Optics Function - Krauss Maffei

Optics Function - Krauss Maffei

Optics Function - Krauss Maffei

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

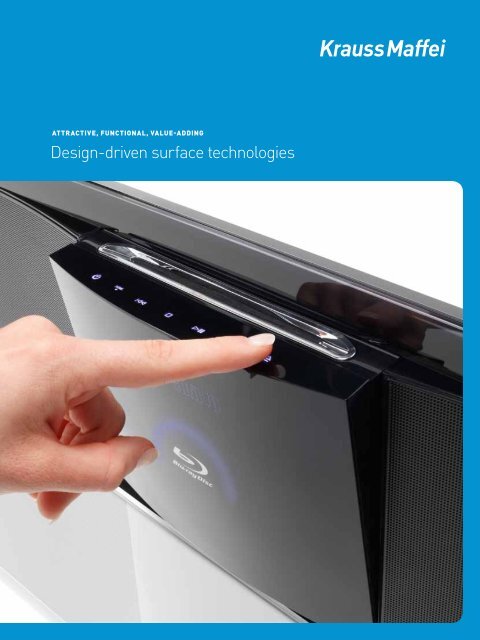

AttrActive, functionAl, vAlue-Adding<br />

Design-driven surface technologies

PArtnering WitH induStrY<br />

<strong>Krauss</strong><strong>Maffei</strong> is a premium partner for the<br />

plastics and rubber processing industries<br />

worldwide<br />

Whatever you aim to achieve in plastics or rubber<br />

processing, <strong>Krauss</strong><strong>Maffei</strong> is your partner. We are the only<br />

company in the market with expertise in the three major<br />

machine technologies for plastics processing – injection<br />

molding, reaction processing and extrusion. We continually<br />

integrate this know-how across the different technologies to<br />

develop new processes and machinery for plastics and<br />

rubber processing.<br />

People for plastics<br />

As an international company, <strong>Krauss</strong><strong>Maffei</strong> has<br />

a presence in all the major markets for the plastics<br />

and rubber processing industries and employs<br />

around 3,000 people worldwide. Our sales and<br />

service network keeps us close to all our customers<br />

around the world.<br />

commitment to customers<br />

Cutting edge technologies and outstanding machinery<br />

are one part of the answer – comprehensive<br />

support by experts committed to your interests<br />

is the other. Our know-how is based on many<br />

decades’ experience and steady investment in<br />

research and development. We deliver what you<br />

need – from the product idea to a customer-specific<br />

system solution.<br />

Adding value for customers<br />

We put our expertise to work for your success.<br />

With machine ranges engineered for modularity,<br />

we can deliver application-specific solutions<br />

based on our wide range of standard modules<br />

and specially engineered solutions. This strategy<br />

offers customers technical and cost advantages.<br />

close to customers around the world<br />

We are the “people for plastics”. We are your partner<br />

from the first exploratory discussion, through<br />

development of the optimal solution to commissioning,<br />

servicing and operating your system, including<br />

moving and final disposal of your system. At all<br />

times, you are assured of outstanding competence<br />

in planning and engineering, reliable spare parts,<br />

logistics and fast-response service and support.

Sector-SPecific SolutionS<br />

<strong>Krauss</strong><strong>Maffei</strong> solutions are as diverse as the<br />

