goer manufacturing - Cincinnati Industrial Auctioneers, Inc.

goer manufacturing - Cincinnati Industrial Auctioneers, Inc.

goer manufacturing - Cincinnati Industrial Auctioneers, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

12’ Holzma Optimat Model HPP81-38 Front Loading CNC Panel Saw<br />

4-Axis Shoda NCW-516-2462 CNC Twin Table CNC Router<br />

Tuesday, April 25th<br />

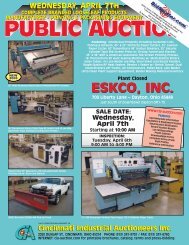

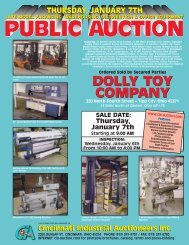

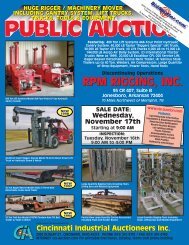

WOODWORKING MACHINERY AND FACTORY EQUIPMENT<br />

STORE FIXTURE AND CABINET MANUFACTURER<br />

NEW<br />

2000<br />

NEW<br />

1998<br />

Featuring: Shoda NCW-516-2462, Axxiom MC-26-5W2 and<br />

Motion Master MOOS8-55T CNC Routers, Morbidelli U26 CNC Point-<br />

To-Point Boring Machine and Alberti Formatt 90 CNC Point to<br />

Point Drill, 12’ Holzma Optimat (2000), 14’ Holzma Topmatic (1993)<br />

Panel Saws, 50 MM 3/4” IDM Idimatic 66/20 CNC Edge Bander,<br />

16” SCMI and Holz-Her Sliding Carriage Saws,<br />

Planer, Jointers, Shapers, Table Saws, Drills, Boring Machines,<br />

Infra Red Oven, 50 HP & 100 HP Air Compressors<br />

and Shop Equipment<br />

GOER<br />

MANUFACTURING<br />

SALE DATE:<br />

Tuesday,<br />

April 25th<br />

Starting at 9:00 AM<br />

INSPECTION:<br />

Monday,<br />

April 24th<br />

10:00 AM to 4:00 PM<br />

PLANT CLOSED<br />

2695 W. Highway 56 – Cedar City, Utah 84720<br />

(150 miles northeast of Las Vegas)<br />

LATE MODEL<br />

WOODWORKING<br />

MACHINERY<br />

www.cia-auction.com<br />

WEBSITE FEATURES<br />

Upcoming Sale Information,<br />

Printable Color Brochures,<br />

Printable Catalogs,<br />

Complete Terms of Sale<br />

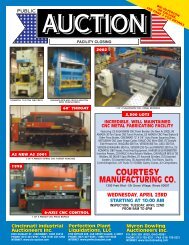

3-Axis Morbidelli Model U26 Point-to-Point CNC Boring Machine 20’ IDM Woodworking Machinery Model IDIMATIC 66/20 CNC Edge Bander<br />

SALE UNDER THE MANAGEMENT OF<br />

<strong>Cincinnati</strong> <strong>Industrial</strong> <strong>Auctioneers</strong> <strong>Inc</strong>.<br />

<strong>Cincinnati</strong> <strong>Industrial</strong> <strong>Auctioneers</strong> <strong>Inc</strong>.<br />

2020 DUNLAP ST., CINCINNATI, OHIO 45214 PHONE (513) 241-9701 / FAX (513) 241-6760<br />

INTERNET: cia-auction.com for printable brochures, catalog, terms and pre-bidding

