Welding World magazine June 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISSUE 03 JUNE <strong>2018</strong><br />

£8.99<br />

WHEN SOLD<br />

www.awd.org.uk<br />

IN THIS ISSUE<br />

WELDING WORLD AWARDS <strong>2018</strong><br />

ALSO IN THIS ISSUE•JOB KNOWLEDGE • SIFTIPS<br />

WELDING WORLD APP: why not grab it now?<br />

PLUS: PRODUCT REVIEWS • WELDING NEWS • AND MUCH MORE

WELCOME 3<br />

INSIDE<br />

4<br />

NEWS<br />

4 COVER STORY – <strong>2018</strong> <strong>Welding</strong> <strong>World</strong><br />

Awards Special<br />

On a remarkable night for the welding<br />

industry a total of 12 major accolades were<br />

presented at the Awards this year<br />

9 President’s Hall of Fame<br />

Oscar Kjellberg<br />

10 Power tool inventor<br />

Talks Mag drills – part 2<br />

12 Sweissen & Schneiden 2021<br />

Messe Essen extends contract<br />

12 LTI Metaltech<br />

Call for more women to enter workforce<br />

13 Polysoude Awards Ceremony<br />

Recognising the human investment . . .<br />

13 BOHS confirm prestigious honour<br />

for Steve Hails<br />

16 Finding the Hidden Benefits<br />

of your Trade Association – AWD and WWA<br />

16 Calendar<br />

Don’t miss these dates for your diary<br />

17 Maritime Integration and Support<br />

BAE Systems announces a £10 million<br />

investment programme<br />

17 Call for Evidence<br />

Government review to help business<br />

embrace new technology<br />

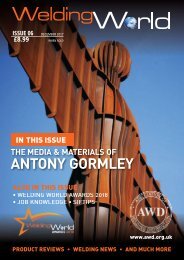

18 Ray Lonsdale – Artist<br />

The journey from owning a steel fabrication<br />

business to becoming one of our most<br />

talked about artists<br />

18 Group earnings increase<br />

January to March <strong>2018</strong>: Linde makes a good<br />

start to the new year<br />

NEW PRODUCTS<br />

22 A guide to some of the<br />

latest technologies<br />

FEATURES<br />

28 Job Knowledge<br />

Rotary Friction <strong>Welding</strong><br />

REGULARS<br />

21 President’s Message<br />

21 The Board<br />

30 SifTips<br />

<strong>Welding</strong> Inspection Essentials<br />

31 And Finally<br />

A message from the board<br />

18<br />

28<br />

EDITOR’S NOTE<br />

Welcome to this edition of <strong>Welding</strong> <strong>World</strong>.<br />

The second <strong>Welding</strong> <strong>World</strong> Awards has meant this has been quite a time for the welding<br />

industry as friends, colleagues and peer businesses have been able to get together and truly<br />

discuss the state of the industry.<br />

As Editor of <strong>Welding</strong> <strong>World</strong> it is always a delight to be able to catch up with so many of you in<br />

this field and not only talk shop, but also enjoy what is fast-becoming the number one social<br />

event in the calendar.<br />

JOIN THE<br />

JCONVERSATION<br />

@<strong>Welding</strong><strong>World</strong>1<br />

<strong>Welding</strong> <strong>World</strong> Retweeted<br />

Extractability @Extractability Download<br />

our new Fume Extraction range<br />

Catalogue weld.<br />

Of course along with the remarkable networking and sheer enjoyment of the night, we must<br />

not forget that we also gathered to highlight and give accolades to those who have not only<br />

made a major impact in the industry in the past year, but those who have contributed over a<br />

much greater length of time.<br />

The awards evening, so skillfully hosted by Eamonn Holmes, celebrated what is best about<br />

welding, but it was merely a pause rather that a full stop. While we hope that you like the<br />

picture spreads of the event and are reminded of a great night, we are of course aware that<br />

there is still a busy time ahead in what are fast-changing conditions.<br />

Despite this though, we applaud all of our winners and those who were shortlisted on the<br />

night and to all those who were there on the evening, we say how great it is to see such a<br />

lively and engaged <strong>Welding</strong> <strong>World</strong> family.<br />

Darren Isted,<br />

Editor, <strong>Welding</strong> <strong>World</strong><br />

editor@welding-world.com<br />

Retweeted eden pr @edenprnews<br />

#Did you know client @FosterindNews<br />

brought home the award for<br />

Best <strong>Welding</strong> Distributor to the<br />

#eastmidlands @<strong>Welding</strong><strong>World</strong><br />

<strong>Welding</strong> <strong>World</strong> @<strong>Welding</strong><strong>World</strong>1<br />

What steel crisis? We’re stable say<br />

Chinese although steel has increased<br />

77% this year! @thetimes<br />

thetimes.co.uk/tto/business/i...<br />

www.awd.org.uk |<br />

<strong>Welding</strong><strong>World</strong>1

4<br />

NEWS / AWARDS <strong>2018</strong><br />

WELDING WORLD<br />

Adrian Hawkins Managing Director of <strong>Welding</strong> <strong>World</strong><br />

with Eamonn Holmes and AWD President Bob Stacey<br />

On a remarkable night of celebration for<br />

the welding industry a total of 12 major<br />

accolades were presented at the <strong>Welding</strong><br />

<strong>World</strong> Awards <strong>2018</strong>.<br />

Held at the Hotel Metropole,<br />

Birmingham, this was the second edition<br />

of the awards which have moved from<br />

strength to strength highlighting some<br />

remarkable success stories and honouring<br />

those who have helped to keep the<br />

industry so buoyant.<br />

In an opening address, Adrian Hawkins,<br />

Managing Director of <strong>Welding</strong> <strong>World</strong>,<br />

welcomed the audience and reminded all<br />

those present that the awards underlined<br />

the industry’s ability to overcome adversity<br />

and also how customers are put at the<br />

very centre of the industry.<br />

Foster Industrial Ltd were the first<br />

winners onto the podium on the evening<br />

when they were announced as the Best<br />

E-Commerce Website Organisation.<br />

They were followed by Lorch<br />

Schweisstechnik Ltd who claimed the Best<br />

New <strong>Welding</strong> Product Supplier and then<br />

Extractability who were named as Best<br />

Safety Product Supplier.<br />

Best Surface Finishing was awarded for<br />

the first time this year and SIA Abrasives<br />

(GB) were the inaugural winners while<br />

AIS Training (Speciality Welds) claimed the<br />

honour for Best <strong>Welding</strong> Industry Training<br />

Provider.<br />

The <strong>Welding</strong> <strong>World</strong> Award was<br />

presented by AWD Company Secretary<br />

Dave Ellwood (the winner in 2016) to<br />

The Weldability-Sif Foundation and Best<br />

<strong>Welding</strong> Machine Supplier was claimed by<br />

EWM Hightec <strong>Welding</strong> (UK).<br />

General <strong>Welding</strong> Supplies (NW)<br />

Ltd were announced as Best <strong>Welding</strong><br />

Distributor and the final scheduled voted<br />

award of the evening was the Best Gas<br />

Agent and it was Fowlmere Engineering<br />

Ltd who took the honours, they have now<br />

won the same award on two occasions<br />

having taken the honour in 2016 as well.<br />

Among the achievement and services<br />

awards which were announced on the<br />

night, Helen Brewin from PGS training<br />

was handed the Services to the Industry<br />

and Association while the Lifetime<br />

Achievement Award was presented to Jon<br />

Pearsall from Pearsall Training.<br />

WESTERMANS INTERNATIONAL<br />

PROUD SPONSORS AT THIS YEAR’S WELDING WORLD AWARDS<br />

Westermans international<br />

Ltd. has once again been<br />

proud to play a key role in<br />

this year’s <strong>Welding</strong> <strong>World</strong><br />

Awards. The Leicesterbased<br />

company, which has<br />

specialised in the sourcing and<br />

supply of refurbished welding<br />

equipment to customers both<br />

in the UK and worldwide for<br />

some 50 years, sponsored<br />

the Best <strong>Welding</strong> Machines<br />

Supplier category at this year’s<br />

event. It is a role which, says<br />

founder Peter Westerman,<br />

is a perfect match for the<br />

company’s business –<br />

“The ongoing commitment<br />

by equipment manufacturers<br />

to keep pushing the<br />

boundaries of technology is at<br />

the heart of an industry that<br />

is central to so many products<br />

that are familiar to us all,” he<br />

says. “This belief in innovation<br />

and constant development<br />

also has a direct impact on our<br />

customers because it helps us<br />

to offer advanced refurbished<br />

Peter Westerman of Westermans International presents<br />

Best <strong>Welding</strong> Machine Supplier to EWM Hightec <strong>Welding</strong> (UK)<br />

