Preforming and In-mould Lamination in one Operation - Krauss Maffei

Preforming and In-mould Lamination in one Operation - Krauss Maffei

Preforming and In-mould Lamination in one Operation - Krauss Maffei

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Decoration Dur<strong>in</strong>g <strong>In</strong>jection Mould<strong>in</strong>g. Large-area, three-<br />

dimensional lam<strong>in</strong>ated parts, such as boot l<strong>in</strong><strong>in</strong>gs have until now<br />

been manufactured <strong>in</strong> multiple operations on vertical presses by<br />

melt str<strong>and</strong> deposition. A new production method allows the<br />

textile lam<strong>in</strong>ate to be preformed <strong>and</strong> <strong>in</strong>jection compression lami-<br />

nated (back <strong>in</strong>jection compression) <strong>in</strong> the <strong>in</strong>jection <strong>mould</strong> <strong>in</strong> a<br />

s<strong>in</strong>gle operation – with significant cost advantages.<br />

I n<br />

JOCHEN MITZLER<br />

HENRY JANSSON<br />

GEORG KAUFMANN<br />

the automotive <strong>in</strong>dustry, cost pressures<br />

are lead<strong>in</strong>g to permanent <strong>in</strong>novations<br />

<strong>and</strong> developments. Manufacturers<br />

of plastic parts <strong>and</strong> modules are<br />

endeavour<strong>in</strong>g to reduce the number of<br />

process operations by, among other<br />

th<strong>in</strong>gs, comb<strong>in</strong><strong>in</strong>g different methods.<br />

Tailored automation can also <strong>in</strong>crease the<br />

productivity of the manufactur<strong>in</strong>g cell.<br />

These are the aims that are also be<strong>in</strong>g<br />

pursued by mach<strong>in</strong>e manufacturer<br />

<strong>Krauss</strong>-<strong>Maffei</strong>, Munich/Germany, the<br />

automotive subcontractors Coll<strong>in</strong>s &<br />

Aikman, Skara/Sweden, <strong>and</strong> the <strong>mould</strong><br />

manufacturer Georg Kaufmann AG,<br />

Bussl<strong>in</strong>gen/Switzerl<strong>and</strong>, <strong>in</strong> an ongo<strong>in</strong>g<br />

successful jo<strong>in</strong>t project.<br />

On an <strong>in</strong>jection <strong>mould</strong><strong>in</strong>g mach<strong>in</strong>e, a<br />

highly three-dimensional, decorated boot<br />

Translated from Kunststoffe 3/2004, pp. 70–74<br />

i<br />

Manufacturer<br />

<strong>Krauss</strong>-<strong>Maffei</strong> Kunststofftechnik GmbH<br />

<strong>Krauss</strong>-<strong>Maffei</strong>-Straße 2<br />

D-80997 Munich<br />

Germany<br />

Ph<strong>one</strong> +49 (0) 89/88 99-0<br />

Fax +49 (0) 89/88 99-3092<br />

E-mail: <strong>in</strong>fo@krauss-maffei.de<br />

www.krauss-maffei.de<br />

Kunststoffe plast europe 3/2004<br />

Fig. 1. Boot l<strong>in</strong><strong>in</strong>g for a rear door of a new<br />

vehicle generation (photos, except 5: <strong>Krauss</strong>-<strong>Maffei</strong><br />

Kunststofftechnik)<br />

l<strong>in</strong><strong>in</strong>g for a rear door (Fig. 1) is produced<br />

by back <strong>in</strong>jection-compression <strong>mould</strong><strong>in</strong>g<br />

by the Decoform process patented by<br />

<strong>Krauss</strong>-<strong>Maffei</strong>. The novelty of the process<br />

is that the carpet decorative lam<strong>in</strong>ate does<br />

not need to be preformed before it is <strong>in</strong>jection<br />

lam<strong>in</strong>ated on the <strong>in</strong>jection <strong>mould</strong><strong>in</strong>g<br />

mach<strong>in</strong>e. Automation plays a crucial<br />

role <strong>in</strong> this.The <strong>in</strong>tegrated preform<strong>in</strong>g only<br />

becomes possible with the correct choice<br />

of automation <strong>and</strong> precise <strong>in</strong>teraction between<br />

the <strong>in</strong>dividual plant modules.<br />

Coll<strong>in</strong>s & Aikman have more than ten<br />

years’ experience <strong>in</strong> low-pressure technologies.<br />

The company produces pillar<br />

<strong>and</strong> boot l<strong>in</strong><strong>in</strong>gs by the Decoform <strong>and</strong><br />