NEW<br />

2000<br />

12’ Holzma Optimat Model HPP81-38 Front Loading CNC Panel Saw<br />

NEW<br />

1993<br />

14’ Holzma Topmatic Model HPP81-42 Front Loading CNC Panel Saw<br />

4-Axis Axxiom Model MC-2615W2 Twin Table CNC Router<br />

Tuesday, April 25th<br />

4-Axis Shoda NCW-516-2462 CNC Twin Table CNC Router<br />

CNC PANEL SAWS<br />

12’ Holzma Optimat Model HPP81-38<br />

Front Loading CNC Panel Saw; s/n 0-240-<br />

15-1041, 12’ x 8’ Front Loading Area, (3) 25 1/2”<br />

x 85” Front Air Clamping Tables, 87” D x 148” W<br />

Rear Off-Load Area, (6) Vertical Pneumatic Hold<br />

Down Clamps, Holzma Cadmatic CNC Control<br />

(New 2000) SEE PHOTO<br />

14’ Holzma Topmatic Model HPP81-42<br />

Front Loading CNC Panel Saw; s/n 930-317,<br />

14’ x 8’ Front Loading Area, (3) 25 1/2” x 85”<br />

Front Air Clamping Tables, 200” Deep x 163”<br />

Wide Rear Off-Load Area, (7) Vertical Pneumatic<br />

Clamps, Holzma Topmatic CNC Control<br />

(New 1993) SEE PHOTO<br />

FINISHED PRODUCT INVENTORY<br />

(100+) Lots Goer Finished Display Case<br />

Inventory Consisting of; Glass Top Display<br />

Cases of Various Styles, Lighted Corner Display<br />

Cases, Laminate Bases, Various Sizes and Styles<br />

SEE PHOTO<br />

DUST COLLECTION SYSTEM<br />

& DUST COLLECTORS<br />

125 HP Torit /Day Baghouse Dust<br />

Collector; KAF2260, Job# 183393, 12’ Diameter,<br />

42’ High (New 1994)<br />

100 HP Torit/Day Baghouse Dust Collector;<br />

s/n KAF2258, Job# 183393, 12” Diameter, 42’<br />

High (New 1994)<br />

200 HP Carter Dav Baghouse Dust<br />

Collector; Style # 542BI-CALIV-CWVB-I<br />

Torit/Day Koger/Air Transfer Blower; s/n<br />

KAF2252<br />

12’ Diameter X 50’ High Silo Holding Bin<br />

Vibranetics Model BD-7 Vibranetics Model<br />

BD-7 Vibratory Shaker Unit; s/n BD6730,<br />

Customer# 21025/KD20B-B2609<br />

40 HP Cyclone Type Dust Collector; 14,900<br />

CFM<br />

4-Axis Motion Master Model MODSB-55T CNC Router (100+) Lots Goer Finished Display Case Inventory<br />

