FLEISCHWIRTSCHAFT international 6/2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

...............................................<br />

24<br />

Fleischwirtschaft <strong>international</strong> 6_<strong>2018</strong><br />

Casings<br />

Edible coatings show their potential<br />

Advantages<br />

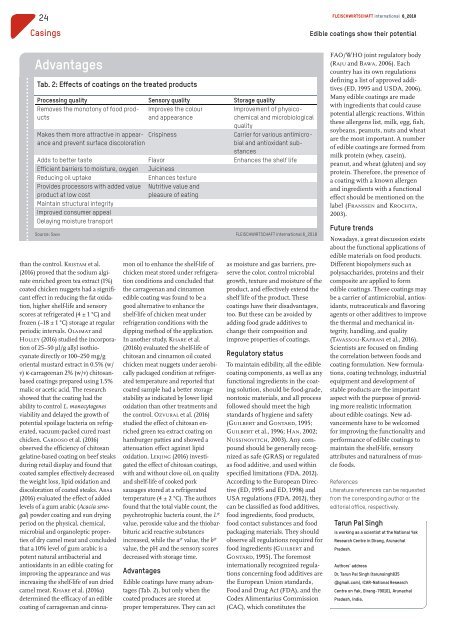

Tab. 2: Effects of coatings on the treated products<br />

Processing quality Sensory quality Storage quality<br />

Removes the monotony of food products<br />

Improves the colour<br />

and appearance<br />

Improvement of physicochemical<br />

and microbiological<br />

quality<br />

Makes them more attractive in appearance<br />

and prevent surface discoloration<br />

Crispiness<br />

Carrier for various antimicrobial<br />

and antioxidant substances<br />

Adds to better taste Flavor Enhances the shelf life<br />

Efficient barriers to moisture, oxygen Juiciness<br />

Reducing oil uptake<br />

Enhances texture<br />

Provides processors with added value<br />

product at low cost<br />

Nutritive value and<br />

pleasure of eating<br />

Maintain structural integrity<br />

Improved consumer appeal<br />

Delaying moisture transport<br />

Source: SINGH <strong>FLEISCHWIRTSCHAFT</strong><strong>international</strong> 6_<strong>2018</strong><br />

