rental inspection procedure - Rossignol

rental inspection procedure - Rossignol

rental inspection procedure - Rossignol

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

VISUAL INSPECTION<br />

The boot/binding system may not operate correctly with boots that do not comply<br />

with international standard, ISO 5355. The technician is responsible for visual<br />

<strong>inspection</strong> of the boot before assembly and adjustment.<br />

BOOTS<br />

Visually inspect BOTH BOOTS for the following:<br />

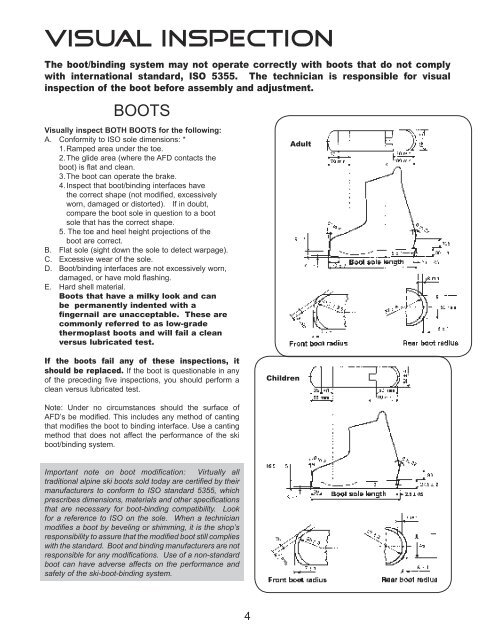

A. Conformity to ISO sole dimensions: *<br />

1. Ramped area under the toe.<br />

2. The glide area (where the AFD contacts the<br />

boot) is flat and clean.<br />

3. The boot can operate the brake.<br />

4. Inspect that boot/binding interfaces have<br />

the correct shape (not modified, excessively<br />

worn, damaged or distorted). If in doubt,<br />

compare the boot sole in question to a boot<br />

sole that has the correct shape.<br />

5. The toe and heel height projections of the<br />

boot are correct.<br />

B. Flat sole (sight down the sole to detect warpage).<br />

C. Excessive wear of the sole.<br />

D. Boot/binding interfaces are not excessively worn,<br />

damaged, or have mold flashing.<br />

E. Hard shell material.<br />

Boots that have a milky look and can<br />

be permanently indented with a<br />

fingernail are unacceptable. These are<br />

commonly referred to as low-grade<br />

thermoplast boots and will fail a clean<br />

versus lubricated test.<br />

If the boots fail any of these <strong>inspection</strong>s, it<br />

should be replaced. If the boot is questionable in any<br />

of the preceding five <strong>inspection</strong>s, you should perform a<br />

clean versus lubricated test.<br />

Note: Under no circumstances should the surface of<br />

AFD’s be modified. This includes any method of canting<br />

that modifies the boot to binding interface. Use a canting<br />

method that does not affect the performance of the ski<br />

boot/binding system.<br />

Important note on boot modification: Virtually all<br />

traditional alpine ski boots sold today are certified by their<br />

manufacturers to conform to ISO standard 5355, which<br />

prescribes dimensions, materials and other specifications<br />

that are necessary for boot-binding compatibility. Look<br />

for a reference to ISO on the sole. When a technician<br />

modifies a boot by beveling or shimming, it is the shop’s<br />

responsibility to assure that the modified boot still complies<br />

with the standard. Boot and binding manufacturers are not<br />

responsible for any modifications. Use of a non-standard<br />

boot can have adverse affects on the performance and<br />

safety of the ski-boot-binding system.<br />

4<br />

Children<br />

Adult