Decopress process. Coll<strong>in</strong>s & Aikman use<br />

the vertical Decopress technology (back<br />

compression) for the production of largearea<br />

carpet-decorated side trim for the<br />

boot. These parts have a relatively simple<br />

three-dimensional geometry.<br />

However, the design expectations are<br />

higher for the development of new vehicle<br />

generations. Designers require tighter<br />

radii <strong>and</strong> more three-dimensionally complex<br />

parts (Fig. 2). At the same time, an<br />

AUTOMOTIVE • INJECTION MOULDING ■<br />

<strong>Preform<strong>in</strong>g</strong> <strong>and</strong> <strong>In</strong>-<strong>mould</strong><br />

<strong>Lam<strong>in</strong>ation</strong> <strong>in</strong> <strong>one</strong> <strong>Operation</strong><br />

identical or similar production concept is<br />

used, <strong>in</strong> which a non-preformed carpet is<br />

processed. Dur<strong>in</strong>g the development work,<br />

the Decoform process developed by<br />

<strong>Krauss</strong>-<strong>Maffei</strong> proved the ideal manufactur<strong>in</strong>g<br />

method for three-dimensional<br />

parts. Back <strong>in</strong>jection compression on an<br />

<strong>in</strong>jection <strong>mould</strong><strong>in</strong>g mach<strong>in</strong>e permits a<br />

substantially wider process<strong>in</strong>g w<strong>in</strong>dow<br />

<strong>and</strong> more flexible production than production<br />

on a vertical back compression<br />

press.<br />

Production without Separate<br />

<strong>Preform<strong>in</strong>g</strong><br />

<strong>In</strong> the case of parts with a pronounced<br />

three-dimensional shape, it was until now<br />

Fig. 2. Side trim for the boot area of new vehicle<br />

generations require tight radii <strong>and</strong> parts with<br />

three-dimensional complexity<br />

1

■ AUTOMOTIVE • INJECTION MOULDING<br />

Fig. 3. Compact production cell:<br />

<strong>Krauss</strong>-<strong>Maffei</strong> Decoform series KM<br />

420-3500DF <strong>in</strong>jection <strong>mould</strong><strong>in</strong>g<br />

mach<strong>in</strong>e with <strong>in</strong>frared radiator<br />

bank <strong>and</strong> l<strong>in</strong>ear robot. The carpet is<br />

preheated by <strong>in</strong>frared radiators<br />

mounted above the <strong>mould</strong><br />

necessary to preform the carpet on a<br />

thermoform<strong>in</strong>g l<strong>in</strong>e, because otherwise<br />

the carpet tears or the surface is damaged<br />

by the press<strong>in</strong>g.<br />

It is precisely this stage of separate preform<strong>in</strong>g<br />

that is elim<strong>in</strong>ated by the new<br />

Decoform manufactur<strong>in</strong>g cell (Fig. 3). <strong>In</strong>stead,<br />

the carpets are only formed <strong>in</strong> the<br />

<strong>mould</strong>. To carry out this form<strong>in</strong>g on the<br />

<strong>in</strong>jection <strong>mould</strong><strong>in</strong>g mach<strong>in</strong>e, <strong>in</strong>frared<br />

radiators heat the carpets shortly before<br />

process<strong>in</strong>g at a suitable temperature before<br />

they are immediately <strong>in</strong>serted by a<br />

h<strong>and</strong>l<strong>in</strong>g system <strong>in</strong> the <strong>mould</strong>. The <strong>mould</strong><br />

closes <strong>and</strong> the carpet is preformed by the<br />

three-dimensional contour of the <strong>mould</strong><br />

core side.<br />

To avoid wr<strong>in</strong>kles or cracks <strong>in</strong> the carpet,<br />