challenges facing our customers<br />

Automotive<br />

Automotive components for all<br />

vehicle areas – chassis, cockpit,<br />

frame and engine compartment – are<br />

made on <strong>Krauss</strong><strong>Maffei</strong> machines and<br />

systems. Over 500 companies from<br />

the global automotive and automotive<br />

components industry are among our<br />

customers.<br />

life Sciences<br />

Products for the healthcare and<br />

pharmaceuticals industries must be<br />

manufactured to stringent cleanliness<br />

and quality standards. With many years’<br />

experience, our expertise in compliance<br />

and cost-effectiveness is second to none.<br />

Our system solutions are qualified for<br />

high cleanroom classes.<br />

White goods<br />

Efficient thermal insulation is a key<br />

factor in reducing the power consumption<br />

of fridges, freezers and chillers.<br />

PUR rigid foam systems ensure optimal<br />

insulation even in relatively thin layers.<br />

<strong>Krauss</strong><strong>Maffei</strong> Italiana is a competence<br />

center for PUR rigid foams.<br />

electrical / electronics<br />

The electrical and electronics industries<br />

make extensive use of plastics.<br />

They produce a huge range of plastics<br />

products, often with highly specialized<br />

properties. Optimal electrical insulation<br />

and resistance to thermal and<br />

mechanical stress are among the key<br />

properties.<br />

construction<br />

Plastics are widely used in the construc<br />

tion industry, where they offer<br />

striking benefits, such as light weight,<br />

weather- and UV-resistance, impact<br />

resistance, resistance to scratching,<br />

easy installation and good thermal<br />

insulation. Many construction plastics<br />

are extruded and here customers can<br />

count on productive solutions from<br />

<strong>Krauss</strong><strong>Maffei</strong>.<br />

Packaging<br />

Plastics open up endless possibilities<br />

for packaging. They are extremely<br />

lightweight, design potential is limitless<br />

and recycling is unproblematic.<br />

Many companies operating in the<br />

packaging industry are longstanding<br />

<strong>Krauss</strong><strong>Maffei</strong> customers.

overvieW<br />

See, touch, enjoy<br />

It is a scientifically proven fact: our shopping<br />

experience is always guided by what we see and<br />

feel. A stunning design, a pleasant touch, timeless<br />

beauty and decoration are hallmarks of the most<br />

successful consumer products, from a tiny MP3<br />

player to a car interior. And now, surfaces with<br />

functional layers are playing an increasing role<br />

in innovative products.<br />

design determines market success<br />

Soft-touch, depth effects, transparent, scratchproof<br />

surfaces, electrical conductivity or the lotus effect –<br />

surface properties are as varied as the wealth of<br />

product designs on the market. And rightly so, for<br />

product design is fast becoming the factor that<br />

clinches a sale. The trend is definitely shifting away<br />

from parts laboriously produced from solid materials<br />

and toward coated plastic parts. This conserves<br />

scarce resources, makes the product lighter and<br />

reduces unit manufacturing costs.<br />

Page 4 Solutions for surfaces<br />

in-line processes are more cost-effective<br />

Often, the specified effect can be achieved with<br />

a layer just a few micrometers thick. The days<br />

of producing parts, storing them, conditioning<br />

them and then painting or coating them are numbered.<br />

More and more processors are turning<br />

to <strong>Krauss</strong><strong>Maffei</strong>’s in-line processes which meld<br />

different process technologies together to improve<br />

the end-product and boost value-added. In-line,<br />

multitechnology processes are also ideal for adding<br />

extra protective layers to extend the life of the<br />

surface effect.<br />

Maximum economy and yield<br />

More and more new combinations of materials<br />

with matching process solutions are opening the<br />

way for new surface effects. These can be a specific<br />

look&feel, value-adding functionality or extra decorative<br />

scope. The real challenge lies in configuring<br />

a production solution for these surfaces that is both<br />

cost-competitive and highly repeatable. <strong>Krauss</strong><strong>Maffei</strong><br />

has already developed a portfolio of processing<br />

solutions all of which meet these criteria; they<br />

maximize productivity and return on investment.<br />

<strong>Krauss</strong><strong>Maffei</strong> is unique in having in-house expertise<br />

in injection molding, extrusion and reaction processes.<br />

Combining these processes in what we call<br />

“Technology to the Power of Three” generates unrivalled<br />

scope when it comes to innovative surfaces.

Overview<br />

Page 5

Contents<br />

<strong>Optics</strong> <strong>Function</strong><br />

Brilliant colors and glass-clear<br />

transparency for memorable<br />

first impressions<br />

8 – 11<br />

Page 6 Solutions for surfaces<br />

Integrated sensors, resistance<br />

to environmental impact, and<br />

intelligence – for an intensive<br />

product experience 12 – 15

Haptics Decoration<br />

A good grip, soft-touch and<br />

all-round comfort – tangible<br />

added value<br />

16 – 19<br />

Maximizing optics, haptics<br />

and functionality by adding<br />

decors<br />

20 – 23<br />

Page 7

<strong>Optics</strong><br />

Page 8 Solutions for surfaces

Brilliant colors and glass-clear transparency:<br />

<strong>Krauss</strong><strong>Maffei</strong> has the right processes for<br />

products with flawless surfaces meeting<br />

demanding specifications.<br />

Page 9

oPticS<br />

For that critical first impression<br />

The first impression of a product is often the de -<br />

fining impression. But high-spec optical properties<br />

are often critical for functionality – for instance,<br />

with lenses or headlight components. Modular<br />

machine design means that <strong>Krauss</strong><strong>Maffei</strong> can offer<br />

