i -inch on different sides<br />

to give different thicknesses of slabs. The slabs are then set aside until they are<br />

very firm and will give crisp edges when cut with a scraper. Slabs are joined by<br />

scratching and then wetting the areas to be joined and pressed very firmly<br />

together. Small slab pieces which are applied to the basic form are often pierced<br />

through and then cut diagonally with the scraper to give a fin-like form , strong<br />

at the attachment and very fine at the edge. These forms become even more<br />

dramatic when glazed as the thin areas absorb much less glaze and the whole<br />

effect is heightened.<br />

Although some of Bryan's slab works are in the form of industrial towers,<br />

harbour and river scenes, landscapes and transport systems, he says he is not<br />

making a social comment on man's use of his environment. He feels that many<br />

craftsmen while decrying the polluting effects of industry are only too willing to<br />

enjoy its fruits.<br />

<strong>In</strong>tending to be a painter, Bryan commenced art studies at Camberwell<br />

School of Art when he was sixteen. After some time there he started to become<br />

more interested in pottery and this interest became a total involvement. He still<br />

sometimes paints for his own pleasure, landscapes mostly in a traditional style.<br />

Although he feels that learning ceramics at art school probably took him longer<br />

to become proficient at the wheel he was able to learn the techniques and<br />

philosophies of various teachers. It can happen that potters who learn as apprentices<br />

become mere satellites of the master potter and often find this hard to<br />

overcome.<br />

From conducting workshops in all States and also, working at Victor<br />

Greenaway's studio, preparing an exhibition held at the Craft Centre, Melbourne,<br />

20

Stoneware tea-pots by Bryan Newman_ Exhibited at the Craft Centre, Melbourne.<br />

Bryan imagines that there will possibly be an <strong>Australia</strong>n influence on his future<br />

work. This may be reflected in some of his slab pieces. As he took the train<br />

across the Nullabor from Adelaide to Perth he was deeply impressed by the<br />

forms and colours of the landscapes. He also has at least three resolutions he<br />

plans to adopt on leaving <strong>Australia</strong>. The first is to strengthen his body (presumably<br />

his clay one), the second is to explore the effects of clay and glaze in the<br />

firing range between I 100°C and 1200°C and the third is to take more holidays.<br />

With such a full and exacting programme behind him now he no doubt will need<br />

the last and I'm sure all the potters who learnt so much from him here will wish<br />

him well and know he will succeed in his first two resolves.<br />

With the layers of the past exerting their influence on us and our hopes and<br />

the uncertainties of the future, now Bryan feels is the time to be an individual.<br />

<strong>No</strong> particular style or fashion has been impressed upon us and we must work at<br />

our own ideas until they are personal and satisfying.<br />

BRY AN NEWMAN GLAZES--All reduced stoneware.<br />

W9-W14 W9 WI4<br />

Cornish Stone 50 50<br />

Dolomite 20 20<br />

China Clay 25 25<br />

Whiting 5 5<br />

Quartz <strong>15</strong> 5<br />

Matt white opaque glaze 1270°C-90°C. Good over slips. Apply medium thick.<br />

21

11 Potash Feldspar 40<br />

Whiting <strong>15</strong><br />

Ball Clay 5<br />

China Clay 10<br />

Quartz 20<br />

Iron Oxide 9<br />

Black breaking to rust 1260°C-80°C. Useful glaze alone or with other glazes on<br />

top, such as 12 or 31. Apply medium thick.<br />

ABC<br />

31 Potash Feldspar 24 24 24<br />

Dolomite 3 3 3<br />

Whiting 5 5 5<br />

Zinc Oxide 1 3 3<br />

China Clay 3 10 1<br />

Quartz 20 <strong>15</strong> 25<br />

A is white, semi-matt and milky; over II gives a blue.<br />

B is white, semi-matt and milky; over 11 gives a grey.<br />

C is white, semi-matt and milky; over 11 gives a white. .<br />

D is white, semi-matt and milky; over II gives a grey. Apply medium thick.<br />

LSL Potash Feldspar 40<br />

Whiting 20<br />

Ball Clay <strong>15</strong><br />

China Clay <strong>15</strong><br />

Quartz 30<br />

Red Iron Oxide 2t<br />

Green semi-matt glaze 1280°C, good with pigment of 1 Iron Oxide 1 China Clay.<br />

