MEM39

Marine Engineers Messenger, Volume 2, Issue 39

Marine Engineers Messenger, Volume 2, Issue 39

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGINE MONITORING<br />

CMAXS FOR MOL NEWBUILDS<br />

Daihatsu Diesel’s CMAXS LC-A engine monitoring solution will be supplied to two newbuilds under<br />

construction for Mitsui O.S.K. Lines (MOL).<br />

The Japanese enginebuilder introduced the cloud-based engine condition monitoring (ECM) and diagnostic<br />

solution to engender safer vessel operation and reduce in life-cycle costs.<br />

The CMAXS, launched at Norshipping 2017, provides a common platform for the centralised monitoring and<br />

management of NK-CMAXS alliance member’s main engines, auxiliary engines and auxiliary devices. This new<br />

service is offered through ClassNK Consulting Services, acting as distributors and managers of the service<br />

platform.<br />

The CMAXS LC-A’s key support functions stem from its ability to perform engine condition diagnosis based<br />

on data obtained from various sensors, and provide preventive maintenance alerts to correct incipient failures<br />

before they develop. This contributes to the avoidance of downtime from possible engine failure. To<br />

supplement and assist the customer’s onboard maintenance, a trouble-shooting function has also been<br />

installed, which displays the part that is most likely the cause of a fault and then links organically with our<br />

maintenance manuals, service parts lists and the service information screen.<br />

A CMAXS Web Service provides a dedicated website for centrally managing the CMAXS–contracted vessels.<br />

Automatic sharing of engine data is<br />

possible via ship-to-land<br />

communication, providing fleet<br />

overviews and targeted vessel<br />

monitoring of engines and auxiliary<br />

devices from any location.<br />

SAVE MILLIONS IN DRYDOCK<br />

COSTS AND OFF-HIRE TIME<br />

HVAC<br />

AERIUS CHILLS FOR CRYSTAL<br />

The MV Werften shipyard has<br />

contracted Aerius Marine to provide<br />

the air conditioning systems for three<br />

Endeavor class mega-yachts.<br />

The ships are being built for Genting<br />

Hong Kong’s Crystal Cruises brand,<br />

with delivery of the first of class,<br />

Crystal Endeavor, planned for 2019.<br />

The three luxury cruise ships have an<br />

ice class of PC6 and permit tours from<br />

the tropics to the polar regions.<br />

“We’re immensely proud to be<br />

contributing to these ships and<br />

bringing our experience that is based<br />

on the design and construction of air<br />

conditioning systems on more than 50<br />

complex passenger ships to MV<br />

Werften,” says Thomas Arlit, CEO of<br />

Aerius Marine. “And we’re delighted<br />

to be part of, that passenger ships are<br />

being built at the MV Werften<br />

locations again.”<br />

“Already during basic design for<br />

the Endeavor class, the cooperation<br />

between the shipyard and our team<br />

worked very well,” emphasises Stefan<br />

Schleper, Director Passenger Ship<br />

Aerius Marine and added that “in<br />

addition to competence on both sides,<br />

an important factor for the successful<br />

completion of the ships is the ability<br />

to speak one language and, despite an<br />

international orientation, also remain<br />

connected to the region. “<br />

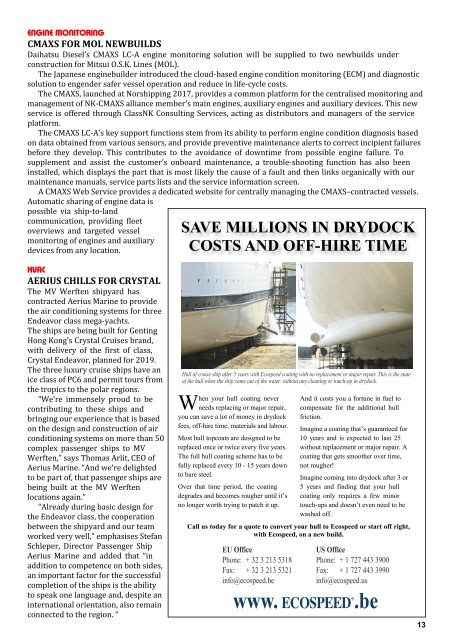

Hull of cruise ship after 5 years with Ecospeed coating with no replacement or major repair. This is the state<br />

of the hull when the ship came out of the water, without any cleaning or touch-up in drydock.<br />

When your hull coating never<br />

needs replacing or major repair,<br />

you can save a lot of money in drydock<br />

fees, off-hire time, materials and labour.<br />

Most hull topcoats are designed to be<br />

replaced once or twice every five years.<br />

The full hull coating scheme has to be<br />

fully replaced every 10 - 15 years down<br />

to bare steel.<br />

Over that time period, the coating<br />

degrades and becomes rougher until it’s<br />

no longer worth trying to patch it up.<br />

www.<br />

And it costs you a fortune in fuel to<br />

compensate for the additional hull<br />

friction.<br />

Imagine a coating that’s guaranteed for<br />

10 years and is expected to last 25<br />

without replacement or major repair. A<br />

coating that gets smoother over time,<br />

not rougher!<br />

Imagine coming into drydock after 3 or<br />

5 years and finding that your hull<br />

coating only requires a few minor<br />

touch-ups and doesn’t even need to be<br />

washed off.<br />

Call us today for a quote to convert your hull to Ecospeed or start off right,<br />

with Ecospeed, on a new build.<br />

EU Office<br />

Phone: + 32 3 213 5318<br />

Fax: + 32 3 213 5321<br />

info@ecospeed.be<br />

US Office<br />

Phone: + 1 727 443 3900<br />

Fax: + 1 727 443 3990<br />

info@ecospeed.us<br />

.be<br />

13