Refurb Projects August 2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

REFURB PROJECTS THE JOURNAL OF REPAIR, MAINTENANCE AND RETROFIT AUGUST <strong>2017</strong>

Contents<br />

Vol. 28 No. 185 AUGUST <strong>2017</strong><br />

2<br />

18<br />

34<br />

13<br />

24<br />

Managing Editor<br />

Tony Prior<br />

Editor<br />

Peter Ashmore<br />

Editorial Assistant<br />

Sue Watson<br />

News Editor<br />

John Grant<br />

Advertising / Marketing<br />

Caroline Warby<br />

Design / Graphics<br />

James Kennett<br />

Kay Miall<br />

Ian Purves<br />

Co-Publishers<br />

Tony Prior and Carole Titmuss<br />

Printed by Manson Group<br />

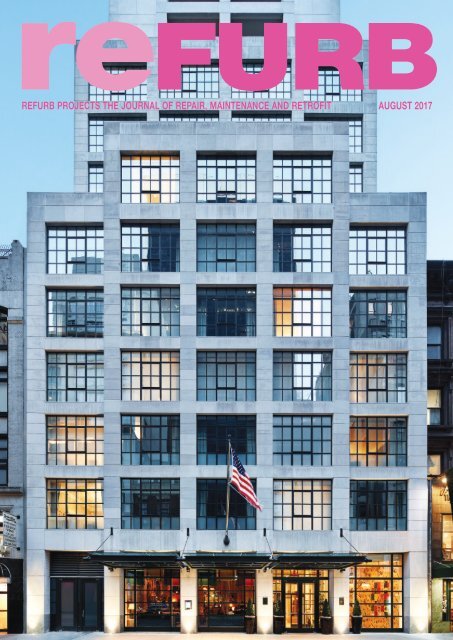

Front Cover<br />

New York City’s newest<br />

boutique luxury hotel makes a<br />

bold statement in upper<br />

midtown Manhattan, thanks in<br />

no small part to the extensive<br />

use of Crittall steel windows,<br />

doors and internal screens and<br />

partitions.<br />

Full story page 14<br />

This journal includes editorial photographs<br />

provided and paid for by suppliers.<br />

<strong>Refurb</strong>ishment <strong>Projects</strong> incorporating<br />

<strong>Refurb</strong>ishment Products is published by<br />

Sheen Publishing Ltd<br />

50 Queens Road,<br />

Buckhurst Hill,<br />

Essex, IG9 5DD, UK<br />

Tel: 020 8504 1661<br />

Fax: 020 8505 4336<br />

Web: www.refurbprojects.com<br />

Email: editor@refurbprojects.com<br />

Twitter: @<strong>Refurb</strong><strong>Projects</strong><br />

<strong>Refurb</strong>ishment <strong>Projects</strong> is available on<br />

subscription annual rate UK £25.<br />

Europe £36 Overseas £40.<br />

Single Copies £3.50 UK £6 Overseas.<br />

ISSN 1475-1135<br />

REFURB PROJECTS CONTENTS<br />

04 Energy Efficiency<br />

Improving comfort for hospital visiting families<br />

06 School Building<br />

Equipping schools for future needs<br />

08 Quiet Please<br />

How the right insulation can prevent noise nuisance<br />

11 Kew Fit-Out<br />

<strong>Refurb</strong> of the National Archives in Kew<br />

12 Social Housing<br />

Wireless emergency lighting in social housing<br />

19 Rooflights<br />

The future is daylight<br />

20 <strong>Refurb</strong><br />

Reinvigoration of 1930’s cinema<br />

21 Project<br />

Redevelopment of Lincoln University<br />

28 Architecturally Ambitious<br />

30 Roofing<br />

A watertight solution<br />

31/36 Secure Times<br />

Supplement on fire, safety and security<br />

REFURBISHMENT PROJECTS, august <strong>2017</strong> 1

PROJECT<br />

Historic London Church Restoration<br />

Focus Consultants has been appointed to project manage a plan for a major restoration at one of London’s<br />

