Cummins_eMag_Summer_2014 Final Single

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

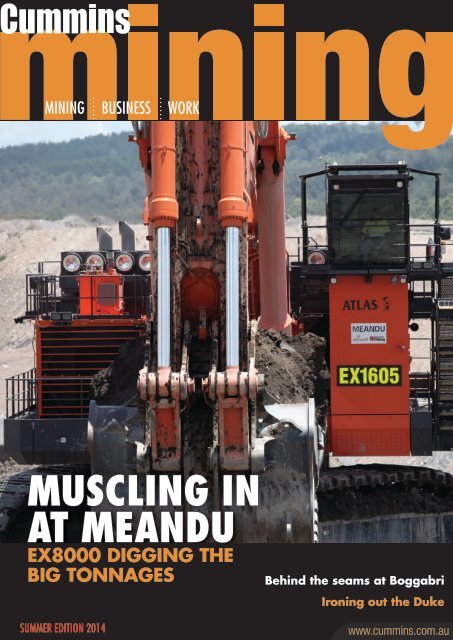

MINING BUSINESS WORK<br />

MUSCLING IN<br />

AT MEANDU<br />

EX8000 DIGGING THE<br />

BIG TONNAGES<br />

Behind the seams at Boggabri<br />

Ironing out the Duke<br />

SUMMER EDITION <strong>2014</strong><br />

www.cummins.com.au

04 05<br />

08 09 Power station at Fortescue’s Christmas Creek<br />

mine comprises 27 QSK78 gensets.<br />

16 17<br />

One of the three EX2600-6 excavators achieving high availability at Iron Duke.<br />

When Contract Power decided to<br />

become the first major user of <strong>Cummins</strong><br />

QSK78 generator sets in the world with<br />

the construction of a power station at<br />

Christmas Creek in the Pilbara, it could<br />

have been viewed as a bold move in<br />

such a remote and harsh region.<br />

At the time, Contract Power general<br />

manager Marc Grosser dismissed any<br />

possible concerns: “We like trying new<br />

equipment… we believe it gives us a<br />

leading edge over our competitors.”<br />

The power station in question was<br />

completed early in 2012, its generators<br />

vital to the operation of Fortescue’s<br />

Christmas Creek mine, in particular<br />

the two ore processing facilities that<br />

have an annual through-put capacity<br />

of more than 50 million tonnes.<br />

EX8000 recently loaded 110,440 tonnes in a day.<br />

This is the biggest diesel power station<br />

in Australia, designed and built by<br />

Perth-based Contract Power and<br />

owned and operated by the same<br />

company – a progressive outfit that<br />

boasts the ability to do power generation<br />

business “anywhere in the world”.<br />

It is also the largest single installation<br />

of prime power <strong>Cummins</strong> QSK78<br />

generator sets in the world, each of<br />

the 27 units able to deliver 2 MW.<br />

In a previous issue of <strong>Cummins</strong><br />

Commentary (Issue 34, August 2011),<br />

we featured the first development<br />

stage of the power station. Undertaken<br />

in 2011, this first stage saw the<br />

installation of 14 generators, while the<br />

second and final stage was completed<br />

early in 2012 with the commissioning<br />

of a further 13 QSK78 units.<br />

The reliability of the power station is<br />

A fleet of <strong>Cummins</strong>-powered haul mine is owned by Idemitsu Australia<br />

trucks and excavators is achieving Resources, a subsidiary of Japanese<br />

availability targets for mining<br />

petroleum company Idemitsu Kosan<br />

contractor Downer Mining at Boggabri Co., Ltd. Construction of the mine<br />

Coal in the Gunnedah Basin, NSW. began in January 2006 and the first<br />

coal was produced in October.<br />

<strong>Cummins</strong>’ on-site support also rates<br />

highly at Boggabri with the mine operating Downer Mining’s current contract with<br />

