Loup Generator - Summer2019

This issue of the Loup Power District Generator includes updates on repairs at the the Genoa Headworks, a story about the Telechron Master Clock, employee anniversaries, and more.

This issue of the Loup Power District Generator includes updates on repairs at the the Genoa Headworks, a story about the Telechron Master Clock, employee anniversaries, and more.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

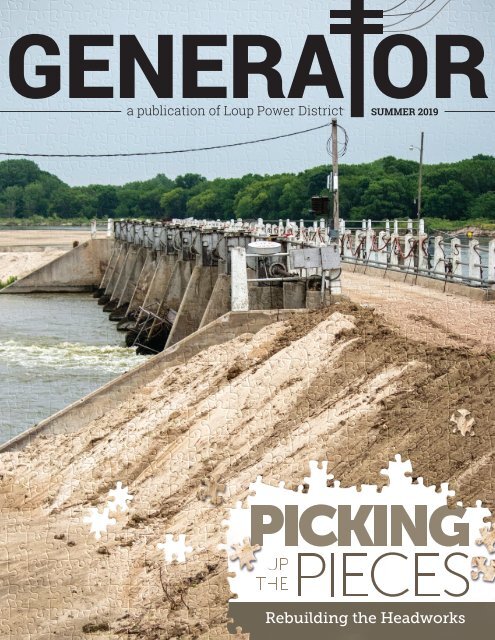

GENERA OR<br />

a publication of <strong>Loup</strong> Power District SUMMER 2019<br />

PICKING<br />

THEPIECES<br />

UP<br />

Rebuilding the Headworks

BOARD<br />

OF DIRECTORS<br />

Larry Zach<br />

Chairman<br />

Chris Langemeier<br />

First Vice Chairman<br />

Ross Knott<br />

Second Vice Chairman<br />

Alan Drozd<br />

Secretary<br />

Dick Tooley<br />

Treasurer<br />

Rich Aerni<br />

Robert Cerv<br />

Jim Donoghue<br />

Mike Fleming<br />

Steve Heesacker<br />

EXECUTIVE STAFF<br />

Neal Suess<br />

President/ CEO<br />

Walt Williams<br />

Vice President,<br />

Administrative Services/CFO<br />

David Bell<br />

Vice President,<br />

Development/Marketing<br />

Ron Ziola<br />

Vice President, Engineering<br />

Dan Hellbusch<br />

Vice President, Operations<br />

The <strong>Loup</strong> <strong>Generator</strong> is<br />

published quarterly as a<br />

service for <strong>Loup</strong> employees,<br />

families, friends and<br />

associates.<br />

For feedback, story ideas<br />

and submissions, contact:<br />

Stacy Wemhoff<br />

Communications Coordinator<br />

402-562-5711<br />

swemhoff@loup.com<br />

2,011 public power utilities<br />

provide electricity to 49 million people in 49 states<br />

and five U.S. territories. While each utility is unique,<br />

public power is characterized by some key values.<br />

COMMUNITY OWNED<br />

Public power utilities are owned by the communities<br />

they serve. They provide local jobs and support the<br />

local economy. You’ll see your friendly utility staff at the<br />

ball games and the grocery store.<br />

LOCALLY OPERATED<br />

Public power utilities are run by the city. They are<br />

regulated and governed by the city council or a board<br />

with local representatives. If you live in a public power<br />

community, you have a voice in decision-making for<br />

your utility.<br />

RESPONSIVE<br />

Public power utilities focus on delivering the highest<br />

level of service and value to customers. They are<br />

committed to meeting the needs of the community<br />

through environmental stewardship, high reliability<br />

and economic development.<br />

NONPROFIT<br />

Surplus revenues stay in the community and are<br />

invested in system improvements, shared with the local<br />

government, or used to lower your electric bills.<br />

Revenues are not distributed among outside<br />

shareholders.<br />

LOW-COST<br />

Public power utilities have access to tax-exempt<br />

financing and generally have stronger credit ratings<br />

than privately owned utilities. Community-owned<br />

utilities operate efficiently, and many have access to<br />

less expensive federal hydropower.<br />

2 GENERATOR

PRESIDENT'S MESSAGE<br />

‘It won’t happen overnight’<br />

Rebuilding Headworks will take several years<br />

Many people around Nebraska continue<br />

to be in awe at the destruction caused by the<br />

mid-March storm event (or bomb cyclone).<br />

From the damage at Nebraska Public Power<br />

District’s Spencer Dam, to road damage on<br />

Dodge Street in Omaha, to the bridges that<br />

were damaged near Schuyler, Monroe and<br />

Genoa, to the levees that were breached<br />

along the Missouri River, to all the sand that<br />

has been deposited outside of the river beds<br />

throughout Nebraska — the damage caused<br />

by this one event will be felt for many years<br />

by the people throughout Nebraska.<br />