a wide choice of processes which are strongly innovative,<br />

but already tried and tested in the field.<br />

Planetcalander for optical clarity in film<br />

and sheet<br />

There are many applications for film where optics<br />

play a major role – think of packaging or technical<br />

films for surface applications. The extrusion lines<br />

used to produce them must meet the highest criteria<br />

for precision and repeatability. Homogenous ma -<br />

terial processing is important, and the polishing<br />

stack also plays a decisive role in extruding optically<br />

clear film and sheet. Engineered for great flexibility,<br />

<strong>Krauss</strong><strong>Maffei</strong> Berstorff’s PlanetCalander can adapt<br />

cooling performance to different materials and<br />

sheet thicknesses. Furthermore, it’s engineered<br />

for rapid set-up to significantly speed up product<br />

changes.<br />

Precise reproduction of even miniscule<br />

structures<br />

Gentle processing of the raw materials is the first<br />

essential step towards premium surface quality.<br />

Especially for transparent materials, such as PC,<br />

the way the polymer is melted and homogenized is<br />

of first importance. Over the years, <strong>Krauss</strong><strong>Maffei</strong><br />

has built up immense competence in this field. In<br />

addition, we have a high level of vertical integration<br />

in the design and manufacture of plasticizing<br />

units, as well as an in-house R&D team working<br />

Page 10 Solutions for surfaces<br />

on screw geometries. It all adds up to plasticizing<br />

units that guarantee gentle melt processing and<br />

very good mixing of additives and pigment for<br />

many different materials.<br />

Painting and coating in open and closed molds<br />

The ColorForm process, the latest addition to the<br />

Technology3 family, combines injection molding<br />

with a polyurethane reaction process. A paint system<br />

is applied to the substrate in the closed mold –<br />

precisely, in thin layers and with very economical<br />

use of paint. These paints cure completely in the<br />

closed mold. Instead of a substrate that still needs<br />

to be painted, the ColorForm process adds value by<br />

producing a ready-painted part. The reliability and<br />

reproducibility of the coating process and the use of<br />

highly compatible material combinations together<br />

reduce the reject rate to close to zero and drastically<br />

shorten the manufacturing cycle. <strong>Krauss</strong><strong>Maffei</strong><br />

is currently the only company offering processes<br />

where coatings and paint are applied in open and<br />

in closed molds.<br />

lfi process for smooth surfaces<br />

Some structural parts, subject to high mechanical<br />

stresses, nonetheless need decorative surface<br />

coatings. <strong>Krauss</strong><strong>Maffei</strong>’s LFI process produces<br />

glassfiber-reinforced parts with smooth surfaces.<br />

Fiber from a roving is chopped to length in a cutter<br />

unit, wetted with the polyurethane system in the<br />

mixing head and discharged into the mold, where<br />

the part is pressed into shape. The LFI process<br />

stands for high fiber content and smooth surfaces.<br />

Processors can add value to the part by combining<br />

LFI with cost-effective surface coating processes.

PRODUCT: Tractor engine cover Same Deutz<br />

MaTeRial: Glassfiber-reinforced polyurethane<br />

+ paint<br />

TeCHNOlOGY: In-Mold Painting (IMP)<br />

Long Fiber Injection (LFI)<br />

CUSTOMeR BeNeFiT: Coating large-format parts<br />

with paint systems in an open mold is a cost-competitive<br />

alternative to conventional painting.<br />

PRODUCT: Optically clear sheet<br />

MaTeRial: PC, PMMA, PETG, APET, PS, SAN, ABS<br />

TeCHNOlOGY: PlanetCalander<br />

CUSTOMeR BeNeFiT: High precision, far quicker<br />

product changes.<br />

<strong>Optics</strong><br />

PRODUCT: Frontend<br />

MaTeRial: PC/PBT<br />

TeCHNOlOGY: Molded in Color<br />

CUSTOMeR BeNeFiT: Easy, low-cost method of<br />

adding value by coloring the material used to mold<br />

frontends – high-performance HPS screws ensure<br />

easy, efficient mixing of color masterbatch.<br />

PRODUCT: Tool case (design study)<br />

MaTeRial: PA/PET, TPE, polyurethane paint system<br />

for high-gloss decor accents<br />

TeCHNOlOGY: ColorForm<br />

CUSTOMeR BeNeFiT: The ColorForm process can<br />

successfully replace conventional painting, including<br />

pre- and post-painting steps. It increases the yield<br />

and cuts manufacturing cost for parts requiring a<br />

high-gloss finish.<br />

Page 11

<strong>Function</strong><br />

Page 12 Solutions for surfaces

<strong>Krauss</strong><strong>Maffei</strong> offers a wide choice of techniques<br />