24/7 and set to produce more than Idemitsu, which runs to December<br />

5.0 million tonnes of coal in <strong>2014</strong>.<br />

2016, involves drilling and blasting, mine<br />

planning, and loading and haulage.<br />

Downer Mining has been the mining<br />

contractor at Boggabri Coal since<br />

Overburden haulage at Boggabri is<br />

2006 when production began. The spearheaded by 17 Komatsu 930E trucks<br />

The world’s first Hitachi EX8000 backhoe<br />

excavator is in full flight at Stanwell Corporation’s<br />

Meandu coal mine in south east Queensland,<br />

digging the big tonnages expected of it.<br />

With its dual Tier II <strong>Cummins</strong> QSK60 MCRS engines<br />

pumping out close to 4000 hp, the 837-tonne EX8000<br />

went into service in September and is moving 2700<br />

to 3000 BCMs (bank cubic metres) an hour.<br />

“The EX8000 is expected to move 14 million<br />

BCMs per year over the next three years,<br />

removing mainly overburden,” says Jim<br />

Young, Meandu Mine asset manager.<br />

A pointer to the machine’s capability is that it recently<br />

loaded 110,440 tonnes in a day. The EX8000 is<br />

equipped with a 45 cubic metre bucket and is moving<br />

around 75 tonnes per bucket load, feeding a fleet of<br />

220-tonne capacity Komatsu 830E dump trucks.<br />

One of the biggest hydraulic excavators in the<br />

world, the EX8000’s dual 60-litre <strong>Cummins</strong> QSK60<br />

engines power its hydraulic system – a system<br />

of 16 main pumps which move 8000 litres of oil<br />

a minute to achieve maximum working force.<br />

Although it’s early days yet for the EX8000<br />

at Meandu Mine, Jim Young is confident the<br />

machine will achieve its targets based on his<br />

extensive knowledge of the Hitachi product.<br />

“We plan to have the machine operating around<br />

5700 hours a year,” says the man who started<br />

at Meandu Mine during its construction in the<br />

late 1970s. It’s not surprising that Jim Young<br />

knows virtually every square metre of the Meandu<br />

complex which today comprises five active pits.<br />

Stanwell is a diverse energy company owned by<br />

the Queensland Government and has coal, gas and<br />

water assets that are used to generate electricity<br />

for Australia’s wholesale electricity market.<br />

Jim Young, Meandu Mine asset manager… “We plan to have the<br />

EX8000 operating around 5,700 hours a year.”<br />

critical to Fortescue – Australia’s third<br />

largest producer of iron ore behind<br />

Rio Tinto and BHP Billiton – as it<br />

continues to ramp up production.<br />

For Contract Power’s Marc Grosser,<br />

“hitting the maintenance targets” is<br />

one of the key pointers to the<br />

efficiency of the power station.<br />

“Mechanically, the engine/alternator<br />

package is performing very well,” he says<br />

without hesitation. “Some of the gensets<br />

have clocked up over 10,000 hours<br />

and are hitting the maintenance targets<br />

that we have in place with <strong>Cummins</strong>.<br />

“Our experience at Christmas Creek is<br />

that maintenance costs of the QSK78<br />

genset are lower than competitors’ costs.<br />

“Fuel economy of the QSK78 is<br />

also very competitive,” he says.<br />

He points out the maintenance targets<br />

set with <strong>Cummins</strong> include injector<br />

change-out at 10,000 hours – a<br />

target that is being achieved.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong><br />

<strong>Cummins</strong> on-site technician Casey Haywood (right) with<br />

Downer Mining’s reliability supervisor Adam Morrison.<br />

with a 290-tonne payload capacity, and<br />

the force behind their tractive effort is the<br />

<strong>Cummins</strong> QSK60 engine rated at 2700 hp.<br />

The reliability of the 930E trucks is<br />

critical as they contribute significantly<br />

to a total annual overburden and coal<br />

movement of around 36 million BCMs.<br />

The oldest 930Es had clocked up around<br />

9,000 hours near the end of 2013,<br />

with the youngest at 5000 hours.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong><br />

CONTENT<br />

mining<br />

<strong>Cummins</strong><br />

mining<br />

<strong>Cummins</strong><br />

04<br />

YOUR MINING MAGAZINE<br />

Muscling in at Meandu<br />

The world’s first Hitachi EX8000 backhoe excavator is in full<br />

flight at Meandu coal mine in south east Queensland.<br />

USER REPORT<br />

08<br />

Generation X<br />

The biggest diesel power station in Australia, at Christmas<br />

Creek mine in the Pilbara, features <strong>Cummins</strong> QSK78 generator<br />

sets.<br />

04<br />

MUSCLING<br />

IN AT MEANDU<br />

GENERATORS<br />

12<br />

Just keep on digging<br />

Two of the first operational Tier II <strong>Cummins</strong> QSK38 engines<br />

in the world have exceeded life-to-overhaul targets in<br />

mining in south east Queensland.<br />

GENERATION<br />

15<br />

Holding fire<br />

A containerised fire pump incorporating <strong>Cummins</strong> power<br />

has been built for a Pilbara mining project.<br />

08<br />

The generation of electrical power in Western Australia’s<br />

Pilbara region is critical as its iron ore riches continue<br />

to provide Australia with its biggest export earnings.<br />

16<br />

Behind the seams at Boggabri<br />

A fleet of <strong>Cummins</strong>-powered haul trucks and excavators is<br />

achieving availability targets at Boggabri Coal in NSW.<br />

20<br />

Ironing out the Duke<br />

Four <strong>Cummins</strong>-powered Hitachi excavators are exceeding<br />

production and availability targets at the Iron Duke mine in<br />

South Australia.<br />

24 Now we’re pumping<br />

A mine dewatering pump, powered by one of the biggest<br />

<strong>Cummins</strong> CustomPaks in Australia, has gone to a mining<br />

<strong>Cummins</strong><br />

project<br />

Mining<br />

in Africa.<br />

Magazine<br />

Published by <strong>Cummins</strong> South Pacific.<br />

16<br />

20<br />

BEHIND THE SEAMS AT<br />

BOGGABRI<br />

<strong>Cummins</strong> power is specified in all the Cat excavators at Boggabri.<br />

12 13 CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong><br />

IRONING OUT<br />

THE DUKE<br />

Four <strong>Cummins</strong>-powered Hitachi excavators are exceeding<br />

production and availability targets at BGC Contracting’s<br />

iron ore mining operations at Iron Duke in South Australia.<br />

Three of the diggers are 254-tonne EX2600-6 units with<br />

Tier 2 <strong>Cummins</strong> QSK50 engines rated at 1500 hp, while the<br />

fourth is a 239-tonne EX2500-5 with a <strong>Cummins</strong> QSK45<br />

rated at 1350 hp.<br />

All are configured as backhoes and they moved in excess of<br />

15 million BCMs (bank cubic metres) in their first 12 months<br />

at the Iron Duke mine.<br />

USER REPORT<br />

<strong>Cummins</strong> Mining is published by<br />

<strong>Cummins</strong> South Pacific.<br />

2 Carribbean Drive, Scoresby,<br />

Victoria 3179.<br />

Editor<br />

Murray Clifford<br />

Ph. 0419 268 289,<br />

Email: murray.clifford@cummins.com<br />

Marketing Manager<br />

Rachael Reinheimer<br />

rachael.reinheimer@cummins.com<br />

02 03

On Site,<br />

On Demand,<br />

On Time.<br />

Whatever your power requirement, <strong>Cummins</strong> has a range of heavy-duty generator sets ready-to-run at<br />

your mine site.<br />

These generator sets are ready for mine site and mobile application, meaning they are toughened to<br />

withstand the harshest operating conditions.<br />

Designed as fully integrated power packages, <strong>Cummins</strong>’ generator sets span 20 kVA to 1250 kVA.<br />