NEW<br />

1998<br />

CNC ROUTERS<br />

4-Axis Shoda NCW-516-2462 CNC Twin<br />

Table CNC Router; s/n W78A, (2) 5’ x 10’<br />

Independent Work Tables, Fanuc P54 CNC<br />

Control (New 1998) SEE PHOTO<br />

4-Axis Axxiom Model MC-2615W2 Twin<br />

Table CNC Router; s/n 0004, 106” x 61” Tables<br />

w/ Lead Screw Drive, (4) Heads w/ Router and<br />

Drilling Unit, Fanuc Control SEE PHOTO<br />

4-Axis Motion Master Model MODSB-55T<br />

CNC Router; s/n T55B3685, 5’ x 5’ Twin Tables,<br />

Sullair Vacuum Pump SEE PHOTO<br />

CNC POINT - TO - POINT DRILL<br />

Alberti Format 90 CNC Point-To-Point<br />

Drill; s/n 4174, Overall Vacuum Work Table<br />

Dimensions: X-Axis = 3,000 MM (118”), Y-Axis =<br />

1,150 MM (45 ?”) Two Table Work Together or<br />

Individually, Main Boring Head: (28)<br />

Independently Controlled Spindles Inline on X and<br />

Y-Axis, (1) 8-Spindle Individual/Programmable<br />

Drill Block on 32 MM Centers <strong>Inc</strong>line on X-Axis,<br />

(1) 15-Spindle Individual/Programmable Drill<br />

Block on 32 MM Center Inline on Y-Axis, (2) 2-<br />

Spindle Horizontal Boring Blocks at Panel Ends on<br />

X-Axis, 2-Spindle Horizontal Boring Block For<br />

Front and Back End on Y-Axis, (1) 7.5 HP<br />

Horizontal Routing Shaping Unit w/ Speeds:<br />

0-18000 RPM, (1) 9 HP Routing Shaping Unit w/<br />

Speeds: 0-18000 RPM, Both w/ ISO 30-Tool ATC,<br />

6-Position ATC for 9 HP Router w/ ISO 30<br />

Toolholder, Control Technique Commander CD<br />

750 CNC Control (New 1995) SEE PHOTO

Alberti Format 90 CNC Point-To-Point Drill<br />

3-Axis Morbidelli Model U26 Point-to-Point CNC Boring Machine<br />

30” Automac Model AVG-30-<br />

R Horizontal V-Groove<br />

Traveling Head Saw<br />

16” SCMI Model S1-16-WA Sliding Carriage Tilt Arbor<br />

Table Saw<br />

GOER MANUFACTURING<br />

21-Spindle Biese Model Forecon-63<br />

Horizontal Dual Vertical/ Horizontal<br />

Line Boring Machine<br />

NEW<br />

1994<br />

20’ IDM Woodworking Machinery Model IDI-<br />

MATIC 66/20 CNC Edge Bander<br />

CNC BORING MACHINES<br />

3-Axis Morbidelli Model U26 Point-to-<br />

Point CNC Boring Machine; s/n XW-153,<br />

Boring Unit Equipped w/ (16) Independent<br />

Spindles at 32 MM Distance, (13) Spindles on X-<br />

Axis and (3) on Y-Axis; Working Area: 122” x 38”,<br />

Programmable (3) Axes CNC “TRIA 6000”<br />

Control, Equipped w/ (2) 7.5 HP COLUMBO<br />

Routers, Variable Speed: 12,000 - 18,000 RPM<br />

(1/2” Spindle Collet), (1) Horizontal Boring Block<br />

w/ (2) Spindles in the Y-Axis and Grooving Saw in<br />

the X-Axis, Working Table Has (8) Double<br />

Material Supports w/ (2) Vacuum Cups each, (4)<br />

Independent Working Fields, Disappearing<br />

Pneumatic Side and Rear Stops and Double Zero<br />

Setting SEE PHOTO<br />

21-Spindle Biese Model Forecon-63<br />

Horizontal Dual Vertical/Horizontal Line<br />

Boring Machine; s/n 43375, 9” x 42” Work<br />