Apply medium thick.<br />

12 Potash Feldspar 20<br />

Whiting 40<br />

Colemanite 4 Gerstley Borate-<strong>Australia</strong>n substitute.<br />

China Clay 80<br />

Yellow Ochre 5<br />

Fairly dry glaze coloured yellow buff or brown depending on thickness 1260°C-<br />

80°C. Apply thinly.<br />

TRAD Wood Ash 3<br />

Feldspar 3<br />

China Clay 2<br />

Puff or pale brown 1260°C-80°C. Apply medium thick.<br />

Al Wood Ash 50 Apple or oak.<br />

China Clay 50<br />

1250°C-80°C. Pale, dry yellow, breaking buff. Apply very thinly.<br />

A2 Wood Ash 50<br />

China Clay 50<br />

Cobalt Oxide 2<br />

Terrible by itself, but with 12 over gives a soft blue. 1250°C-80°C. Apply very<br />

thinly.<br />

A3 Wood Ash 50<br />

China Clay 50<br />

Nickel Oxide 2<br />

Dry, pinky brown. 1250°C-80°C. Paler with 12 over it. Apply very thinly.<br />

22<br />

D<br />

24<br />

3<br />

5<br />

3<br />

1<br />

5

THOROUGHLY MODERN MILLING<br />

(Part One)<br />

Stephen Harri son<br />

Stephen Harrison, a Sydney potter, lectures part-time at East Sydney Technical College.<br />

A ball mill, owned by the Potters' Society of <strong>Australia</strong> Is available for use to Members and<br />

Associate Members. Telephone: Sydney 31 3<strong>15</strong>1 .<br />

We've all seen and admired Peter Rushforth's rock glaze tenmokus, and Harry<br />

Davis' fine glazes. The individual qualities of these glazes came from the fact that<br />

they were made from materials that were not pure commercial and iron free<br />

materials, but rather, the opposite -<br />

prospected, collected and processed by the<br />

potter.<br />

The word "processed" here means crushed to 200 mesh, and the most common<br />

way of doing this is by ball milling.<br />

Ball mills come in various shapes and sizes from 8 feet diameter down to 4t"<br />

diameter. They essentially comprise a cylindrical jar rotated on its horizontal axis<br />

containing a grinding media of rods, cylinders or balls. When the jar is rotated at<br />

a certain speed, the grinding media will roll up the side and cascade down over<br />

each other to the bottom causing any fine material caught in between to be<br />

reduced in size.<br />

<strong>In</strong>dustry uses many different types of mills but I will concentrate on those<br />

most suitable for studio potters to grind ceramic materials from approximately<br />

YJ a" down to <strong>15</strong>0-200 mesh size. I have chosen 7'i6" as the maximum particle<br />

size, because, if a larger size material is to be considered then another type of<br />

crusher such as a jaw crusher or a roller crusher will need to be employed to bring<br />

the material down to 1A. 6" or finer. Alternatively a very large ball mill will need<br />

to be used to cope with the larger size rock. Either way this is out of the scope of<br />

the studio potter.<br />

Appropriate material of convenient size may be obtained as dust from under<br />

the crushers of large quarries which produce blue metal for road surfacing or<br />

cement aggregates. Such quarries around Sydney are located at Hornsby (Farley<br />

& Lewers), Prospect (Pioneer Concrete) , Bombo (near Kiama) and Mittagong.<br />

Fig. 1. Large ball mill on "A"<br />

frame.<br />

Fig. 2. Small mill jar on<br />

rubber rollers.<br />

The rock from Mittagong is probably the best known to potters for producing the<br />

tea-dust glaze used by the SlUrt workshops for many years.<br />

So--allowing for a starting size of 16 mesh or finer, a mill size of about<br />

5 gallons capacity is probably best. This would have an inside diameter of about<br />