And they are backed by <strong>Cummins</strong>’ unmatched service support network which includes the awardwinning<br />

24/7 <strong>Cummins</strong> Support Centre.<br />

Find your nearest <strong>Cummins</strong> branch at www.cummins.com.au or call +61 3 9765 3120.<br />

To request product information or to arrange for a <strong>Cummins</strong> representative to contact you please get<br />

in touch with us by clicking here.<br />

Experience our rental capabilities<br />

power.cummins.com<br />

Our energy working for you

USER REPORT<br />

MUSCLING<br />

IN AT MEANDU<br />

04 05

EX8000 recently loaded 110,440 tonnes in a day.<br />

The world’s first Hitachi EX8000 backhoe<br />

excavator is in full flight at Stanwell Corporation’s<br />

Meandu coal mine in south east Queensland,<br />

digging the big tonnages expected of it.<br />

With its dual Tier II <strong>Cummins</strong> QSK60 MCRS engines<br />

pumping out close to 4000 hp, the 837-tonne EX8000<br />

went into service in September and is moving 2700<br />

to 3000 BCMs (bank cubic metres) an hour.<br />

“The EX8000 is expected to move 14 million<br />

BCMs per year over the next three years,<br />

removing mainly overburden,” says Jim<br />

Young, Meandu Mine asset manager.<br />

A pointer to the machine’s capability is that it recently<br />

loaded 110,440 tonnes in a day. The EX8000 is<br />

equipped with a 45 cubic metre bucket and is moving<br />

around 75 tonnes per bucket load, feeding a fleet of<br />

220-tonne capacity Komatsu 830E dump trucks.<br />

One of the biggest hydraulic excavators in the<br />

world, the EX8000’s dual 60-litre <strong>Cummins</strong> QSK60<br />

engines power its hydraulic system – a system<br />

of 16 main pumps which move 8000 litres of oil<br />

a minute to achieve maximum working force.<br />

Although it’s early days yet for the EX8000<br />

at Meandu Mine, Jim Young is confident the<br />

machine will achieve its targets based on his<br />

extensive knowledge of the Hitachi product.<br />

“We plan to have the machine operating around<br />

5700 hours a year,” says the man who started<br />

at Meandu Mine during its construction in the<br />

late 1970s. It’s not surprising that Jim Young<br />

knows virtually every square metre of the Meandu<br />

complex which today comprises five active pits.<br />

Stanwell is a diverse energy company owned by<br />

the Queensland Government and has coal, gas and<br />

water assets that are used to generate electricity<br />

for Australia’s wholesale electricity market.<br />

Jim Young, Meandu Mine asset manager… “We plan to have the<br />

EX8000 operating around 5,700 hours a year.”

EX8000 is powered by dual <strong>Cummins</strong> QSK60<br />

engines pumping out close to 4000 hp.<br />

Meandu Mine was bought from Rio Tinto in<br />

2008 to secure a long-term fuel source for<br />

the two adjacent Tarong power stations.<br />

Construction of the mine began in 1981<br />

after the Queensland Government made<br />

the decision to build the first Tarong<br />

power station. In 1984, the mine began<br />

regular supply of coal to the 1400 MW<br />

power station – supply that increased<br />

with the construction of the second<br />

Tarong power station (443 MW) in 2003.<br />

to do much walking,” says Jim Young.<br />

Other machines in the excavator fleet<br />

include a 518-tonne EX5500-5 which had<br />

run 43,250 hours near the end of 2013<br />

(it has dual <strong>Cummins</strong> QSK45 engines<br />

rated at 1350 hp), and a 359-tonne<br />

EX3600-6 which had worked 23,000 hours<br />

(it is powered by a single Tier II <strong>Cummins</strong><br />

QSK60 MCRS engine rated at 1944 hp).<br />

The QSK60 with its modular common<br />

rail fuel system (MCRS) achieved<br />

18,850 hours in the EX3600-6 before<br />

rebuild, and <strong>Cummins</strong> mining business<br />

manager Stewart McKeddie expects<br />

a similar life to overhaul with the dual<br />

Tier II QSK60 engines in the EX8000.<br />

The 19-strong dump truck fleet at Meandu<br />

is spearheaded by Komatsu 830E AC<br />

The mine is currently producing 4.8<br />

Mtpa but has reached as high as 7.2<br />

Mtpa. Downer EDI is providing the<br />

mining services at Meandu although<br />

Stanwell owns most of the plant.<br />

Hitachi is the preferred excavator<br />

brand at Meandu, the oldest machine<br />

on site – an EX3500 with dual 880<br />

hp <strong>Cummins</strong> K38 engines – having<br />

clocked up around 84,000 hours since<br />

its commissioning in 1992. “It’s on easy<br />

work these days where it doesn’t have<br />

06 07<br />

Meandu Mine has five active pits…pictured are the west and central pits.