Table, Single 21-Spindle Horizontal Unit, (2) 21-<br />

Spindle Vertical Boring Units, (5) Pneumatic Top<br />

Clamps, 220 Volt, 3 Phase, Boring and Foot Pedal<br />

Control SEE PHOTO<br />

2-Spindle Delta Horizontal Boring<br />

Machine; 1 HP Motor, 110 Volt, Single Phase,<br />

Foot Pedal Control SEE PHOTO<br />

CNC EDGE BANDER<br />

20’ IDM Woodworking Machinery Model<br />

IDIMATIC 66/20 CNC Edge Bander; s/n<br />

AL/004151, Panel Thickness: 10 MM Min. - 50<br />

MM Max., Standard Advance Speed: 12-18<br />

Mt./Min., Minimum Working Width: 60 MM,<br />

Minimum Length of Panel: 140 MM, (New 1999),<br />

Equipped w/ (2) Pre-Grinding/Sanding Units; (2)<br />

Premilling Units, Lower Glue Apply and Pressure<br />

Roller Unit, (2) Front and Back Cut-Off Saw<br />

Units, (2) Top and Bottom Rough Beveling Trim<br />

Units, (2) Top and Bottom Rough Trim Units, (2)<br />

Top and Bottom Fine Trim Units, (2) Front and<br />

16” Holz-Her Model 1245E Sliding Carriage Tilt Arbor<br />

Table Saw<br />

Executive Contour Edge Bander<br />

Rear Corner Trim Units, (2) Front and Rear<br />

Contour Shaper Units, (2) Top and Bottom<br />

Scraper Units, (2) Top and Bottom Buffing Units,<br />

Straight Edge Belt Sanding Unit, 256” L x 2 3/4”<br />

W Rubber Covered Nylon Chain Drive Belt, 3<br />

1/2” x 286” Long 0-45 Degree Sliding Work<br />

Support Arm SEE PHOTO<br />

Executive Contour Edge Bander<br />

SEE PHOTO<br />

TABLE SAWS/NOTCHER<br />

16” SCMI Model S1-16-WA Sliding<br />

Carriage Tilt Arbor Table Saw; s/n AB-<br />

17408, 630 MM x 1150 MM, 350 MM x 3050<br />

MM Sliding Table Carriage Table (114” x 119”),<br />

3400 MM Table Stroke, 0 Degree to 45 Degree<br />

Saw Blade Tilt, 0-5’/153MM Rip Fence<br />

Adjustment, 5.5 HP Motor SEE PHOTO<br />

16” Holz-Her Model 1245E Sliding<br />

Carriage Tilt Arbor Table Saw; s/n<br />

531/9409, 15” x 126 1/4” Sliding Carriage Table<br />

Dimensions, Stroke, 0 Degree to 45 Degree Saw<br />

Blade Tilt, 49” /124 CM Rip Fence Adjustment<br />

(New 1994) SEE PHOTO<br />

(3) 12” Powermatic Model 68 Tilt Arbor<br />

Table Saws; s/n 89680043, 8568078, N/A, 38”<br />

x 48” Table Size, Biesmeyer T-Square Blade Guard<br />

System, 120” Rip Fence, 0-45 Degree Saw Blade<br />

Tilt Adjustment SEE PHOTO<br />

14” Rockwell Tilt Arbor Table Saw; s/n<br />

9189-A, 38” x 48” Table, Biesmeyer T-Square<br />

Blade Guard System, 48” Rip Fence, 0-45 Degree<br />

Saw Blade Tilt Adjustment<br />

12” Powermatic Model 68 Tilt Arbor Table<br />

Saw; s/n 8968045, 38” x 48” Table Size,<br />

Biesmeyer T-Square Blade Guard System, 48” Rip<br />

Fence, 0-45 Degree Blade Adjustment<br />

1 of (3) 12” Powermatic Model 68 Tilt Arbor<br />

Table Saws

5’ x 12’ Newman Hydraulic Down Acting Glue Press<br />

SHAPERS<br />

Paolani Model T-140 Tilting Arbor Spindle<br />

Shaper; s/n 0093, 33 1/4” Wide x 4 1/2” Ripe<br />

Fence, 16” x 51” Work Area, 7” Arbor Lift w/<br />

Powermatic New PH-3 3-Roll Power Feeder<br />