equipment very cost effectively.<br />

The more technology advances,<br />

the greater the performance<br />

and capability of our<br />

refurbished stock – all of which<br />

we can then tailor to exact<br />

customer needs.”<br />

Peter Westerman and his<br />

colleagues were delighted not<br />

only to play a full supporting<br />

role for the awards but were<br />

also pleased to enjoy the<br />

event itself – which, this year,<br />

was hosted by Eamonn Holmes<br />

OBE. “The camaraderie<br />

and commitment towards<br />

achieving ever greater goals<br />

underpin the association<br />

and was clearly in evidence<br />

at the event. By sponsoring<br />

one of the principal awards,<br />

we believe we have made an<br />

important contribution that<br />

benefits not just the winners<br />

but the whole industry,”<br />

concludes Peter Westerman.<br />

“Our congratulations to<br />

all finalists, winners and<br />

organisers of the event.”<br />

WELDING WORLD MAGAZINE | ISSUE 03

NEWS / AWARDS <strong>2018</strong> 5<br />

AWARDS <strong>2018</strong><br />

THE WINNERS<br />

To fittingly complete the evening the<br />

AWD and <strong>Welding</strong> <strong>World</strong> Association<br />

Directors Award was presented to Adrian<br />

Hawkins.<br />

On a night of top entertainment for<br />

the audience, along with the tension of<br />

the awards, there was some light relief as<br />

modern jazz band Bella and the Bourbon<br />

Boys played through the evening meal<br />

while there was also close-up table magic<br />

from magician Matthew Knight and an<br />

unexpected (but scheduled!) musical<br />

interlude from one of the ‘waiting staff.’<br />

The chosen charity on the evening<br />

was Kidney Cancer UK which is the UKs<br />

leading kidney cancer charity, which aims<br />

to increase knowledge and awareness of<br />

the disease whilst also supporting research<br />

into causes, prevention and treatment.<br />

After a remarkable speech from Dave<br />

Ellwood, who described his own battle<br />

with the disease, a fantastic £10,276 was<br />

raised for the charity.<br />

BEST E-COMMERCE<br />

WEBSITE ORGANISATION<br />

Foster Industrial Ltd<br />

Alice Dewey (Development & Project Officer)<br />

of Kidney Cancer UK with Voluntary Community<br />

Fundraiser, Shirley Chapman and Eamonn Holmes<br />

BEST NEW WELDING<br />

PRODUCT SUPPLIER<br />

Lorch Schweisstechnik Ltd<br />

BEST SAFETY PRODUCT SUPPLIER<br />

Extractability<br />

BEST SURFACE FINISHING<br />

SIA Abrasives (GB)<br />

Modern jazz band Bella and<br />

the Bourbon Boys perform<br />

BEST WELDING INDUSTRY<br />

TRAINING PROVIDER<br />

AIS Training (Speciality Welds)<br />

THE WELDING WORLD AWARD<br />

The Weldability-Sif Foundation<br />

BEST WELDING MACHINE SUPPLIER<br />

EWM Hightec <strong>Welding</strong> (UK) Ltd<br />

BEST WELDING DISTRIBUTOR<br />

General <strong>Welding</strong> Supplies (NW) Ltd<br />

BEST GAS AGENT<br />

Fowlmere Engineering Ltd<br />

SERVICES TO THE<br />

INDUSTRY AND ASSOCIATION<br />

Helen Brewin PGS training<br />

“I was humbled for Extractability to be recognised at The<br />

<strong>Welding</strong> <strong>World</strong> Awards <strong>2018</strong>. This was truly a perfect tribute to<br />

the hard work of the entire Extractability team, and a fantastic<br />

recognition of all our hard efforts in the Safety Product field.<br />

And what an amazing night it was, too!” Lee Darton, Extractability<br />

LIFETIME ACHIEVEMENT AWARD<br />

Jon Pearsall from Pearsall Training<br />

AWD AND WELDING WORLD<br />

ASSOCIATION DIRECTORS AWARD<br />

Adrian Hawkins<br />

www.awd.org.uk | J <strong>Welding</strong><strong>World</strong>1

6<br />

NEWS / AWARDS <strong>2018</strong><br />

On a remarkable night of celebration<br />

for the welding industry a total of 12<br />

major accolades were presented at the<br />

<strong>Welding</strong> <strong>World</strong> Awards <strong>2018</strong>. Held at the<br />

Hotel Metropole, Birmingham, this was<br />

the second edition of the awards which<br />

have moved from strength to strength<br />

highlighting some remarkable success<br />

stories and honoring those who have<br />

helped to keep the industry so buoyant.<br />

This year the event was hosted by TV<br />

presenter Eamonn Holmes.<br />

WELDING WORLD<br />

Quotes from the awards<br />

“It has been an exceptional evening on all fronts. We have won<br />

an award, won a raffle and even won one of the silent auctions<br />

Ray Bardsley SIA Abrasives<br />

so it doesn’t get much better than that!”<br />

Event organiser Alexis Hawkins with Eamonn Holmes<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong><br />

“It is nice to see that people in the industry appreciate the hard<br />

work you have put in - Its good to be recognised”<br />

Martin Chantrill SAF-FRO<br />

“This award and the other awards which have been given out<br />

tonight represent what we are all about which is the customer”<br />

Toby Gourley Air Products<br />

“It has been an excellent evening, with possibly 280 people<br />

here tonight and it has been great for networking with a really<br />

good atmosphere. <strong>2018</strong> has had a great start for the welding<br />

industry and lets hope it continues for the rest of the year”<br />

Arran Nicoll Fowlmere Engineering

NEWS / AWARDS <strong>2018</strong> 7<br />

AWARDS <strong>2018</strong><br />

evening<br />

Adrian Hawkins addresses the audience<br />

“All the people who have turned up tonight have enjoyed it and<br />

all the comments I have heard have underlined their happiness<br />

with the event. There are lots of positive comments about the<br />

industry and where the industry is going.<br />

Given what we are trying to achieve with <strong>Welding</strong> <strong>World</strong> and<br />

Adrian Hawkins<br />

with the AWD I simply couldn’t wish for more”<br />

“I have had an excellent evening and am sure that everyone enjoyed. It it is very important<br />

that we support and continue to support the AWD in all the crucial work that it does for the<br />

Bob Stacey, President AWD<br />

welding industry”<br />

A musical interlude for the audience<br />

Eamonn Holmes gets the proceedings underway<br />

Bob Stacey<br />

www.awd.org.uk | J <strong>Welding</strong><strong>World</strong>1

8<br />

NEWS / AWARDS <strong>2018</strong><br />

“We really care for this industry and my family business<br />

and so many other family businesses are putting so much<br />

work into developing it and making it bigger and better and<br />

we will hopefully all be winners. That is what is so important<br />

Adrian Hawkins<br />

to everybody”<br />

“It has been an excellent evening, with possibly 280 people<br />

here tonight and it has been great for networking with a really<br />

good atmosphere. <strong>2018</strong> has had a great start for the welding<br />

industry and lets hope it continues for the rest of the year”<br />

Arran Nicoll Fowlmere Engineering<br />

Alice Dewey (Development & Project Officer)<br />

of Kidney Cancer UK with Voluntary Community<br />

Fundraiser, Shirley Chapman and Eamonn Holmes<br />

“This support will help us to support awareness and to continue<br />

to undertake vital research into Kidney Cancer”<br />

Alice Dewey, Development and Project Officer for Kidney Cancer UK<br />

Thank You for Supporting the Kidney Cancer UK Charity at the<br />

<strong>Welding</strong> <strong>World</strong> Awards <strong>2018</strong>.<br />

