Ultrasonic Chemical Reactors

Ultrasonic Chemical Reactors

Ultrasonic Chemical Reactors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Ultrasonic</strong> <strong>Chemical</strong> <strong>Reactors</strong><br />

<strong>Ultrasonic</strong> <strong>Chemical</strong> <strong>Reactors</strong><br />

Igor I. Savin, Sergey N. Tsyganok, Andrey N. Lebedev, Student member, IEEE, Dmitry V. Genne,<br />

Student Member, IEEE, Elena S. Smerdina, Student Member, IEEE<br />

Biysk Technological Institute (branch) of Altay State Technical University after I.I. Polzunov, Biysk,<br />

Russia<br />

Abstract— The article is devoted to different types ultrasonic<br />

chemical reactors for laboratory and industrial using.<br />

Experimental results are given.<br />

Index Terms—ultrasonic, sonochemistry, ultrasonic reactor,<br />

cavitations.<br />

I.INTRODUCTION<br />

The present-day industrial enterprises continuously<br />

increase tempo of industrial production. Usually, for this<br />

purpose it is necessary to modernize or completely to change<br />

the process flowsheet. It is widely known, that using of high<br />

intensity ultrasonic oscillations allows intensifying many<br />

technological processes, such as impregnating of composite<br />

materials, drilling of brittle and extra-hard materials,<br />

dissolution, extraction, emulsification, washing and clearing.<br />

[1,2]<br />

A plenty of researches being carried out at present moment<br />

specify that speed of passing the majority of chemical<br />

reactions increases under action of an acoustic field and that<br />

some reactions do not pass without action of ultrasonic<br />

oscillations [3-5].<br />

Cavitation is considered as a major factor which influences<br />

on reaction speed. The temperature inside cavitation bubbles<br />

while collapsing attains approximately 5000 K, pressure<br />

attains approximately 100 MPa and velocity of a collapse<br />

attains about 400 km/h. At such bubble collapsing the<br />

powerful shockwave [3] is created.<br />

Providing of similar requirements is possible at intensity of<br />

ultrasonic action from 100 W/cm2. Since the acoustic<br />

oscillations of audio frequency and high intensity providing is<br />

rather difficult, using of ultrasonic frequency oscillations<br />

(above 20 kHz) obtains wide extending.<br />

For implementation of such technological processes there<br />

is a special class of technological apparatus called ultrasonic<br />

reactors; and for providing researches of reaction passing<br />

under action of acoustic oscillations there is a science called<br />

acoustic chemistry.<br />

II.ULTRASONIC REACTORS FOR LABORATORY<br />

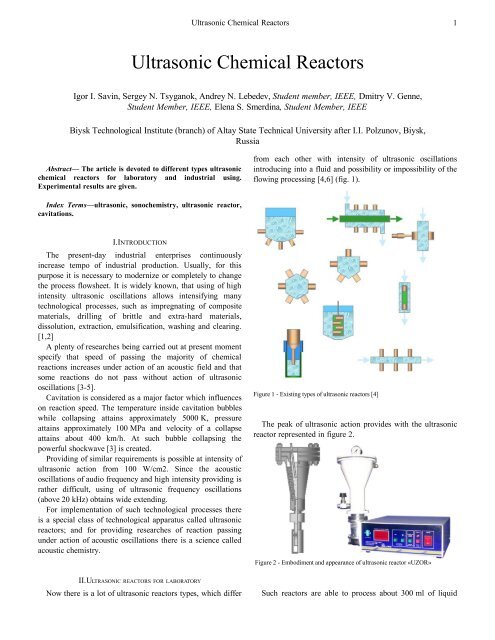

Now there is a lot of ultrasonic reactors types, which differ<br />

from each other with intensity of ultrasonic oscillations<br />

introducing into a fluid and possibility or impossibility of the<br />

flowing processing [4,6] (fig. 1).<br />

Figure 1 - Existing types of ultrasonic reactors [4]<br />

The peak of ultrasonic action provides with the ultrasonic<br />

reactor represented in figure 2.<br />

Figure 2 - Embodiment and appearance of ultrasonic reactor «UZOR»<br />

Such reactors are able to process about 300 ml of liquid<br />

1

<strong>Ultrasonic</strong> <strong>Chemical</strong> <strong>Reactors</strong><br />