a tension<strong>in</strong>g frame is <strong>in</strong>stalled<br />

on the fixed side of the<br />

<strong>mould</strong> (Fig. 4). Before the<br />

core side penetrates <strong>in</strong>to the<br />

carpet, the decorative lam<strong>in</strong>ate<br />

is clamped between the<br />

movable <strong>mould</strong> side <strong>and</strong> the<br />

tension<strong>in</strong>g frame. The pressure<br />

forces exerted by the tension<strong>in</strong>g<br />

frame determ<strong>in</strong>e the<br />

slip of the decorative lam<strong>in</strong>ate<br />

<strong>and</strong> must be matched to the<br />

particular decorative lam<strong>in</strong>ate<br />

used.<br />

After preform<strong>in</strong>g <strong>in</strong> the<br />

<strong>mould</strong>, the actual back <strong>in</strong>jection<br />

compression process<br />

takes place. <strong>In</strong> the Decoform<br />

process, with the melt <strong>in</strong>jection,<br />

the <strong>mould</strong> opens by the<br />

gap for the compression<br />

stroke. The width of this compression<br />

gap depends on the<br />

decorative lam<strong>in</strong>ate <strong>and</strong> on the part<br />

geometry. <strong>In</strong> this case it is between 5 <strong>and</strong><br />

50 mm. The gap is adjusted such that the<br />

melt flow<strong>in</strong>g <strong>in</strong> (polypropylene with<br />

20 % talc) adheres to the side with the<br />

decorative lam<strong>in</strong>ate. <strong>In</strong> addition, the material<br />

still flow<strong>in</strong>g <strong>in</strong> holds the melt cake<br />

<strong>in</strong> balance, <strong>and</strong> prevents it slipp<strong>in</strong>g between<br />

the <strong>mould</strong> halves. Then the <strong>mould</strong><br />

clos<strong>in</strong>g stroke compresses the melt <strong>in</strong> the<br />

cavity.<br />

The cavity pressure dur<strong>in</strong>g compression<br />

<strong>in</strong> the Decoform process is<br />

below 70 bar. The relatively low pressure<br />

can prevent damage to the decorative<br />

lam<strong>in</strong>ate surface, such as iron<strong>in</strong>g effects,<br />

melt impressions, or compression marks.<br />

Uniform Preheat<strong>in</strong>g with<br />

<strong>In</strong>frared Radiators<br />

For the three-dimensional form<strong>in</strong>g,<br />

it is particularly important to<br />

preheat the decorative lam<strong>in</strong>ate<br />

uniformly to the correct temperature<br />

over its entire surface. The<br />

heat is transmitted from unscreened<br />

<strong>in</strong>frared radiators. The<br />

<strong>in</strong>dividual radiators can be controlled<br />

so that – despite the high<br />

chimney effect <strong>in</strong> the upper region<br />

of the decorative lam<strong>in</strong>ate –<br />

the temperatures are not higher<br />

than <strong>in</strong> the lower region. The correct<br />

temperature is essential for the uniformly<br />

high quality of the part surface<br />

(Fig. 5).<br />

The radiator bank is mounted on the<br />

mach<strong>in</strong>e directly above the clamp<strong>in</strong>g unit.<br />

Because of its proximity, the h<strong>and</strong>l<strong>in</strong>g sys-<br />

<strong>In</strong>jection-compression <strong>mould</strong><br />

Fig. 4. Section through the <strong>mould</strong> with tension<strong>in</strong>g frame used <strong>in</strong> the Decoform<br />

process<br />

tem can <strong>in</strong>troduce the carpet <strong>in</strong>to the<br />

<strong>mould</strong> with<strong>in</strong> a few seconds after the heat<strong>in</strong>g<br />