Thank you to everyone that attended<br />

the <strong>Welding</strong> <strong>World</strong> Awards Gala Evening<br />

<strong>2018</strong> at the Hilton Metropole Hotel at<br />

the NEC in Birmingham in April, hosted<br />

by Eamonn Holmes OBE.<br />

The Evening was vibrant with the<br />

entertainment, conversations and many<br />

AWD/WWA Members. Also good to<br />

see New Companies supporting the<br />

<strong>Welding</strong> <strong>World</strong> Awards for their first<br />

time. Congratulations to all the <strong>Welding</strong><br />

<strong>World</strong> Awards Finalists and a<br />

Big Congratulations to the Award<br />

Winners of <strong>2018</strong>.<br />

<strong>Welding</strong> <strong>World</strong> and AWD nominated<br />

‘Kidney Cancer UK Charity’ for <strong>2018</strong>. On<br />

the evening KCUK Charity spoke about<br />

Awareness to Kidney Cancer and how<br />

they help both the person and their<br />

family through the journey of getting<br />

well again. I was also asked to share<br />

with everyone my personal journey after<br />

getting Kidney Cancer and the recovery<br />

after my operation.<br />

The Unity and Generosity of the<br />

people at the <strong>Welding</strong> <strong>World</strong> Awards<br />

evening was overwhelming. The support<br />

you gave raised £10,267.00 on the<br />

evening for KCUK Charity. This will be<br />

put to Medical Research into Kidney<br />

Cancer and Help for the patients and<br />

their families.<br />

I would like to say a personal Thank<br />

You to Everyone for the Charitable<br />

Support you have given to beat Kidney<br />

Cancer. You have made a difference to<br />

help where help is needed. Thank you.<br />

Dave Ellwood<br />

AWD-WWA Director<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

NEWS 9<br />

PRESIDENT’S HALL OF FAME: #2<br />

On our last trip in our time machine, we talked about a pioneer left, this being a lime type substance. This was used in the early<br />

for the safe compression of Acetylene, Mr Nils Gustaf Dalen. experimentation of the first covered electrode, the man who<br />

We also identified that from the early manufacturing of had the vision to pioneer with this line of experiments was a Mr<br />

acetylene using a water to calcium carbide method, a waste is Oscar Kjellbergs.<br />