Obviously the <strong>Loup</strong> Power District was<br />

affected by this storm. The District saw<br />

damages to (1) the substations in St. Edward,<br />

Cedar Rapids and the sand plant south and<br />

by NEAL SUESS<br />

President/CEO<br />

The District is in the process of finalizing<br />

the temporary design repair drawings and<br />

submitting them to the Federal Energy<br />

Regulatory Commission (FERC) which has<br />

oversight of this project.<br />

The District will be designing permanent<br />

canal repairs to assist with future storm<br />

events. The District is also in the process<br />

of finalizing the root cause analysis for the<br />

damages. This report indicates the level<br />

of water and debris that was contained<br />

in the <strong>Loup</strong> River during the storm event<br />

was beyond any design capabilities of the<br />

Headworks and Canal system.<br />

For the near future, especially through the<br />

summer, fall and winter months, the entirety<br />

of the Headworks will be closed off to the<br />

west of Genoa, (2) subtransmission and distribution<br />

lines near the Headworks and south and west of<br />

Columbus, and (3) the obvious breaches and damage to<br />

the Canal system near the Headworks, as well as damage<br />

in the Tailrace section of the Canal, south and east of<br />

Columbus.<br />

District employees and contractors continue to<br />

work on all of these, but I want to focus mostly on the<br />

Headworks and Canal repairs for this article.<br />

The District continues to work to seal up the breaches<br />

that occurred along the Canal, south and west of Genoa.<br />

The breaches have been sealed up enough to allow the<br />

District to bring a certain amount of water into the<br />

Canal; however, this amount is far below that for normal<br />

operation and will continue in this manner for some<br />

time, probably through the end of 2020.<br />

As the District starts to get into more temporary<br />

and permanent repairs, we expect water levels in the<br />

Canal to fluctuate, in order to manage and complete the<br />

repairs.<br />

public for recreation purposes.<br />

With the construction activity ongoing and the heavy<br />

equipment being used to move sand, dirt and gravel<br />

from one area to another, it is too dangerous to open<br />

any of these areas to the public. We realize this creates<br />

some inconveniences. However, the public safety is too<br />

great of a concern to allow these areas to open. The<br />

District will let everyone know when it is safe to use<br />

these areas again.<br />

We want everyone to know we are working as quickly<br />

as possible to make the repairs to all of our systems and<br />

get back to normal operation. This will be a process that<br />

will last many months and take several years. It will not<br />

happen overnight.<br />

The District appreciates everyone’s patience, prayers,<br />

thoughts and ideas. We know that we are part of your<br />

communities and we plan to be in your communities for<br />

a very long time.<br />

Continue to look at the District’s website and social<br />

media outlets for updated information.<br />

SUMMER 2019 3

Henry Ellis Warren<br />

MASTER<br />

OF TIME<br />

A rare Telechron Type A Master Clock resides<br />

in a display case at the Columbus Powerhouse.<br />

It was invented by Henry Ellis Warren in 1916.<br />

The Master Clock was used to control the frequency<br />

of the alternating current to an even 60 cycles per<br />

minute. This regulation facilitated the rise of the<br />

electric clock in homes across the country.<br />

By 1941, the Warren Telechron Company<br />

produced about 3 million clocks annually.<br />

THE WARREN TELECHRON MASTER CLOCK TYPE A<br />

by Harry S. Holcomb, Ill (VA) and Robert Webb (IA)<br />

Henry Ellis Warren, a native of Boston, graduated from the<br />