historic churches.<br />

The Parish Church of St<br />

Marylebone, home to the<br />

internationally respected<br />

Healing and Counselling<br />

Centre and innovative NHS<br />

Marylebone Health Centre, has been<br />

awarded initial support of £700,000<br />

from The Heritage Lottery Fund<br />

(HLF) to develop proposals for the<br />

£8.6m restoration of the church and<br />

the renewal of community facilities.<br />

The historical Grade I listed<br />

London landmark has appointed<br />

Focus Consultants as project<br />

directors and project managers.<br />

The scheme is set to include new<br />

building work adjoined to the<br />

current structure to include a<br />

welcome and reception area,<br />

additional exhibition space and a<br />

café for visitors. In addition to this,<br />

extensive repairs and conservation<br />

efforts are expected to take place on<br />

the existing building.<br />

Focus Consultants partner Ellie<br />

Clarke said: “St Marylebone Church<br />

is an important building in London<br />

and the team at Focus is very<br />

pleased to have been appointed to<br />

help with the development in the<br />

next chapter of its history.<br />

“We have significant experience<br />

of working on such projects and are<br />

looking forward to project managing<br />

these inspiring proposals.”<br />

Constructed in 1817, the<br />

Anglican church located on the<br />

Marylebone Road is the third<br />

building used for the parish church<br />

in the borough’s 900-year-old<br />

history. The present church was the<br />

venue for the wedding of Robert<br />

Browning to Elizabeth Barrett and<br />

the baptism of Charles Dickens’ son.<br />

In the 1980s, the Parish took a huge<br />

leap in converting the unusable<br />

crypts of the church to create a<br />

range of complementary facilities<br />

for community uses.<br />

The Rector of St Marylebone, The<br />

Revd Canon Stephen Evans,<br />

commented: “The regeneration will<br />

allow the parish to become a<br />

Community Hub which will tell the<br />

story of St Marylebone "the great<br />

city north of Oxford Street".<br />

The Rector and Parochial Church<br />

Council will be partnering the<br />

Church Army’s Marylebone Project in<br />

providing a Community Café, staffed<br />

by women who would otherwise be<br />

homeless, Vital Regeneration, an<br />

innovative community enterprise<br />

project based in Church Street, one<br />

of Westminster’s most deprived<br />

areas, working with local young<br />

people who are not in employment<br />

or education, the Building Crafts<br />

College in Stratford (which was<br />

founded in and had its premises in<br />

Marylebone for nearly 100 years)<br />

and a host of other individuals and<br />

agencies.<br />

The Changing Lives project will<br />

lead to a more sustainable future for<br />

the church - creating a vibrant,<br />

welcoming hub and enabling visitors<br />

to learn more about the heritage of<br />

the church and the wider<br />

Marylebone area.<br />

The Focus team is currently<br />

working to develop the bid ready for<br />

submission to the HLF in Summer<br />

2018. The project is expected to be<br />

completed in 2020.<br />

Focus, which is based in<br />

Nottingham, has offices in London,<br />

Leicester and Boston in Lincolnshire.<br />

This project is being led by the<br />

London office. The company has,<br />

since 1994, secured for clients more<br />

than £953 million of grants for<br />

projects and businesses across the<br />

UK and delivered more than £1.3<br />

billion worth of projects and<br />

programmes – making it one of the<br />

most successful businesses of its<br />

kind in the country.<br />

It also offers a range of services<br />

to the property and construction<br />

industry, including building<br />

surveying, quantity surveying,<br />

project management, and<br />

sustainable development support.<br />

For more information, visit<br />

www.focus-consultants.co.uk<br />

2 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

N E W S • N E W S • N E W S • N E W S • N E W S • N E W S • N E W S • N E W S<br />

1970’s Office Building brought back to life<br />

Architect Stride Treglown has<br />

transformed a dated 1970s<br />

office building in the<br />

UNESCO World Heritage<br />

Setting of Bath.<br />

Originally built in 1972, the sixstorey<br />

building at 20 Manvers Street<br />

did not meet the demands of<br />

modern occupiers, with plant at the<br />

end of its useful life and dark, dated<br />

interiors.<br />

Despite the constraints of its<br />

setting between two listed buildings,<br />

Stride Treglown has successfully<br />

repositioned the building within the<br />

Bath office market with the scheme<br />

being fully let to DC Thomson and<br />

Chase DeVere prior to completion.<br />

Removed plinth – one metre<br />

high, ground floor slab to back edge<br />

of pavement to remove visual barrier<br />

and improve relationship with street<br />

scene. Planning gain –<br />

improvements mitigated additional<br />

space on roof.<br />

A new glazed entrance has been<br />

introduced at pavement level with<br />

the original plinth being removed to<br />

vastly improved the building’s street<br />

presence. A rooftop glass box,<br />

providing an additional storey, adds<br />

a further contemporary feel to the<br />

scheme whilst giving occupiers<br />

panoramic views over the city.<br />

A spacious reception area<br />

designed using a palette of<br />

high quality materials creates a<br />

sense of arrival. Communal<br />

areas are designed with highquality,<br />

durable finishes and<br />

the provision of shower,<br />

changing and locker facilities<br />

encourages the use of cycling,<br />

running and walking, as well as<br />

the possibility of exercising at<br />

lunchtimes.<br />

The previous substandard<br />

office floors have been<br />

refurbished into highly<br />

desirable modern workspace.<br />

The replacement of the existing<br />

windows with full height, high<br />

performance glazing has<br />

created a light, airy open plan<br />

space. Externally the Bath<br />

stone of the facades has been<br />

repaired, repointed and<br />

cleaned.<br />

The building layout and<br />

services have been designed to<br />

provide maximum flexibility in<br />

occupation whilst the client’s<br />

sustainability brief was<br />

exceeded with the building<br />

achieving a BREEAM rating of<br />

‘Very Good’ and EPC A, superior<br />

to many new buildings.<br />

Web: www.stridetreglown.com<br />

In-Ground (Flip Lid) Units<br />

Retractable Service<br />

supplying electricity, water and<br />

Units data points to public places<br />

Our Pop Up Power<br />

Units have been<br />

specified on:<br />

• Markets<br />

• Heritage<br />

• Town Centres<br />

• Universities<br />

• Recreational Areas<br />

• Sports Stadiums<br />

Power Bollards<br />

Pop Up Power Supplies ® Ltd<br />

Telephone 020 8227 0208<br />

Email info@popuppower.co.uk<br />

Web www.popuppower.co.uk<br />

Pop Up Units<br />

P O W E R W H E N Y O U N E E D I T. . . H I D D E N W H E N Y O U D O N ’ T<br />

REFURBISHMENT PROJECTS, AUGUST <strong>2017</strong> 3

ENERGY EFFICIENCY<br />

Improving comfort for visiting families<br />

Tony Prior looks at how the latest air conditioning technology is being used to keep families in<br />