OSCAR KJELLBERG 1870-1931<br />

by AWD President Bob Stacey<br />

Pic of Oscar<br />

He was the eldest of five<br />

children, born to Johannes<br />

and Karolina, Kjellberg in<br />

the village of Motterud, in<br />

Sweden.<br />

It was said that as a pupil,<br />

he was always hardworking<br />

and diligent. In his early days<br />

as an engineer he had, by<br />

chance, a conversation with<br />

a Mr Axel Brostrom, who<br />

commented someone should<br />

invent a process so that the<br />

plates on a ship’s hull could<br />

be welded and not riveted,<br />

as was the norm.<br />

The main problem with<br />

the early type of arc welding<br />

was that they attempted to<br />

use a bare wire, (SWEDISH<br />

OR NORWAY IRON) this<br />

would produce a brittle and<br />

porous, weld due to the<br />

surrounding atmosphere,<br />

attacking the molten weld<br />

pool. Another method had<br />

to be found.<br />

Kjellberg rented a<br />

workshop to experiment,<br />

trying to overcome these<br />

problems. His first patent<br />

was dated July 1905. The<br />

description of this patent<br />

is more of puddle welding,<br />

when an arc is struck and a<br />

small weld pool is formed<br />

followed by using a hammer<br />

on the still molten weld<br />

pool to fashion some type<br />

of weld.<br />

In his detailed description,<br />

he explains how to hold the<br />

electrode in the left hand so<br />

that the hammer can be held<br />

in the right hand. In 1904<br />

he had the theoretical basis<br />

for what was to become the<br />

covered electrode.<br />

A big breakthrough came<br />

in <strong>June</strong> 1907. This patent<br />

was called Procedure for<br />

Electric <strong>Welding</strong>. This<br />

included the electrode. Its<br />

revolutionary property was<br />

that Kjellberg had coated<br />

the welding electrode, with<br />

a non-conductive material.<br />

The main advantage using<br />

this procedure was that<br />

the coating generated a<br />

protective gas (Co2) when<br />

the covering melted, this<br />

produced a weld without<br />

the formation of iron oxides<br />

in the weld pool, and for<br />

the first time, longer welds<br />

could be accomplished.<br />

After some successes using<br />

these lime based coverings,<br />

he then formulated a recipe<br />

for the coating that melted<br />

at the same rate as the<br />

metal rod.<br />

He found that a crater<br />

was formed at the tip of<br />

the electrode and this aided<br />

the direction of the flow<br />

of molten weld pool, thus<br />

giving some sort of control<br />

for overhead welding. This<br />

was only possible after<br />

many experiments with<br />

different recipes.<br />

Mastering difficult<br />

welding positions was a<br />

challenge and this would<br />

lead to another, third<br />

patent. From this we had<br />

the basis for all modern<br />

electrodes.<br />

Kjelberg became the<br />

MD for the ELEKTRISKA<br />

SVETSNINGS AKTIEBOLAGET,<br />

the known abbreviation is<br />

ESAB.<br />

<strong>Welding</strong> would prove<br />

itself during the First <strong>World</strong><br />

War 1914-1918. Due to the<br />

need to replace and repair<br />

navel tonnage, welding was<br />

proven as strong as riveting<br />

and could reduce the sheet<br />

metal weight by up to 10%.<br />

But it wasn’t until 1920<br />

that the Lloyds Register<br />

in London was to give<br />

approvals for an all welding<br />

as a production method. The<br />

first all welded ship was the<br />

ESAB 1V, this was launched<br />

on December 29, 1920. This<br />

became the world’s first all<br />

welded ship to be classified<br />

by Lloyds.<br />

So without Oscar<br />

Kjellberg, there is no doubt<br />

we would not have MMA<br />

welding as we know it - so a<br />

worthy place for our hall of<br />

fame hero.<br />

MATERIALS USED FOR ELECTRODE WELDING.<br />

THE TECHNICAL PART.<br />

Rutile is a mineral obtained from rutile<br />

bearing sands. It contains about 88-94% of<br />

Ti02 and is probably the most widely used<br />

material for electrode coatings.<br />

• Calcium carbonate or limestone is the<br />

covering for basic coverings of electrodes.<br />

• Solka flock is a cellulose acetate and<br />

is prepared from wood chip. It is the<br />

main constituent for class 1 of cellulose<br />

electrodes.<br />

An example of different Electrode<br />

Flux composition, and commonly used<br />

electrodes.<br />

RUTILE<br />

6013 High titania potassium AC OR DC either<br />

polarity.<br />

HYDROGEN CONTROLLED.<br />

7016 Low Hydrogen potassium AC or DCEP<br />

7018 Low Hydrogen potassium iron powder<br />

AC or DCEP<br />

We will Travel again in the next Edition,<br />

for more Hall of Fame Heroes.<br />

www.awd.org.uk | J <strong>Welding</strong><strong>World</strong>1

10<br />

NEWS<br />

POWER TOOL INVENTOR<br />

Part 2 of 2<br />

TALKS MAG DRILLS<br />

Nathan Ford, Area Sales Manager for<br />

Fein Power Tools in the UK, previously<br />

discussed what you should look for<br />

when purchasing a mag drill and the<br />

applications some can now achieve.<br />

He also briefly covers Fein’s own<br />

mag drill range, some new into<br />

the UK market.<br />

When it comes to drilling materials a<br />

little away from the norm then the<br />

correct accessory is essential. The correct<br />

cutter selection can make the difference<br />

between hours of frustration and<br />

expense, or getting a job done well.<br />

High Speed Steel, Tungsten Carbide,<br />

Titanium coated and High cobalt are<br />

some of the different cutter types<br />

available, and will all perform differently<br />

on different materials. It is worth seeking<br />

advice on which cutter would suit you<br />

application best and pairing it with the<br />

correct machine.<br />

We have a function on our Fein<br />

website called ‘core drill finder’ which<br />

provides precisely this advice, https://<br />

fein.com/en_uk/drilling/metal-coredrilling/core-drill-finder-t642962/.<br />

It<br />

provides information on the carbide<br />

(Ultra), coated HSS (Dura) and HSS<br />

(Nova) cutters, with various helpful<br />

information on the types of cutter sets<br />

available in the market.<br />

ADDITIONAL FEATURES AND SAFETY.<br />

Once we have the correct drill and<br />

accessories for our application, it is<br />

worth taking a second to look over any<br />

additional features which may set one<br />

machine apart from another.<br />

Capacity: As well as being used on site<br />

many of the larger capacity machines<br />

can replace the need for a conventional<br />

pillar type in the workshop. They make it<br />

easier to take the drill to the work piece<br />

rather than trying to move large pieces<br />

of steel up onto the drill bed. Larger<br />

machines are available with Morse taper<br />

fittings which allow for a wider range of<br />

accessories to be used.<br />

Ease of use: Ease of access to the<br />

controls can be something that is<br />

overlooked. The controls may be easy to<br />

access when the machine is operated in<br />

one direction but when turned around<br />

they may be impossible to reach. Try<br />

to find a machine which has controls<br />

that can be reached regardless of the<br />

orientation of the machine.<br />

Slide adjusters: Over time the slide on<br />

your machine may wear slightly due to it<br />

being metal upon metal, a good quality<br />

machine should have adjustments on<br />

the slides so that you can remove any<br />

play and tighten your guide. Any play<br />

in the guide will lead to movement and<br />

chattering in the cutter which may break<br />

cutters and also lead to an oval hole<br />

being drilled.<br />

As you can see there are a number of<br />

different decisions to be made before<br />

choosing the correct machine – capacity,<br />

depth of cut, applications, accessories,<br />

safety features, ease of use. It can be<br />

useful to ask for a demonstration of the<br />

product before purchasing either via<br />

the machine manufacturer or your local<br />

supplier to ensure that it is suited to<br />

your application.<br />

Fein has a large range of mag drills.<br />

In November of last year Fein launched<br />

its brand new cordless (AKBU 35) and<br />

compact (KBC 35) mag drills. If you<br />

need an economical mag drill or basic<br />

functionality, Fein is re-launching the<br />

KBE family of mag drills between May-<br />

<strong>June</strong> <strong>2018</strong>.<br />

To find out more about Fein mag<br />

drills check out: https://fein.com/en_uk/<br />

drilling/metal-core-drilling/<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

