EMI Shielding Engineering Handbook EMI Shielding - INSCO Group

EMI Shielding Engineering Handbook EMI Shielding - INSCO Group

EMI Shielding Engineering Handbook EMI Shielding - INSCO Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

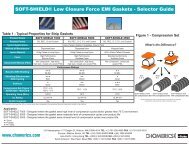

<strong>EMI</strong> <strong>Shielding</strong>/Grounding Spacer Gaskets continued<br />

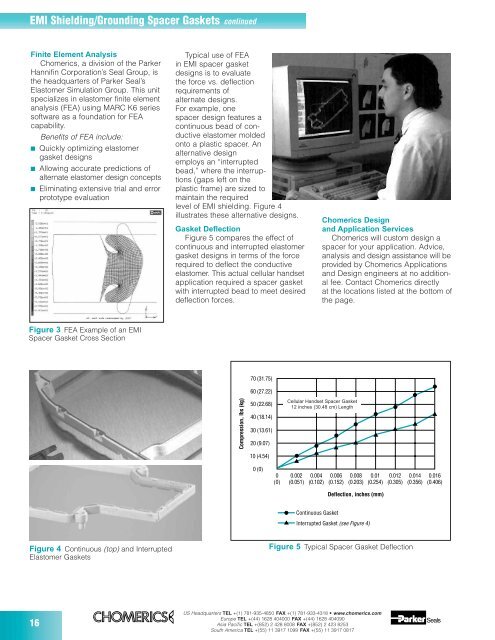

Finite Element Analysis<br />

Chomerics, a division of the Parker<br />

Hannifin Corporation’s Seal <strong>Group</strong>, is<br />

the headquarters of Parker Seal’s<br />

Elastomer Simulation <strong>Group</strong>. This unit<br />

specializes in elastomer finite element<br />

analysis (FEA) using MARC K6 series<br />

software as a foundation for FEA<br />

capability.<br />

16<br />

Benefits of FEA include:<br />

■ Quickly optimizing elastomer<br />

gasket designs<br />

■ Allowing accurate predictions of<br />

alternate elastomer design concepts<br />

■ Eliminating extensive trial and error<br />

prototype evaluation<br />

Figure 3 FEA Example of an <strong>EMI</strong><br />

Spacer Gasket Cross Section<br />

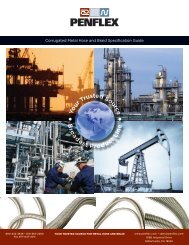

Figure 4 Continuous (top) and Interrupted<br />

Elastomer Gaskets<br />

Typical use of FEA<br />

in <strong>EMI</strong> spacer gasket<br />

designs is to evaluate<br />

the force vs. deflection<br />

requirements of<br />

alternate designs.<br />

For example, one<br />

spacer design features a<br />

continuous bead of conductive<br />

elastomer molded<br />

onto a plastic spacer. An<br />

alternative design<br />

employs an “interrupted<br />

bead,” where the interruptions<br />

(gaps left on the<br />

plastic frame) are sized to<br />

maintain the required<br />

level of <strong>EMI</strong> shielding. Figure 4<br />

illustrates these alternative designs.<br />

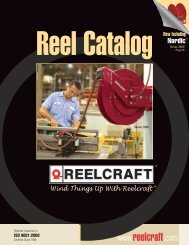

Gasket Deflection<br />

Figure 5 compares the effect of<br />

continuous and interrupted elastomer<br />

gasket designs in terms of the force<br />

required to deflect the conductive<br />

elastomer. This actual cellular handset<br />

application required a spacer gasket<br />

with interrupted bead to meet desired<br />

deflection forces.<br />

Compression, lbs (kg)<br />

70 (31.75)<br />

60 (27.22)<br />

50 (22.68)<br />

40 (18.14)<br />

30 (13.61)<br />

20 (9.07)<br />

10 (4.54)<br />

0 (0)<br />

0<br />

(0)<br />

0.002<br />

(0.051)<br />

0.004<br />

(0.102)<br />

US Headquarters TEL +(1) 781-935-4850 FAX +(1) 781-933-4318 • www.chomerics.com<br />

Europe TEL +(44) 1628 404000 FAX +(44) 1628 404090<br />

Asia Pacific TEL +(852) 2 428 8008 FAX +(852) 2 423 8253<br />

South America TEL +(55) 11 3917 1099 FAX +(55) 11 3917 0817<br />

Chomerics Design<br />

and Application Services<br />

Chomerics will custom design a<br />

spacer for your application. Advice,<br />

analysis and design assistance will be<br />

provided by Chomerics Applications<br />

and Design engineers at no additional<br />

fee. Contact Chomerics directly<br />

at the locations listed at the bottom of<br />

the page.<br />

Cellular Handset Spacer Gasket<br />

12 inches (30.48 cm) Length<br />

0.006<br />

(0.152)<br />

0.008<br />

(0.203)<br />

0.01<br />

(0.254)<br />

Deflection, inches (mm)<br />

Continuous Gasket<br />

Interrupted Gasket (see Figure 4)<br />

0.012<br />

(0.305)<br />

Figure 5 Typical Spacer Gasket Deflection<br />

0.014<br />

(0.356)<br />

0.016<br />

(0.406)