for adding design and functionality to surfaces.<br />

Page 13

function<br />

All-round performers:<br />

functional surfaces add value<br />

Modern processing solutions from <strong>Krauss</strong><strong>Maffei</strong><br />

produce parts that look brilliant and perform<br />

important functions as well – such as holding,<br />

protecting, and insulating. For instance, heavy-duty<br />

brackets guarantee a secure hold, while barrier<br />

layers protect against frictional wear and tear,<br />

block emissions and prevent deterioration caused<br />

by weathering.<br />

Weatherable and uv-resistant sheet<br />

<strong>Krauss</strong><strong>Maffei</strong> Berstorff extrusion lines take all<br />

kinds of raw materials and turn them into sheet<br />

material that is transparent, scratchproof, impactand<br />

UV-resistant. Weatherable PVC free-foam sheet<br />

is produced to a high surface finish on extrusion<br />

lines featuring a embossing/haul-off combination.<br />

And you will find complete systems for producing<br />

PVC siding profiles for building exteriors in our<br />

solutions portfolio, too.<br />

reliable protection with a few micrometers<br />

The CoverForm process, developed by <strong>Krauss</strong><strong>Maffei</strong><br />

and Evonik, makes transparent PMMA parts<br />

scratchproof and wear-resistant. A protective layer<br />

just a few micrometers thick is applied in the mold<br />

straight after the injection molding stage. This saves<br />

the logistics effort for intermediate storage and<br />

post-mold coating. It also eliminates any factors<br />

that could impair quality.<br />

functional integration in one step<br />

Parts injection molded from transparent polymers<br />

such as PC and PMMA are increasingly replacing<br />

their heavier glass counterparts. Apart from<br />

the weight savings, benefits include more design<br />

Page 14 Solutions for surfaces<br />

freedom combined with excellent surface quality.<br />

<strong>Krauss</strong><strong>Maffei</strong> offers a range of compression<br />

molding processes for producing these kinds of lowstress<br />

parts. Compression molding is also ideal for<br />

large-format parts with an area of more than one<br />

square meter, such as bezels for large TV screens,<br />

and automotive glazing. Thanks to SpinForm, our<br />

swivel-platen technology, extra functionality can<br />

be integrated into the part in a single-sequence process.<br />

A center platen, with a swivel unit, mounted<br />

between the mold clamping platens enables separate<br />

high-precision compression processes in two<br />

parting lines. Combining swivel-platen technology<br />

with glazing technology makes for single-cycle,<br />

cost-effective production of design-driven parts,<br />

for example, parts which look stunning and also<br />

integrate concealed mounting elements.<br />

High-quality surfaces<br />

for fiber-reinforced parts<br />

Our reaction process machinery portfolio encompasses<br />

a large number of fiber-composite technologies.<br />

They will produce parts featuring mechanical<br />

strength, high-quality surfaces and give you the<br />

option of integrating extra functionality. The parts<br />

can provide thermal and acoustic insulation, a<br />

pleasant, soft-touch effect or enhanced mechanical<br />

performance. Typical examples are glassfiberreinforced<br />

parts which combine low weight with<br />

high mechanical strength. The real challenge here<br />

is to create a flawless surface with no visible fibers.<br />

<strong>Krauss</strong><strong>Maffei</strong> also supplies in-line processes to add<br />

value to these parts with coatings and other surface<br />

finishes.