12<br />

NEWS<br />

SCHWEISSEN & SCHNEIDEN 2021<br />

Messe Essen extends contract with most important<br />

Asian sectoral society, CMES Cooperation strengthens<br />

the world’s leading sectoral event.<br />

Messe Essen is extending its longstanding<br />

collaboration with the Chinese Mechanical<br />

Engineering Society. Both partners have<br />

agreed to cooperate with regard to both<br />

leading trade fairs, SCHWEISSEN<br />

& SCHNEIDEN and Beijing Essen<br />

<strong>Welding</strong> & Cutting.<br />

China, the world’s largest steel<br />

producer with a strong demand for<br />

modern technology, is continuing to<br />

place its faith in the German based fair.<br />

The announcement was made by Oliver<br />

P. Kuhrt, CEO of Messe Essen, and Lu<br />

Daming, the new Vice President& General<br />

Secretary of CMES, at their joint contract<br />

signing ceremony. The Chinese engineering<br />

association which was founded in 1936 has<br />

over 180,000 members.<br />

For several decades, CMES has been<br />

present at the world’s leading fair in the<br />

sector, SCHWEISSEN & SCHNEIDEN, with a<br />

large number of exhibitors.<br />

At Messe Essen, over 1,000 exhibitors<br />

introduce innovations in joining, cutting<br />

and surfacing technologies every four<br />

years. Together, both partners, CMES and<br />

Messe Essen, organise the second largest<br />

fair in the sector, Beijing Essen <strong>Welding</strong> &<br />

Cutting. It has developed into an important<br />

sectoral platform and makes it possible for<br />

foreign companies to establish contacts<br />

into the region.<br />

China is an Important Market for the<br />

SCHWEISSEN & SCHNEIDEN Fair and for Lu<br />

Daming, the new number two at CMES,<br />

the contract signing ceremony was his first<br />

trip to Messe Essen: “I am pleased to get to<br />

know our important partner in person and<br />

to express my thanks for the outstanding<br />

cooperation, the deep trust and the success<br />

of the events. With our ideas and our<br />

proximity to the market, we will jointly<br />

accompany the fairs and develop them<br />

even further.”<br />

Oliver P. Kuhrt, CEO of Messe Essen,<br />

emphasised: “This contract extension<br />

highlights our commitment to offering<br />

the optimum fair platforms to the<br />

international welding sector. Thus, we are<br />

now already laying a foundation stone<br />

LTI METALTECH CALL FOR MORE WOMEN<br />

TO ENTER ENGINEERING WORKFORCE<br />

An award-winning Oxfordshire engineering company<br />

specialising in the green energy sector is calling for more<br />

women to enter into a career in British engineering and to<br />

sign up for the huge opportunities open to them in the sector.<br />

The UK currently has the worst percentage in Europe of<br />

women employed as engineers, languishing at less than ten<br />

per cent; something that urgently needs to be addressed, says<br />

LTI, if UK manufacturing is to remain competitive and more<br />

women are to be encouraged to join the industry.<br />

<strong>World</strong> leaders in advanced fabrication and welding<br />

techniques, Abingdon-based LTi Metaltech appreciates all<br />

too well the barriers many women endure when trying to<br />

break into traditionally male-dominated industries, such<br />

as discrimination and lack of resources. However, as an<br />

enterprising engineering company specialising in the precision<br />

fabrication of high performance vessels and structures, the<br />

company actively seeks employment of and supports both<br />

men and women, but the company’s Technical Director<br />

Edgar Rayner is still frustrated at the small number of female<br />

applicants wishing to embark on a career in the sector.<br />

Says Edgar Rayner, “At LTi, we actively encourage women<br />

to join our engineering team, and yet we are barely making<br />

in-roads, despite excellent opportunities and a recognition that<br />

women can bring unique skills to an industry still dominated<br />

by men. We need more women in engineering so younger<br />

for the next SCHWEISSEN & SCHNEIDEN<br />

which we will stage at Messe Essen from<br />

September 13 to 17, 2021.” This event<br />

will take place at the new Messe Essen<br />

for the first time: After the successful<br />

modernisation, one of the technically most<br />

innovative fair sites in Germany will be<br />

available to exhibitors and trade visitors<br />

from all over the world. Simple orientation,<br />

logistical flexibility and a modern<br />

infrastructure will ensure comfort, the best<br />

service and a high quality of stay.<br />

generations have role models to look up to and to know that a<br />

career in engineering is possible for them.”<br />

At present, women make up only 19 percent of senior roles<br />

in the UK, and an even smaller number of women (11%) make<br />

up the country’s engineering workforce, despite 15 per cent of<br />

UK engineering graduates being women.<br />

Stevie Clayton, 34, graduated with a BEng in Manufacturing<br />

Engineering from The University of Nottingham in 2017, and<br />

began work in the engineering industry, firstly as a Process<br />

Engineer. With hard work and perseverance, she worked her<br />

way up to her former role as Senior Quality Engineer at LTi,<br />

and after a recent promotion, became the company’s Quality<br />

Manager, living proof that women can compete and overcome<br />

stereotypical barriers to achieve career success.<br />

“Being a female in a male-dominated role has its own<br />

challenges. Women often need to work harder just to prove<br />

themselves and have their voices heard. But, if you walk<br />

in ready to get your hands dirty, have an open mind and<br />

communicate well, you can be successful in an Engineering<br />

Career. Working for a company that treats genders as equals<br />

is essential for this.” said Stevie Clayton, Quality Manager, LTi<br />

Metaltech<br />

For more information about LTi Metaltech’s work with<br />

women in engineering, visit: lti-metaltech.com or contact us<br />

on 01235 827 060.<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

NEWS- COVER STORY 13<br />

POLYSOUDE<br />

AWARDS CEREMONY<br />

Recognising the human investment…<br />

The majority of representatives from our global<br />

sales network were present for the ceremony<br />

Polysoude recently organised the<br />

second edition of the Polysoude Sales<br />

Awards at the company headquarters<br />

in Nantes. Polysoude invited<br />

representatives of their worldwide<br />

business partners, subsidiaries and<br />

offices participate in this ceremony.<br />

These awards were to recognise<br />

the best performances in the<br />

commercial, development and client<br />

service areas. Hans-Peter Mariner,<br />

the company CEO, had the honour of<br />

awarding the prizes at the prestigious<br />

Château des Ducs in Nantes city centre.<br />

Mr Mariner expressed his pleasure<br />

in awarding the cooperation between<br />

Polysoude employees and its partners.<br />

“It’s the recognition of team spirit and<br />

merit, major assets that I now share<br />

with you, by awarding for the second<br />

time these “prizes of excellence”.<br />

To reflect each effort given in 2017<br />

in the different activity sectors, many<br />

categories were given awards.<br />

For the category of the highest<br />

progression of orbital welding sales,<br />

the winners were as follows: 1st prize<br />

– Astro Arc Polysoude, subsidiary in<br />

USA, 2nd prize – Polysoude UK, office<br />

in UK and 3rd prize – Polysoude India,<br />

subsidiary in India.<br />

Special thanks also went out to<br />

teams and partners in South Korea<br />

(Chemiko) and in Japan (GMT) for their<br />

exceptional contribution regarding the<br />

volume of sales in 2017.<br />

In the area of automated welding<br />

and weld overlay cladding, they looked<br />

The majority of representatives from our global<br />

sales network were present for the ceremony<br />

towards SALWO with their impressive<br />

contribution, who received the award.<br />

Effectively, SALWO actively supports<br />

Polysoude welding and cladding<br />

operations in the Middle-East,<br />

especially orders from companies<br />

such as Gulf Steel Works and Aasia<br />

Steel. Those last two being extremely<br />

significant companies, working in the<br />

Oil and Gas industry.<br />

When looking at customer service,<br />

it’s the Polysoude France team<br />

who received first prize. This team,<br />

supported by all the services at the<br />

headquarters, developed their actions<br />

to combine spare parts sales and other<br />

services such as welding assistance,<br />

and material rentals all year long,<br />

contributing to a turnover of more than<br />

1.5 million euros in 2017.<br />

The awards ceremony was followed<br />

by cocktails and a meal with the festive<br />

atmosphere in the halls of the historic<br />

Château. Mr Mariner continued to<br />

express his willingness in working with<br />

volunteer groups and listening to their<br />

customer needs. He also mentioned<br />

that “Polysoude is now, more than ever,<br />

motivated to anticipate change”.<br />

BOHS CONFIRMS<br />

PRESTIGIOUS HONOUR<br />

FOR STEVE HAILS<br />

Steve is the Director of Health, Safety and<br />

Wellbeing at Tideway – the organisation<br />

responsible for delivering the Thames<br />

Tideway Tunnel. Steve has more than<br />

20 years’ experience in developing and<br />

implementing effective strategies, policies<br />

and systems in the engineering and<br />

construction sectors.<br />

He is a Chartered Member of IOSH;<br />

a Practitioner of IEMA; and has a<br />

Masters degree in Health, Safety and<br />

Environment. BOHS’ Honorary Fellowships<br />

are offered to only a small number<br />

of respected individuals, who have<br />

demonstrated significant effectiveness in<br />

working, influencing and advocating for<br />

improvement in worker health protection<br />

at a national level.<br />

Karen Bufton, immediate past president<br />

of BOHS, said: “It’s only fitting that Steve<br />

has been honoured for the significant<br />

and valuable contribution he has made<br />

to BOHS and occupational hygiene<br />

during the past few years, especially in<br />

terms of his involvement in the Breathe<br />

Freely in Construction campaign. We are<br />

privileged to have benefited from his<br />

extensive experience and expertise, and his<br />

involvement in groups such as: Health<br />

in Construction Leadership Group,<br />

and Mates in Mind.<br />

Speaking about the announcement,<br />

Steve commented: “I’m delighted to have<br />

had the opportunity to contribute to the<br />

valuable work that BOHS undertakes,<br />

by supporting its Breathe Freely in<br />

Construction campaign. Breathe Freely<br />

has not only helped shine a much-needed<br />

spotlight on the health risks faced by<br />

construction workers, but also – most<br />

importantly – it offers a wide range<br />

of free, expert training materials and<br />

information: this is accessible to all and<br />

can be downloaded from the website,<br />

offering valuable resources for managers<br />

and supervisors in the construction<br />

industry. Tools such as these can make a<br />

significant contribution to helping both<br />

employers and employees understand<br />

health risks in a construction environment,<br />

and subsequently to improve working<br />

conditions and working practices via<br />

suitable, inexpensive, effective and<br />

practical exposure control measures.”<br />

www.awd.org.uk | J <strong>Welding</strong><strong>World</strong>1

16<br />

NEWS<br />

FINDING THE HIDDEN BENEFITS<br />

OF YOUR TRADE ASSOCIATION –<br />

The word ‘Association’,<br />

AWD AND WWA. what does it mean?<br />

Organisation of people with a common purpose<br />

and having a formal structure:<br />

The act of associating or state of being associated:<br />

friendship; companionship: networking: sharing ideas:<br />

When you first thought about joining<br />

the AWD-WWA it was probably for<br />

one of several reasons. Your company<br />

may have been new or you needed to<br />

find out information or required help<br />

from the many of the benefits that are<br />

part of being a member of the AWD.<br />

Legal advice, technical advice, insurance<br />

advice, company medical schemes,<br />

advertising in <strong>Welding</strong> <strong>World</strong> Magazine,<br />

being seen in the AWD buyers’ guides<br />

and many others.<br />

The AWD is a conduit of welding<br />

information that is there to be shared<br />

and used. The <strong>Welding</strong> <strong>World</strong> <strong>magazine</strong>,<br />