(New 1995) SEE PHOTO<br />

Powermatic Model 26 Spindle Shaper; s/n<br />

85260087, 1” Dia. Spindle, 3 7/8” Cap. Under<br />

Nut, 3” Spindle Travel w/ Handwheel Adjustment,<br />

28” x 24” Cast Iron Work Table w/ Miter Slot, 7”<br />

Insert Opening in Work Area, w/ Powermatic 3-<br />

Roll Power Feeder SEE PHOTO<br />

JOINTERS/PLANER<br />

8” Grizzley Model G1018 Jointer; s/n<br />

508893, 0-1 1/2” Depth of Cut Adjustment, Push<br />

Button Controls SEE PHOTO<br />

6” Grizzly Jointer; 0-1/2” Depth of Cut<br />

Adjusment<br />

15” Grizzly Model G1021 Thickness<br />

Planer; 16 FPM - 20 FPM Speed Ranges, 15” x<br />

15” Infeed and Outfeed Roller Conveyors, 2 HP<br />

Motor, Push Button Control SEE PHOTO<br />

EDGE SANDERS<br />

6” LASM S.N.C. diValpato Model LBK-160<br />

Oscillating Edge Belt Sander; s/n 1355169,<br />

10” - 11 1/2” D x 37 1/2” W Front Work Table,<br />

Front Table Tilt Adjustment, 220 Volt, 3 Phase<br />

SEE PHOTO<br />

6” Edge Belt Sander; 33” W x 8’ D Front Work<br />

Table, 2” Tilt Adjustment, 33” W x 8” D Rear<br />

Work Table w/ Motorized Table Adjustment, 2 HP<br />

Drive Motor<br />

6” Delta Catalog #31-340 Edge Belt<br />

Sander; s/n 92D24654, 60” Wide x 11 3/4”<br />

Front Work Table w/ Tilt Adjustment, 60” W x 11<br />

3/4” D Rear Work Table, 17 1/2” W x 11 3/4” D<br />

Adjustable Height End Work Table<br />

DRILLS<br />

20” Delta Catalog #70-200 Single Spindle<br />

Floor Model Drill Press; 1 HP Motor<br />

20” Central Machinery Single Spindle H.D.<br />

Floor Model Drill Press; 9-Speeds, 1 1/2 HP<br />

Motor SEE PHOTO<br />

(2) 14” Central Machinery Modle T-586<br />

Single Spindle Bench Model Drill Presses;<br />

16-Speeds, 3/4 HP Motor<br />

14” Central Machinery Model No. 30697<br />

Spindle Bench Model Drill Press; 16-Speeds,<br />

3/4 HP Motor<br />

17” Continental Model DPCF-17 Heavy<br />

Duty S.S. Floor Model Drill Press; 12-<br />

Speeds, 1/2 HP Motor, w/ #0-1/4” Tapmatic<br />

Tapping Head<br />

15” Clausing Model 1764 S.S. Floor Model<br />

Drill Press; s/n 531557, 20-Speeds, Speed<br />

Range: 1200-1800 RPM, 3/4 HP Motor<br />

Tuesday, April 25th<br />

GLUE PRESS – LAMINATE<br />

MACHINERY<br />

5’ x 12’ Newman Hydraulic Down Acting<br />

Glue Press; s/n N/A, 18” Stroke, 33 1/2” Shut<br />

Height, 146” L-R x 60” F-B Bed Size, (3) Dual<br />

Ram, 48” x 60” Downacting Cylinder Plates, (3)<br />

24” W x 96” L Chain Link Motorized Exit<br />

Conveyor Drives on Bed, 139” x 60” 4-Section<br />

Exit Roller Conveyor, 10 HP Abex Denison<br />

Hydraulic Unit SEE PHOTO<br />

Ramarch D.E. Model PN-28 Pneumatic<br />

Dual Station Case Clamp; s/n 13316, (2) 72”<br />

L-R x 26” F-B x 48” High Top-To-Bottom<br />

Clamping Stations (New 1999) SEE PHOTO<br />

60” Evans Model 0256 Pneumatic Down<br />

Acting Laminate Rolling Machine; s/n<br />

216203, (2) 5” x 62” Top and Bottom Laminate<br />

Rolls, 1 1/2” Arbors, 110 Volt, Single Phase, 80<br />

P.S.I. SEE PHOTO<br />

