Senior Design Expo 2019

The Senior Design Expo, held annually in May at Columbia University, is an opportunity for Columbia Engineering students to showcase what they have learned in their foundational math and science courses together with their engineering courses in innovative, creative, and purposeful designs and prototypes. Each year the Expo showcases more than 60 projects across all nine departments. Projects have included cutting-edge robotics, the New York City subway system, language technology, proposals for bridges to span the Hudson river, and much more.

The Senior Design Expo, held annually in May at Columbia University, is an opportunity for Columbia Engineering students to showcase what they have learned in their foundational math and science courses together with their engineering courses in innovative, creative, and purposeful designs and prototypes. Each year the Expo showcases more than 60 projects across all nine departments. Projects have included cutting-edge robotics, the New York City subway system, language technology, proposals for bridges to span the Hudson river, and much more.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Shoe Tying Robot<br />

Arturo Mori, Cesar Trujillo, Eric Li, Rafael<br />

Corrales Fatou<br />

Robotic dexterity is a complex skill to<br />

achieve. Today, researchers are pushing the<br />

limits with the goal of increasing dexterity. In<br />

the shoe industry, increasing dexterity would<br />

mean an increase in supply chain. According<br />

to the CEO of Adidas “The biggest challenge<br />

the shoe industry has is how do you create a<br />

robot that puts the lace into the shoe” [1].<br />

A study published by AVG technologies<br />

which surveyed families across the USA,<br />

Canada, and the EU5, showed that toddlers<br />

(2-5years old) are more likely to know how<br />

to play a basic computer game than be able to<br />

tie their shoes [2]. Today, there are industry<br />

leading companies such as Nike and Puma<br />

conducting R&D into self-tying shoes with<br />

the applications varying from an everyday<br />

shoe to professional sports.<br />

Our project takes a different approach to this<br />

rising problem. The goal of this project is to<br />

create the first robot that will be able to<br />

different types of shoes instead of one single<br />

shoe. With the incorporation of different<br />

sensors, the possibility of a closed loop<br />

system is no longer unattainable. What sets<br />

this apart from the previous shoe tying robots<br />

is that this has the goal of incorporating<br />

practical usability compared to previous<br />

attempts which did not allow a user to have<br />

the shoe on.<br />

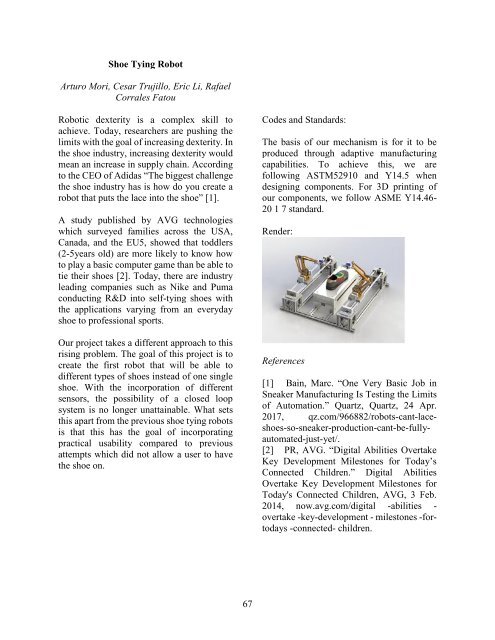

Codes and Standards:<br />

The basis of our mechanism is for it to be<br />

produced through adaptive manufacturing<br />

capabilities. To achieve this, we are<br />

following ASTM52910 and Y14.5 when<br />

designing components. For 3D printing of<br />

our components, we follow ASME Y14.46-<br />

20 1 7 standard.<br />

Render:<br />

References<br />

[1] Bain, Marc. “One Very Basic Job in<br />

Sneaker Manufacturing Is Testing the Limits<br />

of Automation.” Quartz, Quartz, 24 Apr.<br />

2017, qz.com/966882/robots-cant-laceshoes-so-sneaker-production-cant-be-fullyautomated-just-yet/.<br />

[2] PR, AVG. “Digital Abilities Overtake<br />

Key Development Milestones for Today’s<br />

Connected Children.” Digital Abilities<br />

Overtake Key Development Milestones for<br />

Today's Connected Children, AVG, 3 Feb.<br />

2014, now.avg.com/digital -abilities -<br />

overtake -key-development - milestones -fortodays<br />

-connected- children.<br />

67