Jim Young with Alex Mier, <strong>Cummins</strong> SE Asia manager for mining.<br />

“<br />

The EX8000 is expected to move 14 million<br />

BCMs per year over the next three years.<br />

“<br />

units powered by 2500 hp <strong>Cummins</strong><br />

QSK60 engines. The oldest engines have<br />

gone through the 14,000-hour market on<br />

their way to the 25,000-hour rebuild target.<br />

Hitachi is currently using Meandu<br />

Mine as part of its trial development<br />

of a comprehensive suite of<br />

technologies aimed at providing<br />

more autonomous equipment to the<br />

surface mining industry by 2017.<br />

to identify haul roads, intersections and<br />

mine locations such as loading areas,<br />

stockpiles and crushers. The trucks also<br />

have a control system that allows precise<br />

speed control, helping them to safely<br />

negotiate steep slopes at the mine.<br />

An interesting point is that Komatsu also<br />

used Meandu Mine – in 2001-2002 – for<br />

development of its automated truck,<br />

a number of which are now in use at<br />

Rio Tinto mines in the Pilbara, WA.<br />

Three 296-tonne payload capacity<br />

EH5000AC-3 trucks powered by the<br />

<strong>Cummins</strong> QSK60 engine rated at 2850<br />

hp will eventually be part of the trial at<br />

Meandu over a three-year period.<br />

Hitachi points out that dump truck<br />

loading, haulage and dumping operation<br />

will be entirely automated and that<br />

the trucks will be able to interact with<br />

other human-operated equipment.<br />

The trucks will use a highly advanced<br />

GPS to control their location, speed and<br />

direction. The GPS system has the ability<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

GENER<br />

GENERATORS<br />

The generation of electrical power in Western Australia’s<br />

Pilbara region is critical as its iron ore riches continue<br />

to provide Australia with its biggest export earnings.<br />

08 09 Power station at Fortescue’s Christmas Creek<br />

mine comprises 27 QSK78 gensets.

ATION<br />

When Contract Power decided to<br />

become the first major user of <strong>Cummins</strong><br />

QSK78 generator sets in the world with<br />

the construction of a power station at<br />

Christmas Creek in the Pilbara, it could<br />

have been viewed as a bold move in<br />

such a remote and harsh region.<br />

At the time, Contract Power general<br />

manager Marc Grosser dismissed any<br />

possible concerns: “We like trying new<br />

equipment… we believe it gives us a<br />

leading edge over our competitors.”<br />

The power station in question was<br />

completed early in 2012, its generators<br />

vital to the operation of Fortescue’s<br />

Christmas Creek mine, in particular<br />

the two ore processing facilities that<br />

have an annual through-put capacity<br />

of more than 50 million tonnes.<br />

This is the biggest diesel power station<br />

in Australia, designed and built by<br />

Perth-based Contract Power and<br />

owned and operated by the same<br />

company – a progressive outfit that<br />

boasts the ability to do power generation<br />

business “anywhere in the world”.<br />

It is also the largest single installation<br />

of prime power <strong>Cummins</strong> QSK78<br />

generator sets in the world, each of<br />

the 27 units able to deliver 2 MW.<br />

In a previous issue of <strong>Cummins</strong><br />

Commentary (Issue 34, August 2011),<br />

we featured the first development<br />

stage of the power station. Undertaken<br />

in 2011, this first stage saw the<br />

installation of 14 generators, while the<br />

second and final stage was completed<br />

early in 2012 with the commissioning<br />

of a further 13 QSK78 units.<br />

The reliability of the power station is<br />

critical to Fortescue – Australia’s third<br />

largest producer of iron ore behind<br />

Rio Tinto and BHP Billiton – as it<br />

continues to ramp up production.<br />

For Contract Power’s Marc Grosser,<br />

“hitting the maintenance targets” is<br />

one of the key pointers to the<br />

efficiency of the power station.<br />

“Mechanically, the engine/alternator<br />

package is performing very well,” he says<br />

without hesitation. “Some of the gensets<br />

have clocked up over 10,000 hours<br />

and are hitting the maintenance targets<br />

that we have in place with <strong>Cummins</strong>.<br />

“Our experience at Christmas Creek is<br />

that maintenance costs of the QSK78<br />

genset are lower than competitors’ costs.<br />

“Fuel economy of the QSK78 is<br />

also very competitive,” he says.<br />

He points out the maintenance targets<br />

set with <strong>Cummins</strong> include injector<br />

change-out at 10,000 hours – a<br />

target that is being achieved.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

TESTING<br />

Contract Power general manager Marc Grosser…<br />

QSK78 gensets are “hitting the maintenance targets”.<br />

Some of the gensets<br />

have clocked up<br />

over 10,000 hours<br />

and are hitting the<br />

maintenance targets<br />

we have in place<br />

with <strong>Cummins</strong>.<br />

“We’ve had several issues outside the<br />

QSK78 engine/alternator package, but<br />

<strong>Cummins</strong> stands behind its product and its<br />

warranty which we believe is a very good<br />

trait. It’s nice to know that a manufacturer<br />

will back its product. Overall, <strong>Cummins</strong><br />

has reacted very well to our requirements.”<br />

Contract Power’s maintenance regime<br />

at Christmas Creek is a no-compromise<br />

affair. “There can be no compromises in<br />

such a harsh environment as the Pilbara,”<br />

says Marc Grosser. “The dust is highly<br />

abrasive and ruthless on everything…<br />

oil filter integrity needs to be spot on.”<br />

To ensure best possible filtration,<br />

<strong>Cummins</strong>’ Eliminator system is used,<br />

replacing the traditional disposable<br />

spin-on ‘paper’ element filters. Routine<br />

servicing is at 250-hour intervals and oil<br />

sampling is carried out every 500 hours.<br />

The ability of the power station to<br />

operate at maximum capacity in very<br />

high ambient temperatures – as high<br />

as 50 degrees C – also demands peak<br />

cooling system efficiency. As Marc Grosser<br />

points out, Marble Bar is reputedly the<br />

hottest place in Australia and it’s only<br />

150 km north-west of Christmas Creek.<br />

It’s no secret that Contract Power<br />

is eagerly awaiting <strong>Cummins</strong>’ new<br />

QSK95 generator set – the biggest<br />

genset ever developed by <strong>Cummins</strong>.<br />

<strong>Cummins</strong> Perth’s power generation sales executive<br />

Bhavani Sambhara (left) with Marc Grosser.<br />

Scheduled to go into production in late<br />

<strong>2014</strong>, the new 3.5 MW generator set<br />

is powered by the QSK95, a 95-litre<br />

V16 and the highest output diesel<br />

engine ever developed by <strong>Cummins</strong>.<br />

Marc Grosser has studied the<br />

QSK95 closely and describes it as<br />

an “awesome platform” for power<br />

generation. In particular, he rates the<br />

design and positioning of the external<br />

‘hang on’ components highly for<br />

serviceability and maintenance.<br />

The <strong>Cummins</strong> engine currently most<br />

10 11

The ability of the power station to operate at maximum capacity in very high ambient<br />

temperatures – as high as 50 degrees C – demands peak cooling system efficiency.<br />

