Pottery in Australia Vol 17 No 1 Autumn 1978

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

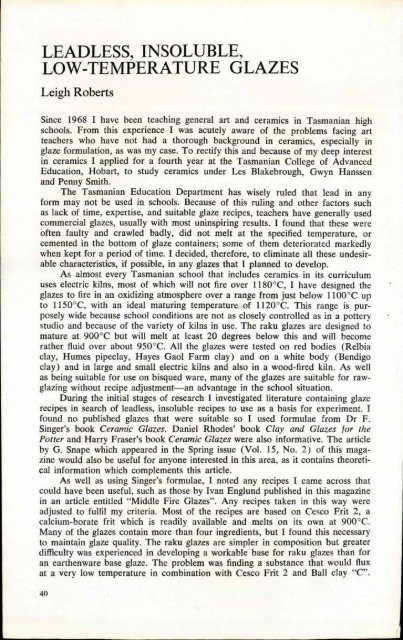

LEADLESS, INSOLUBLE,<br />

LOW-TEMPERATURE GLAZES<br />

Leigh Roberts<br />

S<strong>in</strong>ce 1968 I have been teach<strong>in</strong>g general art and ceramics <strong>in</strong> Tasmanian high<br />

schools. From this experience I was acutely aware of the problems fac<strong>in</strong>g art<br />

teachers who have not had a thorough background <strong>in</strong> ceramics, especially <strong>in</strong><br />

glaze formulation, as was my case. To rectify this and because of my deep <strong>in</strong>terest<br />

<strong>in</strong> ceramics I applied for a fourth year at the Tasmanian College of Advanced<br />

Education, Hobart, to study ceramics under Les Blakebrough, Gwyn Hanssen<br />

and Penny Smith.<br />

The Tasmanian Education Department has wisely ruled that lead <strong>in</strong> any<br />

form may not be used <strong>in</strong> schools. Because of this rul<strong>in</strong>g and other factors such<br />

as lack of time, expertise, and suitable glaze recipes, teachers have generally used<br />

commercial glazes, usually with most un<strong>in</strong>spir<strong>in</strong>g results. I found that these were<br />

often faulty and crawled badly, did not melt at the specified temperature, or<br />

cemented <strong>in</strong> the bottom of glaze conta<strong>in</strong>ers; some of them deteriorated markedly<br />

when kept for a period of time. I decided, therefore, to elim<strong>in</strong>ate all these undesirable<br />

characteristics, if possible, <strong>in</strong> any glazes that I planned to develop.<br />

As almost every Tasmanian school that <strong>in</strong>cludes ceramics <strong>in</strong> its curriculum<br />

uses electric kilns, most of which will not fire over IISO°C, I have designed the<br />

glazes to fire <strong>in</strong> an oxidiz<strong>in</strong>g atmosphere over a range from just below 1 100°C up<br />

to l1S0°C, with an ideal matur<strong>in</strong>g temperature of I 120°C. This range is purposely<br />

wide because school conditions are not as closely controlled as <strong>in</strong> a pottery<br />

studio and because of the variety of kilns <strong>in</strong> use. The raku glazes are designed to<br />

mature at 900°C but will melt at least 20 degrees below this and will become<br />

rather fluid over about 950°C. All the glazes were tested on red bodies (Relbia<br />

clay, Humes pipeclay, Hayes Gaol Farm clay) and on a white body (Bendigo<br />

clay) and <strong>in</strong> large and small electric kilns and also <strong>in</strong> a wood-fired kiln. As well<br />

as be<strong>in</strong>g suitable for use on bisqued ware, many of the glazes are suitable for rawglaz<strong>in</strong>g<br />

without recipe adjustment-an advantage <strong>in</strong> the school situation.<br />

Dur<strong>in</strong>g the <strong>in</strong>itial stages of research I <strong>in</strong>vestigated literature conta<strong>in</strong><strong>in</strong>g glaze<br />

recipes <strong>in</strong> search of leadless, <strong>in</strong>soluble recipes to use as a basis for experiment. I<br />

found no published glazes that were suitable so I used formulae from Dr F.<br />

S<strong>in</strong>ger's book Ceramic Glazes. Daniel Rhodes' book Clay and Glazes for the<br />

Potter and Harry Fraser's book Ceramic Glazes were also <strong>in</strong>formative. The article<br />

by G. Snape which appeared <strong>in</strong> the Spr<strong>in</strong>g issue (<strong>Vol</strong>. 15, <strong>No</strong>.2) of this magaz<strong>in</strong>e<br />

would also be useful for anyone <strong>in</strong>terested <strong>in</strong> this area, as it conta<strong>in</strong>s theoretical<br />

<strong>in</strong>formation which complements this article.<br />

As well as us<strong>in</strong>g S<strong>in</strong>ger'S formulae, I noted any recipes I came across that<br />

could have been useful, such as those by Ivan Englund published <strong>in</strong> this magaz<strong>in</strong>e<br />

<strong>in</strong> an article entitled "Middle Fire Glazes". Any recipes taken <strong>in</strong> this way were<br />

adjusted to fulfil my criteria. Most of the recipes are based on Cesco Frit 2, a<br />

calcium-borate frit which is readily available and melts on its own at 900°C.<br />

Many of the glazes conta<strong>in</strong> more than four <strong>in</strong>gredients, but I found this necessary<br />

to ma<strong>in</strong>ta<strong>in</strong> glaze qUality. The raku glazes are simpler <strong>in</strong> composition but greater<br />

difficulty was experienced <strong>in</strong> develop<strong>in</strong>g a workable base for raku glazes than for<br />

an earthenware base glaze. The problem was f<strong>in</strong>d<strong>in</strong>g a substance that would flux<br />

at a very low temperature <strong>in</strong> comb<strong>in</strong>ation with Cesco Frit 2 and Ball clay "C".<br />

40