Pottery In Australia Vol 35 No 1 Autumn 1996

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Deflocculated slip<br />

- Clay Adhesive<br />

'I learned of using deflocculated slip<br />

as an adhesive compound from John Dermer'.<br />

Article by IVOR LEWIS.<br />

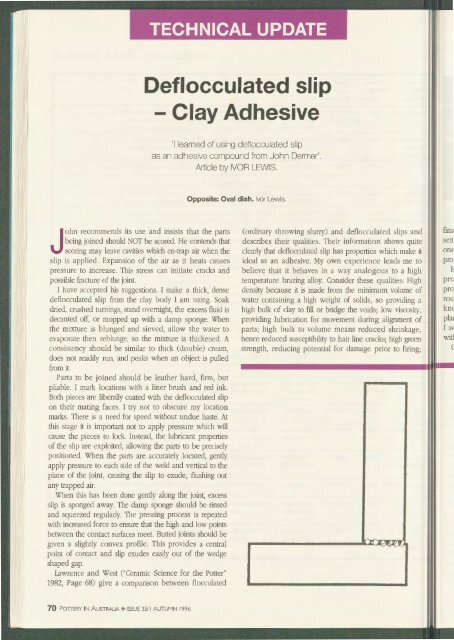

Opposite: Oval dish. Ivor Lewis.<br />

J<br />

ohn recommends its use and insists that the parts<br />

being joined should NOT be scored. He contends that<br />

scoring may leave cavities which en-trap air when the<br />

slip is applied. Expansion of the air as it heats causes<br />

pressure to increase. This stress can initiate cracks and<br />

possible fracture of the joint.<br />

I have accepted his suggestions. I make a thick, dense<br />

deflocculated slip from the clay body I am using. Soak<br />

dried, crushed turnings, stand overnight, the excess fluid is<br />

decanted off, or mopped up with a damp sponge. When<br />

the mixture is blunged and sieved, allow the water to<br />

evaporate then reblunge, so the mixture is thickened. A<br />

consistency should be similar to thick (double) cream,<br />

does not readily run, and peaks when an object is pulled<br />

from it.<br />

Parts to be joined should be leather hard, firm, but<br />

pliable. I mark locations with a liner brush and red ink.<br />

Both pieces are liberally coated with the deflocculated slip<br />

on their mating faces. I try not to obscure my location<br />

marks. There is a need for speed without undue haste. At<br />

this stage it is important not to apply pressure which will<br />

cause the pieces to lock. <strong>In</strong>stead, the lubricant properties<br />

of the slip are exploited, allowing the parts to be precisely<br />

positioned. When the parts are accurately located, gently<br />

apply pressure to each side of the weld and vertical to the<br />

plane of the joint, causing the slip to exude, flushing out<br />

any trapped air.<br />

When this has been done gently along the joint, excess<br />

slip is sponged away. The damp sponge should be rinsed<br />

and squeezed regularly. The pressing process is repeated<br />

with increased force to ensure that the high and low points<br />

between the contact surfaces meet. Butted joints should be<br />

given a slightly convex profile. This provides a central<br />

point of contact and slip exudes easily out of the wedge<br />

shaped gap.<br />

Lawrence and West ("Ceramic Science for the Potter"<br />

1982, Page 68) give a comparison between flocculated<br />

(ordinary throwing slurry) and deflocculated slips and<br />

describes their qualities. Their information shows quite<br />

clearly that deflocculated slip has properties which make it<br />

ideal as an adhesive. My own experience leads me to<br />

believe that it behaves in a way analogous to a high<br />

temperature brazing alloy. Consider these qualities: High<br />

density because it is made from the minimum volume of<br />

water containing a high weight of solids, so providing a<br />

high bulk of clay to fill or bridge the voids; low viscosity,<br />

providing lubrication for movement during alignment of<br />

parts; high bulk to volume means reduced shrinkage,<br />

hence reduced susceptibility to hair line cracks; high green<br />

strength, reducing potential for damage prior to firing;<br />

fina<br />

sett<br />

onE<br />

pro<br />

l1<br />

pro<br />

pro<br />

rou<br />

knc<br />

plat<br />

I ac<br />

witl<br />

C<br />

70 POTTERY IN AUSTRALIA+ ISSUE <strong>35</strong>/ I AUTUMN <strong>1996</strong>