PRODUCT: Cover element for a convertible car<br />

MaTeRial: Substrate: Polyurethane<br />

Surface: UV-resistant PU<br />

TeCHNOlOGY: Long Fiber Injection (LFI)<br />

CUSTOMeR BeNeFiT: This lightweight part is<br />

produced in one cycle by the proven LFI process,<br />

with simultaneous integration of fasteners.<br />

PRODUCT: Foamed PVC sheet<br />

MaTeRial: PVC<br />

TeCHNOlOGY: Sheet extrusion with a<br />

32D twin-screw extruder<br />

CUSTOMeR BeNeFiT: Weather-resistant siding<br />

panels with depth effects created by compression<br />

technology.<br />

<strong>Function</strong><br />

PRODUCT: Test visor<br />

MaTeRial: PMMA cf, Plexiglas<br />

TeCHNOlOGY: CoverForm Evonik Röhm/<br />

<strong>Krauss</strong><strong>Maffei</strong><br />

CUSTOMeR BeNeFiT: CoverForm ® produces<br />

these parts with a scratch- and chemicalresistant<br />

coating.<br />

PRODUCT: Sunroof<br />

MaTeRial: PC/PC colored<br />

TeCHNOlOGY: Glazing, SpinForm<br />

CUSTOMeR BeNeFiT: Transparent polymers offer<br />

more design freedom than glass, as well as weight<br />

savings. Glazing technology combined with the<br />

SpinForm process makes it possible to produce<br />

large, low-stress transparent parts and to integrate<br />

connector elements or sensors in one process cycle.<br />

Page 15

Haptics<br />

Page 16 Solutions for surfaces

The touch of class – <strong>Krauss</strong><strong>Maffei</strong> offers a<br />

number of technology and process options<br />

for creating pleasant haptics.<br />

Page 17

HAPticS<br />

Luxury at economy rates:<br />

near-natural touch<br />

Millions of receptors on our skin are constantly<br />

receiving information from our surroundings<br />

about hardness, texture, smoothness or roughness,<br />

absorbency and temperature. People have developed<br />

a preference for certain surfaces because,<br />

to their minds, such surfaces are associated with<br />

high-quality goods. <strong>Krauss</strong><strong>Maffei</strong> offers a choice<br />

of process for cost-competitive production of<br />

surfaces with very attractive haptics.<br />

Multinject for hard-soft combinations<br />

Product designers are increasingly creating parts<br />

that have both hard and soft areas, eg, for a better<br />

grip or to create a pleasant look&feel. Multicomponent<br />

technology from <strong>Krauss</strong><strong>Maffei</strong> offers virtually<br />

unlimited scope for producing such hard-soft combinations.<br />

The outcome is parts with the optimum<br />

symbiosis of touch and looks and, given the right<br />

combination, added value.<br />

leather-like feel for the touch of luxury<br />

Around the world, leather upholstery in cars is<br />

perceived as a visible and tangible sign of luxury.<br />

SkinForm from <strong>Krauss</strong><strong>Maffei</strong> is the first process to<br />

simulate leather reproducibly and cost-effectively<br />

using polymers. This multicomponent process<br />

combines injection molding and polyurethane processing<br />

– a thermoplastic substrate is molded in the<br />

first cycle and then immediately overmolded with a<br />

soft PU surface. Soft-touch surfaces have a realistic<br />

grain and are deceptively like natural leather in<br />

the way they feel. What is more, they are highly<br />

scratch-resistant and durable.<br />

Page 18 Solutions for surfaces<br />

Aging-resistant, scratchproof sheets<br />

<strong>Krauss</strong><strong>Maffei</strong> Berstorff extrusion lines are used to<br />

convert various kinds of materials into technical<br />

sheets for vehicle interiors, instrument panels and<br />

door panels as well as decor films for furniture.<br />

Not only are the sheet and films free of halogens<br />

and plasticizers, they are also scratch-resistant,<br />

and impart a touch of luxury to every car interior.<br />

Again, the elegant leather look with its high-resolution<br />

grain structures is created on <strong>Krauss</strong><strong>Maffei</strong><br />

machinery. And the films and sheet offer exemplary<br />

low-temperature flexibility and aging resistance.<br />

coating complex 3d shapes<br />

Our Reaction Process Machinery division can<br />

supply various processes for enhancing the tactile<br />

properties of parts. These include fully automated<br />

processes for casting skins of high-quality<br />

surfaces and constant wall thickness. SpraySkin<br />

is another popular process – a robot mounting a<br />

special mixing head sprays a polyurethane skin<br />

into a mold. This method can produce complex<br />

three-dimensional shapes and a range of surface<br />

grainings.