use of the AWD-WWA logo on your<br />

company information profiles and your<br />

website. All are very strong and powerful<br />

benefits which mean your company can<br />

benefit by being a member.<br />

In some ways it is like a health club.<br />

Just because you joined the gym, this in<br />

itself does not make you lose weight or<br />

CALENDAR – MAKE SURE YOU DON’T MISS...<br />

July 15-20 <strong>2018</strong><br />

IIW <strong>2018</strong> Annual Assembly and<br />

International Conference<br />

In conjunction with the IIW General<br />

Annual Assembly, the International<br />

Conference aims provide a forum for<br />

networking and knowledge exchange<br />

among scientists, researchers, and<br />

industry related to welding and joining.<br />

Bali Nusa Dua Convention Center,<br />

Denpasar, Bali, INDONESIA<br />

October 16-17, <strong>2018</strong><br />

<strong>2018</strong> <strong>Welding</strong> Summit<br />

Due to the volume of construction<br />

projects taking place in the Gulf Coast,<br />

this year’s <strong>Welding</strong> Industry Summit<br />

will take place in League City, Texas,<br />

minutes from downtown Houston.<br />

South Shore Harbor Conference Center,<br />

League City, Texas<br />

tone those muscles. No, you have to join<br />

in and get the best out of the equipment<br />

and the advice they offer. You joined to<br />

get fit and improve by being part of a<br />

group of likeminded people. To share<br />

new ideas and the goals you set when<br />

you joined. This is when you see the<br />

value of your membership!<br />

When you joined the AWD<br />

(Association of <strong>Welding</strong> Distribution) it<br />

was for some very sound reasons.<br />

To improve what you are already<br />

doing, to get better communication<br />

with likeminded people. To become<br />

known. It is a very powerful benefit that<br />

should not be hidden and you must use<br />

your membership.<br />

Please remember to be associated with<br />

your association. Do not leave your AWD<br />

membership in the office drawer. Take<br />

part in the AWD during the year and<br />

keep your company fit and in front of<br />

the competition.<br />

October 23-26, <strong>2018</strong><br />

EuroBLECH <strong>2018</strong><br />

Sheet metal working professionals from<br />

all over the world will meet again in<br />

Hanover, Germany, at the largest trade<br />

fair for this industry sector. EuroBLECH<br />

offers its audience a comprehensive<br />

overview of prevailing trends in sheet<br />

metal working, with an impressive range<br />

of machines, tools and systems live on<br />

display across eight exhibition halls.<br />

Hanover Exhibition Grounds, Hanover,<br />

Germany<br />

November 6-8, <strong>2018</strong><br />

FABTECH<br />

FABTECH brings a wealth of innovation<br />

and technology solutions to Atlanta.<br />

More than 35,000 attendees and over<br />

1,500 exhibiting companies are expected<br />

to gather once again to celebrate metal<br />

Dave Ellwood, Director and Company Secretary,<br />

<strong>Welding</strong> <strong>World</strong><br />

If you have any questions please do<br />

not hesitate to contact Dave Ellwood<br />

on 07860 258309<br />

or email dave@britweld.co.uk<br />

manufacturing at its best.<br />

Georgia <strong>World</strong> Congress Center,<br />

285 Andrew Young International Blvd NW,<br />

Atlanta, GA 30313<br />

December 5-6 <strong>2018</strong><br />

International Conference <strong>Welding</strong> and<br />

related technologies<br />

The International Conference <strong>Welding</strong><br />

and related technologies, organised<br />

by the Paton Electric <strong>Welding</strong> Institute<br />

of NAS of Ukraine, at the Ukrainian<br />

National Academy of Sciences in Kiev,<br />

Ukraine, will cover areas like welding<br />

and related technologies.<br />

Ukrainian National Academy of Sciences,<br />

Kiev, Ukraine

NEWS 17<br />

MARITIME INTEGRATION AND SUPPORT<br />

BAE Systems has announced a £10 million<br />

investment programme to upgrade<br />

its Maritime Integration and Support<br />

Centre (MISC) in Portsmouth – a specialist<br />

facility providing vital support for Royal<br />

Navy warships whilst researching future<br />

combat systems and technologies.<br />

Located on Portsdown Hill and shaped<br />

like a Type 45 destroyer, the MISC is a<br />

unique facility that accurately replicates<br />

real-life ship conditions using the same<br />

combat system technology found across<br />

the Royal Navy’s surface fleet - including<br />

systems used to track threats, co-ordinate<br />

weapons and manage on-deck aircraft<br />

movements. The facility enables highly<br />

skilled engineers to develop and test key<br />

elements of combat systems before they<br />

are installed on ships and, once in service,<br />

provide them with through-life support.<br />

Supporting the development of future<br />

combat systems, BAE Systems’ £10 million<br />

investment programme will research new<br />

technologies such as artificial intelligence,<br />

information and electronic warfare,<br />

unmanned vehicles and new weapons.<br />

The MISC will benefit from new<br />

facilities including a state of the art<br />

visualisation suite able to display live<br />

tactical data from any Royal Navy warship<br />

anywhere in the world, further enhancing<br />

warship support. The pioneering<br />

technology will provide BAE Systems’<br />

Naval Combat Systems Integration<br />

Support Services (NCSISS) engineers with<br />

all the information they need to keep<br />

ships battle ready and support them in<br />

their deployments.<br />

CALL FOR EVIDENCE<br />

Government review to help business embrace new technology and boost wages and profits<br />

In a bid to increase productivity<br />

and with it the nation’s wages and<br />

profits, Chancellor Philip Hammond<br />

has announced a Call for Evidence on<br />

the UK’s productivity, seeking views<br />

on how to boost the performance of<br />

Britain’s businesses.<br />

The Business Productivity Review<br />

will focus on how firms across the<br />

country can take advantage of leading<br />

technologies, management practices<br />

and business support services. Increasing<br />

productivity leads to a long-term boost<br />

to workers’ wages and businesses’<br />

profits – a key part of the government’s<br />

modern Industrial Strategy.<br />

Through the Industrial Strategy, the<br />

government is building upon the UK’s<br />

position as one of the best places in the<br />

world to start and grown a business.<br />

Around 1,100 businesses start every day<br />

in Britain. However, UK productivity is<br />

below the average for the rest of the<br />

G7 advanced economies.<br />

Research from the CBI suggests<br />

that by encouraging more businesses<br />

to adopt the best tried and tested<br />

technologies available – such as cloud<br />

computing, mobile technology and<br />

e-purchasing – the UK economy could<br />

receive a £100 billion boost and see a<br />

5% reduction in income inequality.<br />

Acknowledging the UK’s significant<br />

economic strengths, the Chancellor told<br />

the Confederation of British Industry<br />

(CBI) that we can do more to make the<br />

most of our untapped potential.<br />

Business Secretary Greg Clark said:<br />

“For centuries Britain has been a nation<br />

of discoveries, but these ideas haven’t<br />

always been commercialised in the UK<br />

and new ideas applied in practice.<br />

”Now our modern Industrial Strategy<br />

is ensuring that firms across the UK can<br />

take advantage of leading technologies<br />

and management practices, potentially<br />

adding £100 billion to the economy and<br />

boosting people’s earning power right<br />

across the country.”<br />

The Chancellor also announced £20<br />

million government investment for the<br />

Made Smarter pilot scheme aimed at<br />

boosting productivity and growth in the<br />

north west.<br />

The industry-led pilot will help<br />

up to 3,000 small and mediumsized<br />

manufacturers become more<br />

competitive through greater use of<br />

digital technology in the manufacturing<br />

process and in supply chains.<br />

The Business Productivity Review<br />

Call for Evidence is open until 4 July<br />

<strong>2018</strong> and the government encourages<br />

businesses, trade associations and other<br />

interested parties to contribute their<br />

views to it.<br />

www.awd.org.uk | J <strong>Welding</strong><strong>World</strong>1

18<br />

NEWS<br />

RAY LONSDALE – ARTIST<br />

The journey from owning a steel fabrication business to becoming one<br />

of our most talked about artists has been a swift one for Ray Lonsdale.<br />

After working at Coles Cranes in<br />

Sunderland, and then forming his own<br />

steel fabrication business, producing<br />

items such as bins and seats, he has since<br />

made headlines in the art world with his<br />

business Two Red Rubber Things.<br />

Speaking to <strong>Welding</strong> <strong>World</strong> <strong>magazine</strong>,<br />