MISCELLANEOUS MACHINERY<br />

30” Automac Model AVG-30-R Horizontal<br />

V-Groove Traveling Head Saw; s/n Mc-1444,<br />

30” Horizontal Travel, Pneumatic Lift and Travel,<br />

30” x 3 1/2” Channel, 0-100 Feed Speed, Lineal<br />

and Cross Grooving Capability, Inlet Air and Hold<br />

Down Bar Air Controls, Single Palm Button<br />

Control SEE PHOTO<br />

52” Onsrud Model W-1136 Overarm Pin<br />

Router; s/n 8357, 36 1/2” Throat, 36” x 48”<br />

Work Table<br />

Powermatic Model Mortising Machine; 1<br />

HP Motor, 110 Volt, Single Phase SEE PHOTO<br />

Powermatic Model<br />

Mortising Machine<br />

Paolani Model T-140 Tilting Arbor Spindle<br />

Shaper<br />

2-Spindle Delta Horizontal<br />

Boring Machine<br />

NEW<br />

1995<br />

• 8” Grizzley Model G1018 Jointer<br />

• 6” Grizzly Jointer<br />

15” Grizzly Model G1021<br />

Thickness Planer<br />

20” Central Machinery<br />

Single Spindle H.D.<br />

Floor Model Drill Press<br />

Powermatic Model 26 Spindle Shaper<br />

6” LASM S.N.C. diValpato Model<br />

LBK-160 Oscillating Edge Belt<br />

Sander<br />

60” Evans Model 0256<br />

Pneumatic Down Acting<br />

Laminate Rolling Machine

HALOGEN DRYING & CURING<br />

OVEN<br />

Prime Heat Halogen Systems Dual Chamber<br />

Halogen Drying Oven; 113” W x 105” H Infeed<br />

Opening, 101” W x 105” H Out Feed Opening, (3)<br />

Temperature Zones w/ West 6500 Controls, Stainless<br />

Steel Interior Panel Construction, (48) 18” Halogen<br />

Lamps, 480 Volt, 3 Phase, 125 Amps SEE PHOTO<br />

(17) 88” W x 48” D x 60” H 8-Shelf Portable<br />

Steel Drying/Curing Racks; Tubular and Angle Steel<br />

Construction<br />

PAINT SPRAY EQUIPMENT<br />

(2) 10’ W x 6’ H x 6’ D Top Exhaust Wet Spray<br />

Booths; Fabric Filtration<br />

(2) 6’ W x 7’ H x 5’ D Rear Exhaust Wet Spray<br />

Booths; Fabric Filter Wall<br />

Binks & Graco 55 Gal. Drum Spray Pumps &<br />

Agitator; Assorted Spray Guns<br />

Overhead Paint Conveyor System<br />

AIR COMPRESSORS<br />

50 HP Ingersoll Rand Model SSR 50-450HP<br />

Rotary Screw Cabinet Enclosed Air Compressor;<br />

s/n 0225991010G-CE, 20,397 Hours, 4,460 Idling<br />

Hours<br />

100 HP LeRoi Model A7191326 Rotary Screw<br />

Air Compressor; s/n 4180X111, 9,929.9 Hours<br />

100 HP Joy Twistair Model A7191326 Rotary<br />

Screw Air Compressor; 17090 Hours<br />

100 Gal. Roye Hanson Air Receiving Tank<br />

WELDERS<br />

(2) 250 Amp Miller Millermatic 250 CC AC/DC<br />

Arc Welders<br />

250 Amp Miller Syncrowave 250 CC AC/DC Arc<br />

Welder<br />

(2) 250 Amp Miller Dialarc AC/DC Arc Welders<br />

300 Amp Lincoln Idealarc R3R-300 AC/DC Arc<br />

Welder<br />

200 Amp P&H DAR-200HS6W AC/DC Arc<br />

Welder<br />

200 Amp Lincoln Idealarc SP-200 AC/DC Arc<br />

Welder<br />

50 KVA Federal PA-1-18 Spot Welder<br />

Tuesday, April 25th<br />

Prime Heat Halogen Systems Dual Chamber Halogen Drying Oven 50 HP Ingersoll Rand Model SSR 50-450HP Rotary Screw Cabinet<br />

