Download - MeWa Recycling Maschinen und Anlagenbau GmbH

Download - MeWa Recycling Maschinen und Anlagenbau GmbH

Download - MeWa Recycling Maschinen und Anlagenbau GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

Metal recycling<br />

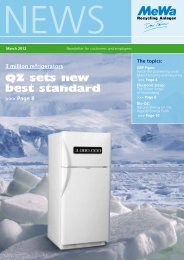

Stripped down twice:<br />

One QZ<br />

with two jobs<br />

It‘s its versatility that makes it so valuable. In Portugal,<br />

the <strong>MeWa</strong> Querstromzerspaner QZ now also strips<br />

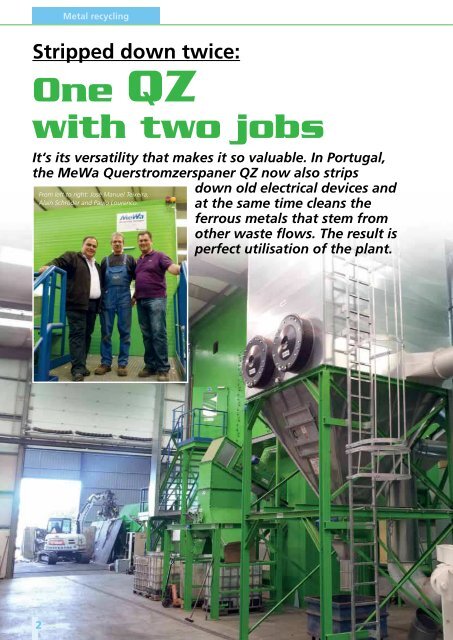

From left to right: José Manuel Teixeira,<br />

Alain Schröder and Paulo Lourenco.<br />

down old electrical devices and<br />

at the same time cleans the<br />

ferrous metals that stem from<br />

other waste flows. The result is<br />

perfect utilisation of the plant.<br />

The Portuguese company Transucatas<br />

has its origins in metal recycling,<br />

with several sites across Portugal.<br />

With its expansion in recent years, plants<br />

for recycling tyres and various industrial waste<br />

products have also been added. Transucatas<br />

also uses turn-key <strong>MeWa</strong> plants with<br />

pre-granulation, granulation and separating<br />

technology to produce homogeneous<br />

substitute fuels in defined grain sizes from<br />

mixed industrial waste.<br />

In these plant types, a magnetic separator<br />

removes the ferrous metals from<br />

the material flow after pre-granulation.<br />

However, there are often still plastic films<br />

and textiles attached to the sharp-edged<br />

wires and metal profiles. This significantly<br />

impairs the intrinsic value of the metal<br />

fraction. Further processing of the metals<br />

is therefore recommended.<br />

Transucatas has now implemented<br />

a solution in Maia, near Porto, which is<br />

trend-setting in two ways: Recently, the<br />

company also started recycling electronic<br />

scrap and in doing so drafted a plant plan<br />

together with <strong>MeWa</strong> and the Portuguese<br />

<strong>MeWa</strong> sales partner Gruman, which can<br />

strip down electronic scrap and also separate<br />

metals from different origins.<br />

With the <strong>MeWa</strong> QZ 2000 HD Querstromzerspaner,<br />

it is possible to meet all<br />

the requirements of the European WEEE<br />

directive regarding environmentally friendly<br />

recycling of waste electrical and electronic<br />

equipment and, at the same time,<br />

guarantee highly economical utilisation<br />

of the plant.<br />

Chains instead of knives<br />

This is primarily due to the recycling<br />

principle of the patented <strong>MeWa</strong> machine.<br />

In contrast to shredding plants, which<br />

are operated in Portugal too by competitor<br />

companies, the QZ Querstromzerspaner<br />

does not rely on cutting tools. Instead,<br />

chains, which are fitted to the floor<br />

of a tank, accelerate the material at high<br />

speeds. The reciprocal physical stress and<br />

the impact against the drum wall cause<br />

the material to break down. And it does<br />

this in a gentle manner. Large parts break<br />

up, but small parts exit the outlet opening<br />

of the machine intact.<br />

Looks like plastic waste... ...but is 70% ferrous metal.<br />

Metal recycling<br />

This principle is particularly beneficial<br />

for electrical equipment. Environmentally<br />

harmful parts, such as batteries and capacitors,<br />

remain <strong>und</strong>amaged. At the same<br />

time, plastic housings, transformers, aluminium<br />

components, computer PCBs and<br />

other components are separated. The metals<br />

incorporated in shafts and electric motors,<br />

for example, present no obstacle to<br />

the Querstromzerspaner. The wear costs<br />

are minimal compared to those of shredder<br />

plants, and contamination due to destroyed<br />

capacitors and batteries is not a<br />

problem.<br />

The plant in Maia takes full advantage<br />

of these benefits. In addition to electrical<br />

scrap, metal separator fractions can be dispatched<br />

in the QZ. Plastics and textiles separate<br />

from the metals and lie freely on the<br />

evacuation conveyor ready for subsequent<br />

sorting. After the Querstromzerspaner, the<br />

material runs through various classification<br />

and separating technologies as well as Fe/<br />

NFe separation. A downstream sorting cabin<br />

is used for quality assurance. At the<br />

end, the fractions are ready for sale in maximum<br />

purities. Depending on the material<br />

composition, throughputs of four to six<br />

tons per hour can be achieved.<br />

Satisfied partners<br />

The Transucatas partners, José Manuel<br />

Teixeira and Carlos Teixeira, are impressed<br />

with the investment: „With the versatility<br />

of the <strong>MeWa</strong> QZ, we will later be able<br />

to run the plant in three-shift operation.<br />

After the successful test phase, we can<br />

promise ourselves the best output results<br />

and high profitability.“ ■<br />

3