with intensity up to 200 W/cm 2 .<br />

In cases when for experimental purpose it is enough to<br />

process several tens of milliliters the ultrasonic apparatus for<br />

processing liquid in test tubes is used. Distinguishing feature<br />

of such apparatus is presence of two replaceable working<br />

tools for a ultrasonic oscillatory system. One working tool is<br />

intended for direct input of oscillations in the test tube, and<br />

another one is for noncontact processing of liquids. The<br />

working tool has shape of the hollow cylinder in which test<br />

tube with reagents is placed, in space between walls of test<br />

tube and the working tool there is a liquid through which<br />

transmission of oscillations to test tube walls is carried out<br />

(figure 3).<br />

Figure 3 - The ultrasonic reactor for processing liquids in test tubes<br />

Due to small volumes of the processing liquid it is possible<br />

to achieve the intensity of ultrasonic action about 300 W/cm 2 .<br />

III.ULTRASONIC REACTORS FOR INDUSTRIAL APPLICATION<br />

The major drawback of the foresaid reactors is the small<br />

processing volume per unit of time. For laboratory it is not a<br />

major drawback, but for the industrial applications the other<br />

embodiment of the reactor is required. In this case, the<br />

optimal solution is the flowing processing of liquid.<br />

The laboratory of ultrasonic processes and apparatus<br />

designs a lot of apparatus for the flowing processing of liquid<br />

mediums with power from 400 VA up to 6000 VA (fig. 4).<br />

Distinguishing feature of apparatus with power more than<br />

2000 VA is use of the working tool with the extended<br />

radiating surface. The working tool is the series joined<br />

several step-radial concentrators; such form of the working<br />

tool allows to extend the radiating surface in several times in<br />

comparison with classical single- and two-half-wave<br />

oscillatory systems. (fig. 5)<br />

Figure 5 - The ultrasonic oscillatory system in technological volume<br />

a) b) c)<br />

d) e) f)<br />

a) ultrasonic apparatus «MUSA» (400 VA), b) ultrasonic apparatus «Potok» (630 VA), c) ultrasonic apparatus «Crystal - 2» (1000 VA), d) ultrasonic apparatus<br />

«Potok-3» (1000 VA), e) ultrasonic apparatus «Bulava», model 1000-3 (3000 VA), f) ultrasonic apparatus «Bulava», model 1000-6 (6000 VA)<br />

Figure 4 - <strong>Ultrasonic</strong> reactors of various powers<br />

2

<strong>Ultrasonic</strong> <strong>Chemical</strong> <strong>Reactors</strong><br />

For providing super intensive action on liquid mediums, it<br />

is promising to design the embodiment of ultrasonic reactor<br />

for the flowing processing in form of truncated dodecahedron<br />

with piezoceramic assemblies on its hexangular sides. Using<br />

of such radiator embodiment will allow achieving the<br />

intensity of 500 W/cm 2 [7] (fig. 6).<br />

1 - technological volume, 2 - ultrasonic transducer, 3 - the channel for delivery of<br />

initial components and evacuation of reaction product, 4 - the piezoelectric<br />