12" and an internal length of 14" approximately. Larger jars (over 12" diameter)<br />

usually have their own axles and run on plumber blocks, mounted on "A" frames<br />

23

(see Fig. 1). But for small mills, 12" or less, the jar is usually placed on two<br />

rubber coated rollers, one of which is driven, and the other free running (see<br />

Fig. 2). <strong>In</strong> this case the opening for loading and unloading must be at the end or<br />

co-axial with the cylindrical jar.<br />

The traditional type of jar is made of porcelain, and for this size would need<br />

to be about I" thick. When loaded with charge, balls and water, it weighs between<br />

<strong>15</strong>0 and 200 pounds. This is as heavy as can be lifted onto the rollers and why<br />

any larger jars must be permanently mounted.<br />

Grinding<br />

Ball mills perform a few functions -<br />

one of them being that of a grinder.<br />

There are two theories as to when the most efficient grinding occurs. As<br />

stated, the action is one of impact and rubbing caused by the cascading of the<br />

balls. This cascading action is determined by the speed of the mill. If the mill is<br />

stationary the balls and charge will lie in the bottom of the jar (see Fig. 3) and<br />

as the speed is increased, the balls will begin to ride up the side of the jar (see<br />

Fig. 4) and eventually will ride the circumference, and at this point the mill is<br />

said to have reached its critical speed (Fig. 5) .<br />

This speed will be different for each mill depending on its diameter. Larger<br />

mills have a low critical speed and as the diameter d.ecreases the critical speed<br />

increases (for a mill of 12" diameter, the critical speed is 77 r.p.m.). The critical<br />

speed then, can be defined as "the lowest possible speed necessary to centrifuge<br />

the media next to the mill lining". The critical speed can be calculated by the<br />

following formula.<br />

54.18<br />

Critical speed = ---<br />

y'Rft where R is expressed in feet<br />

It is said that the best speed for grinding is between 64% and 87 % of the<br />

critical speed. This is the range when the balls are cascading over each other. As<br />

the speed is increased towards the upper limit (87% ) the balls tend to ride and<br />

leave the wall of the mill and are projected into the void above the general mass<br />

of the media and come crashing down with considerable force - thus achieving<br />

the greatest impact (Fig. 6 ).<br />

24<br />

Fig. 3. Mill While<br />

stationary or slowly<br />

moving.<br />

Fig. 4. Ball action when<br />

speed j ncreases.<br />

Fig. 5. Ball action at<br />

speeds greater than the<br />

critical speed.<br />

Fig. 6. Ball action at<br />

higher grinding speeds.<br />

Fig. 7. Ball action at<br />

lower grinding speeds.

This type of action is best when grinding or reduci~g particle. size is of<br />

primary importance. It also causes the greatest wear of gnndmg medIa and t~e<br />

lining. At the slower speed, the balls will leave the lining at a much lower pomt<br />

and will then roll down the sloping mass of charge (Fig. 7). <strong>In</strong> this way the whole<br />

mass of balls is in motion, each rolling over and rubbing against its neighbours.<br />

The lower speeds are favoured for larger mills where wear and tear on the grinding<br />

media and lining is kept to a minimum, but the milling time is greatly increased.<br />

A faster speed is generally preferred for small mills, particularly in the case of<br />

studio potters where the mill is only used intermittently and where wear of the<br />

lining and contamination of the product are not such important considerations.<br />

For a mill of 12" diameter, a suitable percentage of critical speed would<br />

be 80% .<br />

Good grinding is said to occur when the angle between the radius to the<br />

point where the outer balls break from the periphery and the vertical is about 54 0 •<br />

This angle is called "the angle of break" (Fig. 8).<br />

The percentage of critical speed and angle of break are theoretical figures<br />

only, and in actual practice it may be found that better milling takes place at<br />

values other than the theoretical ones. But, since calculated curves agree closely<br />

with photographed paths of balls in mills operating at maximum efficiency, it is<br />

believed that variations above and below the theoretical values should be small.<br />