comfort whilst visiting their children in hospital.<br />

Iget a lot of case studies across<br />

my desk each month and<br />

invariably they are notable and<br />

worthy but this month I really<br />

wanted to focus on one because of<br />

the use of the building itself as well<br />

as the state-of-the-art technology<br />

being used.<br />

Ronald McDonald House<br />

Charities offers vital support to<br />

families with a child in hospital,<br />

providing them with a comfortable<br />

place to stay that’s just a stone’s<br />

throw away from the hospital<br />

building.<br />

The house at Guy’s and St<br />

Thomas’ in London was the very first<br />

facility of this type and since it<br />

opened in 1990 it has helped<br />

thousands of families stay close to<br />

their child during a hospital stay. In<br />

2015 alone 325 families made use of<br />

this vital facility and avoided having<br />

to make long distance journeys from<br />

home or pay for costly hotel rooms.<br />

The success of the house has<br />

expedited the need for the brand<br />

new 59-bedroom building at Evelina<br />

London Children’s Hospital - part of<br />

Guy’s and St Thomas’ NHS<br />

Foundation Trust. The new Lambeth<br />

Road accommodation takes the form<br />

of a four story residential block and<br />

will allow families to prepare their<br />

own meals and get a good night’s<br />

sleep, providing a home away from<br />

home and a degree of stability in an<br />

often distressing and uncertain time.<br />

The 59-bedroom building for<br />

Ronald McDonald House Charities is<br />

utilising a water-based air<br />

conditioning system to provide<br />

comfortable accommodation to<br />

families in their hour of need.<br />

ENERGY EFFICIENT HEATING AND<br />

COOLING<br />

As part of this new build, project<br />

consultants Jones King identified the<br />

need for an energy efficient heating<br />

and cooling system and a regular<br />

supply of fresh air. VRF (Variable<br />

Refrigerant Flow) air conditioning<br />

was initially considered for the<br />

entire building but it was eventually<br />

decided that a Hybrid VRF system<br />

(HVRF) would be the best overall fit<br />

in the accommodation rooms.<br />

The ground floor, designed as a<br />

communal area for resident families,<br />

is served by a City Multi VRF system<br />

and Lossnay Mechanical Ventilation<br />

with Heating Recovery (MVHR) units,<br />

whilst the first, second and third<br />

floors, accommodating individual<br />

residency rooms, benefit from a<br />

HVRF system. In total, 76 family<br />

rooms are served by the Hybrid<br />

solution.<br />

Mitsubishi Electric’s HVRF system<br />

provides comfortable and stable air<br />

temperature control, without using<br />

refrigerant in occupied spaces. A<br />

truly integrated solution, this twopipe<br />

solution offers simultaneous<br />

heating and cooling, flexible controls<br />

and high seasonal efficiency.<br />

The unique Hybrid VRF system<br />

removes the need for leak detection<br />

in occupied spaces because it uses<br />

water to transfer heating and<br />

cooling between a special Hybrid<br />

Branch Controller (HBC)<br />

However, in this case the<br />

developers have also included leak<br />

detection between the outdoor unit<br />

and the HBC, due to the extended<br />

pipe run connecting the two parts<br />

of the system.<br />

On the ground floor, the Lossnay<br />

mechanical ventilation with heat<br />

recovery system provides energy<br />

efficient fresh air ventilation,<br />

improving air quality and comfort<br />

for residents. The Lossnay series of<br />

products use state-of-the-art heat<br />

exchange technology that enable<br />

CO2 reduction and energy saving.<br />

The newly installed Lossnay system<br />

extracts stale air from the Lambeth<br />

Road property, recovering heat<br />

energy through its paper core and<br />

transferring it into the fresh<br />

incoming air.<br />

No modern heating and cooling<br />

solution is complete without the<br />

right controls to ensure that the<br />

system can be monitored and<br />

adjusted with the minimum of fuss.<br />

The new charity house<br />

incorporates a touch screen<br />

centralised controller, capable of<br />

controlling up to 50 units and<br />

providing detailed analysis on energy<br />

consumption. In addition, individual<br />

wall mounted room controllers<br />

enable guest families to alter the<br />

temperature in their rooms.<br />

Sugoi Solutions - a Mitsubishi<br />

Electric accredited installer - carried<br />

out the installation and director Ben<br />

May made sure that everything went<br />

according to plan. He comments,<br />

“During the final design stage of the<br />

project it became apparent to Sugoi<br />

that leak detection would be<br />

required due to the refrigerant pipe<br />

work distances. Leak detection was<br />

an element that hadn’t been<br />

included within the project budget<br />

and therefore created a problem for<br />

all concerned.<br />

“The selection and installation of<br />

the Hybrid VRF system removed the<br />

need for leak detection and kept the<br />

project within original cost plans.”<br />

With the new systems in place<br />

the house is now ready to accept its<br />

first guests, providing them with a<br />

warm and peaceful environment<br />

away from the stresses of the<br />

hospital ward.<br />

Web: www.airconditioning.<br />

mitsubishielectric.co.uk<br />

4 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

0118 918 1400<br />

C h i l l e r s b u i l t f o r y o u<br />

Call or email today for a brochure or a free<br />

no-obligation site survey<br />

www.thermagroup.com/chillers | sales@thermagroup.com<br />

ThermOzone<br />

T h e C o o l i n g S p e c i a l i s t s<br />

Major energy savings<br />

Nationwide service<br />

FREE design service<br />

2- 5 years warranty<br />

Typical installation 30<br />

days min<br />

NuChill<br />

A T h e r m O z o n e P r o d u c t

SCHOOL BUILDING<br />

Equipping schools for the needs of the future<br />

By Craig Smailes, Project Director at Kajima Partnership<br />

Kings Langley School. and below, Goffs School’s main entrance.<br />

The demand for school places is<br />

reaching breaking point and is<br />

threatening to jeopardise<br />

standards of education: official<br />

figures suggest that by 2025, an<br />

extra 750,000 school places will be<br />

needed to keep pace with an<br />

expanding population. Policy makers<br />

are increasingly recognising the need<br />

for innovative solutions to bridge<br />

the gap between supply and demand<br />

and to deliver modern, fit for<br />

purpose, future-proofed schools.<br />

The last six years have seen<br />

significant changes to the ways that<br />

schools are procured, developed,<br />

constructed and maintained.<br />

Launched in 2011 the Conservative<br />

Government’s Priority School<br />

Building Programme (PSBP) was<br />

designed to replace the schools in<br />

the worst state of repair, providing<br />

new, modern premises that are<br />

equipped for the future. Below,<br />

Craig Smailes, Project Director at<br />

Kajima discusses the PSBP and<br />

Kajima’s role in developing seven<br />

schools part of the programme.<br />

A new generation of schools is<br />

needed in order for us to cope with<br />

the increasing pressure on the<br />

education system, which is<br />

hamstrung by the challenge of<br />

reduced funding and a growing<br />

demand for places. Appointed by the<br />

Education Funding Agency (EFA) in<br />

2015, Kajima and investment partner<br />

Interserve were awarded the<br />

contract for the first batch of PSBP<br />

(PF2) schools located in<br />

Hertfordshire, Luton and Reading<br />

and assumed primary responsibility<br />

for the design, construction and<br />

facility management of the schools.<br />

Kajima recently announced the<br />

completion of these seven secondary<br />

schools through a £135 million<br />

construction project, providing over<br />

8000 pupils with purpose built<br />

facilities. The schools are<br />

characterised by innovative and<br />

modern designs, each of which<br />

responded to numerous site<br />

constraints, whilst simultaneously<br />

meeting strict design, environmental<br />

and pedagogical standards within a<br />

challenging project budget. The<br />

seven schools comprise of the Kings<br />

Langley School, Bishop’s Hatfield<br />

Girls’ School in Hatfield, Goffs<br />

School in Cheshunt, Longdean<br />

School in Hemel Hempstead,<br />

Reading Girls’ School, Stopsley High<br />

School in Luton and Westfield<br />

Academy in Watford.<br />

Addressing the individual needs of<br />

the seven schools was tempered with<br />

a rationalised approach to design<br />

around a standardised theme of<br />

orientation, basic layout and building<br />

components, resulting in<br />

predominantly three storey structures<br />

of simple arrangement. The designs<br />

optimise whole life costs and<br />

operational efficiency through passive<br />

environmental solutions, maximising<br />

natural daylight and ventilation and<br />

by utilising the inherent thermal mass<br />

of the structure for night time<br />

cooling and purging. These solutions,<br />

combined with fully integrated<br />

building management system ensure<br />

that energy use is accurately<br />

monitored and consumption of course<br />

is kept to a minimum.<br />

A degree of flexibility has been<br />

integrated into the design to<br />

facilitate changes in room use,<br />

teaching methods and to<br />

accommodate future expansion with<br />

minimal disruption and intervention.<br />

Bespoke elements were introduced<br />

wherever possible into the building<br />

fabric to recognise the importance<br />

of each school’s unique identity and<br />

culture reinforcing its place in the<br />

community. Elements of the school<br />

were designed to encourage out of<br />

core hour’s use by third parties<br />

thereby offering much needed<br />

additional income generation.<br />

The Priority School Building<br />

Programme has been central to<br />

creating schools which are modern,<br />

efficient and future proofed whilst<br />

not sacrificing quality design. The<br />

programme has empowered schools<br />

to respond positively to the unique<br />

challenges they face, through new<br />

buildings that inspire learning and<br />

improve educational outcomes.<br />

Web: www.kajima.co.uk<br />

6 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

Paul Winch Furness. Source D&D London<br />

Traditional style outside.<br />

Exceptional performance inside.<br />

When converting a Listed C19th gym into a restaurant for the King’s Cross<br />

Central Limited Partnership, architect Allies and Morrison found that the<br />

Janisol Arte steel renovation window from Schueco Jansen delivered the<br />

perfect combination of appearance and performance. With narrow face-widths<br />

of just 25 mm or 40 mm, a wide range of opening types, multi-point locking<br />

and U w<br />

values from 0.8 W/m 2 K, Janisol Arte is also soon to be available in<br />

stainless steel and Corten steel. www.schueco.co.uk

INSULATION<br />

Quiet Please<br />

Noise nuisance has become one of the greatest environmental challenges of our time. Here, Anthony Barnett,<br />

Technical Marketing Manager at Armacell, looks at how development of specialist foams and a better<br />

