Pottery in Australia Vol 17 No 1 Autumn 1978

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

\I~c-uum<br />

(;.\lAt"n!!>F.9..<br />

....<br />

PUCsMILL<br />

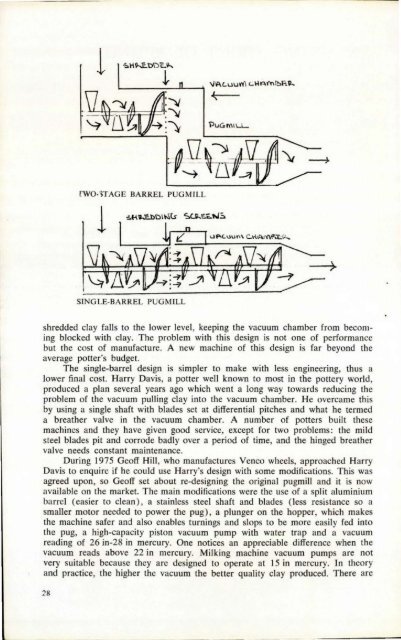

rwo:rrAGE BARREL PUGMILL<br />

SINGLE-BARREL PUGMll.L<br />

shredded clay falls to the lower level, keep<strong>in</strong>g the vacuum chamber from becom<strong>in</strong>g<br />

blocked with clay. The problem with this design is not one of performance<br />

but the cost of manufacture. A new mach<strong>in</strong>e of this design is far beyond the<br />

average potter's budget.<br />

The s<strong>in</strong>gle-barrel design is simpler to make with less eng<strong>in</strong>eer<strong>in</strong>g, thus a<br />

lower f<strong>in</strong>al cost. Harry Davis, a potter well known to most <strong>in</strong> the pottery world,<br />

produced a plan several years ago which went a long way towards reduc<strong>in</strong>g the<br />

problem of the vacuum pull<strong>in</strong>g clay <strong>in</strong>to the vacuum chamber. He overcame this<br />

by us<strong>in</strong>g a s<strong>in</strong>gle shaft with blades set at differential pitches and what he termed<br />

a breather valve <strong>in</strong> the vacuum chamber. A number of potters built these<br />

mach<strong>in</strong>es and they have given good service, except for two problems: the mild<br />

steel blades pit and corrode badly over a period of time, and the h<strong>in</strong>ged breather<br />

valve needs constant ma<strong>in</strong>tenance.<br />

Dur<strong>in</strong>g 1975 Geoff Hill, who manufactures Yenco wheels, approached Harry<br />

Davis to enquire if he could use Harry's design with some modifications. This was<br />

agreed upon, so Geoff set about re-design<strong>in</strong>g the orig<strong>in</strong>al pugmill and it is now<br />

available on the market. The ma<strong>in</strong> modifications were the use of a split alum<strong>in</strong>ium<br />

barrel (easier to clean) , a sta<strong>in</strong>less steel shaft and blades (less resistance so a<br />

smaller motor needed to power the pug) , a plunger on the hopper, which makes<br />

the mach<strong>in</strong>e safer and also enables turn<strong>in</strong>gs and slops to be more easily fed <strong>in</strong>to<br />

the pug, a high-capacity piston vacuum pump with water trap and a vacuum<br />

read<strong>in</strong>g of 26 <strong>in</strong>-28 <strong>in</strong> mercury. One notices an appreciable difference when the<br />

vacuum reads above 22 <strong>in</strong> mercury. Milk<strong>in</strong>g mach<strong>in</strong>e vacuum pumps are not<br />

very suitable because they are designed to operate at 15 <strong>in</strong> mercury. ln theory<br />

and practice, the higher the vacuum the better quality clay produced. There are<br />

28