Australian Blade Ed 3 Dec 2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

After having forged and completed over 25,000 blades during my 30 year career, I have come to identify<br />

four distinct purposes of cold forging: to flatten, to finish, to shape and to refine. These four goals must be<br />

balanced with the real possibility of damaging the steel from over working it. I recommend that the<br />

bladesmith cold forge one knife out of a batch of similar knives to the point of failure (cracking) to<br />

discover where the threshold is for that particular steel type. The remaining blades can then be cold forged<br />

just shy of the failure point for best results.<br />

The most basic result of cold forging is that the thicker, or protruding areas, get hammered down to the<br />

thinner, or lower portions of the blade which results in the flattening of the blade. Systematic hammering<br />

over the whole blade will result in an attractive, smooth surface finish that will not need to be ground or<br />

polished on the finished blade. Minor widening and curvature can be added to the blade, i.e., more<br />

hammering can be done to the cutting edge of a blade to curve it upwards like a scimitar, or more<br />

towards the spine of a blade to curve it down like that of a sickle or kopis shape. Lastly, the hammering<br />

of the blade after annealing results in blades that have better balance between edge sharpness, edge<br />

retention and ease of sharpening.<br />

It is important to see cold forging as a significant contribution to the overall final performance of a<br />

blade, but rendered meaningless if ideal forging, annealing, quenching and tempering procedures are not<br />

realized. Like a champion in figure skating, a perfect score is only realized when the performance is<br />

flawless from start to finish.<br />

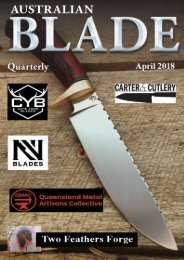

Murray Carter<br />

ABS Master <strong>Blade</strong>smith<br />

17th Generation Yoshimoto <strong>Blade</strong>smith<br />

2038 NW Aloclek Drive #225<br />

Hillsboro, Oregon 97124<br />

www.cartercutlery.com<br />

Office: 503.466.1331<br />

Cell: 503.816.6556<br />

murray@cartercutlery.com