Enclosed Air Compressor<br />

ELECTRIC PALLET TRUCKS<br />

6,000 Lbs. Clark Model HWD 30 Walk Behind<br />

Electric Pallet Truck<br />

5,000 Lbs. Clark Model HWD 25 Walk Behind<br />

Electric Pallet Truck<br />

LAWN TRACTOR<br />

International Cub Cadet Model I-185 Lowboy<br />

Lawn Tractor; s/n 2000113U039879, Gasoline<br />

Engine, w/ Cub Cadet Model 3160A Mowing Deck, s/n<br />

31001610011534<br />

PICKUP TRUCK<br />

1984 Dodge 4-Wheel Drive Model 150SE<br />

Prospector Pickup Truck; VIN#<br />

1B7HW14W5FS591056, Gasoline V-8 Engine, 8’ Bed,<br />

Mileage: 35,280 (Miles Over)<br />

SHOP & OFFICE EQUIPMENT<br />

Shop Equipment Consisting of: Hardware,<br />

Portable Dust Collectors, Genie Lift, Bench Top Bead<br />

Blast Cabinet, Double End Pedestal and Bench Grinders,<br />

Rens Tornado 2000 Pipe and Bolt Threader, Battery<br />

Chargers and Much More<br />

Office Furniture and Equipment Consisting of:<br />

Double Pedestal Steel Desks w/ Formica Tops, Chairs,<br />

Office Partitioning, File Cabinets, Fax Machine, Copiers,<br />

Computers and More<br />

TO BE SOLD VIA PHOTOGRAPH<br />

Inspection by Appointment Only – Call Auctioneer<br />

HolzHer Model 1435SEL Automatic Edge<br />

Bander; s/n 6500, Glue System, Buffing Station,<br />

Located in Thorton, Colorado SEE PHOTO<br />

Filtrex Model S102002470 Dust Collection<br />

System by Steelcraft Corp.; Serial #F-49475, 12,000<br />

CFM, The tower on this unit is nine feet in diameter and<br />

twenty-eight feet tall from bottom of cone to the top. The<br />

following are a list of ductwork for this system: 36”—-<br />

80 ft, 24”—-50 ft, 14” and smaller there are various sizes<br />

and amounts, 36” Elbow—- 1, Located in Paris, TX<br />

CM Positech Model K-96 Vacuum Panel Lift;<br />

100LB Load Capacity, Serial #20649, Series #10120-<br />

5598, SCFM 57, Located in Paris, TX<br />

17” X 34” Throat Wood Hog Grinder; 20’ Load<br />

Conveyor, Located in Paris, Texas SEE PHOTO<br />

Partial View of Welders Partial View. Large<br />

quantity of late model<br />

shop equipment<br />

52” Onsrud Model<br />

W-1136 Overarm Pin<br />

Router<br />

Ramarch D.E. Model PN-28 Pneumatic Dual Station Case Clamp<br />

** HolzHer Model 1435SEL Automatic Edge Bander ** To Be Sold<br />

Via Photo<br />

** 17” X 34” Throat Wood Hog Grinder ** To Be Sold Via<br />

Photo

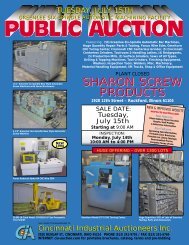

Woodworking Machinery and Factory Equipment<br />

Store Fixture and Cabinet Mfg.<br />

Plant Closed<br />

GOER<br />

MANUFACTURING<br />

2695 W. Highway 56 – Cedar City, Utah 84720<br />

(150 miles northeast of Las Vegas)<br />

SALE DATE:<br />

Tuesday, April 25th<br />

STARTING: 9:00 AM<br />

INSPECTION:<br />

Monday, April 24th<br />

10:00 AM to 4:00 PM<br />

<strong>Cincinnati</strong> <strong>Industrial</strong><br />

<strong>Auctioneers</strong> <strong>Inc</strong>.<br />

2020 DUNLAP ST., CINCINNATI, OHIO 45214<br />

PHONE (513) 241-9701 / FAX (513) 241-6760<br />

INTERNET: cia-auction.com<br />

IF YOU CANNOT ATTEND<br />

this sale in person, you can submit a proxy bid by<br />

mail or fax. In either case your bid must be<br />

accompanied by a check in an amount equal to<br />

