Pottery In Australia Vol 35 No 1 Autumn 1996

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Sl<br />

g<br />

w<br />

g<br />

SI<br />

P'<br />

tr<br />

o·<br />

M<br />

g<br />

The Glebe potters suggested that formalising the financial<br />

agreements between members may be an advantage. TI1ere<br />

should also be written agreement regarding details of what<br />

happens when one member wants to leave. 1his safeguards<br />

the others.<br />

Overheads:<br />

These need to be worked out so that each member of the<br />

new studio knows in advance what their financial<br />

responsibility is. Don't forget items like the relocation and<br />

installation of kilns and other heavy equipment. <strong>In</strong>stalling<br />

three phase electricity can be a very expensive business for<br />

electric kilns of any size. This is a cost that cannot be<br />

avoided as professional installation is essential. Gas kilns<br />

will also need certificates of compliance.<br />

The Glebe Potters each have their own kilns but share<br />

other equipment like slab rollers. They found it was more<br />

productive to each have their own kiln which they were<br />

used to firing. As each potter's work was different in both<br />

style and scale so their needs regarding firings was<br />

different. A kiln also dictates the rhythm of work and each<br />

potter again had different requirements.<br />

More mundane, but none the less, essential items for the<br />

studio will include shelving, paint and possible plumbing<br />

alterations. Even if you decide to do this yourself there is a<br />

cost in terms of time. Time away from producing your<br />

work. Don't underestimate this cost in terms of your current<br />

production of work to sell.<br />

Setting Up and Settling <strong>In</strong>:<br />

You may have allowed for the time it takes to move into<br />

the studio but what happens after you have moved?<br />

Bernadette Magee stressed the amount of time needed to<br />

settle into regular production. Even if you are using the<br />

same kiln you had before, chances are, now it is moved, it<br />

will fire differently. The Glebe potters set up their kilns<br />

near the workspace for maximum convenience of loading<br />

and found that the airflow patterns were such that they<br />

couldn't ventilate the kilns properly. This involved further<br />

disruption as the kilns were moved further away.<br />

You must also take into account that your work patterns<br />

will change and productivity may be affected at first. It is<br />

important to have money or stock to get you through this<br />

period.<br />

Producing Work:<br />

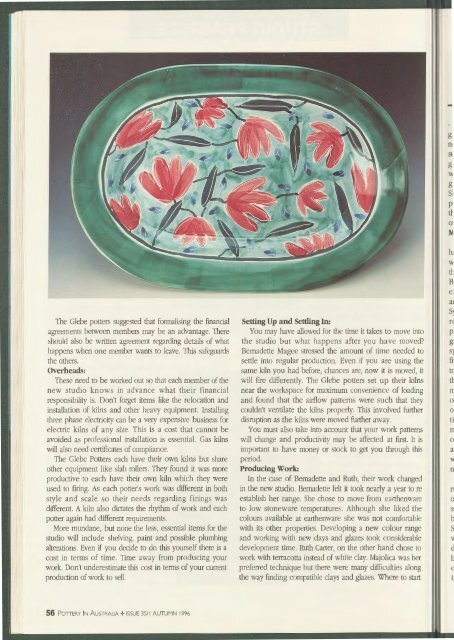

<strong>In</strong> the case of Bernadette and Ruth, their work changed<br />

in the new studio. Bernadette felt it took nearly a year to re<br />

establish her range. She chose to move from earthenware<br />

to low stoneware temperatures. Although she liked the<br />

colours available at earthenware she was not comfortable<br />

with its other properties. Developing a new colour range<br />

and working with new clays and glazes took considerable<br />

development time. Ruth Carter, on the other hand chose to<br />

work with terracotta instead of white clay. Majolica was her<br />

preferred technique but there were many difficulties along<br />

the way finding compatible clays and glazes. Where to start<br />

h:<br />

w<br />

tr<br />

B<br />

e:<br />

a1<br />

s~<br />

fE<br />

p<br />

g:<br />

S1<br />

fi,<br />

tc<br />

tr<br />

rr<br />

ol<br />

0 1<br />

ti<br />

rr<br />

o<br />

w<br />

rr<br />

re<br />

0<br />

sr<br />

b<br />

S<br />

w<br />

d<br />

b<br />

0<br />

ir<br />

56 POTTERY IN AUSTRALIA+ ISSUE <strong>35</strong>/1 AUTUMN <strong>1996</strong>