IMCO - 2017 Comprehensive End Mill Catalog

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

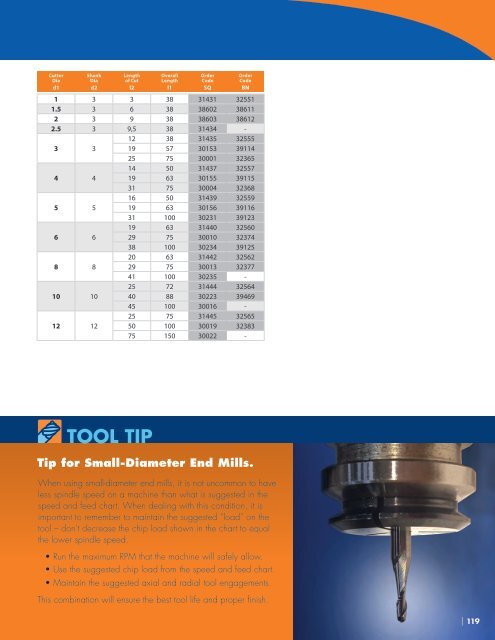

Cutter<br />

Dia<br />

Shank<br />

Dia<br />

Length<br />

of Cut<br />

Overall<br />

Length<br />

Order<br />

Code<br />

Order<br />

Code<br />

d1 d2 l2 l1 SQ BN<br />

1 3 3 38 31431 32551<br />

1.5 3 6 38 38602 38611<br />

2 3 9 38 38603 38612<br />

2.5 3 9,5 38 31434 -<br />

12 38 31435 32555<br />

3 3<br />

19 57 30153 39114<br />

25 75 30001 32365<br />

14 50 31437 32557<br />

4 4<br />

19 63 30155 39115<br />

31 75 30004 32368<br />

16 50 31439 32559<br />

5 5<br />

19 63 30156 39116<br />

31 100 30231 39123<br />

19 63 31440 32560<br />

6 6<br />

29 75 30010 32374<br />

38 100 30234 39125<br />

20 63 31442 32562<br />

8 8<br />

29 75 30013 32377<br />

41 100 30235 -<br />

25 72 31444 32564<br />

10 10 40 88 30223 39469<br />

45 100 30016 -<br />

25 75 31445 32565<br />

12 12 50 100 30019 32383<br />

75 150 30022 -<br />

TOOL TIP<br />

Tip for Small-Diameter <strong>End</strong> <strong>Mill</strong>s.<br />

When using small-diameter end mills, it is not uncommon to have<br />

less spindle speed on a machine than what is suggested in the<br />

speed and feed chart. When dealing with this condition, it is<br />

important to remember to maintain the suggested “load” on the<br />

tool – don’t decrease the chip load shown in the chart to equal<br />

the lower spindle speed.<br />

• Run the maximum RPM that the machine will safely allow.<br />

• Use the suggested chip load from the speed and feed chart.<br />

• Maintain the suggested axial and radial tool engagements.<br />

This combination will ensure the best tool life and proper finish.<br />

119