understanding of where noise is generated is helping address the issue.<br />

ArmaComfort AB and ArmaComfort<br />

AB Alu is a new range of acoustic<br />

foams designed specifically by<br />

Armacell for noise control in<br />

plumbing applications.<br />

Much work has been<br />

carried out in the area<br />

of building acoustics<br />

over the last few years<br />

aimed at mitigating sound<br />

transmittance. One of the reasons<br />

for this is that noise at work, in<br />

public buildings or in the home, has<br />

become one of the greatest<br />

environmental issues of our time.<br />

A considerable amount of focus<br />

has always been put into ensuring<br />

that excessive noise from external<br />

sources such as roads, railways and<br />

aeroplanes does not transmit into<br />

the building.<br />

However, what is often<br />

overlooked is the fact that most<br />

noise is generated from inside the<br />

building, from sources such as<br />

plumbing, rainwater, walking on<br />

hard floors and transmittance of<br />

peoples’ voices. It is not uncommon<br />

for measures such as triple glazed<br />

windows to be specified to reduce<br />

external noise and then overlook<br />

these internal sources of noise<br />

disturbance.<br />

INTERNAL NOISE DISTURBANCE<br />

Plumbing and WC systems are a<br />

common source of noise<br />

disturbance, which can be more<br />

noticeable at night when they are<br />

replenishing. We can all testify to<br />

the disruptive nature of these in the<br />

middle of the night. This noise is<br />

transmitted through pipework and is<br />

amplified by boarding. Rushing<br />

water, loose fittings, or rainwater<br />

cascading through gutters and<br />

downpipes can also cause<br />

disturbance for building occupants.<br />

All buildings have the potential<br />

to generate unwanted noise,<br />

although it is a particular concern in<br />

multi occupancy buildings such as<br />

apartments as well as hospitals, care<br />

homes, hotels and schools. In these<br />

situations, because of the number of<br />

people, it can quickly cause a<br />

problem for occupants. In the<br />

majority of these cases, specifying<br />

acoustic insulation foams, which are<br />

relatively inexpensive and easy to<br />

install, can remedy the problem.<br />

The insulation industry has<br />

responded by developing flexible<br />

technical insulation materials that<br />

are designed specifically for<br />

attenuating noise in these situations.<br />

Construction of these acoustic<br />

foams consists of a 2mm thick foil<br />

faced acoustic EPDM-EVA barrier<br />

with 4kg/m2 weight and a 10mm<br />

polyurethane foam layer for<br />

decoupling, which makes it more<br />

effective compared to traditional<br />

products. In comparison to<br />

traditional acoustic insulation<br />

products, tests show that flexible<br />

insulation foams achieve a much<br />

greater reduction in sound level, and<br />

with a thinner wall thickness.<br />

For example, independent tests<br />

by CSTB (Centre Scientifique et<br />

Technique du Bâtiment) confirmed<br />

that these acoustic foams are able<br />

to reduce airborne sound pressure<br />

level of a Geberit roof drainage<br />

system by 16 dB (A) at 2 l/s water<br />

flow. Similar tests on a PVC pipe,<br />

where the vibrations caused by<br />

flowing water are stronger because<br />

of the lighter weight PVC, achieved<br />

a noise reduction of 12 dB (A). The<br />

human ear perceives a reduction of<br />

10 dB (A) as halving the volume. By<br />

choosing the correct flexible<br />

acoustic foam it is possible to<br />

achieve a weighted sound reduction<br />

index (Rw) up to 28 dB when pipe<br />

and elbows are insulated.<br />

Acoustic foam materials such as<br />

this have very good acoustic<br />

damping and acoustic isolation<br />

properties across the frequency<br />

range relevant for building acoustics<br />

– irrespective of whether it is<br />

installed on cast iron or PVC pipes.<br />

They also display very good fire<br />

behaviour, achieving the best fire<br />

class for organic products in the<br />

European SBI test. Contractors will<br />

find that the thinner thicknesses<br />

required to achieve the required<br />

decibel reduction is an advantage<br />

because it makes installation in tight<br />

spaces much easier.<br />

The consequences of not taking<br />

adequate steps to reduce noise<br />

generated from plumbing and<br />

rainwater systems usually only<br />

becomes apparent when the<br />

building is occupied, at which stage<br />

it is much more costly to remedy. It<br />

is therefore essential that noise<br />

abatement measures from external<br />

and internal sources are considered<br />

as early as possible in the design<br />

process.<br />

CONCLUSION<br />

Increased awareness of the need to<br />

address noise pollution in buildings<br />

has resulted in the development of a<br />

number of solutions by the<br />

insulation industry. Where effective<br />

sound insulation is specified it<br />

increases both the comfort for<br />

residents as well as the appeal and<br />

therefore the asset value for the<br />

building owner. Specifiers and<br />

installers that choose flexible<br />

insulation foams specifically<br />

designed for acoustic applications<br />

can demonstrate to their client that<br />

they have considered the needs of<br />

all parties involved.”<br />

The new ArmaComfort AB Alu<br />

acoustic insulation material are<br />

presented on YouTube and at<br />

www.armacell.co.uk<br />

8 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

Spacetherm ® Wallboard mitigates<br />

Thermal Bridging for Grade II building<br />

Spacetherm Wallboard has<br />

been supplied by the A.<br />

Proctor Group to mitigate<br />

thermal bridging for the<br />

historic Electricity House building in<br />

Bristol, recently converted by Crest<br />

Nicolson into a series of luxury flats<br />

ranging from £230,000 to £530,000.<br />

The renowned architect, Sir Giles<br />

Gilbert Scott, the creator of the<br />

iconic Battersea Power Station,<br />

designed the original Grade II listed<br />

building.<br />

Used in this instance as a<br />

Window Reveal Board, Spacetherm<br />

Wallboard was developed to prevent<br />

thermal bridging through a<br />

component or element of a<br />

structure.<br />

Spacetherm Wallboard is a high<br />

performance laminate, which<br />

consists of Spacetherm Aerogel<br />

insulation blanket bonded to<br />

plasterboard, and is ideal for use in<br />

applications where low U-values are<br />

required, and space is at a premium.<br />

Planning requirements stipulated<br />

that the original window opening<br />

aperture sizes had to be maintained,<br />

and to alleviate thermal bridging on<br />

the existing window reveals, a thin<br />

insulation solution was crucial.<br />

Spacetherm offers superior<br />

thermal performance, which enabled<br />

the contractor to insulate the<br />

existing window reveals with just<br />

17.5mm overall thickness, whilst still<br />

providing a high performing thermal<br />

conductivity of only 0.015 W/mK.<br />

Engineered for unsurpassed<br />

thermal performance in spacecritical<br />

applications, Spacetherm<br />

offers exceptional thermal<br />

conductivity, plus breathability allied<br />

to hydrophobic characteristics.<br />

Spacetherm Blanket is an ideal<br />

choice for timber or steel frame<br />

structures and on request can be cut<br />

to a variety of widths and sizes to<br />

suit different applications.<br />

In addition, it can also be<br />

bonded to a wide range of boards<br />

and substrates.<br />

Its flexibility and ease of use,<br />

combined with exceptional thermal<br />

performance qualities, which can be<br />

retained for up to 50 years, make it<br />

a preferred choice for many<br />

architects and specifiers.<br />

For more information and technical details contact our website:<br />

www.proctorgroup.com<br />

The Proctor Group, The Haugh, Blairgowrie, Perthshire PH10 7ER<br />

Tel: 01250 872261 Fax: 01250 872727 Email: contact@proctorgroup.com<br />

REFURBISHMENT PROJECTS, AUGUST <strong>2017</strong> 9

COMMENT<br />

A Self-Builders guide to<br />

Sustainable Property Construction<br />

If the government is to reduce the UK’s greenhouse gas emissions - as outlined in the Climate Change Act - by<br />

at least 80% of 1990 levels by 2050, it’s not only largescale developers that need to remain committed to<br />

progressing energy-smart construction processes - smaller, independent builders can play their part, too, writes<br />

Ben Warren, Managing Director at global building materials manufacturer, Baumit UK.<br />