than the control. KRISTAM et al.<br />

(2016)proved that the sodium alginate<br />

enriched green tea extract (1%)<br />

coated chicken nuggets had asignificant<br />

effect in reducing the fat oxidation,<br />

higher shelf-life and sensory<br />

scores at refrigerated (4 ±1°C) and<br />

frozen (−18 ±1°C) storage at regular<br />

periodic intervals. OLAIMAT and<br />

HOLLEY (2016)studied the incorporation<br />

of 25–50 µl/g allyl isothiocyanate<br />

directly or 100–250 mg/g<br />

oriental mustard extract in 0.5% (w/<br />

v) κ-carrageenan 2% (w/v) chitosanbased<br />

coatings prepared using 1.5%<br />

malic or acetic acid. The research<br />

showed that the coating had the<br />

ability to control L. monocytogenes<br />

viability and delayed the growth of<br />

potential spoilage bacteria on refrigerated,<br />

vacuum-packed cured roast<br />

chicken. CARDOSO et al. (2016)<br />

observed the efficiency of chitosan<br />

gelatine-based coating on beef steaks<br />

during retail display and found that<br />

coated samples effectively decreased<br />

the weight loss, lipid oxidation and<br />

discoloration of coated steaks. ABAS<br />

(2016)evaluated the effect of added<br />

levels of agum arabic (Acacia senegal)powder<br />

coating and sun drying<br />

period on the physical, chemical,<br />

microbial and organoleptic properties<br />

of dry camel meat and concluded<br />

that a10% level of gum arabic is a<br />

potent natural antibacterial and<br />

antioxidants in an edible coating for<br />

improving the appearance and was<br />

increasing the shelf-life of sun dried<br />

camel meat. KHARE et al. (2016a)<br />

determined the efficacy of an edible<br />

coating of carrageenan and cinnamon<br />

oil to enhance the shelf-life of<br />

chicken meat stored under refrigeration<br />

conditions and concluded that<br />

the carrageenan and cinnamon<br />

edible coating was found to be a<br />

good alternative to enhance the<br />

shelf-life of chicken meat under<br />

refrigeration conditions with the<br />

dipping method of the application.<br />

In another study,KHARE et al.<br />

(2016b) evaluated the shelf-life of<br />

chitosan and cinnamon oil coated<br />

chicken meat nuggets under aerobically<br />

packaged condition at refrigerated<br />

temperature and reported that<br />

coated sample had abetter storage<br />

stability as indicated by lower lipid<br />

oxidation than other treatments and<br />

the control. OZVURAL et al. (2016)<br />

studied the effect of chitosan enriched<br />

green tea extract coating on<br />

hamburger patties and showed a<br />

attenuation effect against lipid<br />

oxidation. LEKJING (2016)investigated<br />

the effect of chitosan coatings,<br />

with and without clove oil, on quality<br />

and shelf-life of cooked pork<br />

sausages stored at arefrigerated<br />

temperature (4 ±2°C). The authors<br />

found that the total viable count, the<br />

psychrotrophic bacteria count, the L*<br />

value, peroxide value and the thiobarbituric<br />

acid reactive substances<br />

increased, while the a*value, the b*<br />

value, the pH and the sensory scores<br />

decreased with storage time.<br />

Advantages<br />

Edible coatings have many advantages<br />

(Tab. 2), but only when the<br />

coated produces are stored at<br />

proper temperatures. They can act<br />

as moisture and gas barriers, preserve<br />

the color,control microbial<br />

growth, texture and moisture of the<br />

product, and effectively extend the<br />

shelf life of the product. These<br />

coatings have their disadvantages,<br />

too. Butthese can be avoided by<br />

adding food grade additives to<br />

change their composition and<br />

improve properties of coatings.<br />

Regulatory status<br />

To maintain edibility,all the edible<br />

coating components, as well as any<br />

functional ingredients in the coating<br />

solution, should be food-grade,<br />

nontoxic materials, and all process<br />

followed should meet the high<br />

standards of hygiene and safety<br />

(GUILBERT and GONTARD,1995;<br />

GUILBERT et al., 1996; HAN,2002;<br />

NUSSINOVITCH,2003). Any compound<br />

should be generally recognized<br />

as safe (GRAS) or regulated<br />

as food additive, and used within<br />

specified limitations (FDA, 2012).<br />

According to the European Directive<br />

(ED, 1995 and ED, 1998) and<br />

USA regulations (FDA, 2012), they<br />

can be classified as food additives,<br />

food ingredients, food products,<br />

food contact substances and food<br />

packaging materials. They should<br />

observe all regulations required for<br />

food ingredients (GUILBERT and<br />

GONTARD,1995). The foremost<br />

<strong>international</strong>ly recognized regulations<br />

concerning food additives are<br />

the European Union standards,<br />

Food and Drug Act(FDA), and the<br />

Codex Alimentarius Commission<br />

(CAC), which constitutes the<br />

FAO/WHO joint regulatory body<br />

(RAJU and BAWA,2006). Each<br />

country has its own regulations<br />

defining alist of approved additives<br />

(ED, 1995 and USDA, 2006).<br />

Many edible coatings are made<br />

with ingredients that could cause<br />

potential allergic reactions. Within<br />

these allergens list, milk, egg, fish,<br />

soybeans, peanuts, nuts and wheat<br />

are the most important. Anumber<br />

of edible coatings are formed from<br />

milk protein (whey,casein),<br />

peanut, and wheat (gluten) and soy<br />

protein. Therefore, the presence of<br />

acoating with aknown allergen<br />

and ingredients with afunctional<br />

effect should be mentioned on the<br />

label (FRANSSEN and KROCHTA,<br />

2003).<br />

Future trends<br />

Nowadays, agreat discussion exists<br />

about the functional applications of<br />

edible materials on food products.<br />

Different biopolymers such as<br />

polysaccharides, proteins and their<br />

composite are applied to form<br />

edible coatings. These coatings may<br />

be acarrier of antimicrobial, antioxidants,<br />

nutraceuticals and flavoring<br />

agents or other additives to improve<br />

the thermal and mechanical integrity,handling,<br />

and quality<br />

(TAVASSOLI-KAFRANI et al., 2016).<br />

Scientists are focused on finding<br />

the correlation between foods and<br />

coating formulation. Newformulations,<br />

coating technology,industrial<br />

equipment and development of<br />

stable products are the important<br />

aspect with the purpose of providing<br />

more realistic information<br />

about edible coatings. Newadvancements<br />

have to be welcomed<br />

for improving the functionality and<br />

performance of edible coatings to<br />

maintain the shelf-life, sensory<br />

attributes and naturalness of muscle<br />

foods.<br />

References<br />

Literature references can be requested<br />

from the corresponding author or the<br />

editorial office, respectively.<br />

Tarun Pal Singh<br />

is working as ascientist at the National Yak<br />

Research Centre in Dirang, Arunachal<br />

Pradesh.<br />

Authors’ address<br />

Dr.Tarun Pal Singh (tarunsingh835<br />

@gmail.com), ICAR-National Research<br />

Centre on Yak, Dirang-790101, Arunachal<br />

Pradesh, India.