PRODUCT: Instrument panel<br />

MaTeRial: PU aromatic or aliphatic<br />

TeCHNOlOGY: RimSkin<br />

CUSTOMeR BeNeFiT: Extremely uniform skin thick-<br />

ness. Can be applied in the smallest radii, unlimited<br />

color options and multiple colors. Waste reduction<br />

through optimized use of materials.<br />

PRODUCT: Film and sheet for automotive interiors<br />

MaTeRial: TPO<br />

TeCHNOlOGY: Film extrusion<br />

CUSTOMeR BeNeFiT: Leather look, high-quality<br />

grain, scratch resistance.<br />

Haptics<br />

PRODUCT: Handle for disposable razor<br />

MaTeRial: PS + thermoplastic elastomer<br />

TeCHNOlOGY: SpinForm<br />

CUSTOMeR BeNeFiT: Hard-soft combinations, as in<br />

this disposable razor, add value to low-cost products<br />

by improving the grip. They can be manufactured<br />

cost-competitively and in bulk with SpinForm.<br />

PRODUCT: Hood for kinematic drawer for the<br />

BMW 5 GT<br />

MaTeRial: Thermoplastic support and PU<br />

TeCHNOlOGY: SkinForm<br />

CUSTOMeR BeNeFiT: Flexible color styling thanks to<br />

MicroDos color management. Cost-efficient surface<br />

finishing, with leather-like feel.<br />

Page 19

Decoration<br />

Page 20 Solutions for surfaces

Good looks with a purpose – decorative surfaces<br />

for films, fabrics or carpets have many functions,<br />

but they can all be produced on <strong>Krauss</strong><strong>Maffei</strong><br />

machines.<br />

Page 21

decorAtion<br />

From simple films to eye-catching decors<br />

Surface decoration can produce a wealth of<br />

different effects – from informative in-mold labels<br />

to transparent coatings that produce a deep-gloss<br />

surface finish.<br />

film and foil reduce printing effort<br />

Decors are often applied by injecting a plastic<br />

substrate behind a film or foil, which may or may<br />

not have been preshaped. In-mold labeling saves the<br />

cost and effort of printing on 3-dimensional containers;<br />

instead the preprinted decor film is inserted in<br />

the mold before the container is injection molded.<br />

InsertForm is a process whereby preformed film and<br />

foil is back injected. A great variety of ma terials<br />

can be used, eg, metallic film which gives a part<br />

not only the look of steel, but also the metal’s coldtouch<br />

effect.<br />

no solvents or adhesives with decoform<br />

The DecoForm process can produce parts with<br />

textile, carpet or film surfaces. A <strong>Krauss</strong><strong>Maffei</strong><br />

robot inserts the decor in the mold. An injection<br />

molding machine then injects a backing or substrate<br />

behind the insert material in a back-injection or<br />

back-compression process. The low cavity pressures<br />

required by this process make it ideal for surface<br />

decors that are highly pressure- and temperaturesensitive.<br />

DecoForm has lower environmental<br />

impact, because it requires no solvents or adhesives.<br />

Page 22 Solutions for surfaces<br />

The DecoForm process is also right for processing<br />

natural materials, such a wood veneers, and any<br />

type of film. Many of the films inserts used have<br />

been produced on <strong>Krauss</strong><strong>Maffei</strong> Berstorff film<br />

extrusion lines.<br />

Perfect mixing however small the shot<br />

Luxury deep-gloss effects can be produced costcompetitively<br />

with Clear Coat Molding. Highquality<br />

substrates, such as luxury wood veneers, are<br />

coated, in the mold, with a thin layer of a highly<br />

transparent 2-component PU system. Optimized<br />

temperature control ensures precision metering even<br />

at very low output rates. Here too, <strong>Krauss</strong><strong>Maffei</strong><br />

supplies complete solutions, including mold, mold<br />

carriers and post-mold trimming. Another process<br />

uses paints and PU systems.

