Issue_4_2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

14<br />

show preview: anuga foodtec<br />

Anuga FoodTec 2018<br />

In edition 1 2018, foodeurope will publish a comprehensive preview of this<br />

important trade show. Below is a flavour of what to expect next March.<br />

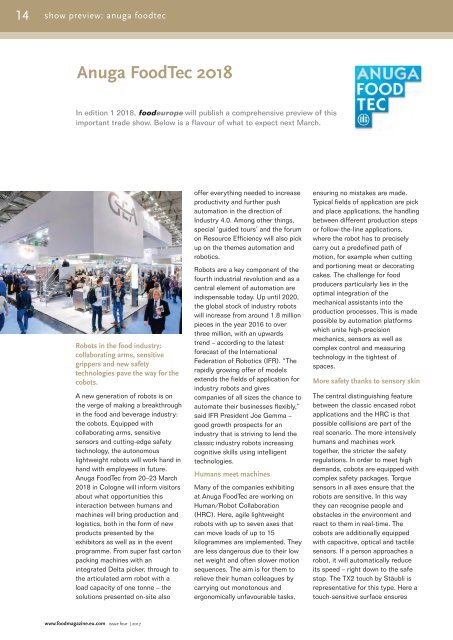

Robots in the food industry:<br />

collaborating arms, sensitive<br />

grippers and new safety<br />

technologies pave the way for the<br />

cobots.<br />

A new generation of robots is on<br />

the verge of making a breakthrough<br />

in the food and beverage industry:<br />

the cobots. Equipped with<br />

collaborating arms, sensitive<br />

sensors and cutting-edge safety<br />

technology, the autonomous<br />

lightweight robots will work hand in<br />

hand with employees in future.<br />

Anuga FoodTec from 20–23 March<br />

2018 in Cologne will inform visitors<br />

about what opportunities this<br />

interaction between humans and<br />

machines will bring production and<br />

logistics, both in the form of new<br />

products presented by the<br />

exhibitors as well as in the event<br />

programme. From super fast carton<br />

packing machines with an<br />

integrated Delta picker, through to<br />

the articulated arm robot with a<br />

load capacity of one tonne – the<br />

solutions presented on-site also<br />

offer everything needed to increase<br />

productivity and further push<br />

automation in the direction of<br />

Industry 4.0. Among other things,<br />

special ‘guided tours’ and the forum<br />

on Resource Efficiency will also pick<br />

up on the themes automation and<br />

robotics.<br />

Robots are a key component of the<br />

fourth industrial revolution and as a<br />

central element of automation are<br />

indispensable today. Up until 2020,<br />

the global stock of industry robots<br />

will increase from around 1.8 million<br />

pieces in the year 2016 to over<br />

three million, with an upwards<br />

trend – according to the latest<br />

forecast of the International<br />

Federation of Robotics (IFR). “The<br />

rapidly growing offer of models<br />

extends the fields of application for<br />

industry robots and gives<br />

companies of all sizes the chance to<br />

automate their businesses flexibly,”<br />

said IFR President Joe Gemma –<br />

good growth prospects for an<br />

industry that is striving to lend the<br />

classic industry robots increasing<br />

cognitive skills using intelligent<br />

technologies.<br />

Humans meet machines<br />

Many of the companies exhibiting<br />

at Anuga FoodTec are working on<br />

Human/Robot Collaboration<br />

(HRC). Here, agile lightweight<br />

robots with up to seven axes that<br />

can move loads of up to 15<br />

kilogrammes are implemented. They<br />

are less dangerous due to their low<br />

net weight and often slower motion<br />

sequences. The aim is for them to<br />

relieve their human colleagues by<br />

carrying out monotonous and<br />

ergonomically unfavourable tasks,<br />

ensuring no mistakes are made.<br />

Typical fields of application are pick<br />

and place applications, the handling<br />

between different production steps<br />

or follow-the-line applications,<br />

where the robot has to precisely<br />

carry out a predefined path of<br />

motion, for example when cutting<br />

and portioning meat or decorating<br />

cakes. The challenge for food<br />

producers particularly lies in the<br />

optimal integration of the<br />

mechanical assistants into the<br />

production processes. This is made<br />

possible by automation platforms<br />

which unite high-precision<br />

mechanics, sensors as well as<br />

complex control and measuring<br />

technology in the tightest of<br />

spaces.<br />

More safety thanks to sensory skin<br />

The central distinguishing feature<br />

between the classic encased robot<br />

applications and the HRC is that<br />

possible collisions are part of the<br />

real scenario. The more intensively<br />

humans and machines work<br />

together, the stricter the safety<br />

regulations. In order to meet high<br />

demands, cobots are equipped with<br />

complex safety packages. Torque<br />

sensors in all axes ensure that the<br />

robots are sensitive. In this way<br />

they can recognise people and<br />

obstacles in the environment and<br />

react to them in real-time. The<br />

cobots are additionally equipped<br />

with capacitive, optical and tactile<br />

sensors. If a person approaches a<br />

robot, it will automatically reduce<br />

its speed – right down to the safe<br />

stop. The TX2 touch by Stäubli is<br />

representative for this type. Here a<br />

touch-sensitive surface ensures<br />

www.foodmagazine.eu.com issue four | <strong>2017</strong>