One of eight 1250 kVA <strong>Cummins</strong> PowerBox generator sets, mounted on specially built trailers,<br />

deployed by Contract Power for commissioning of Fortescue’s Solomon mine development.<br />

widely used by Contract Power in power<br />

generation is the KTA50, a 50-litre V16<br />

with a reputation for being bullet proof.<br />

Contract Power recently deployed eight<br />

1250 kVA <strong>Cummins</strong> PowerBox generator<br />

sets, each powered by the KTA50, for<br />

commissioning of Fortescue’s Solomon<br />

mine development, 120 km west of<br />

Christmas Creek and Cloudbreak.<br />

The PowerBox is a fully integrated<br />

power system with the genset installed<br />

in an ISO container. Contract Power<br />

engineered eight trailers specially<br />

for the commissioning and the<br />

PowerBoxes were mounted on these<br />

trailers along with transformers and<br />

6000 litres of diesel fuel capacity.<br />

Leon Hodge’s Contract Power<br />

is today a group of companies<br />

providing power generation solutions<br />

both in Australia and overseas.<br />

Hodges started out in business in the early<br />

1990s as a lone contractor with a ute,<br />

providing remote on-site servicing and<br />

supply of power generation equipment to<br />

the mining industry in Western Australia.<br />

He didn’t exactly having a burning ambition<br />

at the time to build a big business. “My<br />

intention then was to keep food on the<br />

table, look after the kids,” he recalls.<br />

Within a couple of years Hodges had<br />

over 20 employees and was one of<br />

the few companies providing a 24/7<br />

on-call service to mining clients.<br />

In 1995 Contract Power began<br />

building power stations. Today, the<br />

company boasts the ability to do<br />

business “anywhere in the world”<br />

and, in fact, conducts business in six<br />

countries across three continents.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

Two of the first operational <strong>Cummins</strong><br />

QSK38 Tier 2 MCRS engines in the<br />

world have exceeded life-to-overhaul<br />

targets in mining in south east<br />

Queensland.<br />

Powering Hitachi EX1900-6 excavators in<br />

service with Golding Contractors, one QSK38<br />

achieved 19,199 hours while the other<br />

reached 18,653 hours before change-out.<br />

Initial planning was for a 16,000-hour life.<br />

The highest-hour QSK38 achieved its<br />

milestone at Evolution Mining’s Mt Rawdon<br />

gold mine, while the other engine exceeded<br />

its target at the Kogan Creek coal mine.<br />

We recently visited the Kogan Creek mine near<br />

Chinchilla (300 km west of Brisbane) where the<br />

18,300-hour QSK38 had just been replaced<br />

with a certified support bank engine from<br />

<strong>Cummins</strong>’ Master Rebuild Centre in Brisbane.<br />

The mine provides coal – 2.5 million tonnes a year<br />

– to fuel the adjacent Kogan Creek power station.<br />

Golding Contractors developed the mine from<br />

a greenfield site and began operations in 2006<br />

under an 11-year contract to mine the thin seam<br />

deposit to a suitable quality for power generation.<br />

The power station – one of Australia’s most<br />

efficient coal-fired power stations – can provide<br />

up to 750 MW of baseload electricity, enough<br />

to power around one million homes.<br />

12 13

ENGINE LIFE<br />

QSK38 ENGINE LIFE<br />

19,199 hours - Mt Rawdon<br />

18,653 hours - Kogan Creek<br />

<strong>Cummins</strong> QSK38 in Hitachi EX1900-6 excavator<br />

achieved 18,653 hours before change-out.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