Massachu setts Institute of Technology in 1894. He settled<br />

in Ashland, MA, in 1907, and set up a small workshop there<br />

where, as a hobby, he tinkered with electrically driven clocks.<br />

He developed a battery-driven clock and took out his first<br />

patent on this clock in July 1909.<br />

The Warren Clock Company was founded in 1912 and<br />

his commercial production of battery driven clocks began in<br />

1915. However, he considered these clocks inadequate and<br />

unreliable, and thus sought other methods of telling time<br />

accurately.<br />

Although the idea of driving electric clocks with alternating<br />

current was not new, Henry Warren was the first to develop,<br />

in early 1916, a simple self-starting alternating current motor<br />

which was truly “synchronous” with an alternating current and<br />

which could be produced inexpensively.<br />

However, he discovered that the synchronous motor clock,<br />

when driven by alternating electricity from the local power<br />

company, still did not keep perfect time, losing up to 15<br />

minutes per day. The reason for this was because the power<br />

companies had difficulty controlling precisely the alternations<br />

or frequency of their generators.<br />

Henry Warren realized that the next problem he faced was<br />

“to bring about in some manner the accurate regulation of<br />

the alternating current impulses which were being sent in all<br />

directions over the wires so that these impulses, in connection<br />

with the newly designed motor, might be used to supply<br />

power companies’ customers with a dependable time-telling<br />

device.”<br />

He went to work and “took only a few months to design and<br />

build a thoroughly satisfactory master clock which could be<br />

used at power stations so as to indicate errors in the average<br />

frequency, which were hundreds of times smaller than could<br />

be measured with instruments then in use.”<br />

His first clock was installed for demonstration purposes at<br />

the L Street Station of the Boston Edison Company on October<br />

23, 1916. The company was so impressed with the clock that<br />

they insisted on keeping it.<br />

The concept of the Telechron Master Clock is very simple.<br />

Its large five-minute dial carries two hands, both of which<br />

are center mounted. One hand is connected to an accurate<br />

pendulum clock and the other to a synchronous motor. The<br />

synchronous motor is so geared that when the frequency of<br />

4 GENERATOR

A page from the Master Clock instruction manual. Thanks to Cliff Wilson and the Ashland (Mass.) Historical Society.<br />

Columbus Powerhouse operators used this<br />

Telechron clock to keep the official time<br />

for the State of Nebraska until 1950.<br />

the generators is correct (exactly 60 cycles per second) the gold hand will<br />

rotate at exactly the same speed as the black pendulum-regulated hand.<br />

As described by J. E. Coletnan, “The generating station operator watches<br />

the clock and adjusts his turbine governors regulating the frequency so as to<br />

keep the black and gold hands in line.<br />

By doing this, the other synchronous clocks plugged into the system automatically<br />

keep correct time.”<br />

There was a second benefit for the power company from the use of the<br />

Master Clock. Since the current (cycles per second) could be regulated very<br />

precisely, it became possible for several generators of generating plants to<br />

hook together efficiently in one large grid system.<br />

By 1921, the Master Clock Type A, or improved versions of it, and the<br />

synchronous motor-driven electric clock were in widespread use.<br />

In addition to the large 5-minute dial previously mentioned, there is a<br />

lower 12-hour dial with hour and minute hands. The upper five-minute dial<br />

has one hand driven by a synchronous motor. This is an auxiliary clock motor<br />