Ray said: “This was the direction that I<br />

wanted to take and there just wasn’t the<br />

time for me to take an art degree so I<br />

went ahead and took a chance in 2007.<br />

Most of the work I undertake is fabricated<br />

from Corten steel in a 3D mosaic style.<br />

This is basically just random shape and<br />

size pieces plasma cut from mainly 3mm<br />

sheet. These pieces are then reassembled<br />

to produce the finished article. All the<br />

sculptures are made freehand and are<br />

basically three dimensional sketches.”<br />

With more than 30 life sized statues<br />

completed Ray has won warm acclaim for<br />

his works ‘Freddie Gilroy and the Belsen<br />

Stragglers’ and ‘Eleven O One’.<br />

The latter stands at 9ft 5ins tall and is<br />

situated in Seaham, County Durham. Its<br />

name is given to the time and date of the<br />

<strong>World</strong> War I armistice in 1918 and looks<br />

GROUP EARNINGS INCREASE<br />

Corporate News<br />

• Group revenue: EUR 4.044 bn (up 1.4<br />

percent after adjusting for exchange<br />

rate effects and the impact from the<br />

first-time application of IFRS 15)<br />

• Group operating profit : EUR 1.081 bn<br />

(up 12.1 percent after adjusting for<br />

exchange rate effects)<br />

• Earnings per share adjusted for special<br />

items: EUR 2.19 (2017: EUR 1.77)<br />

• Group outlook for <strong>2018</strong> confirmed<br />

• Completion of merger with Praxair still<br />

planned for the second half of <strong>2018</strong><br />

Technology company The Linde Group<br />

saw positive business trends in the<br />

first quarter of <strong>2018</strong>. After adjusting<br />

for exchange rate effects and for the<br />

impact of the first-time application<br />

of new accounting standard IFRS 15,<br />

revenue rose by 1.4 percent compared<br />

with the first quarter of 2017. Group<br />

operating profit increased significantly<br />

by 12.1 percent after adjusting for<br />

exchange rate effects. Linde was able<br />

to improve its operating margin by<br />

300 basis points to 26.7 percent (2017:<br />

23.7 percent).<br />

Caption if needed<br />

“We have continued to grow and<br />

have achieved a substantial increase in<br />

our profitability,” said Professor Dr Aldo<br />

Belloni, Chief Executive Officer of Linde<br />

AG. “The significant improvement in<br />

our Group margin is the result of the<br />

efficiency measures we have introduced,<br />

continued portfolio optimisation and<br />

good macroeconomic conditions.”<br />

In the Gases Division, Linde generated<br />

revenue in the first quarter of <strong>2018</strong> of<br />

EUR 3.512 bn, a decrease of 7.6 percent<br />

when compared with the figure for<br />

the first quarter of 2017 of EUR 3.799<br />

bn. After adjusting for exchange rate<br />

effects and for the impact of the firsttime<br />

application of IFRS 15, revenue<br />

in the Gases Division increased by 2.8<br />

percent. On a comparable basis (after<br />

also adjusting for changes in the price<br />

of natural gas), revenue growth was<br />

2.6 percent. Operating profit was EUR<br />

1.079 bn, which was 2.5 percent higher<br />

than the figure for the prior-year<br />

period of EUR 1.053 bn. After adjusting<br />

for exchange rate effects, operating<br />

profit increased by 10.9 percent. At<br />

30.7 percent, the operating margin was<br />

set to be exhibited<br />

permanently after a<br />

campaign to keep<br />

the 1.2 tonne statue<br />

in the town.<br />

Freddie Gilroy is located on North Bay<br />

in Sacrborough and is based on a retired<br />

miner friend of Ray who he later found<br />

out was one of the first soldiers to liberate<br />

the Bergen-Belsen concentration camp at<br />

the end of <strong>World</strong> War II.<br />

“Both the ‘Freddie Gilroy’ and ‘Eleven<br />

O One’ sculptures were built on spec and<br />

not commissioned. They were put out on<br />

loan and fortunately bought by members<br />

of the public then donated for display,”<br />

said Ray.<br />

Ray is currently working on an sculpture<br />

of Emily Wilding Davison (the suffragette<br />

who was killed by the kings horse in<br />

1913). This will be sited in Morpeth,<br />

Northumberland near where she is buried.<br />

Caption if needed<br />

January to March <strong>2018</strong>: Linde makes a good start to the new year – significant increase in Group earnings<br />

significantly higher than the figure for<br />

the first quarter of 2017 of 27.7 percent.<br />

Positive trends were to be seen<br />

in the EMEA segment in almost all<br />

product areas. In the liquefied gases<br />

and cylinder gas product areas in<br />

particular, revenue increased in virtually<br />

all regions. In the on-site business, there<br />

were volume reductions as a result of<br />

the sale of parts of a production facility.<br />

Engineering Division:<br />

Margin significantly above the target of<br />

around 9 percent<br />

Revenue in the Engineering Division<br />

fell in the first quarter of <strong>2018</strong> by 7.1<br />

percent to EUR 602 m (2017: EUR 648<br />

m). Operating profit increased to EUR<br />

60 m (2017: EUR 53 m). At 10.0 percent,<br />

the operating margin was significantly<br />

above the figure for the first quarter<br />

of 2017 of 8.2 percent and exceeded<br />

the target of around 9 percent which<br />

Linde Engineering has set itself for the<br />

<strong>2018</strong> financial year. This was due not<br />

only to higher earnings from individual<br />

plant construction projects, but also to<br />

improved capacity utilisation.<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

20<br />

NEWS<br />

WHAT IS JOB KNOWLEDGE?<br />

Job Knowledge is written into and<br />

recognised by most Welder Qualification<br />

standards and, dependent on the<br />

standard, can become a mandatory<br />

requirement (for example, in ISO 24394<br />

or BS EN ISO 14732).<br />

Its purpose is to provide welders and<br />

operators with a thorough<br />

understanding of the welding process<br />

being used. Job Knowledge covers<br />

the associated Health and Safety<br />

risks, weld defects and how to reduce<br />

their occurrence, the variables which<br />

can influence a change of welding<br />

parameters, and the importance and<br />

understanding of the Inert Gas Envelope,<br />

to name just a few. Job Knowledge also<br />

satisfies HSE requirements that welders<br />

and operators have been adequately<br />

trained, which is clearly of benefit to<br />

employers. Providing welders with a<br />

better understanding of the adopted<br />

welding process reduces weld failures<br />

and improves overall weld quality,<br />

and this is where Job Knowledge really<br />

becomes effective.<br />

If you have any questions on Job<br />

Knowledge or would like more information<br />

please get in touch with our office and we<br />

will be happy to answer your questions or<br />

discuss your requirements.<br />

Phone: 01327 879500<br />

Mobile: 07702 120686<br />

Email: jake.rambaldini@outlook.com<br />

Website: www.rambaldiniwelding.co.uk<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

NEWS 21<br />

THE BOARD<br />

Dave P. Ellwood<br />

Director & Company Secretary<br />

Tel:<br />

01252 333661<br />

07860 258309<br />

E-mail:<br />

dave@weldingworld.com<br />

AWD National Council<br />

PRESIDENT<br />

Bob Stacey<br />

Tel: T +44 (0) 5600 494 599<br />

E-mail: president@awd.org.uk<br />

PAST PRESIDENT<br />

John Wilkinson OBE<br />

Tel: +44 (0)1952 290036<br />

REGIONAL OFFICERS<br />

North<br />

Iain Pickles – Regional Officer<br />

<strong>Welding</strong> Alloys Ltd<br />

Tel: +44 (0) 1763 207568<br />

07826 546797<br />

E-mail:<br />

iain.pickles@welding-alloys.com<br />

Central<br />

South East<br />

Gareth Hawkins – Regional Officer<br />

Weldability-Sif<br />

Tel: +44 (0)1462 482200<br />

0797 6830017<br />

E-mail:<br />

gareth@weldability-sif.com<br />

Adrian Hawkins<br />

Managing Director<br />

Tel:<br />

01462 482200<br />

07793 220800<br />

E-mail:<br />

adrian@welding-world.com<br />

Lee Darton<br />

Finance Director<br />

Harry Reade – Membership Manager<br />

AWD<br />

Tel: +44 (0)7584 088061<br />

E-mail: harryreade@aol.com<br />

South West<br />

Caretaker of Region – Robert Pullen<br />

(Regional Officer)<br />

Tel: +44 (0)1639 777012<br />

Mob: +44 (0)7807 275089<br />

E-mail: Rob@mhmplant.com<br />

WORK GROUPS<br />

Product Safety and Quality<br />

(PSQ) Committee<br />

Chairman: Nigel Hasted, BOC<br />

Education and Training<br />

Committee<br />

Chairman: Dave Ellwood,<br />

Britannia <strong>Welding</strong><br />

Tel:<br />

01462 482200<br />

07734 857044<br />

E-mail:<br />

lee@weldingworld.com<br />

Membership Committee<br />

Chairman: James Westhorp, <strong>Welding</strong><br />

Engineering Services<br />

Personnel Safety and<br />

Occupational<br />

Health (PSOH)<br />

Chairman: Tony Ashall, Plymovent<br />

PRESIDENT’S MESSAGE<br />

For all those who joined me at our latest <strong>Welding</strong> <strong>World</strong><br />

Awards, I know I can speak for everyone present when I say<br />

what a fantastic evening it was.<br />

I would like to pass my congratulations to all of the<br />

worthy winners of the <strong>Welding</strong> <strong>World</strong> Awards and also to<br />

the finalists.<br />

We have all contributed to our industry, in one way or<br />

another, and it is only fitting that the winners and finalists are<br />

recognised for these efforts.<br />

It was a joy to see manufacturers, distributors and all<br />

present, contributing to a very special evening.<br />

We all may be different on how we approach the end user<br />

market, and competitors, but remember that we are all trying<br />

to earn a living in a sometimes, difficult business climate.<br />

I had a fantastic time at the awards evening, it was a real<br />

pleasure to meet up with old friends from all different sectors<br />

of our industry. It was also an honour and a privilege to have<br />

been your President, on this special occasion.<br />

Thank you to everyone who supported The <strong>Welding</strong> <strong>World</strong><br />