phase. This rapid transfer avoids cool<strong>in</strong>g<br />

of the carpet or tear<strong>in</strong>g dur<strong>in</strong>g the<br />

compression stroke (Fig. 6). The preheat<strong>in</strong>g<br />

takes place with<strong>in</strong> the normal cycle<br />

time.<br />

Precise H<strong>and</strong>l<strong>in</strong>g<br />

At the end of the cycle, the f<strong>in</strong>ished part<br />

is removed at the mov<strong>in</strong>g half. At the<br />

same time, a new preheated decorative<br />

lam<strong>in</strong>ate is mounted on the tension<strong>in</strong>g<br />

frame <strong>and</strong> fixed there with hold<strong>in</strong>g clips<br />

(Fig. 7). The l<strong>in</strong>ear robots from Neureder<br />

AG, part of <strong>Krauss</strong> <strong>Maffei</strong> Kunst-<br />

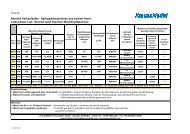

Decoform<br />

Melt str<strong>and</strong><br />

deposition<br />

Cycle time + –<br />

Protection of decorative lam<strong>in</strong>ate + +<br />

Decorative lam<strong>in</strong>ates<br />

<strong>and</strong> part h<strong>and</strong>l<strong>in</strong>g<br />

+ –<br />

Mach<strong>in</strong>e <strong>in</strong>vestment + –<br />

Mould <strong>in</strong>vestment – +<br />

Reproducibility + –<br />

Production flexibility + –<br />

Footpr<strong>in</strong>t + –<br />

Table 1. Comparison of the Decoform process with melt<br />

str<strong>and</strong> deposition<br />

stofftechnik GmbH, that are used h<strong>and</strong>le<br />

the complete <strong>in</strong>sertion <strong>and</strong> removal <strong>in</strong><br />

less than 6 s. Thanks to the short removal<br />

time, the mach<strong>in</strong>e is optimally utilised.<br />

The robots <strong>and</strong> grippers are designed<br />

for the specific process requirements<br />

<strong>and</strong> were developed <strong>in</strong> close<br />

collaboration between the<br />

<strong>mould</strong> manufacturer <strong>and</strong> automation<br />

specialists.<br />

When feed<strong>in</strong>g from the<br />

magaz<strong>in</strong>e, the double gripper<br />

only picks up a s<strong>in</strong>gle piece of<br />

carpet from the stack. For this<br />

purpose, the carpet gripper<br />

side is equipped with special<br />

needle grippers. Pneumatically<br />

driven needles pierce the<br />

carpet <strong>and</strong> anchor like barbs<br />

because of their angled position.<br />

This prevents the carpet<br />

detach<strong>in</strong>g from the gripper<br />

before it is preheated <strong>and</strong> <strong>in</strong>serted<br />

<strong>in</strong> the <strong>mould</strong>. The part<br />

pick-up side of the gripper is<br />

equipped with vacuum suck-<br />

ers, which grip the part from<br />

the plastic side. Deposition on<br />

a conveyor belt is implement-<br />

2 © Carl Hanser Verlag, München Kunststoffe plast europe 3/2004

Fig. 5. <strong>In</strong>frared micrograph of the preheated carpet (photo: GTT Willi Ste<strong>in</strong>ko)<br />

ed by means of the C-axis on the l<strong>in</strong>ear<br />

robot.<br />

Summary<br />

The most important benefits of the Decoform<br />

variant described here is that it<br />

completely dispenses with separate preform<strong>in</strong>g.<br />

<strong>In</strong>stead, the carpets are heated<br />

with <strong>in</strong>frared radiators <strong>and</strong> transformed<br />

<strong>in</strong>to a three-dimensional shape directly<br />

<strong>in</strong> the <strong>mould</strong>. The <strong>in</strong>vestment costs for<br />

the entire process are therefore lower than<br />

for preform<strong>in</strong>g with a thermoform<strong>in</strong>g<br />

Temperature profile<br />

Fig. 6. Heat<strong>in</strong>g <strong>and</strong> cool<strong>in</strong>g behaviour of the carpets<br />

l<strong>in</strong>e. <strong>In</strong> addition, the Decoform mach<strong>in</strong>e<br />

requires a much smaller footpr<strong>in</strong>t compared<br />

with similar decoration processes.<br />

With the Decoform process, the logistics<br />

overheads are reduced to a m<strong>in</strong>imum.<br />

There is no need to magaz<strong>in</strong>e <strong>and</strong> convey<br />

preformed carpets.Provision of the carpets<br />

at the mach<strong>in</strong>e is also greatly simplified.<br />

Compared with <strong>in</strong>-<strong>mould</strong> lam<strong>in</strong>ation<br />

by back compression <strong>mould</strong><strong>in</strong>g (meltstr<strong>and</strong><br />

deposition), the process is<br />

characterised by greater reproducibility.<br />

With the hot runner <strong>and</strong> the cascade nozzles,<br />

the shot weight <strong>and</strong> weight distri-<br />

AUTOMOTIVE • INJECTION MOULDING ■<br />

bution are always constant. <strong>In</strong> the Decoform<br />

process, the decorative lam<strong>in</strong>ate is<br />

only mechanically stressed to a small<br />

amount, s<strong>in</strong>ce the melt pressures are relatively<br />

low. The reduced logistics overheads<br />

<strong>and</strong> improved process reliability<br />

for the compression step result <strong>in</strong> greatly<br />

reduced reject quotas compared with<br />

melt-str<strong>and</strong> deposition. Another advantage<br />

lies <strong>in</strong> the flexibility of the <strong>in</strong>jection<br />

<strong>mould</strong><strong>in</strong>g mach<strong>in</strong>e. By simple selection<br />