<strong>Cummins</strong> mining business manager Stewart McKeddie<br />

(left) with Golding maintenance superintendent Ben Victor<br />

(centre) and maintenance supervisor Scott Poulsen.<br />

Both the mine and power station are owned by CS<br />

Energy, a Queensland Government owned corporation<br />

and an electricity generator, trader and retailer.<br />

The QSK38 is an evolution of the long established 38-litre V12<br />

<strong>Cummins</strong> KV-series platform, a mining industry benchmark<br />

for reliability and durability in its horsepower class.<br />

A Tier 2 emissions engine, the QSK38 is rated at 810 kW<br />

(1086 hp) at 1800 rpm in the Hitachi EX1900-6 which<br />

has an operating weight of 192 tonnes. A feature of the<br />

Tier 2 engine is the modular common rail fuel system<br />

(MCRS) that ensures low emissions, quieter operation,<br />

smoother power delivery and faster load acceptance.<br />

Kogan Creek mine provides 2.5 million tonnes of coal a year<br />

to the adjacent power station. Photo courtesy of CS Energy.<br />

Photograph by Nadine Shaw Photography.<br />

At Kogan Creek, the EX1900-6 is working with two other<br />

<strong>Cummins</strong>-powered diggers – a Komatsu PC3000 and Hitachi<br />

EX1800-3 – which feed a fleet of 14 dump trucks. Golding<br />

selected these size diggers because of the nature of the coal<br />

seams, and they move a total of 5.0 million BCMs a year.<br />

Only scheduled maintenance<br />

has ever been carried out on<br />

the QSK38.<br />

<strong>Cummins</strong>’ service and diagnostic tool, Insite, is used by<br />

the Golding maintenance team at Kogan Creek. During the<br />

QSK38 change-out, time was made available for a <strong>Cummins</strong><br />

representative to demonstrate the high-level diagnostic<br />

capability of the Insite tool such as cylinder cut-out testing<br />

and other procedures that reduce troubleshooting time.<br />

All members of the Golding maintenance team take pride<br />

in ‘ownership’ of the entire mining equipment fleet on<br />

site. The diggers, as always, are the backbone of the<br />

operation, and their engine reliability and durability is a<br />

critical requirement to meeting the production targets.<br />

Golding maintenance superintendent at Kogan Creek,<br />

Ben Victor, confirms that “only scheduled maintenance”<br />

has ever been carried out on the QSK38.<br />

A contributor to the long engine life is obviously Golding’s<br />

maintenance regime. “We make sure we put time into<br />

preventive maintenance and we’ve never missed our<br />

contract obligations to the power station,” he says.<br />

Routine servicing intervals are also strictly adhered<br />

to. “We carry out oil changes every 250 hours and<br />

we fit new fuel filters and air cleaners every 250 hours<br />

regardless of the condition they’re in,” he points out.<br />

14 15<br />

Golding developed Kogan Creek mine from<br />

a greenfield site and began operations in 2006 under an<br />

11-year contract to mine the thin seam deposit.

FIRE PUMP<br />

Holding fire<br />

A containerised fire pump,<br />

incorporating an 8.3-litre <strong>Cummins</strong><br />

C-series diesel engine, has been<br />

designed and built by Perth-based<br />

Dynapumps for a mining project in<br />

the Pilbara, WA.<br />

The dual electric/diesel fire pump<br />

system has been installed at the<br />

project by the construction arm<br />

of Forge Group, an engineering,<br />

procurement and construction<br />

service provider to the power and<br />

infrastructure, mineral and resources,<br />

and oil and gas sectors.<br />

Housed in a 40 ft sea container<br />

with lighting, access doors, louvers,<br />

ventilation and monorail, the fire pump<br />

is to AS2941 standard. The container<br />

is acoustically attenuated to 85 dBA<br />

@ 1.0-metre and the construction<br />

enables quick on-site hook up to the<br />

fire ring main.<br />

Mounted within the container are<br />

electric and diesel-driven ISO5199<br />

pumps capable of a duty flow of 6000<br />

litres/min @ 92-metre head each. The<br />

diesel pump is driven by the <strong>Cummins</strong><br />

6CTA engine rated at 260 hp.<br />

“We used a <strong>Cummins</strong> engine for this<br />

project because of the high focus on<br />

quality and reliability of equipment by<br />

Rio Tinto, especially when it comes<br />

to critical safety equipment such<br />

as fire pumps,” says Jason Moore,<br />

applications engineer for Dynapumps.<br />

“Given the long design life of this fire<br />

pump system, we needed an engine<br />

that could ‘go the distance’ with<br />

local support and parts availability<br />

to minimise any downtime of safety<br />

systems while operating in the harsh<br />

environment of the north west.”<br />

Dynapumps points out there are<br />

major benefits of constructing a<br />

pump set within a shipping container.<br />

The container helps increase the<br />

operational reliability of the pump by<br />

protecting it from the harsh conditions<br />

of a mine site. It also reduces the<br />

amount of cleaning and maintenance<br />

required to keep the radiators and<br />

cooling fans working efficiently<br />

by protecting the pump from the<br />

environmental elements. In the event<br />

of a fire, the sea container will slow<br />

the fire’s progress down significantly<br />

and protect the pump from the flames<br />

for a period of time.<br />

The ‘duress pendant’ is a feature of the real-time<br />

monitoring of <strong>Cummins</strong> field service technicians.<br />

Dual fire pump system incorporates a diesel pump powered by <strong>Cummins</strong>.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

MINE REPORT<br />

<strong>Cummins</strong> power is specified in all<br />

the Cat excavators at Boggabri.<br />

16 17

<strong>Cummins</strong> on-site technician Casey Haywood (right) with<br />

Downer Mining’s reliability supervisor Adam Morrison.<br />

BEHIND THE SEAMS AT<br />

BOGGABRI<br />

A fleet of <strong>Cummins</strong>-powered dump<br />

trucks and excavators is achieving<br />

availability targets for mining<br />

contractor Downer Mining at Boggabri<br />

Coal in the Gunnedah Basin, NSW.<br />

<strong>Cummins</strong>’ on-site support rates highly<br />

at Boggabri with the mine operating<br />

24/7 and set to produce more than<br />

5.0 million tonnes of coal in <strong>2014</strong>.<br />

Downer Mining has been the mining<br />

contractor at Boggabri Coal since<br />

2006 when production began. The<br />

mine is owned by Idemitsu Australia<br />

Resources, a subsidiary of Japanese<br />

petroleum company Idemitsu Kosan<br />

Co., Ltd. Construction of the mine<br />

began in January 2006 and the first<br />

coal was produced in October.<br />

Downer Mining’s current contract with<br />

Idemitsu, which runs to December<br />

2016, involves drilling and blasting, mine<br />

planning, and loading and haulage.<br />

Overburden haulage at Boggabri is<br />

spearheaded by 17 Komatsu 930E trucks<br />

with a 290-tonne payload capacity, and<br />

the force behind their tractive effort is the<br />

<strong>Cummins</strong> QSK60 engine rated at 2700 hp.<br />

The reliability of the 930E trucks is<br />

critical as they contribute significantly<br />

to a total annual overburden and coal<br />

movement of around 36 million BCMs.<br />

The oldest 930Es had clocked up around<br />

9,000 hours near the end of 2013,<br />

with the youngest at 5000 hours.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