Awards, and your continuing support to the AWD, whose<br />

part in our industry is vital.<br />

A special thanks has to go to the<br />

organisers who did a most remarkable<br />

job in making this awards evening so<br />

professional and entertaining.<br />

My last mention is a big thank you to all<br />

who donated to a very worthy charity,<br />

Kidney Cancer UK. We heard<br />

some really moving stories<br />

about why it’s so important<br />

to continue our support<br />

for these, in many cases,<br />

unrecognised heroes.<br />

Bob Stacey<br />

President AWD<br />

AWD CUFFLINKS<br />

As part of The Association of<br />

<strong>Welding</strong> Distribution official<br />

merchandise, AWD cufflinks<br />

are available for members<br />

to purchase at £20.00 per pair<br />

(P&P £5.00). Payment may be<br />

made by debit/credit card –<br />

telephone the AWD secretariat<br />

on +44 (0)1952 290 036 or<br />

email: secretariat@awd.org.uk<br />

www.awd.org.uk | J <strong>Welding</strong><strong>World</strong>1

22<br />

PRODUCT NEWS<br />

NEW PRODUCTS<br />

Your<br />

guide to the latest<br />

welding technologies<br />

on the market<br />

FRONIUS LAUNCHES NEW TIG SERIES ON THE MARKET<br />

Fronius has expanded its portfolio of manual power sources<br />

with three new devices for Tungsten Inert Gas welding (TIG). The<br />

MagicWave 230i, 190 and TransTig 230i are extremely practical,<br />

powerful and quiet. Thanks to their rapid signal processors, they<br />

always achieve the exact current curve that allows for maximum<br />

arc stability with the lowest possible noise emissions. With its<br />

intuitive menu navigation, users are able to access the correct<br />

parameters in just a few steps and can then concentrate fully on<br />

what they’re best at – achieving a clean weld seam.<br />

The MagicWave 230i can communicate and be networked with<br />

other devices via Bluetooth, WLAN and NFC technology.<br />

HIGHLY VERSATILE POWER SOURCES<br />

FOR AC WELDING<br />

Whether in pipeline or container<br />

construction, for processing stainless steel<br />

or vehicle repair and maintenance – the<br />

new Fronius TIG welding systems have a<br />

whole range of uses. The most powerful<br />

power source is the MagicWave 230i for AC<br />

welding. It has one particular advantage:<br />

it can communicate with other devices via<br />

Bluetooth, WLAN and NFC technology, The MagicWave 190 is<br />

and can be networked with them. The ideal for welding materials<br />

such as steel, stainless steel<br />

MagicWave 190 is ideal for welding or aluminium.<br />

materials such as steel, stainless steel or<br />

aluminium. The AC power source features gas cooling and is the<br />

best choice for a wide range of uses.<br />

LIGHTWEIGHT FOR DC WELDING<br />

An integral part of the new series is the<br />

TransTig 230i for DC welding. Weighing<br />

just 15.9 kilograms, it is especially light.<br />

This manual power source is suitable<br />

for all welding applications apart from<br />

aluminium. As with the MagicWave 230i,<br />

the power source can also be supplied with<br />

an optional water-cooling system. Using<br />

Bluetooth, WLAN and NFC, the TransTig 230i<br />

can also connect wirelessly to devices such<br />

as an intelligent welding helmet, remote<br />

control or even<br />

a smartphone.<br />

OPTIMUM USER CUSTOMISABILITY<br />

The multilingual operating concept of<br />

the manual power source with a 4.3-inch<br />

full-colour display allows for<br />

intuitive and extremely<br />

simple operation. Using<br />

the favourites button,<br />

welders can easily retrieve and<br />

The pure DC power source<br />

TransTig 230i can optionally<br />

be supplied with a watercooling<br />

system and is suitable<br />

for all welding applications apart<br />

from aluminium.<br />

set parameters that they often use.<br />

The modular design is a particular advantage:<br />

users can expand these devices as desired with<br />

different function packages. These include<br />

the job function, which can store up to 999<br />

jobs at the same time, the PulsPro package to<br />

obtain all pulse functionalities, additional data<br />

documentation and limit monitoring.<br />

The latter aids the user in setting a defined parameter<br />

window and keeping to certain welding parameters. USB ports<br />

allow software updates to be installed and welding data to<br />

be documented.<br />

NEW WELDING TORCH FOR PRECISE HANDLING<br />

Every device is available as a multivoltage<br />

version. Using the Fronius Power Plug – a<br />

lockable plug connector on the rear of the<br />

power source – the mains cable or plug can<br />

be changed quickly and easily depending<br />

on where the device is being used. This<br />

means it can be used anywhere in the<br />

world – even with different mains voltages.<br />

Fronius has also redesigned the welding<br />

torch: an ergonomic grip combined<br />

with a torch changing system as<br />

standard increases comfort and<br />

convenience, and allows for<br />

even more precise handling.<br />

The integrated, highperformance<br />

LED illuminates<br />

the seam area efficiently,<br />

leaving the welder to<br />

concentrate entirely on<br />

their task and achieve<br />

excellent results.<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

DOWNLOAD<br />

<br />

OUR NEW APP<br />

As a special benefit to AWD members<br />

the app will also be FREE<br />

The direct links to the <strong>Welding</strong> <strong>World</strong> app<br />

are as follows:<br />

iOS: http://goo.gl/ZaXVYY<br />

Android: http://goo.gl/USwFjZ<br />

WW_Apr17_19_WW_App.indd 1 19/06/<strong>2018</strong> 15:57

24<br />

PRODUCT NEWS<br />

WESTERMANS INTERNATIONAL BRINGS COST EFFECTIVE PLASMA CUTTING TO A WIDE MARKET<br />

Westermans International Ltd. has built a leading global<br />

reputation for the sourcing and supply of refurbished welding<br />

equipment that meets both performance and budgetary<br />

objectives. The approach has opened up opportunities for<br />

customers in a wide range of industries and geographical<br />

locations to benefit from proven and technically advanced<br />

equipment without the need for capital outlay on new<br />

installations, but still with the benefit of extensive experience<br />

and a broad service capability.<br />

The company’s reputation is not built only on the provision<br />

of welding equipment – from conventional MIG or TIG welders<br />

to advanced orbital welding stations – but also on a long list of<br />

ancillary equipment that is relevant to welding processes. For<br />

the last 25 years, this has included a range of plasma cutting and<br />

associated equipment and, because of Westermans’ access to<br />

multiple manufacturers – there are more than 100 plasma cutting<br />

equipment producers worldwide – the door can be opened for<br />

customers to ensure that the most suitable machinery is supplied<br />

for each specific application very cost-effectively.<br />

“Plasma cutting has come a long way from large machines<br />

found typically in shipyards,” explains Claire Spillane, Company<br />

Secretary at Leicester-based Westermans International. “Today,<br />

modern installations can be far smaller – even operating in some<br />

cases from a lap top – and are invariably noted for their extreme<br />

versatility and low capital investment requirements.”<br />

This is an area in which Westermans has long been a key<br />

supplier to the international welding and cutting industry. The<br />

range of benefits associated with plasma cutting systems can<br />

therefore be brought more readily to appropriate industry sectors.<br />

“Factors such as cut quality, shape and size versatility, batch or<br />

mass production options, high definition or simply the ability to<br />

follow template silhouettes or line drawings – all are associated<br />

with the choice of equipment now on the market – and which we<br />

can make available to our customers,” adds Claire Spillane.<br />

Westermans can source and supply used systems based on<br />

single or multiple cutting torches while most machines, if not<br />

already, can be upgraded and fitted with CNC controllers and/or<br />

additional torches at a later date. The company provides systems<br />

that can operate with a range of metals – from mild and stainless<br />

steel to aluminium – and, in all cases, provides installation<br />

support and warranty options, enabling many customers to bring<br />

their plasma cutting in-house.<br />

Steering a path through the consequent choice of systems is<br />

one of the key roles played by Westermans for its customers. In<br />

all cases, the objective is to ensure the best solution is identified<br />

each time – both in terms of performance and cost. From<br />

the cutting system itself to control systems and mechanical<br />

components, and from fume extraction to CAD/CAM software,<br />

Westermans provides tailored packages to customers worldwide.<br />

“Whether a small fabrication shop or a multi-national oil and<br />

gas system manufacturing enterprise, we are able to work<br />

with each individual customer to help them optimise their<br />

installation and to work towards their continuing success,”<br />

concludes Claire Spillane.<br />

Full details of Westermans’ services can be found at<br />

www.westermans.com<br />

WELDING WORLD MAGAZINE | ISSUE 03 | JUNE <strong>2018</strong>

26<br />

PRODUCT NEWS<br />

PREMIUM QUALITY THAT PAYS – EWM AG PRESENTS THE NEW PM-MIG/MAG WELDING TORCH SERIES<br />

EWM AG expands its range of MIG/MAG welding torches to<br />

include the PM series for professional users. The newly designed<br />

grip guarantees a comfortable hold, even over long periods,<br />

and illuminates the working area with its motion-activated LED<br />

lighting. Thanks to tried-and-tested EWM quality, the PM welding<br />

torches contribute to the improvement of welding properties and<br />

the quality of the welded seams. Weld spatters can be reduced<br />

considerably – this saves time on finishing work. The standard<br />

welding torches of the PM series are – as are all EWM welding<br />