to be kept running at all times in case the primary motor should fail.<br />

The seconds beating clock, when properly regulated, is to run with an<br />

error of less than one second per day using the Graham “clead beat” type<br />

escapement.<br />

The pendulum movement, which drives the black hands on the center<br />

dial and the lower dial, is regulated by two methods. The first means of<br />

adjustment is by adding or subtract ing small weights.<br />

SUMMER 2019 5

The weights are applied to a pan<br />

fastened to the pendulum rod. They<br />

are marked with a numeral displaying<br />

the number of seconds per day which<br />

that particular weight would change the<br />

clock’s rate. Weights are added to the<br />

pan to increase the rate and removed<br />

from the pan to slow it.<br />

A second way of regulating the clock<br />

is with two small rheostats located in<br />

the top of the case. These control the<br />

intensity of a magnetic field set up by<br />

a battery coil in the bottom of the case<br />

and affect the pendulum swing. One<br />

rheostat will set the clock, correcting<br />

small errors of up to five seconds. The<br />

other rheostat will correct the rate of<br />

pendulum movement and acts in the<br />

same manner as the weights on the<br />

pendulum pan.<br />

The pendulum movement is powered<br />

by a spring which is kept wound by a<br />

connection with the synchronous motor.<br />

If the clock should stop, the synchronous<br />

motor must be turned off to prevent<br />

over-winding of the clock spring. The<br />

main and auxiliary synchronous motors<br />

are controlled by means of toggle<br />

switches in the top of the case.<br />

The instruction manual suggests<br />

that the movement be cleaned and<br />

overhauled and that new synchronous<br />

motors be installed every two years.<br />

These clocks were to receive very good<br />

maintenance to ensure reliable service<br />

for the power plants.<br />

Henry Warren’s Master Clock Type A<br />

and the synchronous clock motor, both<br />

relatively simple in concept and design,<br />

were ingenious products.<br />

Their development made possible, for<br />

the first time, the widespread use of the<br />

household electric clock that we know<br />

today.<br />

Article used with permission. This article was originally published in the February 1985 issue of the NAWCC Bulletin (pages 35–37), a journal of the National Association of<br />

Watch & Clock Collectors, Inc. For more information about the Association and its membership benefits, please visit nawcc.org.<br />

“<br />

In the modern electric clocks . . . the function of measuring time<br />

is separate from the function of telling time. Two devices are<br />

necessary, first a single very reliable and accurate master clock<br />

located at some central point on a power system, and second an unlimited<br />

number of synchronous motor clocks located wherever convenient on the<br />

distribution system of the power company. The same generators, wires, and<br />

transformers which carry light, heat and power to all the company’s customers<br />

also carry without any extra charge accurate time impulses to those modern<br />

electric clocks. The only thing that is necessary for the electric clock to do is<br />

to translate the alternating current impulses into time indications. Therefore,<br />

they serve to tell the time which is accurately measured by another device.<br />

TOP: The nameplate from <strong>Loup</strong> Power<br />

District’s Warren Telechron Master<br />

Clock.<br />

BOTTOM: Historical records show<br />

that <strong>Loup</strong>’s clock was initially used at<br />

Muscatine Electric Light Company in<br />

Muscatine, Iowa. <strong>Loup</strong> acquired the<br />

clock sometime in the late 1930s.<br />

Courtesy of Ashland (Mass.) Historical Society.<br />

6 GENERATOR<br />

As a result of this arrangement the mechanical construction of the electric<br />

clock is of a very different nature from that of the ordinary spring and weightdriven<br />

clock. In the latter conservation of power is of the utmost importance.<br />

Only a slight amount of energy is available in a tightly wound spring or a lifted<br />

weight and this naturally must be used in the most miserly way if the delicate<br />

time-measuring escapement device is to perform accurately . . . In the electric<br />

clock, however, it is not difficult to provide an abundance of power which can<br />

be used for the simple task of keeping the clock hands in motion . . .<br />

Synchronous motor clocks may be readily substituted for practically all forms<br />

of ordinary clocks and their field of usefulness may be extended far beyond<br />

that of spring and weight-driven clocks.<br />

The electric movements are small and compact so that they may be mounted<br />

in any ordinary form of case. The dial may be readily illuminated by using<br />

a trifling amount of the energy which is available inside the case itself.<br />

They have already become the most popular form of alarm clock. They<br />

may be arranged to show the time of day by moving numerals in place of<br />

moving hands. They may be arranged to switch electric current on and off<br />

at predetermined times or to give signals according to a regular program. In<br />

fact there seems to be no limit to the field of usefulness of these new timekeepers.<br />