PRODUCT: Instrument panel bezel<br />

MaTeRial: Transparent polyurethane<br />

TeCHNOlOGY: Clear Coat Molding (CCM)<br />

CUSTOMeR BeNeFiT: Coating the parts with a<br />

transparent PU system produces a highly scratchresistant<br />

surface with an optically brilliant, deepgloss<br />

finish.<br />

PRODUCT: Instrument panel Chrysler Crossfire<br />

MaTeRial: PP +20% talcum, TPO/PP foam<br />

TeCHNOlOGY: DecoForm<br />

CUSTOMeR BeNeFiT: Back-injecting decor skins<br />

produces components which pamper the senses and<br />

increase the feeling of well-being, for example in the<br />

passenger compartment of a car. <strong>Krauss</strong><strong>Maffei</strong> offers<br />

fully-automated systems for producing complex,<br />

assembly-ready 3D parts, even with sensitive fabric<br />

or decor surfaces.<br />

Decoration<br />

PRODUCT: Rectangular tub<br />

MaTeRial: PP<br />

TeCHNOlOGY: In-Mold Labeling (IML)<br />

CUSTOMeR BeNeFiT: Back-injecting films improves<br />

the shelf-life of packaging, adds color and design,<br />

and makes it possible to add a wealth of data with a<br />

precision that is impossible with conventional printing.<br />

<strong>Krauss</strong><strong>Maffei</strong> offers complete turnkey solutions<br />

that guarantee precision label handling and very<br />

fast cycles.<br />

PRODUCT: Flooring<br />

MaTeRial: PVC<br />

TeCHNOlOGY: Extrusion and calendering,<br />

double-belt presses (AUMA)<br />

CUSTOMeR BeNeFiT: Processors benefit from quick<br />

and easy color changes and cleaning. Even small<br />

batches can be produced cost-effectively and without<br />

problems. Our production systems for flooring combine<br />

the advantages of our plastics and rubber processing<br />

technologies.<br />

Page 23

viSionS & tecHnologieS<br />

Making intelligent polymer<br />

parts in a single cycle<br />

Page 24 Solutions for surfaces<br />

Looking ahead, totally new functional surfaces are<br />

on the agenda. For instance, <strong>Krauss</strong><strong>Maffei</strong> already<br />

offers production solutions for parts with integrated<br />

heating or with illuminated surfaces. Sensors can<br />

be integrated in a part in a single-sequence injection<br />

process; all that needs to be done post-mold<br />

is to connect them up. When users later touch the<br />

intelligent components they activate defined light<br />

or heating effects.<br />

On the materials side, <strong>Krauss</strong><strong>Maffei</strong> has become<br />

the development partner of choice for leading<br />

manufacturers wanting application-specific processing<br />

solutions for innovative material combinations.<br />

As a result, <strong>Krauss</strong><strong>Maffei</strong> process engineers have a<br />

clear know-how lead. In particular, turnkey process<br />

solutions configured using tried-and-tested components<br />

are an assurance that production can start<br />

immediately. This gives processors a significant<br />

competitive advantage; they can react fast to changing<br />

market trends confident that they will be able to<br />

produce innovative surfaces in very high quality at<br />

an acceptable cost.<br />

Innovative functional integration: sensor and<br />

luminaire functionality are integrated when<br />

the product is injection molded.

KrAuSSMAffei – A Strong PArtner<br />

Technology³: potential for innovative surfaces<br />

<strong>Krauss</strong><strong>Maffei</strong>’s innovative process solutions are<br />

changing the rules in your markets. Again and<br />

again, they open the way to new surface finishes<br />

and substantial cost advantages.<br />

As technology leader, with numerous prizes and<br />

awards to our credit, <strong>Krauss</strong><strong>Maffei</strong> works closely with<br />

the scientific community and with industrial partners<br />

to drive the pace of progress in our sector. One source<br />

of our innovative strength is our unique in-house<br />

expertise across injection molding, polyurethane<br />

processing and extrusion. This Technology 3 strategy is<br />

generating huge innovation potential. Especially when<br />

it’s combined with application-specific automation.<br />

Visions & technologies<br />

Be in the forefront with new trends<br />

New process development is on-going. Think of<br />

color effects added as part of the injection molding<br />

process, so that processors can produce a popular<br />

metal look without a separate painting process. Or<br />

look at the potential for adapting the SkinForm<br />

process to other products. Cost-effective solutions<br />

for brushed metal finishes or a glossy piano lacquer<br />

look promote new trends for decorative elements.<br />

Thanks to <strong>Krauss</strong><strong>Maffei</strong>’s well-established modular<br />