Athird of the UK’s carbon<br />

emissions originate from<br />

heating draughty buildings,<br />

a fact worth retaining when<br />

designing a property with energy<br />

efficiency as its key factor. Before<br />

any plans are drawn-up, however,<br />

and in lieu of materials being<br />

specified, the first thing a selfbuilder<br />

requires in order to construct<br />

a sustainable home is the right<br />

mind-set. They have to begin the<br />

project intent on creating a property<br />

that will be theirs to reside in for<br />

the rest of their lives. This attitude<br />

of domestic permanence is more<br />

prevalent in Europe than the UK. In<br />

Austria, where Baumit has its HQ,<br />

the sustainable mentality is<br />

ingrained in the culture – from the<br />

food they eat, to the properties they<br />

build. Many Austrian restaurants will<br />

not source food outside a 15-mile<br />

radius, whilst builders on average<br />

construct houses to a 0.2 W/m² U-<br />

value, a higher tightness level than<br />

the country’s 0.4 W/m² U-value<br />

regulation for new homes. Their<br />

housebuilders’ general view seems to<br />

be: ‘I’ll build my property with the<br />

right materials and employ the<br />

correct methods in order to<br />

minimise energy consumption’. By<br />

going beyond the call of duty to<br />

construct homes which excel in<br />

terms of thermal performance,<br />

building regulations regarding<br />

energy-efficiency have little<br />

relevance to the Austrian selfbuilder<br />

- they view sustainability as<br />

a matter of course.<br />

FEAT OF CLAY<br />

Having discussed the mentality -<br />

which materials make for a<br />

successful sustainable build? A<br />

timber-frame shell offers an<br />

established, quick and reasonably<br />

energy-efficient solution, but if we<br />

are to pursue the Austrian model<br />

and construct homes which exceed<br />

thermal regulations, alternative<br />

technology is worth considering.<br />

Porotherm, a clay block walling<br />

system, is a popular infrastructure<br />

choice in homes across Europe. It’s<br />

lightweight in construction and<br />

extremely thermally efficient.<br />

Porotherm only requires one course<br />

of bricks, rather than the two used<br />

in cavity wall construction – the<br />

favoured building method in about<br />

90% of largescale building<br />

developments in the UK.<br />

A combination of high-spec<br />

external wall insulation and<br />

Porothem can produce a spectacular<br />

thermal envelope. At a development<br />

in Norwich, Baumit’s OpenSystem -<br />

a thermally-superior EWI solution<br />

which uses unique open-air<br />

technology to allow walls to breathe<br />

- was used in conjunction with<br />

Porotherm to achieve Passive House<br />

performance: 0.15 W/m², in all 14<br />

homes. Thermal efficiency doesn’t<br />

guarantee a home’s comfort and<br />

wellbeing, however. Applying a<br />

standard Expanded Polystyrene (EPS)<br />

system to clay block walling may<br />

well result in good levels of<br />

airtightness, but it would be akin to<br />

wrapping a house in plastic: walls<br />

wouldn’t breathe and moisture<br />

would build-up as a result. The same<br />

moisture retention would occur with<br />

an acrylic top coat applied to an EPS<br />

system. To prevent such occurrences,<br />

the construction of the wall from<br />

the inside-out needs to be<br />

considered. OpenSystem’s<br />

perforations and the application of a<br />

breathable topcoat such as Nanapor,<br />

a mineralic and highly vapourpermeable<br />

technology found in<br />

Baumit paints and renders, offers<br />

free movement of water vapour<br />

through the wall and exits through<br />

the whole system.<br />

Lime-based products when<br />

applied to walls enhance a building’s<br />

interior sustainability. Lime is a very<br />

adaptable product, offering more<br />

flexibility in material, enabling it to<br />

accommodate structural movement.<br />

It also acts as a moisture buffer.<br />

When working in conjunction with a<br />

clay block walling system, it absorbs<br />

and releases moisture in a regulatory<br />

fashion.<br />

SENSE OF WELLBEING<br />

‘Multi-comfort’ is a phrase currently<br />

applied to sustainable building<br />

which suggests sensory aspects such<br />

as sound, touch, light and colour are<br />

all important factors in increasing<br />

levels of wellbeing as well as<br />

thermal efficiency inside homes. In<br />

terms of paint, colour as well as<br />

consistency is important. As with oil<br />

paints, acrylic coverings can contain<br />

VOCs which emit a noxious vapour<br />

and strong odour that can lead to<br />

headaches and nausea for a<br />

building’s occupants. Baumit<br />

produces a number of mineral-based<br />

paint products that are kinder to the<br />

environment and the senses of those<br />

living within the walls to which it is<br />

applied.<br />

Embarking on a sustainable build<br />

requires a massive investment, and<br />

not just in monetary terms. Every<br />

detail, however small, should be<br />

pored over as if it were the most<br />

important: time should not be<br />

spared on any aspect of the project.<br />

Among the more lateral questions to<br />

consider at a building’s design stage<br />

might be: where does the sun rise<br />

and set? This will determine the<br />

amount of thermal gain through<br />

glass and help regulate comfort<br />

levels in a conservatory, for example,<br />

which can be unbearably hot in<br />

summer if the style or size of panes<br />

is left to chance. It’s a reminder that<br />

a home’s year-round interior<br />

comfort not only depends on its<br />

resistance to cold in winter; its<br />

ability to deflect heat in summer is<br />

just as important, particularly with<br />

climate change’s warming effect so<br />

reflective in current, global<br />

temperatures.<br />

Finally, once plans are drawn-up<br />

and approved and a programme of<br />

building works has been agreed,<br />

there’s only one thing a sustainable<br />

self-builder has in mind - get on<br />

with the job and get it done. Having<br />

highlighted the thermal benefits of<br />

Baumit’s OpenSystem when<br />

combined with a Porotherm clay<br />

block walling, aside from the<br />

comfort and wellbeing it creates, it’s<br />

also a rapid-build alternative to<br />

cavity wall construction methods.<br />

With only one course of bricks<br />

required and the EWI in place, work<br />

can begin on a building’s interior,<br />

which ultimately leads to reduced<br />

on-site working times and energy<br />

consumption. It’s a process that<br />

guarantees a project’s sustainability<br />

from beginning to end.<br />

Web: www.baumit.com<br />

10 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

Overbury completes Kew refurbishment<br />

PROJECTS<br />

National fit out and refurbishment specialist Overbury has completed a £780,000 refurbishment at The<br />

National Archives in Kew, London to create a vibrant and versatile new public space. The 4,700 sq ft project by<br />

Overbury represents the biggest change in the 40-year-old building in a decade.<br />

The refurbishment project,<br />

which started in January, is<br />

one of the ways that The<br />

National Archives is redefining<br />

its public areas and breathing new<br />

life into the space. The National<br />

Archives is a non-ministerial<br />

government department, and is the<br />

official archive of the UK<br />

government. With over 180<br />

kilometres of shelving, it is also<br />

home to some of the nation’s most<br />

iconic documents dating back more<br />

than 1,000 years, including the<br />

Domesday Book, Shakespeare’s will<br />

and tweets from Downing Street.<br />

The refurbishment saw the<br />

upgrade of the building’s<br />

mechanical, electrical and data<br />

infrastructure, as well as the<br />

creation of a double-height<br />

auditorium and new modern, open<br />

plan areas for reading and research.<br />

Transforming any public space in<br />

an occupied building with historic<br />

gravitas is a big task, says Bob<br />

Banister, managing director at<br />

Overbury: “We’re used to working in<br />

sensitive environments, and<br />

throughout the years we’ve worked<br />

within many listed buildings,<br />

however this project posed an<br />

entirely unique challenge. Managing<br />

the potential risk of water, fire or<br />

dust damage and maintaining the<br />

integrity of the documents in the<br />

building were principle concerns, as<br />

was keeping the archives open to the<br />

public with as little fuss as possible.”<br />

▲ The double-height auditorium which is available for provate hire.<br />

The entrance to the renovated Natonal Archives. ▼<br />

HIGHLIGHTS OF THE PROJECT<br />

INCLUDED:<br />

• 2.5 tonnes of data cable was<br />

safely removed and disposed of,<br />

supporting the buildings upgrade to<br />

fibre optic data connectivity<br />

• It took 246 hours to remove 8<br />

tonnes of concrete, which was cut<br />

with a hydraulic, high-pressure<br />

diamond saw<br />

• Building a 250 seat doubleheight<br />

auditorium that The National<br />

Archives will be able rent for private<br />

lectures and workshops, opening up<br />

a new revenue source<br />

• Exposing 2,066 sq ft of the<br />

original coffered concrete ceiling to<br />

highlight its architectural merit<br />

• All construction materials used<br />

throughout the project had to be<br />

non-organic to deter moths<br />

• 95% (7 tonnes) of all<br />

construction waste was recycled.<br />

Another consideration was<br />

making sure that the experience of<br />

visitors was not hampered by the<br />

refurbishment – a total of 2,700<br />

hours were worked after closing<br />

time to ensure minimal disturbance<br />

to visitors and staff. In addition, the<br />

project team made sure that the<br />

reading rooms could be used<br />

throughout which meant changing<br />

the access routes regularly, and in<br />

some weeks daily. Noise, dust and<br />

logistics were all carefully managed<br />

to ensure that the project wasn’t an<br />

inconvenience.<br />

Bob continues: “Accommodating<br />

researchers, students and employees<br />

of The National Archives was a<br />

cornerstone of the project. We<br />

needed to remain as flexible as<br />

possible and make sure that the<br />

public still had a great experience<br />

when visiting the archives. The<br />

overall success of the project is a<br />

real credit to the entire consultant<br />

and subcontractor team and we<br />

hope that The National Archives and<br />

community will enjoy the space for<br />

many years to come.”<br />

Lee Oliver, head of venue<br />

management for the National<br />

Archives, adds: “This major new<br />

space is exciting as it will change<br />

the way visitors engage with The<br />

National Archives’ collections on<br />

site. It allows us to expand our<br />

public programme and increase the<br />

range, capacity and frequency of<br />

public talks, events and other<br />

activities. This will in turn allow us<br />

to serve a wider audience including<br />

more families, students and teachers,<br />

community and arts groups as well<br />

as national and international<br />

researchers.”<br />

Web: www.overbury.com<br />

REFURBISHMENT PROJECTS, AUGUST <strong>2017</strong> 11

SOCIAL HOUSING<br />

Wireless emergency lighting in social housing<br />

When refurbishing social housing developments, one of the highest priorities for building owners and specifiers<br />

alike is the safety of residents. So, when Peabody, one of the largest housing associations in the UK, had the<br />

opportunity to overhaul emergency lighting across its estate of over 17,000 blocks, it turned to Harvard<br />