- - ...-==--- -- -tl- - - --<br />

Fig. 8. The angle of break.<br />

Fig. 9. The angle of nip.<br />

Grinding Media<br />

The shape, size, distribution and type of material are all very important<br />

factors in determining efficient grinding.<br />

Shape: The most efficient shapes for grinding media are spherical balls. Many<br />

tests have been made with cylinders, rods and fiat or "natural" shapes. It has been<br />

shown that heavy density ceramic balls can produce the same dispersion in 75%<br />

of the time taken by cylinders. When the ball mill is operated at its correct speed<br />

and when all other conditions are equally correct, the balls follow roughly concentric<br />

and parabolic lines of motion. <strong>In</strong> doing so, and via their own natural rotary<br />

motion, they subject the material under process to 3 distinct assaults : prepeated<br />

impact, abrasion and shear. The superiority of ball over cylinder can be explained<br />

then, by the obviously greater degree of spin that can be imparted to a ball than<br />

to a cylinder. The processing time taken with fiat or natural shapes falls between<br />

25

that of the ball and the cylinder. This is probably because the flat "natural" shape<br />

is closer to the ball than the cylinder.<br />

Size: The size of the balls required for any mill will be dependent on the use<br />

of the mill and the particle size of the charge, usually 2 or possibly 3 sizes of balls<br />

are used. The larger size of balls would grind the material when it is first introduced<br />

to the mill and when partly ground, the material will come within the range<br />

of the smaller balls--the larger balls having served their purpose fulfil no real<br />

function for the rest of the milling time. For this reason, the proportion of larger<br />

balls tends to be only 20% and small balls make up the remainder. The ability of<br />

a ball of certain size, to grind a particle of certain size, in proportion to that of<br />

the ball, has a definite ratio and can be expressed by what is called "the angle of<br />

nip" of the ball.<br />

The angle of nip is an important factor relating to the ball action, particularly<br />

in relation to the size of balls and the size of particles to be ground. Anyone who<br />

has operated a roller crusher has seen lumps of materials ride between the rollers<br />

without being ground. Similar action will take place between the balls, if particles<br />

are too large for the balls to grip them (Fig. 9).<br />

The angle between any 2 balls is called the angle of nip. The following<br />

relation has been developed between the angle of nip, , the radius of the ball, R,<br />

and the diameter of the particle, P.<br />

R<br />

cos-=---<br />

2 P<br />

R+-<br />

2<br />

Theoretical calculations indicate that", is a constant figure and equal to 17°.<br />

Thus, P = 0.0222R.<br />

It has been found that experimental values diller extensively from the<br />

theoretical. This difference is attributed in part to the co-efficient of friction , which<br />

varies greatly with the material to be ground, the mill lining and type of ball.<br />

Thus, for a 12" diameter mill loaded with I" balls, the largest particle that<br />

it is possible to crush would be 0.0111" or 52 mesh. This, I have found to be<br />

untrue in practice. I have a mill of these dimensions and I mill soft material, e.g.,<br />

pumice from 16 mesh to about <strong>15</strong>0-200 mesh in 3 hours, and hard material,<br />

syenite, from 30 mesh to <strong>15</strong>0-200 mesh in 3 hours.<br />

Perhaps, friction can account for the difference, but whatever the reason I'm<br />

sure that if the materials were introduced at 52 mesh then milling time could be<br />

halved. But the effort to collect, crush and sieve the material down to 52 or say<br />

60 mesh by hand-which is the only technique available to most potters- unless<br />

you're lucky enough to have access to a rock crusher-makes it worth running<br />

the ball mill an extra hour or two, because, as I have said before power consumption,<br />

mill wear and contamination of the charge are the least important considerations.<br />

Tests in a mill charged with 400 Ibs. of white [rit showed the relation of ball<br />

size to milling time.<br />

Ball Size<br />

Milling ;nme<br />

1 i" 4 hours<br />

2" 8 hours<br />

U" 9 hours<br />

3" II! hours<br />

Still other tests on a 100 lb. mill showed that 90% o[ the material was<br />

ground sufficiently fine in 3 hours to pass through a 200 mesh screen, but four<br />