of the <strong>in</strong>jection compression side, the<br />

mach<strong>in</strong>e can just as easily be used for<br />

low-pressure technology as for st<strong>and</strong>ard<br />

<strong>in</strong>jection <strong>mould</strong><strong>in</strong>g.<br />

Outlook<br />

With this jo<strong>in</strong>t development, the project<br />

partners have shown that a <strong>Krauss</strong>-<strong>Maffei</strong><br />

<strong>in</strong>jection <strong>mould</strong><strong>in</strong>g mach<strong>in</strong>e with the<br />

Decoform module can be used for the<br />

reproducible <strong>and</strong> cost-effective production<br />

of large-area three-dimensional<br />

parts by <strong>in</strong>-<strong>mould</strong> lam<strong>in</strong>ation. This<br />

technology will be used to an <strong>in</strong>creas<strong>in</strong>g<br />

extent at Coll<strong>in</strong>s & Aikman <strong>in</strong> future.<br />

Further parts with even more highly dem<strong>and</strong><strong>in</strong>g<br />

three-dimensional geometries,<br />

such as door <strong>and</strong> boot side l<strong>in</strong><strong>in</strong>gs are already<br />

at the prototype stage. <strong>In</strong> addition<br />

to carpets, the Decoform process is also<br />

suitable for TPO <strong>and</strong> PVC PP foam<br />

Fig. 7. The double gripper almost simultaneously lays the preheated carpet <strong>in</strong> the<br />

<strong>mould</strong> <strong>and</strong> removes the f<strong>in</strong>ished part<br />

Kunststoffe plast europe 3/2004 3

■<br />

4<br />

AUTOMOTIVE • INJECTION MOULDING<br />

Project Partners<br />

We are grateful to all project partners for<br />

implement<strong>in</strong>g the project:<br />

■ Coll<strong>in</strong>s & Aikman, Skara/Sweden<br />

■ Georg Kaufmann AG, Bussl<strong>in</strong>gen/<br />

Switzerl<strong>and</strong><br />

■ <strong>Krauss</strong>-<strong>Maffei</strong> Kunststofftechnik GmbH,<br />

Munich/Germany<br />

■ IWT <strong>In</strong>frarot Wärmetechnik GmbH,<br />

Altenstadt/Hessen, Germany<br />

■ Neureder AG, Schwaig near Munich/<br />

Germany<br />

■ Dow Benelux B.V., Terneuzen/<br />

Netherl<strong>and</strong>s<br />

■ GTT Willi Ste<strong>in</strong>ko GmbH, Nassau/<br />

Germany<br />

sheet, PVC leathercloth <strong>and</strong> textiles. The<br />

process of gra<strong>in</strong><strong>in</strong>g <strong>in</strong> the <strong>mould</strong> developed<br />

by Kaufmann <strong>and</strong> <strong>Krauss</strong>-<strong>Maffei</strong> –<br />

reported on <strong>in</strong> Kunststoffe plast europe –<br />

also offers new possibilities for surface<br />

design. ■<br />

THE AUTHORS<br />

DIPL.-ING. (FH) JOCHEN MITZLER, born <strong>in</strong> 1973,<br />

product manager at <strong>Krauss</strong>-<strong>Maffei</strong> Kunststofftechnik<br />

GmbH, Munich/Germany, for new processes <strong>and</strong><br />

automation for <strong>in</strong>jection <strong>mould</strong><strong>in</strong>g mach<strong>in</strong>es.<br />

Contact: <strong>in</strong>fo@krauss-maffei.de<br />

ING. HENRY JANSSON, born <strong>in</strong> 1957, is Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>and</strong> Development Manager at Coll<strong>in</strong>s & Aikman<br />

Automotive <strong>In</strong>terior Systems, Skara/Sweden.<br />

GEORG KAUFMANN, born <strong>in</strong> 1944, is owner <strong>and</strong><br />

manag<strong>in</strong>g director of Georg Kaufmann Formenbau<br />

und Tech-Center AG, Bussl<strong>in</strong>gen/Switzerl<strong>and</strong>.<br />

© Carl Hanser Verlag, München Kunststoffe plast europe 3/2004