Technology to provide an innovative lighting solution.<br />

With over 80,000<br />

residents occupying its<br />

extensive estate, the<br />

necessity for effective<br />

and efficient emergency lighting<br />

was fundamental to Peabody’s plans<br />

to revamp its housing blocks. Not<br />

only does the housing provider wish<br />

to protect occupants, they also have<br />

to obey increasing stringent<br />

emergency regulations, which<br />

include the requirement for monthly<br />

and yearly functional and duration<br />

tests compulsory under test<br />

standards. Non-compliance with<br />

such standards would result in<br />

potentially hefty fines and<br />

repercussions for the housing<br />

provider.<br />

The long-awaited revision to the<br />

Emergency Lighting Code of Practice<br />

BS5266:1 2016, issued in May 2016,<br />

has only compounded the necessity<br />

The EyeNut wireless lighting control system.<br />

for sufficient emergency lighting in<br />

social housing blocks and Peabody<br />

were keen to address the issue.<br />

Although the regulations have<br />

been widely accepted as a step in<br />

the right direction for emergency<br />

lighting, especially in large, densely<br />

populated housing blocks, they have<br />

also brought a new unique set of<br />

challenges for both social housing<br />

providers and specifiers. Keen to<br />

address the issue at hand and<br />

improve emergency lighting<br />

significantly, Peabody sought a<br />

solution that would ensure<br />

functional emergency lighting at all<br />

times, whilst also keeping<br />

maintenance and operational costs<br />

to a minimum.<br />

The company understood the<br />

importance of installing an LED<br />

lighting solution that offered<br />

greater efficiency, lower running<br />

costs, and perhaps<br />

most importantly,<br />

improved<br />

illumination when<br />

compared to the<br />

traditional<br />

incandescent<br />

lighting installed<br />

previously. Equally<br />

essential was having<br />

a scalable and<br />

controllable lighting<br />

portfolio across all<br />

its buildings in the<br />

future. With<br />

ambitions to employ<br />

enhanced control<br />

strategies across its<br />

estate including<br />

occupancy detection,<br />

daylight harvesting,<br />

scene setting and time scheduling,<br />

Peabody also needed a system<br />

capable of delivering advanced<br />

control options.<br />

SMART EMERGENCY LIGHTING<br />

Harvard Technology, and fixture<br />

designer and manufacturer Fern<br />

Howard, worked closely with<br />

Peabody and the refurbishment<br />

team to review the social housing<br />

blocks’ requirements and ensure the<br />

best technology fit for the facilities.<br />

The specified solution was an<br />

integrated LED lighting system with<br />

a wireless-enabled emergency<br />

bulkhead fixture, which could link<br />

with the innovative wireless lighting<br />

control system EyeNut.<br />

The system, initially installed in<br />

two housing blocks in phase one of<br />

the project, comprised 80 emergency<br />

bulkhead LED fixtures, with 70% of<br />

these fixtures including an<br />

innovative emergency feature,<br />

enabled through the EyeNut<br />

Combined Emergency driver. The<br />

entire lighting portfolio is controlled<br />

through EyeNut, an intuitive cloudbased,<br />

remote access, wireless<br />

control system for indoor and<br />

outdoor lighting.<br />

Needing to meet emergency<br />

lighting test standards, which<br />

necessitate both monthly and yearly<br />

tests for the full rated duration of<br />

the emergency lights, the retrofit<br />

high-performance driver provided<br />

the perfect solution. An automatic<br />

test feature incorporated within the<br />

driver ensures all tests can be<br />

completed remotely, eliminating the<br />

requirement for monthly site visits.<br />

Results of the automatically<br />

scheduled functional and duration<br />

testing are exported for audit<br />

tracking through the EyeNut Graphic<br />

User Interface (GUI). For Peabody,<br />

this not only ensured complete<br />

compliance with emergency lighting<br />

regulations, but also saved them<br />

substantial time and money on<br />

maintenance.<br />

Connecting thousands of fixtures<br />

across a complex housing estate<br />

using a wired lighting control<br />

solution would prove almost<br />

impossible for Peabody, but wireless<br />

lighting control solutions have<br />

changed that completely. Unlike<br />

wired systems, the cloud-based<br />

EyeNut system is infinitely scalable<br />

and there are no limits to the<br />

number of locations, the number of<br />

gateways, or even the number of<br />

devices, which can be managed<br />

through the central hub.<br />

Using EyeNut, up to 500 EyeNutenabled<br />

devices can be controlled<br />

from a single gateway, via a robust,<br />

secure, ZigBee wireless mesh<br />

network. Facilities Managers can<br />

even manage both indoor and<br />

outdoor lighting fixtures, in car<br />

parks for instance, using the same<br />

system.<br />

For Peabody, this provided untold<br />

advantages. Through the intuitive<br />

EyeNut system, the leading housing<br />

provider can monitor and manage<br />

their entire lighting portfolio with<br />

multi-site control from a single hub.<br />

Accurate real-time energy data,<br />

including kilowatt/hours’ usage and<br />

energy hot spots, is easily accessible<br />

through the system’s GUI allowing<br />

Peabody to implement energy<br />

efficiency strategies and make<br />

further savings. Crucially, from an<br />

emergency lighting standpoint,<br />

maintenance has also been<br />

dramatically improved across the<br />

Peabody estate as any lamp failures<br />

are reported immediately, enabling<br />

necessary repairs to be made.<br />

By installing an LED lighting solution<br />

and wireless lighting controls,<br />

Peabody achieved a marked<br />

reduction in energy consumption<br />

across its two blocks, with energy<br />

savings equating to 44%. Through<br />

enhanced dimming and sensor<br />

control throughout its estate, the<br />

leading housing association is<br />

aiming to reach 50% energy savings.<br />

For more information visit:<br />

www.harvardtechnology.com<br />

12 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

Energy Academy provides a low-tech<br />

lesson for the future<br />

PROJECT<br />

It’s a given that fossil fuels are a finite resource and it’s only a matter of time before they run out. The problem<br />

is buildings use a lot of energy, so planning for the future has never been more important. Faced with this<br />

challenge, the team behind the design of an award-winning building in the Netherlands decided to create a<br />

building which demonstrates innovative design, materials and technologies that will serve as an example at a<br />

time when fossil fuels and other polluting, high consumption solutions are a thing of the past.<br />