26

and a half hours were required to grind 99% of the material in order to pass it<br />

through a 200 mesh screen. Thus t of the time was required to grind 'li 1 of the<br />

frit. An increase in the proportion of smaller balls would have aided in decreasing<br />

the mWing time.<br />

When balls have worn down to an unusable size (and for a 12" mill this<br />

would be half their original size-or less) or have chipped or otherwise lost their<br />

spherical shape then the equivalent weight of new 1" balls should be added to<br />

replace them. <strong>In</strong> cases where 2 sizes of balls are employed then the new balls<br />

should be added as the larger size.<br />

Materials for Balls: Traditionally, French flints were used as grinding media<br />

(and still are in some industries) but lately dense porcelain has all but replaced<br />

them for most uses. Dense porcelain has a specific gravity of beween 3.3 to 3.6,<br />

and obviously the greater the density and hardness of the balls, then the greater<br />

their ability to crush the charge. This is why recently, sintered alumina or<br />

corundum baJJs have become popular in industry for certain applications, for they<br />

have a specific gravity of 3.97 and a theoretical hardness of 9 on Moh's scale as<br />

compared to approximately 7 (Moh) for flint.<br />

The drawback here is that they are so hard and dense that they tend to wear<br />

porcelain jars excessively, particularly if run near the upper limit. They are recommended<br />

for use in rubber lined jars where they cause virtually no wear. Although,<br />

they have been in use at the University of N.S.W. for quite some time in a porcelain<br />

jar, and I am assured by Ivan McMeekin that they have not caused excessive wear,<br />

this could be because the mill there is run nearer the lower limit.<br />

Loading: The relative amounts of balls, charge, water and air space are very<br />

important, and are usually expressed as percentages of the volume of the jar.<br />

The average volume of the balls is usually about 55 % of the volume of the<br />

jar, but can be between 45 % -60%. When spherical objects are stacked up there is<br />

an air space between them and in practice this is found to be about 40% of the<br />

total volume occupied by the spheres. So, 40% of 55 % is about 22%. <strong>In</strong><br />

practice, it has been found that if this space is filled with charge, the best results<br />

are obtained. (Consequently, the real volume of balls is 33% of the volume of<br />

the jar (see Fig. 10). )<br />

The amount of water needed to give best grinding has been found to be about<br />

20% of the volume of the jar. This leaves an air space of 35 % , or about one-third.<br />

The amount of water plays an important role in achieving good results. If there<br />

is too little when the material to be ground starts to be broken up, its surface area<br />

will increase radically and the slip will become thicker. If the slip becomes too<br />

thick, it will act as a cushion between the cascading balls and milling will be<br />

Fig. 10. Relative volume of air,<br />

water, balls and charge.<br />

27

suspended and no more reduction in particle size of the charge will occur no<br />

matter how long the mill is kept running. On the other hand, if there is too much<br />

water, slippage will occur and good ball action will not be achieved, so mill output<br />

will be low.<br />

Blunging<br />

Ball mills can be used as blungers and are very efficient for this purpose,<br />

although a very large sized mill is needed to make it economical if the main<br />

throwing body is to be produced in this way. I have a t-ton sized mill for grinding<br />

feldspar and silica for the body and blunging the porcelain body. A small fivegallon<br />

jar is not suitable for this purpose except in special circumstances. For<br />

example, I've blunged a body containing an irony shale to break up and finely<br />

mix the iron thus giving a very bright orange coloured body. 1 found I could not<br />

achieve this in the ordinary blunger.<br />

I've also used the small mill for blunging small quantities of porcelain body<br />

while testing recipes-6t kilos can be blunged at one time. 1 t hours is ample<br />

time for this, so three charges can be blunged easily in a day allowing discharging<br />

time because the mill does not have to be cleaned thoroughly between charges if<br />

the same material is being milled. If a different material is to be introduced the<br />

mill must be scrupulously cleaned.<br />

When being used as a blunger, the mill is best loaded with less balls -<br />

approximately 35 % to 40% and the air space left can be much less or almost<br />

eliminated, thus greatly increasing the volume attainable to the charge and water.<br />