— HENRY ELLIS WARREN, February 6, 1937<br />

Meeting of the Clock Club in Boston

May 1930 Ladies’ Home Journal ad courtesy of clockhistory.com 7

Top: A view of the two major canal breaches on the north<br />

and south sides of the intake structure at the Genoa<br />

Headworks a few days after the March storm.<br />

Top left: The Nebraska National Guard helped drop<br />

sandbags in the south side breach. Employees added<br />

sand and rock to completely fill the breach.<br />

Bottom left: The storm’s flooding ripped off an addition to<br />

the Headworks building, damaging the break room and<br />

an office. Employees are still using the shop area.<br />

Right: Employees from the neighboring Preferred Sands<br />

of Genoa helped fill the north breach in the days following<br />

the storm.<br />

8 GENERATOR

The storm destroyed the caretaker’s house<br />

at the Genoa Headworks (below). Most of<br />

the house has been removed from the canal.<br />

PICKING<br />

THEPIECES<br />

UP<br />

The March<br />

storm caused<br />

a large canal<br />

breach near<br />

the Highway 22<br />

bridge southwest<br />

of Genoa. Preferrred<br />

Sands employees<br />

helped fill the gap, but<br />

<strong>Loup</strong> employees need to<br />

widen the dike an additional<br />

10 to 20 feet in places.<br />

Ice jams. Rain. Snow melt. Fluctuating temperatures.<br />

They collided violently in mid-March, leaving<br />

behind disaster and destruction throughout much of<br />

Nebraska.<br />

<strong>Loup</strong> Power District’s Genoa Headworks was not<br />

spared. The water breached the canal walls in several<br />

places between the intake structure and the Highway<br />

22 bridge southwest of Genoa. The two largest<br />

breaches flanked the intake structure.<br />

Over the next week, <strong>Loup</strong> employees worked to fill<br />

the breaches and stop the uncontrolled flow of water<br />

from the <strong>Loup</strong> River in to the canal.<br />

They had help from neighboring Preferred Sands of<br />

Genoa. Preferred employees used the business’ large<br />

machinery to haul loads of sand to help fill the gaps<br />

and rebuild roads.<br />

The Nebraska National Guard assisted as well,<br />

dropping 280 massive sandbags in the south breach.<br />

Now, four months later, employees are working<br />

to pick of the pieces and rebuild the area. It is<br />

a frustratingly slow process — made so by a<br />

combination of the extent of damage, the weather,<br />

and the regulatory procedures mandated by the<br />

Federal Energy Regulatory Commission (FERC).<br />

Although some of the pieces are falling into place,<br />

it will take several years to finish the puzzle.<br />

SUMMER 2019 9

Top: The March storm washed away<br />

the decking on the weir bridge at the<br />

Genoa Headworks. This left employees<br />

unable to access the south side of<br />

the canal. New decking was installed<br />

in April.<br />

In this photo, Heavy Equipment Operator<br />

Kurt Mohr (crane operator),<br />

Drege Foreman James Reeg (left)<br />

and Headgates Operator Andy Zarek<br />

(right) install stop logs on April 18.<br />

Right: The weir bridge after the storm.<br />

Bottom: The intake structure received<br />

some damage but remained operational.<br />

10 GENERATOR

Left: The Pawnee II, a dredge used to<br />

remove sand from the canal’s settling<br />

basin, took on about four feet of water<br />

during the flood, damaging the dredge<br />

pump motor.<br />

A portion of the dredge roof was<br />

removed with the help of a crane, which<br />

then lifted out the 11-ton, 3,000hp motor<br />

so it can be refurbished.<br />

The Pawnee II’s predecessor — the<br />

Pawnee — also survived a flood in 1966.<br />

Bottom left: Dredge Operator Joe<br />

Kleckner works to separate the motor<br />

coupling prior to the motor’s removal.<br />

Bottom right: Hydro Superintendent<br />

Brad Morton, Monroe Chief Operator<br />

Jamie Held, and Hydro Electrical/<br />

Mechanical Technician Matt Kathol<br />

discuss dredge repairs.<br />

SUMMER 2019 11

employee notes<br />

RICK SCHAECHER<br />

Meter/Maintenance Superintendent<br />

Retired<br />

Rick Schaecher of Columbus retired from <strong>Loup</strong> Power District after more than 27 years<br />