engineering, machines can be adapted very rapidly<br />

to keep pace with the latest trends in surface design.<br />

It’s a significant competitive advantage for our<br />

customers.<br />

The "Avenue of Technologies" of <strong>Krauss</strong><strong>Maffei</strong> was a striking demonstration of the endless portfolio of technology<br />

solutions for plastics processing.<br />

Page 25

Service, support and spare parts –<br />

when you need them, where you need them<br />

americas:<br />

· Brazil – São Paulo<br />

· Columbia – Bogotá<br />

· Mexico – Estado de México<br />

· USA – Florence<br />

All-round service<br />

Choose the service and support solutions that are<br />

right for your business. We’ll configure your<br />

system, install and commission it, train your staff,<br />

advise on minimizing downtime and maximizing<br />

productivity, and carry out maintenance, repairs<br />

and upgrades.<br />

europe:<br />

· Germany – Munich, Hanover,<br />

Verl, Renningen, Oberding-Schwaig,<br />

Viersen, Georgsmarienhütte,<br />

Treuchtlingen, Schwerin, Schkopau<br />

· Austria – Vienna<br />

· Denmark – Roskilde<br />

· France – Genneviliers Cedex<br />

· Italy – Rezzato, Abbiategrasso<br />

· Netherlands – Breda<br />

· Russia – Moscow, Kazan<br />

· Slovakia – Martin, Zilina<br />

· Sweden – Jönköpping<br />

· Switzerland – Rotkreuz<br />

· United Kingdom – Warrington<br />

asia:<br />

· China – Shanghai, Zhejiang,<br />

Shenzhen<br />

· India – Pune<br />

· Japan – Aichi<br />

· Korea – Seoul<br />

· Taiwan – Taichung<br />

· Thailand – Bangkok<br />

Hands-on training for operators<br />

and service technicians<br />

We’ll train your operators and technicians in our<br />

Training Centers or on your premises anywhere in<br />

the world. Our graded course programme covers<br />

machine operation, process control and maintenance.<br />

We’ll also organize special courses on<br />

customer-specific topics.

talk to us, we’re here to help you<br />

Talk to us about your project. You<br />

can call on our expertise and experience<br />

from the start. We’ll partner<br />

with you to find the optimal solution<br />

for your business.<br />

Contact<br />

Service hotline<br />

Phone: +49 89 8899-0<br />

Fax: +49 89 8899-2206<br />

or write to us<br />

<strong>Krauss</strong><strong>Maffei</strong> Technologies GmbH<br />

<strong>Krauss</strong>-<strong>Maffei</strong>-Strasse 2<br />

80997 Munich<br />

Germany

<strong>Krauss</strong><strong>Maffei</strong> is a premium partner for the plastics and rubber processing<br />

industries worldwide. <strong>Krauss</strong><strong>Maffei</strong> machines and systems are used wherever<br />

plastics and rubber are converted into products. As a knowledge-driven<br />

technology company, we build on many decades of experience and a strong<br />

commitment to research and development.<br />

Plastic components with optical, haptic, decorative and<br />

functional surface properties play a significant role in<br />

purchase decisions. In addition, new material<br />

combinations teamed with the right processing solutions<br />

offer tremendous potential for slimming down production<br />

processes and reducing manufacturing costs.<br />

<strong>Krauss</strong><strong>Maffei</strong> supplies innovative, multiprocess solutions.<br />

Conventional, separate steps for producing and coating<br />

components can be replaced by single-sequence<br />

processes that produce high quality at very competitive<br />

costs. These new processes open up entirely new potential<br />

for surface finishes and part design.<br />

<strong>Krauss</strong><strong>Maffei</strong> technologies gmbH<br />

<strong>Krauss</strong>-<strong>Maffei</strong>-Strasse 2 ··· 80997 Munich<br />

Phone +49 89 8899-0 ··· Fax +49 89 8899-2206<br />

www.kraussmaffei.com<br />

<strong>Krauss</strong><strong>Maffei</strong> Berstorff gmbH<br />

An der Breiten Wiese 3 - 5 ··· 30625 Hannover<br />

Phone +49 511 5702-0 ··· Fax +49 511 561916<br />

www.kraussmaffei.com<br />

1.0 WE . 1st edition 03/2011. … KM 21 A PRO 03/2011 ··· <strong>Krauss</strong><strong>Maffei</strong> reserves the right to make technical changes ··· Printed in Federal Republic of Germany.