Bringing together science,<br />

teaching and business<br />

interests under one roof, the<br />

Energy Academy Europe has<br />

set itself on a path towards a CO2-<br />

neutral university and one that<br />

produce more energy than it<br />

consumes. This exemplary and<br />

inspiring project is without equal<br />

among education-related buildings<br />

in the Netherlands.<br />

AN AMBITIOUS GREEN STRATEGY<br />

BREEAM award-winning and the<br />

most sustainable education-related<br />

building in the Netherlands, the<br />

Energy Academy Europe has been<br />

built on the Zernike Campus<br />

Groningen and provides a meeting<br />

place for students, entrepreneurs<br />

and researchers who work daily on<br />

innovative and sustainable ideas.<br />

Based on the BREEAM guiding<br />

principles, the unique design<br />

demonstrates how a building can<br />

make optimal use of the natural<br />

elements earth, water, air and<br />

sunlight as primary sources of<br />

energy.<br />

Comprising two sections, the<br />

15,000m2 building has research<br />

areas with laboratories and related<br />

offices have been built on the north<br />

side, while the south side houses<br />

workspaces, teaching rooms and a<br />

winter garden which serves as an<br />

important buffer zone, where air can<br />

be acclimatised.<br />

The design team worked along<br />

with these challenging energy<br />

performance standards:<br />

• Zero emissions (after 40 years,<br />

incl construction)<br />

• BREEAM-NL Outstanding<br />

• EPC = 0 or less<br />

• 51 kWh/m2 per year (which is<br />

extremely low for an educationrelated<br />

building)<br />

Earthquake safe (added later on<br />

during the design Phase)<br />

By taking a low-tech approach<br />

to energy, the design of the compact<br />

building makes optimum use of<br />

readily available natural resources,<br />

such as earth, water, air and<br />

sunlight. Energy is generated using<br />

solar panels, a ‘solar chimney’ helps<br />

with natural ventilation, the winter<br />

garden creates a pleasant indoor<br />

climate and geothermal energy is<br />

used to heat and cool the air.<br />

Finally, rainwater is collected for<br />

flushing the toilets and watering the<br />

plants. If natural resources<br />

temporarily prove insufficient, backup<br />

installations have been fitted for<br />

heating, ventilation and lighting<br />

systems.<br />

ROOFTOP ENERGY<br />

In order to achieve these highly<br />

ambitious sustainability objectives,<br />

the building has an unusual design<br />

with a sloping roof facing south for<br />

optimum solar performance. The<br />

roof is fitted with around 1,600<br />

solar panels, arranged in 133<br />

triangles so that natural daylight<br />

can penetrate deeply into the<br />

building, reducing the need for<br />

artificial light.<br />

The solar chimney is a striking<br />

solution for providing natural<br />

ventilation at the right temperature.<br />

The solar chimney on top of the<br />

building is a warm spot that<br />

stimulates the air flow. Air enters<br />

the building underground and flows<br />

slowly through a long system of<br />

ducts (i.e. the 200-meter-longlabyrinth)<br />

under the building, where<br />

it is heated in winter or cooled in<br />

summer with geothermal energy to<br />

ensure the right air temperature.<br />

This natural ventilation saves<br />

approximately 20% in energy. On<br />

warm summer nights there is<br />

additional cooling though a natural<br />

process that requires no energy. Cool<br />

night air flows through the interior<br />

winter garden via the atrium and<br />

through the entire building so that<br />

the next day occupants can start<br />

their day in a cool working<br />

environment.<br />

The building also makes a<br />

sustainable contribution to its<br />

immediate ecological surroundings.<br />

A ‘fauna tower’ and fauna-friendly<br />

green spaces have been designed to<br />

attract bats and swifts, as well as<br />

insects, such as bees and butterflies.<br />

Adjacent verges of wild flowers also<br />

attract insects, which then serve as<br />

food for the birds and bats.<br />

To ensure a pleasant climate the<br />

CO2 levels in every space are<br />

constantly monitored. If they are too<br />

high, the mechanical ventilation will<br />

function as back-up supplying more<br />

fresh air into a space so that<br />

occupants always work in a pleasant<br />

climate.<br />

BELOW GROUND<br />

The heating and cooling comes<br />

mainly from the ground. Two water<br />

reservoirs are located at a depth of<br />

100 metres – one for heating and<br />

one for cooling. In summer the cold<br />

water is pumped up and absorbs<br />

heat in the building. This now<br />

warmed water is then is pumped<br />

back into the second reservoir.<br />

In winter, this process is reversed.<br />

The water is further heated by a<br />

heat pump which efficiently turns<br />

electricity into heat which is<br />

distributed throughout the building<br />

for underfloor heating (60% of the<br />

heating), to heat the airflow through<br />

climate ceilings and to heat tap<br />

water. When needed, cool water can<br />

be used from the nearby pond.<br />

Rainwater that flows down the<br />

sloping roof is filtered and stored in<br />

the reservoir. This water is used to<br />

water the plants in the winter<br />

garden and to flush the toilets.<br />

Fostering innovation in the field<br />

of energy, the Energy Academy<br />

Europe (EAE) brings together<br />

institutes including the owner, The<br />

University of Groningen, Hanze<br />

University of Applied Sciences,<br />

Energy Academy Europe, Energy<br />

Valley and Energy Delta Institute<br />

who will work together towards the<br />

transition to a sustainable energy<br />

future.<br />

Commenting on the benefits of<br />

BREEAM Pieter van Hoesel, Project<br />

Manager, University of Groningen<br />

said: “The BREEAM guidelines help<br />

us to make highly sustainable<br />

buildings, like the Energy Academy<br />

Europe, in an objective and<br />

structural way. The institutes within<br />

the Energy Academy Europe focus<br />

their efforts on the transition to a<br />

reliable, sustainable and affordable<br />

energy future.<br />

“Housing in a BREAAM certified<br />

building supports this important<br />

aim. We want to develop more<br />

highly sustainable buildings in the<br />

future. BREEAM certification helps<br />

to fulfil this policy.”<br />

For more information on BREEAM<br />

visit: www.breeam.com<br />

REFURBISHMENT PROJECTS, AUGUST <strong>2017</strong> 13

PROJECT<br />

New York’s Whitby Hotel<br />

New York City’s newest boutique luxury hotel makes a bold statement in upper midtown Manhattan, thanks<br />

in no small part to the extensive use of Crittall steel windows, doors and internal screens and partitions.<br />

The Whitby is the second in New York opened by Firmdale Hotels<br />

whose owners, Tim and Kit Kemp, have already made a big<br />

impression back across the pond with several stylish and<br />

luxurious properties in central London including Ham Yard and<br />

Soho that also exemplify the use of fenestration by Crittall.<br />

Opened in late February, The Whitby is described as a celebration of<br />

contemporary art and design boasting a stylish restaurant, bar and<br />

conservatory as well as a colourful library, several private event spaces<br />

and a state-of-the-art cinema. Each of the 86 bedrooms has been<br />

individually styled with Kit Kemp’s world-renowned mix of colour,<br />

pattern, texture, and art.<br />

Located on West 56th Street between 5th and 6th Avenues, The<br />

Whitby is just two blocks from Central Park. It is surrounded by worldclass<br />

department stores, luxury designer boutiques and is a short walk<br />

to Broadway.<br />

Its location informed the specific choice of glazing. At Firmdale’s<br />

other NYC hotel, on Crosby Street, W20 steel windows were used. The<br />

Whitby’s position called for even higher acoustic attenuation and so<br />

Crittall MW40 fenestration was selected. These windows can accept up<br />

to 30mm thick glazing providing excellent acoustic as well as thermal<br />

performance.<br />

Nevertheless, the sight lines are virtually the same as with the<br />

Corporate W20, that is to say the slender frames provide for maximum<br />

daylight while ensuring strength and security. All The Whitby’s guest<br />

rooms have floor to ceiling windows as a principal feature. The ground<br />

floor meanwhile (the first floor in American parlance) also features<br />

interior screens and lobby doors by Crittall employing a single-glazed<br />

W20 profile. These are especially versatile for use in association with<br />

door hardware, closers, card entry equipment and so forth, dependent<br />

on their use. Facing the streetscape at ground level are Corporate 20<br />

windows; large full pane windows that are even more robust than<br />

MW40s and which accept up to 28mm glazing.<br />

The Whitby has been designed by New York architectural practice<br />

Stonehill &Taylor, which also designed the Crosby Street Hotel. The<br />

Whitby presents an elegant limestone façade rising 18 storeys and<br />

featuring several balconies and terraces that create a distinctive shape,<br />

stepping back as the building rises from street level.<br />

The building harmonises with the architecture of the immediate<br />

neighbourhood, particularly Fifth Avenue. Says Paul Taylor, lead<br />

architect on the project, and president at Stonehill & Taylor:<br />

“The Crittall steel windows are imbued with old world<br />

craftsmanship and have the narrow sightlines that architects wish for.”<br />

Contractors for the project were Flintlock Construction Services<br />

LLC.<br />

Web: www.crittall-windows.co.uk<br />

14 AUGUST <strong>2017</strong>, REFURBISHMENT PROJECTS

COMMENT<br />

The Green Eyed Monster<br />

by Paul Trace of Lumen Rooflights<br />

Open any trade magazine or visit supplier websites and you will find numerous articles and products offering exceptional ‘green’ credentials. Nowhere is this<br />

more prevalent than in the glass and glazing industry as each manufacturer attempts to outperform the next by offering astounding figures for thermal<br />

performance. What is surprising however, is the regular use of terms such as ‘environmentally friendly’ or ‘green’ simply because a product offers a low u-<br />

value. As more buildings are constructed to Passivhaus standards there appears to be a blurring of the lines between what is good for the environment and<br />

what is thermally efficient. Whilst there is no doubt that increased thermal efficiency contributes to a reduction in burning of fossil fuels; this alone should not be<br />

the deciding factor in whether a product is actually environmentally friendly. The majority of flat rooflights on the market today are manufactured from either PVC<br />

or aluminium and both of these require an exceptional amount of energy to produce and extract a lot of resources from the planet without putting anything back.<br />