of service.<br />

He joined <strong>Loup</strong> in 1992 as the District Substation Meter/Maintenance Superintendent at<br />

the Columbus Service Center and continued in that position until his retirement.<br />

Schaecher was in charge of the Meter and Maintenance Department at <strong>Loup</strong> Power<br />

District. The Meter and Maintenance crew performs high voltage switching, maintenance<br />

and inspections of distribution and transmission substations throughout the district,<br />

as well as metering and relaying. The crew also operates and maintains <strong>Loup</strong>’s SCADA<br />

(Supervisory Control and Data Acquisition) system and irrigation Load Control.<br />

A graduate of Lindsay Holy Family High School, Schaecher has an Associate of Applied<br />

Science degree in Electrical Technology from Southeast Community College in Milford.<br />

He and his wife, Karla, are the parents of two children: Jared and Ryan.<br />

1 year+Promotion<br />

JOHN FRITZGES<br />

Equipment Operator<br />

John Fritzges of St. Edward<br />

joined <strong>Loup</strong> Power District as a<br />

Maintenance Man at the Genoa<br />

Headworks in 2018.<br />

He was promoted to Equipment<br />

Operator in May.<br />

Fritzges is responsible for<br />

maintaining the District’s parks,<br />

facilities and equipment. He also<br />

assists equipment operators and<br />

serves as a dredge deck hand<br />

during the dredging season at the<br />

Genoa Headworks.<br />

He and his wife, Kaitlin, have<br />

three children: Kohen, Reese, and<br />

Rhett, are expecting another in<br />

September.<br />

Transfer<br />

TIM RECEK<br />

Maintenance Man<br />

Tim Recek of Columbus<br />

transferred to the Hydro<br />

Department where he is now<br />

working as a Maintenance Man.<br />

He joined <strong>Loup</strong> Power District<br />

in 2017 as a Utilityman.<br />

In his new role as<br />

Maintenance Man, Recek is<br />

responsible for maintaining<br />

District parks, facilities, and<br />

equipment.<br />

He and his wife, Brenda, have<br />

two children: son, Dylan, and<br />

daughter, Sydney.<br />

Welcome<br />

NANCY NELSEN<br />

Customer Service Rep<br />

Nancy Nelsen of Newman<br />

Grove joined <strong>Loup</strong> Power District<br />

as a part-time Customer Service<br />

Representative in the Newman<br />

Grove office.<br />

In her new position, Nelsen’s<br />

responsibilities include greeting<br />

customers; processing payments;<br />

setting up, transferring, or closing<br />

service; taking service calls; and<br />

preparing reports.<br />

Nelsen graduated from<br />

Lincoln High School and earned<br />

an Associate of Applied Science<br />

degree from Southeast Community<br />

College.<br />

She and her husband, Chris,<br />

have a daughter, Halie.<br />

12 GENERATOR

SHARON TROFHOLZ<br />

Columbus Service Center Coordinator<br />

Sharon Trofholz of Columbus retired after more than 37 years of service.<br />

Trofholz joined <strong>Loup</strong> in 1982 as the Steno-Clerk at the Columbus Service Center. Her<br />

position title was changed to Service Center Coordinator in 1999 and she continued in that<br />

position until her retirement<br />

As the Service Center Coordinator, Trofholz handled communication among the<br />

personnel at the Service Center including linemen, meter and maintenance, shop, and<br />

canal crews. Her duties also included taking service calls including outages, receiving<br />

locate requests, sending irrigation load control messages and handling dispatches. She also<br />

prepared work tickets, service orders, and reports.<br />

Trofholz and her husband, Gary, are the parents of three adult children: Greg, Kelly, and<br />

