You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

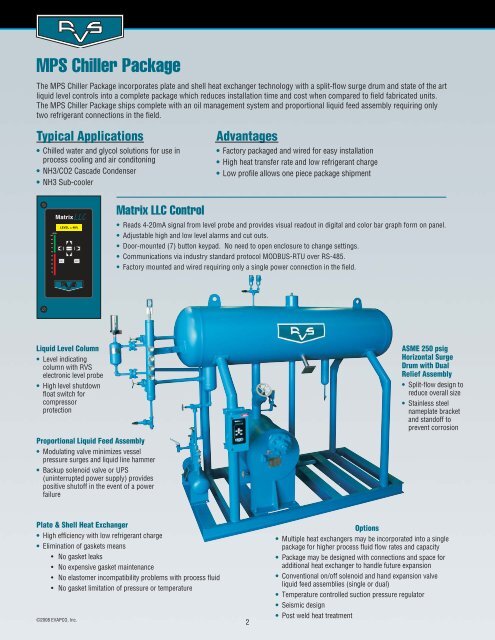

<strong>MPS</strong> Chiller Package<br />

The <strong>MPS</strong> Chiller Package incorporates plate and shell heat exchanger technology with a split-flow surge drum and state of the art<br />

liquid level controls into a <strong>com</strong>plete package which reduces installation time and cost when <strong>com</strong>pared to field fabricated units.<br />

The <strong>MPS</strong> Chiller Package ships <strong>com</strong>plete with an oil management system and proportional liquid feed assembly requiring only<br />

two refrigerant connections in the field.<br />

Typical Applications<br />

• Chilled water and glycol solutions for use in<br />

process cooling and air conditoning<br />

• NH3/CO2 Cascade Condenser<br />

• NH3 Sub-cooler<br />

LEVEL<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

LEVEL = 48%<br />

ENTER<br />

PREV. NEXT<br />

Liquid Level Column<br />

• Level indicating<br />

column with RVS<br />

electronic level probe<br />

• High level shutdown<br />

float switch for<br />

<strong>com</strong>pressor<br />

protection<br />

Proportional Liquid Feed Assembly<br />

• Modulating valve minimizes vessel<br />

pressure surges and liquid line hammer<br />

• Backup solenoid valve or UPS<br />

(uninterrupted power supply) provides<br />

positive shutoff in the event of a power<br />

failure<br />

Matrix LLC Control<br />

• Reads 4-20mA signal from level probe and provides visual readout in digital and color bar graph form on panel.<br />

• Adjustable high and low level alarms and cut outs.<br />

• Door-mounted (7) button keypad. No need to open enclosure to change settings.<br />

• Communications via industry standard protocol MODBUS-RTU over RS-485.<br />

• Factory mounted and wired requiring only a single power connection in the field.<br />

<strong>Plate</strong> & <strong>Shell</strong> Heat Exchanger<br />

• High efficiency with low refrigerant charge<br />

• Elimination of gaskets means<br />

• No gasket leaks<br />

• No expensive gasket maintenance<br />

• No elastomer in<strong>com</strong>patibility problems with process fluid<br />

• No gasket limitation of pressure or temperature<br />

©2008 <strong>EVAPCO</strong>, Inc.<br />

Advantages<br />

• Factory packaged and wired for easy installation<br />

• High heat transfer rate and low refrigerant charge<br />

• Low profile allows one piece package shipment<br />

2<br />

ASME 250 psig<br />

Horizontal Surge<br />

Drum with Dual<br />

Relief Assembly<br />

• Split-flow design to<br />

reduce overall size<br />

• Stainless steel<br />

nameplate bracket<br />

and standoff to<br />

prevent corrosion<br />

Options<br />

• Multiple heat exchangers may be incorporated into a single<br />

package for higher process fluid flow rates and capacity<br />

• Package may be designed with connections and space for<br />

additional heat exchanger to handle future expansion<br />

• Conventional on/off solenoid and hand expansion valve<br />

liquid feed assemblies (single or dual)<br />

• Temperature controlled suction pressure regulator<br />

• Seismic design<br />

• Post weld heat treatment