While most companies will adopt<br />

some sort of environmental policy,<br />

telling customers that their products<br />

use a percentage of recycled<br />

material, this is more likely to be<br />

about cost rather than any real<br />

environmental intentions. After all<br />

recyclables are recycled because it is<br />

the cheapest available option and it<br />

makes more financial sense to do so<br />

rather than to send them to a<br />

landfill – with Landfill tax currently<br />

over £84 per tonne, plus the gate<br />

fee on top.<br />

It stands to reason that<br />

consuming vast amounts of natural<br />

resources to produce the raw<br />

materials of a product negates the<br />

environmental benefits further down<br />

the chain, regardless of what the<br />

product becomes. This has often<br />

been overlooked in the rooflight<br />

industry because of the low<br />

maintenance and long life that<br />

aluminium and PVC can offer the<br />

end user. For decades these two<br />

materials have been unrivalled and<br />

it was widely accepted that flat<br />

rooflights should be manufactured<br />

from one of these materials; until<br />

now.<br />

There is now a real alternative in<br />

the flat rooflight market that not<br />

only offers exceptional thermal<br />

performance, but is also a genuine<br />

environmentally friendly product in<br />

every sense. The Lumen Planus is<br />

manufactured in the UK using<br />

Accoya® wood which is a material<br />

that has been thoroughly tested for<br />

dimensional stability, durability,<br />

paint retention and in-ground<br />

conditions to ensure optimal<br />

performance. It offers a new<br />

standard in high performance,<br />

sustainable and low maintenance<br />

applications.<br />

In addition to the outstanding<br />

performance, Accoya® wood is one<br />

of the very few building products to<br />

have acquired Cradle to CradleSM<br />

Certification on the elusive Gold<br />

level. Cradle to Cradle (C2C) provides<br />

a means to tangibly and credibly<br />

measure achievement in<br />

environmentally-intelligent design<br />

including the use of environmentally<br />

safe and healthy materials and<br />

instituting strategies for social<br />

responsibility.<br />

A carbon footprint assessment<br />

was executed for Accoya® wood by<br />

Verco in line with the World<br />

Business Council for Sustainable<br />

Development and World Resources<br />

Institute’s Greenhouse Gas Reporting<br />

Protocol best practice guidelines,<br />

based on a cradle to factory gate<br />

scenario. This includes sourcing,<br />

harvesting and processing of the<br />

input timber, as well as all energy<br />

and raw material consumption and<br />

waste production. The results are<br />

shown in the graph below.<br />

GREENHOUSE GAS EMISSIONS (KG C02 EQ PER M3 OF MATERIAL)<br />

Today there are some exceptional<br />

flat rooflight products available for<br />

specifiers to choose from. It is a fact<br />

that both aluminium and PVC are<br />

very good at providing superb<br />

thermal performance and that<br />

modern technology has reduced the<br />

end of life environmental impact.<br />

That said, if your project requires a<br />

truly environmentally friendly<br />

product then Accoya® provides<br />

compelling environmental<br />

advantages in every stage of the life<br />

cycle.<br />

For more information on the right<br />

products for your project<br />

information contact Lumen<br />

Rooflight on 0330 300 1090,<br />

email info@lumenrooflight.co.uk<br />

or visit www.lumenrooflight.com<br />

REFURBISHMENT PROJECTS, AUGUST <strong>2017</strong> 15

CONSERVATION<br />

Historic buildings could qualify for redevelopment grants<br />

Funding experts at Focus Consultants are urging the owners of historic buildings to consider following in the<br />

footsteps of Bridgford Hall which has become the first completed project in the East Midlands to benefit from<br />

a Heritage Enterprise Grant.<br />

Focus supported Rushcliffe<br />

Borough Council in its<br />

successful bid for a £1.5<br />

million Heritage Enterprise<br />

Grant from the Heritage Lottery<br />

Fund (HLF) to redevelop the hall in<br />

West Bridgford near Nottingham.<br />

The Grade II listed building has<br />

recently reopened as a luxury<br />

aparthotel and civil wedding<br />

ceremony venue, following a £2.3<br />

million redevelopment – making it<br />

the first Heritage Enterprise project<br />

to be completed in the East<br />

Midlands.<br />

“The Bridgford Hall project is<br />

paving the way in the East Midlands<br />

by illustrating how Heritage<br />

Enterprise Grants are helping to<br />

breathe new life into old buildings,”<br />

said Focus partner Heather<br />

Frecklington. “The team at Focus has<br />

been involved in the project at<br />

Bridgford Hall from the early days<br />

and it’s always a proud moment<br />

when a scheme is successfully<br />

completed.<br />

“This renovation aptly illustrates<br />

how a Heritage Enterprise grant can<br />

open a new chapter in the life of a<br />

building. We’re very proud to have<br />

helped to secure the Heritage<br />

Enterprise grant for his work – the<br />

first to be completed in the East<br />

Midlands. Since helping to secure<br />

the Heritage Enterprise grant for<br />

Bridgford Hall we’ve been involved<br />

in supporting other organisations<br />

across the UK with their bids and we<br />

are looking forward to seeing other<br />

schemes come to fruition in the<br />

future.<br />

“We’d be<br />

delighted to offer<br />

funding advice to<br />

any organisations<br />

that are thinking of<br />

similar projects.”<br />

For many<br />

property owners,<br />

owning a historic<br />

building requires a<br />

great deal of<br />

investment, firstly<br />

potentially restoring<br />

those buildings and<br />

secondly keeping<br />

them in good repair.<br />

The cost of repairing<br />

a neglected historic building is often<br />

so high that restoration is not<br />

commercially viable. The aim of the<br />

HLF’s Heritage Enterprise programme<br />

is to make such schemes possible by<br />

funding some of the repair costs<br />

with grants of £100,000 to £5<br />

million available.<br />

Since supporting Rushcliffe<br />

Borough Council with its Heritage<br />

Enterprise Grant bid, Focus has<br />

helped a number of other<br />

organisations with their applications<br />

including the University of<br />

Northampton Students’ Union, for<br />

its Engine Shed project, and<br />

Waltham Abbey Royal Gunpowder<br />

Mills Foundation Trust on proposals<br />

to bring many of the currently<br />

unused and listed buildings at the<br />

Royal Gunpowder Mills site at<br />

UK System Scaffold Hire shutes into history<br />

Waltham Abbey in Essex back into<br />

use.<br />

“Hundreds of neglected historic<br />

buildings across the UK could qualify<br />

for special grants to help bring them<br />

back into life,” added Heather.<br />

“Funding experts at Focus have<br />

successfully secured millions of<br />

pounds in various grants and funds<br />

for projects over the past 23 years,<br />

and we’d be very pleased to talk to<br />

organisations that feel they could<br />

benefit from Heritage Enterprise<br />

Grants.”<br />

Nottingham-based Focus, which<br />

also has branches in London,<br />

Leicester, and Boston in Lincolnshire,<br />

specialises in funding and economic<br />

development including area<br />

regeneration strategies, funding<br />

applications, economic impact<br />

appraisals, business plans, and<br />

research and evaluation. Since 1994<br />

Focus has also secured for clients<br />

more than £953 million of grants for<br />

projects and businesses across the<br />

UK and delivered more than £1.3<br />

billion worth of projects and<br />

programmes – making it one of the<br />

most successful businesses of its<br />

kind in the country.<br />

It also offers a range of services<br />

to the property and construction<br />

industry, including building<br />

surveying, quantity surveying,<br />

project management, and<br />

sustainable development support.<br />

Web: www.focus-consultants.co.uk<br />

UK SYSTEM SCAFFOLD HIRE specialise in providing temporary public access staircases –<br />