Kari. They have seven grandchildren and two great-grandsons.<br />

Retired<br />

1 Year<br />

ANDY YRKOSKI<br />

Lineman<br />

Andy Yrkoski joined <strong>Loup</strong><br />

Power District as a Lineman on<br />

the Columbus Line Crew at the<br />

Columbus Service Center in 2018.<br />

As a Lineman, Yrkoski is<br />

a member of the crew that is<br />

responsible for the construction,<br />

tree trimming, operation,<br />

and maintenance of electric<br />

transmission and distribution<br />

systems and substations in the<br />

Columbus Division.<br />

Yrkoski is a graduate of<br />

Columbus High school. He earned<br />

an Associate of Applied Science<br />

Degree in Utility Line from<br />

Northeast Community College in<br />

Norfolk.<br />

1 Year<br />

AARON SUNDBERG<br />

Lineman<br />

Aaron Sundberg of Fullerton<br />

joined <strong>Loup</strong> Power District as a<br />

Lineman in the Fullerton Division<br />

in 2018.<br />

He is a member of the<br />

crew that is responsible for<br />

the construction, operation,<br />

and maintenance of electric<br />

transmission and distribution<br />

systems and substations in the<br />

Fullerton Division.<br />

Sundberg is a native of<br />

Clarks and a graduate of High<br />

Plains Community Schools. He<br />

graduated from the Utility Line<br />

program from Metropolitan<br />

Community College.<br />

10 Years<br />

MATT KATHOL<br />

Hydro Electrical/<br />

Mechanical Technician<br />

Matt Kathol joined <strong>Loup</strong> as<br />

Meter, Relay, and Equipment<br />

Technician II in 2009. In 2018,<br />

he transferred to the Hydro<br />

department and began working<br />

as a Hydro Electrical/Mechanical<br />

Technician.<br />

In that role, Kathol maintains<br />

and repairs equipment at<br />

the Columbus and Monroe<br />

Powerhouses.<br />

A graduate of Norfolk High<br />

School, Kathol earned an Associate<br />

of Applied Science Degree in<br />

Electromechanical Technology<br />

from Northeast Community<br />

College in Norfolk.<br />

He and his wife, Ashley, are the<br />

parents of a son, Eli.<br />

SUMMER 2019 13

employee notes<br />

GINNY JOHNSON<br />

Customer Service Representative<br />

25 years<br />

Ginny Johnson of Genoa joined <strong>Loup</strong> in 1994 as a regular part-time Cashier at the<br />

Genoa Office.<br />

In 2009, the position title was changed to Customer Service Representative. Johnson<br />

was promoted to a full-time Customer Service Representative in 2018.<br />

Her responsibilities include greeting customers; processing payments; setting up,<br />

transferring, or closing service; taking service calls; and preparing reports.<br />

Johnson is a graduate of Genoa High School. She also took accounting and computer<br />

courses at Central Community College-Columbus.<br />

Johnson and her husband, Don, are the parents of four sons: J.J., Andy, Craig, and Scott.<br />

