Cummins_eMag_Summer_2014 Final Single

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

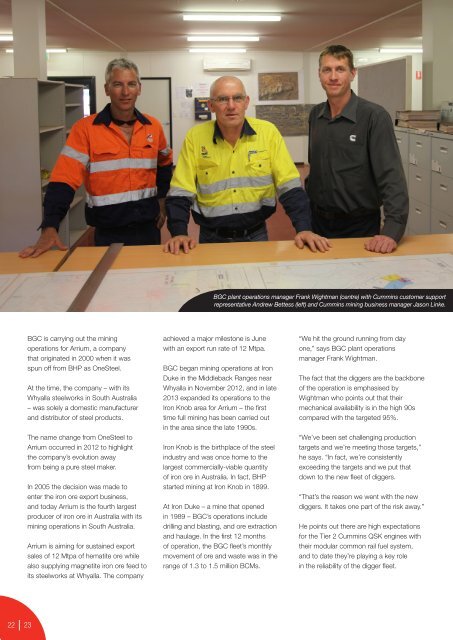

BGC plant operations manager Frank Wightman (centre) with <strong>Cummins</strong> customer support<br />

representative Andrew Bettess (left) and <strong>Cummins</strong> mining business manager Jason Linke.<br />

BGC is carrying out the mining<br />

operations for Arrium, a company<br />

that originated in 2000 when it was<br />

spun off from BHP as OneSteel.<br />

At the time, the company – with its<br />

Whyalla steelworks in South Australia<br />

– was solely a domestic manufacturer<br />

and distributor of steel products.<br />

The name change from OneSteel to<br />

Arrium occurred in 2012 to highlight<br />

the company’s evolution away<br />

from being a pure steel maker.<br />

In 2005 the decision was made to<br />

enter the iron ore export business,<br />

and today Arrium is the fourth largest<br />

producer of iron ore in Australia with its<br />

mining operations in South Australia.<br />

Arrium is aiming for sustained export<br />

sales of 12 Mtpa of hematite ore while<br />

also supplying magnetite iron ore feed to<br />

its steelworks at Whyalla. The company<br />

achieved a major milestone is June<br />

with an export run rate of 12 Mtpa.<br />

BGC began mining operations at Iron<br />

Duke in the Middleback Ranges near<br />

Whyalla in November 2012, and in late<br />

2013 expanded its operations to the<br />

Iron Knob area for Arrium – the first<br />

time full mining has been carried out<br />

in the area since the late 1990s.<br />

Iron Knob is the birthplace of the steel<br />

industry and was once home to the<br />

largest commercially-viable quantity<br />

of iron ore in Australia. In fact, BHP<br />

started mining at Iron Knob in 1899.<br />

At Iron Duke – a mine that opened<br />

in 1989 – BGC’s operations include<br />

drilling and blasting, and ore extraction<br />

and haulage. In the first 12 months<br />

of operation, the BGC fleet’s monthly<br />

movement of ore and waste was in the<br />

range of 1.3 to 1.5 million BCMs.<br />

“We hit the ground running from day<br />

one,” says BGC plant operations<br />

manager Frank Wightman.<br />

The fact that the diggers are the backbone<br />

of the operation is emphasised by<br />

Wightman who points out that their<br />

mechanical availability is in the high 90s<br />

compared with the targeted 95%.<br />

“We’ve been set challenging production<br />

targets and we’re meeting those targets,”<br />

he says. “In fact, we’re consistently<br />

exceeding the targets and we put that<br />

down to the new fleet of diggers.<br />

“That’s the reason we went with the new<br />

diggers. It takes one part of the risk away.”<br />

He points out there are high expectations<br />

for the Tier 2 <strong>Cummins</strong> QSK engines with<br />

their modular common rail fuel system,<br />

and to date they’re playing a key role<br />

in the reliability of the digger fleet.<br />

22 23