elements, 5 - reflective frequency- dropping patches.<br />

Figure 6 - the <strong>Ultrasonic</strong> reactor of ultrahigh intensity<br />

IV.EXPERIMENTAL RESEARCHES<br />

The experimental researches on processing milk and<br />

sewage with ultrasonic oscillations of high intensity have<br />

been carried out using apparatuses designed.<br />

By means of apparatus «MUSA» examination of influence<br />

the ultrasonic oscillations on taste property, biological<br />

parameters of milk and its storage stability was carried out.<br />

Results of test have shown that the radiated milk is kept<br />

longer than not processed one.<br />

Thus the amount of bacteria in milk drops from initial<br />

15000 unities to 5000 in the end of the first processing cycle<br />

and to 1000 in the end of the third cycle (table 1).<br />

TABLE 1<br />

RESULTS OF ULTRASONIC MILK PROCESSING<br />

Experiment amount of<br />

bacteria<br />

Milk 15000<br />

Milk first cycle 2 minutes 10500<br />

Milk first cycle 5 minutes 7000<br />

Milk first cycle 10 minutes 5000<br />

Milk second cycle 2,5 minutes 1000<br />

Milk second cycle 7,5 minutes 6500<br />

Milk third cycle 2,5 minutes 2000<br />

Milk third cycle 7,5 minutes 1500<br />

Milk third cycle 10 minutes 1000<br />

Also it is determined that decrease in processing velocity<br />

from 1 l/min to 0,5 l/min allows to essentially reduce quantity<br />

of milk operation cycles to 1-2 with amount of bacteria in<br />

milk 1000-2000 unities without losses of taste properties.<br />

Changing in the amount of bacteria in milk on the second<br />

cycle of processing are related with variation of productivity<br />

from 1 l/min to 0,5 l/min.<br />

The inoculation of milk was made with Kessler and<br />

Kmafanm mediums, produced by Obninsk-city on GOST<br />

procedures.<br />

The sewage processing was provided with apparatus<br />

«Bulava», model 1000-3 (table 2), the represented results<br />

show efficiency of ultrasonic oscillations using for water<br />

purification.<br />

TABLE 2<br />

RESULTS OF SEWAGE PROCESSING WITH ULTRASONIC OSCILLATIONS OF HIGH INTENSITY<br />

Water parameters input output<br />

рН 7,6 7,7<br />

UEP 0,102 0,0577<br />

Suspended matter >2000 122,2<br />

Solid residue 612,2 305,6<br />

BPK5 276 15,6<br />

Permanganate oxidability 191,8 18,8<br />

Ammonium 46,5 19,5<br />

Phosphates 0,95 0,2<br />

Sulfates 28,9 10,4<br />

APAV 3,21 2,23<br />

Nitrites, nitrates, clarity below the rate<br />

V.CONCLUSION<br />

The represented embodiments allow satisfying the<br />

requirements both the industrial enterprises and the research<br />

organizations. The presented experimental results confirm a<br />

possibility and promising of using the ultrasonic technologies<br />

both in industrial plants and laboratory researches.<br />

REFERENCES<br />

[1] Khmelev V.N., Popova О.V. Multiurpose ultrasonic apparatuses and their<br />

application in conditions of small manufactures, agricultural and<br />

housekeeping: the scientific monography / AltGTU. - Barnaul: AltGTU<br />

[2] Khmelev V.N., Barsukov R.V., Tsyganok S.N. "Drylling of brittle and<br />

hard materials". Barnaul: AltGTU, 1999<br />

[3] Kenneth S. Suslick. "Sonochemistry" Kirk-Othmer Encyclodpedia of<br />

<strong>Chemical</strong> Technology, Fourth Edition, vol. 26; John Willey&Sons, Inc.:<br />

New York, 1998, pp.516-541<br />

[4] Design of Ultrasound <strong>Reactors</strong>: Choice of Working Conditions and Sound<br />

Fields for Precipitation, Particle Fragmentation and Organometal<br />

Reactions, Christian Horst, Yuh Shuh Chen, Jost Kruger, Ulrich<br />

Kunz,Andreas Rosenplnter and Ulrich Hoffmann, Plenary Lecture.<br />

[5] M.G.Sulman Influence of ultrasound on catalysis processes, "Uspehi<br />

Himii", 69(2), 2000, pp.178-191.<br />

[6] C.Horst, A.Lindermeir, U.Hoffman. Design of ultrasound reactors for<br />

techical scale organometallic and electrochemical synthesis, TU Hamburg-<br />

Harburg Reports on Sanitary Engineering 35, 2002.<br />

[7] <strong>Ultrasonic</strong> <strong>Chemical</strong> Reactor, claim of Russian patent №2007101744/15<br />

by 29.11.2006<br />

Igor I. Savin, Ph.D (ultrasound) —<br />

principal engineer of MSIA<br />

department of Biysk technological<br />

institute. Laureate of Russian<br />

Government premium for<br />

achievements in science and<br />

engineering. Area of scientific<br />

interests is application of ultrasound<br />

for an intensification of<br />

technological processes. IEEE<br />

student member since 2001, IEEE<br />

member since 2006.<br />

3

<strong>Ultrasonic</strong> <strong>Chemical</strong> <strong>Reactors</strong><br />

Sergey N. Tsyganok was born in<br />

Biysk, Russia, 1975. Now he is<br />

Ph.D (Machinery), he received<br />

degree on information measuring<br />

engineering and technologies from<br />

Altay State Technical University,<br />

key specialist of electronics.<br />

Laureate of Russian Government<br />

premium for achievements in science<br />

and engineering. His main research<br />

interest are development of high<br />

-effective multifunctional oscillators<br />

for ultrasonic technological devices.<br />

Andrey N. Lebedev (S'03) was<br />

born in Kiselevsk, Russia in 1983.<br />

He received degree on information<br />

measuring engineering and<br />

technologies from Biysk<br />

Technological Institute of AltSTU.<br />

He is post-graduate student of Biysk<br />

Technological Institute.. His<br />

research interests is finite-element<br />

modeling.<br />

Genne V. Dmitry (S’06) was born<br />

in Biysk, Russia in 1982. He<br />

received degree on information<br />

measuring engineering and<br />

technologies from Biysk<br />

Technological Institute of AltSTU.<br />

He is post-graduate student of Biysk<br />

Technological Institute. His main<br />

research interest are development of<br />

high -power electronic generators for<br />

ultrasonic technological devices.<br />

Elena S. Smerdina (S’06) was born in<br />

Pobrade, Lithuania, 1983. She received<br />

degree on Information science and<br />

measuring engineering in Altay State<br />

Technical University. Member of "Woman<br />

in Engineering" IEEE work group since<br />

2006.<br />

4