Speciality Chemicals Magazine October_November 2018

Speciality Chemicals Magazine is the number one and longest published global magazine dedicated exclusively to the fine and speciality chemicals industries. Our unrivalled reputation for comprehensive coverage and perspective on the global chemical industry makes the magazine essential reading for everyone involved in this market. Speciality Chemicals Magazine has the best established global industry specific print and digital circulation with over 52,000 targeted individuals and distribution to shows and events worldwide. These are personalised subscribers who have requested to be sent a copy of the magazine. This circulation has been built up over 37 years of publishing and has been cleared to European Data Protection Standards (EDPS) 2018. In addition to this personalised circulation, selected articles and industry news are posted on our website, social media sites and in your bi-weekly newsletter.

Speciality Chemicals Magazine is the number one and longest published global magazine dedicated exclusively to the

fine and speciality chemicals industries. Our unrivalled reputation for comprehensive coverage and perspective on the global

chemical industry makes the magazine essential reading for everyone involved in this market.

Speciality Chemicals Magazine has the best established global industry specific print and digital circulation with over

52,000 targeted individuals and distribution to shows and events worldwide. These are personalised subscribers who have requested to be sent a copy of the magazine.

This circulation has been built up over 37 years of publishing and has been cleared to European Data Protection Standards (EDPS) 2018.

In addition to this personalised circulation, selected articles and industry news are posted on our website,

social media sites and in your bi-weekly newsletter.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

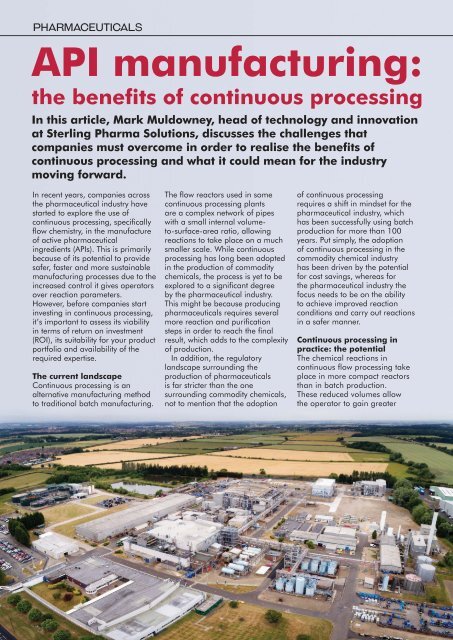

API manufacturing:<br />

the benefits of continuous processing<br />

In this article, Mark Muldowney, head of technology and innovation<br />

at Sterling Pharma Solutions, discusses the challenges that<br />

companies must overcome in order to realise the benefits of<br />

continuous processing and what it could mean for the industry<br />

moving forward.<br />

In recent years, companies across<br />

the pharmaceutical industry have<br />

started to explore the use of<br />

continuous processing, specifically<br />

flow chemistry, in the manufacture<br />

of active pharmaceutical<br />

ingredients (APIs). This is primarily<br />

because of its potential to provide<br />

safer, faster and more sustainable<br />

manufacturing processes due to the<br />

increased control it gives operators<br />

over reaction parameters.<br />

However, before companies start<br />

investing in continuous processing,<br />

it’s important to assess its viability<br />

in terms of return on investment<br />

(ROI), its suitability for your product<br />

portfolio and availability of the<br />

required expertise.<br />

The current landscape<br />

Continuous processing is an<br />

alternative manufacturing method<br />

to traditional batch manufacturing.<br />

The flow reactors used in some<br />

continuous processing plants<br />

are a complex network of pipes<br />

with a small internal volumeto-surface-area<br />

ratio, allowing<br />

reactions to take place on a much<br />

smaller scale. While continuous<br />

processing has long been adopted<br />

in the production of commodity<br />

chemicals, the process is yet to be<br />

explored to a significant degree<br />

by the pharmaceutical industry.<br />

This might be because producing<br />

pharmaceuticals requires several<br />

more reaction and purification<br />

steps in order to reach the final<br />

result, which adds to the complexity<br />

of production.<br />

In addition, the regulatory<br />

landscape surrounding the<br />

production of pharmaceuticals<br />

is far stricter than the one<br />

surrounding commodity chemicals,<br />

not to mention that the adoption<br />

of continuous processing<br />

requires a shift in mindset for the<br />

pharmaceutical industry, which<br />

has been successfully using batch<br />

production for more than 100<br />

years. Put simply, the adoption<br />

of continuous processing in the<br />

commodity chemical industry<br />

has been driven by the potential<br />

for cost savings, whereas for<br />

the pharmaceutical industry the<br />

focus needs to be on the ability<br />

to achieve improved reaction<br />

conditions and carry out reactions<br />

in a safer manner.<br />

Continuous processing in<br />

practice: the potential<br />

The chemical reactions in<br />

continuous flow processing take<br />

place in more compact reactors<br />

than in batch production.<br />

These reduced volumes allow<br />

the operator to gain greater