“ We don’t have any dramas<br />

with <strong>Cummins</strong> here...<br />

“<br />

Downer Mining’s mechanical availability target for the<br />

930Es is 89%, and the Komatsu fleet is exceeding<br />

that target. Engine load factors are averaging 40%<br />

and fuel burn points to a 20,000-hour overhaul.<br />

Like any mine, Boggabri has targets to meet – targets<br />

that are the focus of Downer Mining’s reliability supervisor<br />

Adam Morrison as he looks at ways to reduce downtime<br />

to ensure highest possible availability of equipment.<br />

Support from equipment suppliers is obviously<br />

a key factor in the execution of his task.<br />

<strong>Cummins</strong>’ on-site support at Boggabri has been in place<br />

for two years, and for most of that time has been the<br />

responsibility of technician Casey Haywood, a young man<br />

who takes immense pride in the company’s service support<br />

capability and the relationship that is built with the customer.<br />

He’s supported by the <strong>Cummins</strong> Tamworth field service team<br />

and also product support representative Mick Karafilis.<br />

“We don’t have dramas with <strong>Cummins</strong> here,” says Adam<br />

Morrison. “What we want to see is a proactive approach<br />

from our suppliers and we get that with Casey.”<br />

Adam Morrison’s greatest focus is on the “money makers” in the<br />

18 19

Downer Mining’s Adam Morrison (second from left) with <strong>Cummins</strong>’ service<br />

support team (from left) Mick Karafilis, Jason Linke and Casey Haywood.<br />

Overburden haulage is spearheaded by 17 Komatsu 930E trucks<br />

powered by <strong>Cummins</strong> QSK60 engines rated at 2700 hp.<br />

operation – the excavators. All are <strong>Cummins</strong>-powered Cat units<br />

– three 600-tonne 6060 machines with dual 1500 hp <strong>Cummins</strong><br />

QSK45 engines which are moving overburden, and a 300-tonne<br />

6030 with dual <strong>Cummins</strong> QSK19 engines rated at 675 hp.<br />

The 600-tonners are moving 2000 BCMs an hour, have engine<br />

load factors as high as 75%, and are exceeding their mechanical<br />

availability target of 90%.The oldest 6060 – a face shovel –<br />

had clocked up 11,500 hours near the end of the 2013.<br />

While fuel burn and load factors point to a QSK45 life<br />

to overhaul of 12,000 hours, planned change-out is<br />

in fact 15,000 hours. A 500-litre oil reserve system on<br />

the excavators sees 1000-hour oil drain intervals.<br />

Downer Mining has a maintenance crew dedicated<br />

to the excavator fleet, reflecting a disciplined<br />

approach to maintenance overall.<br />

All the <strong>Cummins</strong> engines at Boggabri – both in the trucks and<br />

excavators – are equipped with the <strong>Cummins</strong> Eliminator oil<br />

purification system. Eliminator replaces the traditional disposable<br />

spin-on ‘paper’ element filters and is a combination of an<br />

automatic, self-cleaning full-flow filter and an integral centrifugal<br />

bypass unit. The system provides better filtration, helps with<br />

servicing efficiency and lowers labour costs. The fact there<br />

are no spin-on filters also means a big waste reduction.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

IRONING OUT<br />

THE DUKE<br />

Four <strong>Cummins</strong>-powered Hitachi excavators are exceeding<br />

production and availability targets at BGC Contracting’s<br />

iron ore mining operations at Iron Duke in South Australia.<br />

Three of the diggers are 254-tonne EX2600-6 units with<br />

Tier 2 <strong>Cummins</strong> QSK50 engines rated at 1500 hp, while the<br />

fourth is a 239-tonne EX2500-5 with a <strong>Cummins</strong> QSK45<br />

rated at 1350 hp.<br />

All are configured as backhoes and they moved in excess of<br />

15 million BCMs (bank cubic metres) in their first 12 months<br />

at the Iron Duke mine.<br />

20 21<br />

One of the three EX2600-6 excavators achieving high availability at Iron Duke.

USER REPORT<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

BGC plant operations manager Frank Wightman (centre) with <strong>Cummins</strong> customer support<br />

representative Andrew Bettess (left) and <strong>Cummins</strong> mining business manager Jason Linke.<br />