25% of your bid total. Also, you may submit bids<br />

over the internet. For complete details, visit our<br />

website: www.cia-auction.com. All bids placed<br />

whether on site, by proxy, or via On-Line are subject<br />

to the terms and conditions as outlined in<br />

our Terms of Sale.<br />

IMPORTANT NOTICE:<br />

Although information has been obtained from sources<br />

deemed reliable, the auctioneer makes no warranty or<br />

guarantee, expressed or implied, as to the accuracy of<br />

the information herein contained. It is for this reason<br />

that buyers should avail themselves of the opportunity<br />

to make inspection prior to the sale. This brochure<br />

is intended to provide general information of the equipment<br />

being offered and is subject to errors, omissions,<br />

additions or deletions. Please check with the Auctioneer’s<br />

Office for a final listing. Items offered may or may not<br />

necessarily be sold as described and/or photographed in<br />

this brochure.<br />

MAIL BIDS ACCEPTED WITH A 25% DEPOSIT<br />

4-Axis Shoda NCW-516-2462 CNC Twin Table CNC Router<br />

FIRST CLASS MAIL! PRE-SORT<br />

FIRST CLASS<br />

U.S. POSTAGE<br />

PAID<br />

CINCINNATI, OHIO<br />

PERMIT NO. 3593<br />

☞<br />

Tuesday, April 25th<br />

DIRECTIONS<br />

From I-15 in Cedar City, Utah, take exit # 59<br />

(Cedar City) turn west off exit onto Hwy<br />

56/200 North follow 1 mile, cross over railroad<br />

tracks to entrance on left. Turn left and<br />

cross over railroad tracks again. Watch for<br />

auction arrows and signs.<br />

AUCTIONEER<br />

Jeffrey L. Luggen<br />

Important Mail<br />

TO BE DIRECTED TO THE ATTENTION<br />

OF EXECUTIVE PERSONNEL<br />

SALE UNDER THE MANAGEMENT OF<br />

<strong>Cincinnati</strong> <strong>Industrial</strong> <strong>Auctioneers</strong> <strong>Inc</strong>.<br />

TERMS OF SALE<br />

All equipment described herein will be sold “as<br />

is”, “where is” to the highest bidder or bidders<br />

for cash in accordance with our regular terms<br />

and conditions of sale. Unless other satisfactory<br />

arrangements are made, a 25% deposit in cash,<br />

certified or cashier’s check payable to <strong>Cincinnati</strong><br />

<strong>Industrial</strong> <strong>Auctioneers</strong>, <strong>Inc</strong>., is required on all<br />

purchases. Firm and personal checks accepted<br />

only if accompanied by a letter from your bank<br />

guaranteeing your funds. All sales are subject<br />

to state and/or local taxes unless a signed<br />

exemption form is presented at the time of purchase.<br />

All balances are due at the conclusion<br />

of the sale. No merchandise may be removed<br />

while the sale is in progress. All bidders must<br />

comply with our Standard Terms of Sale,<br />

copies of which will be available at the sale site<br />

or can be obtained from our website.<br />

A 10% BUYER’S PREMIUM<br />

IN EFFECT FOR THIS SALE.<br />

2020 DUNLAP ST., CINCINNATI, OHIO 45214 PHONE (513) 241-9701 / FAX (513) 241-6760<br />

INTERNET: cia-auction.com for printable brochures, catalog, terms and pre-bidding<br />

NEW<br />

1998<br />

SALE DATE<br />

Tuesday,<br />

April 25th<br />

9:00 am