Cleaning<br />

When the mill is to be emptied this is best done by sieving the opening with a<br />

coarse i" sieve and inverting the jar over a large bucket, then rinsing the jar out<br />

and repeating the process. I use this technique for the plastic jar. But the 5-gallon<br />

porcelain jar, when filled with balls, water, and charge is too heavy for most<br />

people to lift so it is best to take out the balls and put them in a bucket half-filled<br />

with clean water then into another bucket half-filled with clean water and then<br />

into a suitable bowl or bucket for storage, until they are placed back into the mill.<br />

After this procedure, the balls will be quite clean and the first washing bucket will<br />

contain about 5 % of the original charge. This is enough to make it worthwhile<br />

keeping, and after decanting the sediment can be returned to the charge for drying.<br />

The jar now will be only about 30% full and can be lifted by a reasonably strong<br />

person, and the charge poured out into a bucket. If it is still too heavy, the charge<br />

can be ladled out into the bucket. After emptying, the jar must be rinsed and<br />

sponged clean before the balls are put back. This is particularly important if a<br />

different material is to be ground next. I'm told by a friend who works in industry<br />

operating ball mills, that if all the charge is not removed-particularly the ultra fine<br />

section-it will double the milling time or halve the mill output of the next<br />

charge. So they pump the jar empty using compressed air. This also prevents<br />

materials like feldspar from settling as hard as a rock in the bottom of the jar<br />

before it can be removed-un'ortunately not many potters have access to compressed<br />

air-so other ways are available to overcome this. Cardew suggests adding<br />

10% China Clay to give better suspension properties. When grinding igneous type<br />

rocks the milling action increases the temperature and pressure in the jar and some<br />

of the alkali materials are released by the grinding. This causes the ph to rise.<br />

I've found that the best way to overcome this is by adding a very small amount of<br />

diluted HCI acid. This will counteract the high alkalinity of the suspension and<br />

return it to neutral, so that, although the material will still settle while unloading<br />

28

occurs it is very easily stirred up again before it can form a solid rocklike mass in<br />

the bottom. The only problem is that the acid tends to attack the fine brass sieve<br />

lawn and may eventually cause it to wear away sooner than it otherwise wouldbut<br />

even if it does, it's well worth it as far as I'm concerned-and I'm sure anyone<br />

else who has had to try to mix a glaze that "settles" will agree.<br />

If the mill has been used to grind a material with a high iron content after<br />

cleaning, it may still have a discolouration of iron in the pores of the porcelainno<br />

amount of washing will remove this. The easiest and quickest way is to charge<br />

the mill with a couple of kilos of white quartz sand and run the mill for a couple<br />

of hours. This will clean the lining and balls thoroughly. The usual discharging<br />

and washing operation must then be carried out before the mill is recharged.<br />

Dry Grinding<br />

I've not had much experience with dry milling but I understand it is best to<br />

run the mill 10% slower than for wet milling. This is because the friction factor<br />

is so much higher for dry milling and the balls carry farther up the wall of the jar<br />

before cascading. If you run your mill at the upper limit, like I do, then if the mill<br />

is loaded for dry milling, the charge may ride the lining and not cascade at all -<br />

thus very little grinding will occur and the mill lining may suffer excessive wear.<br />

Also, if dry milling the volume of balls can be dropped to between 35 % -45 %.<br />

Dry milling is normally only used when the material being ground is water soluble<br />

or if it is thought that the milling process will break down the internal bonds of<br />

the material releasing solubles. A good example of this is Nepheline Syenite.<br />

Milling Rock<br />

The time required for milling rocks varies greatly and is dependent on:<br />

hardness of the rock,<br />

starting size of the rock dust,<br />

the way the mill is charged,<br />

speed of the mill,<br />

the type of grinding media and its shape and size.<br />

After the charge has been ground sufficiently fine it then has to be sieved.<br />

