Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

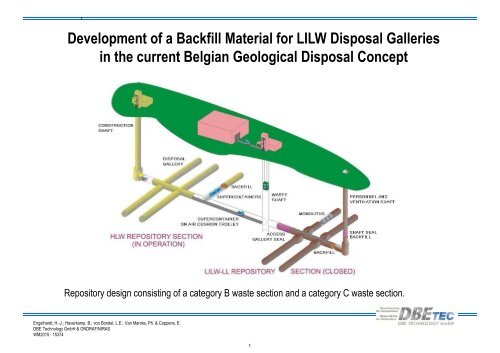

<strong>Development</strong> of a <strong>Backfill</strong> Material for <strong>LILW</strong> Disposal Galleries<br />

in the current Belgian Geological Disposal Concept<br />

Repository design consisting of a category B waste section and a category C waste section.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> – Project & ONDRAF/NIRAS<br />

Tests B 31/07/2014 & C Techno (MPA – Meeting Braunschweig)<br />

Category <strong>WM2015</strong> Brussels, -B <strong>15374</strong> & 21/02/2013 C<br />

1

It is planned to produce the backfill above ground and<br />

to pump it into the galleries.<br />

Objectives of the backfill measure<br />

1) filling the void space in the disposal galleries<br />

2) limiting the amount of free water in the repository<br />

3) providing stability to the galleries<br />

4) providing a chemical environment consistent with the design concept<br />

4a) no disturbance of the corrosion-protective environment<br />

4b) no formation of mobile radionuclide complexes<br />

5) no damage of the gallery walls<br />

6) limited strength to enable the retrieval of waste packages<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> – Project & ONDRAF/NIRAS<br />

Tests B 31/07/2014 & C Techno (MPA – Meeting Braunschweig)<br />

Category <strong>WM2015</strong> Brussels, -B <strong>15374</strong> & 21/02/2013 C<br />

2

<strong>Backfill</strong> requirements<br />

Hydraulic transport of the backfill.<br />

1) filling the void space in the disposal galleries<br />

2) limiting the amount of free water in the repository<br />

3) providing stability to the galleries<br />

→ Negligible amount of bleed water<br />

(development of a water layer on the surface of a suspension)<br />

separation of water and suspension during the pump process<br />

and in the galleries<br />

→ Segregation resistance<br />

(capacity of a suspension to preserve a homogeneous<br />

grain size distribution)<br />

→ High flowability and good spreading behaviour<br />

during a time span of approximately 5 hours.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

3

<strong>Backfill</strong> requirements<br />

Objectives of the backfill measure<br />

4) providing a chemical environment consistent with the design concept<br />

→ Limitation of soluble chlorides, sulphur-containing substances, organic materials.<br />

The chemical requirements influence the selection of the ingredients (no fly ash,<br />

no burnt slates, no slag containing materials, e.g. CEM III-cement, blast-furnace slag, etc.)<br />

5) no damage of the gallery walls<br />

→ Limitation of the autogenous swelling or shrinkage of the backfill.<br />

6) limited strength to enable the retrieval of waste packages<br />

→ Limitation of the compressive strength.<br />

A high porosity of the backfill (diffusion and flow of gases) and<br />

a high thermal conductivity (galleries with heat-generating waste) are favourable.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

4

Initial series of investigation<br />

CEM II/A-LL 32.5 + calcareous powder + river sand + water<br />

CEM II/A-LL 32.5 + barite powder + silica fume + river sand + water<br />

CEM II/A-LL 32.5 + silica fume + river sand + water<br />

Step 1) Determination of the composition of non-bleeding, segregation resistant<br />

mixtures.<br />

Step 2) Comparison of the mixtures.<br />

Mixtures with silica fume show<br />

the best flow and spreading behaviour, low thixotropy<br />

and the highest total porosity.<br />

Results of laboratory bleed water tests which were carried out<br />

to identify the border between bleeding and non-bleeding mixtures.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

5

Second series of investigation (specification of a reference mixture)<br />

It is assumed that mixtures with a mini-slump of more than 200 mm (during a mix<br />

time of 5 hours) have a sufficient flowability.<br />

According to the intersection points of the mixture trend lines and the “200 mm-slump-line” results that<br />

flowable mixtures have contents of<br />

> 11.4 wt.-% cement, > 11.9 wt.-% silica fume, < 33.5 wt.-% sand, and > 43.5 wt.-% water.<br />

This approach results in a minimum water-cement-ratio of 3.8.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