BGC is carrying out the mining<br />

operations for Arrium, a company<br />

that originated in 2000 when it was<br />

spun off from BHP as OneSteel.<br />

At the time, the company – with its<br />

Whyalla steelworks in South Australia<br />

– was solely a domestic manufacturer<br />

and distributor of steel products.<br />

The name change from OneSteel to<br />

Arrium occurred in 2012 to highlight<br />

the company’s evolution away<br />

from being a pure steel maker.<br />

In 2005 the decision was made to<br />

enter the iron ore export business,<br />

and today Arrium is the fourth largest<br />

producer of iron ore in Australia with its<br />

mining operations in South Australia.<br />

Arrium is aiming for sustained export<br />

sales of 12 Mtpa of hematite ore while<br />

also supplying magnetite iron ore feed to<br />

its steelworks at Whyalla. The company<br />

achieved a major milestone is June<br />

with an export run rate of 12 Mtpa.<br />

BGC began mining operations at Iron<br />

Duke in the Middleback Ranges near<br />

Whyalla in November 2012, and in late<br />

2013 expanded its operations to the<br />

Iron Knob area for Arrium – the first<br />

time full mining has been carried out<br />

in the area since the late 1990s.<br />

Iron Knob is the birthplace of the steel<br />

industry and was once home to the<br />

largest commercially-viable quantity<br />

of iron ore in Australia. In fact, BHP<br />

started mining at Iron Knob in 1899.<br />

At Iron Duke – a mine that opened<br />

in 1989 – BGC’s operations include<br />

drilling and blasting, and ore extraction<br />

and haulage. In the first 12 months<br />

of operation, the BGC fleet’s monthly<br />

movement of ore and waste was in the<br />

range of 1.3 to 1.5 million BCMs.<br />

“We hit the ground running from day<br />

one,” says BGC plant operations<br />

manager Frank Wightman.<br />

The fact that the diggers are the backbone<br />

of the operation is emphasised by<br />

Wightman who points out that their<br />

mechanical availability is in the high 90s<br />

compared with the targeted 95%.<br />

“We’ve been set challenging production<br />

targets and we’re meeting those targets,”<br />

he says. “In fact, we’re consistently<br />

exceeding the targets and we put that<br />

down to the new fleet of diggers.<br />

“That’s the reason we went with the new<br />

diggers. It takes one part of the risk away.”<br />

He points out there are high expectations<br />

for the Tier 2 <strong>Cummins</strong> QSK engines with<br />

their modular common rail fuel system,<br />

and to date they’re playing a key role<br />

in the reliability of the digger fleet.<br />

22 23

At Iron Duke BGC’s operations include drilling and blasting, and ore extraction and haulage.<br />

We’ve been set challenging production targets<br />

and we’re meeting those targets...<br />

“We have a lot of <strong>Cummins</strong> engines in our<br />

other operations and we don’t have a lot<br />

of problems, full stop,” he says. “We’re<br />

getting good support from <strong>Cummins</strong> too.”<br />

He points out that fuel burn is monitored<br />

closely – consumption is checked<br />

monthly – and the figures go into<br />

life cost modeling as a key factor<br />

behind “purchasing decisions”.<br />

Routine servicing at Iron Duke is carried<br />

out fortnightly when the machines are<br />

taken out of service for one shift. New<br />

fuel filters are fitted every 250 hours while<br />

oil/filter changes are every 500 hours.<br />

For most of the first 12 months at Iron<br />

Duke, BGC’s haul truck fleet included<br />

five Komatsu HD1500 units powered<br />

by <strong>Cummins</strong> QSK45 engines rated<br />

at 1500 hp. The 144-tonne payload<br />

capacity trucks played their part, too,<br />

in BGC achieving production targets.<br />

The five Komatsu trucks have since been<br />

transferred to Iron Knob and there’s<br />

the likelihood of a further six HD1500<br />

units to be added to this operation.<br />

One digger, a Hitachi EX2600-6, is<br />

working initially at Iron Knob and will be<br />

joined by a <strong>Cummins</strong> QSK60-powered<br />

Komatsu PC4000 by mid-<strong>2014</strong>.<br />

Komatsu HD1500 trucks have played their part in meeting production targets.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

DEWATERING<br />

Now we’re<br />

pumping<br />

A mine dewatering pump, powered by one of<br />

<strong>Cummins</strong>’ biggest CustomPaks in Australia<br />

and capable of pumping 250 litres/second<br />

at 200 metres head, has been manufactured<br />

by Weir Minerals Multiflo (WMM) for a<br />

mining project in Zambia, Africa.<br />

A leading dewatering specialist, WMM started<br />

designing and manufacturing dewatering<br />

pumps in Australia in 1976. WMM is<br />

one of three divisions of the Weir Group,<br />

headquartered in Scotland, which provides<br />

engineering solutions to the minerals, oil<br />

and gas, and power markets globally.<br />

The Multiflo MF-420EX heavy-duty<br />

dewatering pump was ordered by Kalumbila<br />

Minerals, a fully-owned subsidiary of First<br />

Quantum Minerals (FQM) for its Sentinel<br />

copper project in Zambia. Worldwide, FQM<br />

24 25

Dewatering pump capable of pumping 250 litres/second at 200 metres head.<br />

operates seven mines – including the<br />

Ravensthorpe nickel mine in Western<br />

Australia – and is currently developing<br />

other world class projects. At the request<br />

of FQM the unit was custom-engineered<br />

and manufactured to be powered by<br />

the <strong>Cummins</strong> QST30 CustomPak.<br />

The CustomPak powerpack is designed<br />

around <strong>Cummins</strong>’ QST30 engine, a<br />

30-litre V12 rated at 1050 hp. In high<br />

duty cycle mining applications such as<br />

rotary blasthole drilling, the QST30 is<br />

noted for its reliability and durability.<br />

<strong>Cummins</strong> CustomPaks have earned<br />

a reputation for robustness and the<br />

ability to operate in intense heat. All<br />

CustomPak cooling systems provide<br />

for continuous operation in ambient<br />

temperatures of plus 50 deg. Celsius.<br />

WMM points out that its Multiflo MF-<br />

420E pump was upgraded in late 2011<br />

to achieve the higher pressure ratings the<br />

market was seeking. This was done by<br />

improving the wet-end casing, allowing<br />

the system to go from running at 1400<br />

rpm to a maximum of 1700 rpm.<br />

With operations based in Coolum on<br />

Queensland’s Sunshine Coast and in<br />

Balikpapan, Indonesia, WMM is a leading<br />

supplier of custom-engineered dewatering<br />

pump units in the Asia Pacific region.<br />

CUMMINS SOUTH PACIFIC SUMMER <strong>2014</strong>

Send your story ideas, comments and feedback<br />

on this issue of <strong>Cummins</strong> Mining to:<br />

rachael.reinheimer@cummins.com<br />

<strong>Cummins</strong> after-hours assistance<br />

One number for Australia-wide parts and service.<br />

Experienced <strong>Cummins</strong> technicians on hand to answer your calls.<br />

All 250 <strong>Cummins</strong> field service vehicles fitted with GPS.<br />

Improved efficiency in meeting customer needs.<br />

<strong>Cummins</strong> has one number for after-hours assistance.<br />

For best-in-class support, call<br />

Australia -1300<strong>Cummins</strong> (1300 286 646)<br />

New Zealand - 0800 286 846<br />

Subscribe to the <strong>Cummins</strong> Mining Magazine - Click here