I use only 60 mesh just to eliminate any pieces of chipped balls or any of the<br />

original charge that might have got caught in the gap between the lid and the jar<br />

and so missed out being ground. Once sieved the usual procedure is to leave it to<br />

settle. The water is decanted and it is finally put on a drying bed. I've found that<br />

the technique of hanging slip up in filter cloth bags to dry in the wind is virtually<br />

useless for clay slip or any fairly plastic material-but for non-plastics, this method<br />

is excellent. After sieving and setting the slip is poured into a bucket lined with<br />

filter cloth and when almost full , the edges of the cloth are gathered up and tied.<br />

The "bag" of slip is then hung up in a place that is outside in the wind, but<br />

sheltered from the rain. I've found this technique to be twice as fast for drying as<br />

on a drying bed.<br />

I hope these notes are of some use to anyone interested in obtaining a ball<br />

mill . There are a few small and large ones turning up on the second hand market<br />

each year. But new, they are completely uneconomical. So, for the next issue, I<br />

hope to have ready what r plan as a second part of this article--"How to build a<br />

small ball mill---

A DAY IN IZCUCHACA<br />

May Davis<br />

The saga of Harry and May Davis in Peru is always worth some space in POTIERY IN<br />

AUSTRALIA. The Davises are setting up a pottery in Izchucaca in order to train locals as<br />

potters, giving them employment and so preventing the drift to the cities and inevitable<br />

unemployment. Part of a newsletter from May is reproduced.<br />

Harry up at 5.30 (candle-light) and I get a cup of tea in bed. At 6.00 he's out<br />

working on a jigger for crucible making and planning the work for the day. At<br />

7.00 the workers arrive. Javier is to make maketas (unglazed hanging flower pots).<br />

Maximo tries to pump up a flat tyre, but the pump won't work, even for Harry.<br />

Harry and I have breakfast of porridge, tea and rolls. The latter have got<br />

stale and are rock-hard but by holding over steam till they are soggy aud then<br />

toasting in a flame they are fine. 1 sweep through, wash-up and boil water to fill<br />

the filter. 7.45 I leave with three men to get clay. We go to the local petrol pump<br />

first to borrow a pump. "It's out of order." We hail a passing truck with the same<br />

request and get the same answer. 1 get suspicious, but it is probably all true as a<br />

passing bus stops, and they carry compressed air, so the tyre is fixed . A stop in<br />

the village for me to get eggs from a scruffy man with six dogs. (Everyone has<br />

dogs as protection against thieves, though the professional thieves poison the dogs<br />

first.) The matter of change for my 100 sole note is difficult. Ten eggs come to<br />

35 soles (1 sole = 1 U.K. penny or 2 N.Z. cents). He has 65 soles but he can't<br />

do the sum and daren't trust me. He spends ten minutes finding 100 soles in change<br />

from the neighbours which he gives to me. I then pay him back 35 soles. (<strong>No</strong>te<br />

the tyre and eggs have taken at least five times as long as they would have done<br />

elsewhere. Small but typical examples.) On the way back I go to the bank for<br />

change. There is a man in front of me cashing a cheque. On receiving the money<br />

he hands a 50 sole note back to the clerk, who says "thank you" and puts it in<br />

his breast pocket. They behave as though this tipping was a normal transaction.<br />

I give the men money to get a drink, as it is hard work getting the clay. The drink<br />

is chicha, alcoholic, home-made from maize or the berries of the pepper tree<br />

(schinus molle) . It is sold from an open bucket at 2 cents a glass. Back by 9.30,<br />

Harry says "For God's sake make some tea." He is feeling awful as we went last<br />

week to get bracing for the kiln from a mine above Huancavelica, at J 4,000 feet.<br />

It took three days, two travelling, and the height gave Harry soroche (altitude<br />

sickness) , and on top of that we replenished our water containers from what we<br />

thought would be a high safe stream and it was lethal! We both had two days of<br />