6

Second series of investigation - specification of a reference mixture<br />

> 11.4 wt.-% cement, > 11.9 wt.-% silica fume, < 33.5 wt.-% sand, > 43.5 wt.-% water, water-cement-ratio > 3.8.<br />

water-cement-ratio > 2.8 → compressive strength < 10 MPa<br />

→ water-cement-ratio of the reference backfill = 4.25.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

7

CEM II/A-LL 32,5<br />

Bei der Verfüllung von Strecken mit wärmeentwickelnden Abfallen teilweiser<br />

Austausch des Silikastaubs gegen Eisenoxide.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

8

Simulation of the backfill process with Plexiglas tubes<br />

Stationary Zyklos 100 L pan mixer<br />

High-shear / high-speed hand mixer<br />

Screw pump and flexible pipeline (1 inch) with pressure sensors<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

9

Simulation of the backfill process with Plexiglas tubes<br />

Flow rate between 3 litres and 5 litres per minute (mix temperature 23 °C).<br />

Tube 1: Hollow cylinder (length 2 m, diameter 0.5 m)<br />

Failure of the high-shear mixer<br />

during the first 2 mix batches<br />

→ Increase of silica fume content<br />

→ <strong>Development</strong> of bleed water and<br />

a wavy surface (ripple marks)<br />

The bleed water and air left the tube.<br />

The tube was completely filled with the<br />

exception of some air bubbles.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

10

Simulation of the backfill process with Plexiglas tubes<br />

Tube 2: Cylinder (length 2 m, diameter 0.5 m) with two supercontainer models<br />

Negligible amount of bleed water (water film).<br />

The tube was completely filled without<br />

a problem.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

11

Simulation of the backfill process with Plexiglas tubes<br />

Temperature development<br />

Temperature increase of 15 K (corrected value 21 K).<br />

Good agreement with the calculated value (24 K).<br />

Low stresses during the warming phase<br />

(material creep).<br />

Possibility of thermal induced<br />

crack formation during cooling<br />

(category B) due to the length<br />

of the backfill sections (30 m).<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

12

Simulation of the backfill process with Plexiglas tubes<br />

Autogenous shrinkage < 70 mm/30 m (length of the backfill section) or<br />

< 2 mm/0.8 m (maximum distance supercontainer-tunnel liner) according to the<br />

calculated chemical shrinkage of the backfill material.<br />

A laboratory test showed comparable values.<br />

The backfill in the Plexiglas tubes showed no shrinkage cracks.<br />

It is assumed that shrinkage cracks will occur more or less perpendicular to the<br />

axis of the disposal galleries.<br />

Higher risk of shrinkage cracks in the galleries with category B waste<br />

(no thermal expansion of the backfill due to decay heat).<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

13

Evaluation of the backfill injection<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

14

Evaluation of the backfill injection<br />

The evaluations come to the conclusion that standard equipment, such as tanks, pumps, pipelines,<br />

pig trap stations, and damper can be used for the installation of the backfill system.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

15

The laboratory experiments illustrate the feasibility to backfill the disposal<br />

galleries according the requirements.<br />

Possible optimizations:<br />

Category B:<br />

Use of air-entraining agents.<br />

→ Increase of gas-filled pore space (storage volume for gas).<br />

→ The capillary-breaking pores reduce the pore saturation<br />

with Boom Clay pore solution.<br />

Category C: Addition of iron oxides (pigments) ± increase of the sand content 1 ±<br />

superplasticizers<br />

→ Increase of the thermal conductivity<br />

Index 1 : cf. Xu, Y. & Chung, D.D.L. (2000) Effect of sand addition on the specific heat and thermal conductivity of cement. Cement<br />

and Concrete Research, 30: 59-61.<br />

Engelhardt/Haverkamp<br />

Engelhardt, H.-J.; Haverkamp, B.; von Borstel, L.E.; Van Marcke, Ph. & Coppens, E.<br />

ONDRAF/NIRAS DBE Technology GmbH – <strong>Backfill</strong> Project – Project & ONDRAF/NIRAS<br />

B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, <strong>WM2015</strong> -B 07. <strong>15374</strong> & 21/02/2013 November C 2014<br />

16

Engelhardt/Haverkamp<br />

ONDRAF/NIRAS – <strong>Backfill</strong> Project – Project B Tests & C B 31/07/2014 Techno & C Techno (MPA – Meeting Braunschweig)<br />

Category Brussels, B 07. & 21/02/2013 November C 2014<br />

17