They have six grandchildren.<br />

5 Years<br />

CAMERON KNOPIK<br />

Journeyman Lineman<br />

Cameron Knopik joined <strong>Loup</strong> Power District in<br />

2014 as a Lineman in Albion and was promoted to<br />

Journeyman Lineman in 2017.<br />

Knopik is a member of the line crew that is in<br />

responsible for the construction, operation, and<br />

maintenance of <strong>Loup</strong>’s electrical transmission and<br />

distribution system in the Albion Division.<br />

He is a native of Fullerton and a graduate of<br />

Fullerton High School. He earned an Associate of<br />

Applied Science Degree in Utility Line from Northeast<br />

Community College in Norfolk.<br />

Knopik and his wife, Connie, live in Albion.<br />

Transfer<br />

ZACH REICKS<br />

Meter, Relay & Equipment<br />

Technician<br />

Zach Reicks of Columbus recently transferred to<br />

Meter, Relay and Equipment Technician.<br />

He joined <strong>Loup</strong> in 2007 as an Apprentice Lineman<br />

at the Columbus Retail Division based out of the<br />

Columbus Service Center. Later that year he was<br />

promoted to Lineman. In 2011, he was promoted to<br />

Journeyman Lineman.<br />

In his new role, Reicks is part of the team that<br />

is responsible for installation and maintenance of<br />

substation power equipment for the District.<br />

A graduate of Columbus Lakeview High School,<br />

Reicks has an Associate of Applied Science Degree in<br />

Utility Line from Northeast Community College in<br />

Norfolk.<br />

He and his wife, Ashley, are the parents of three<br />

children: Leyton Michael, Camden Lee, and Lily Jean.<br />

14 GENERATOR

MARIE ZACH<br />

Administrative Assistant — Engineering<br />

Marie Zach of Columbus joined <strong>Loup</strong> in 1999 as a Cashier at the District’s Columbus<br />

General Office. She was promoted to Computer Operator in 2001 and to Lead Customer<br />

Service Representative in 2011. She was promoted to Administrative Assistant for the<br />

Engineering Department in 2014.<br />

Zach provides support to the Vice President of Engineering and other department<br />

personnel. She maintains work order files, state and federal forms, consultant materials,<br />

internal reports, and more.<br />

A native of Humphrey, Nebraska, Zach is a graduate of Humphrey St. Francis High<br />

School. She earned an Associate of Applied Science Degree in Business Administration<br />

and a Management Diploma from Central Community College -- Columbus.<br />

Zach and her husband, Steve, are the parents of four children: Wes, Austin, Danny,<br />

and Laura. They have 11 grandchildren.<br />

20 Years<br />

Welcome<br />

DREW GRAHAM<br />

Utilityman<br />

Drew Graham is a Utilityman<br />

based out of the Columbus Service<br />

Center in June.<br />

In his role as Utilityman,<br />

Graham’s duties include servicing<br />

the District’s rental water heaters,<br />

delivering interoffice mail, and<br />

assisting on other projects as<br />

needed.<br />

Graham is a native of Silver<br />

Creek and graduated from Twin<br />

River High School. He earned a<br />

degree in Heating Ventilation and<br />

Air Conditioning/Refrigeration<br />

from Northeast Community<br />

College.<br />

He and his wife, Jordan, live in<br />

Columbus.<br />

Welcome<br />

JACOB CZARNICK<br />

Lineman<br />

Jacob Czarnick is a Lineman<br />

based out of the Columbus Service<br />

Center.<br />

Czarnick is a member of the<br />

crew that is responsible for<br />

the construction, operation<br />

and maintenance of electric<br />

transmission and distribution<br />

systems in the Columbus area.<br />

He graduated from Columbus<br />

High School and earned his Utility<br />

Line degree from Northeast<br />

Community College last month.<br />

Czarnick interned at <strong>Loup</strong><br />

during the summers of 2017 and<br />

2018.<br />

Welcome<br />

BEAU SCHOMMER<br />

Lineman<br />

Beau Schommer is a Lineman<br />

based out of the Columbus Service<br />

Center.<br />

In his new role, Schommer<br />

is a member of the crew that is<br />

responsible for the construction,<br />

operation and maintenance<br />

of electric transmission and<br />

distribution systems in the<br />

Columbus area.<br />

Schommer graduated from<br />

Norfolk Catholic High School and<br />

earned his Utility Line degree from<br />

Northeast Community College. He<br />

interned with <strong>Loup</strong> Power District<br />

in Humphrey last summer.<br />

SUMMER 2019 15

employee notes<br />

TIM RAMAEKERS<br />

Meter/Maintenance Superintendent<br />

Promotion<br />

Tim Ramaekers was promoted to Meter/Maintenance Superintendent at <strong>Loup</strong> Power<br />

District.<br />

In his new position, Ramaekers oversees the Meter and Maintenance Department.<br />

The Meter and Maintenance crew performs high voltage switching, maintenance and<br />

inspections of distribution and transmission substations throughout the district, as<br />

well as metering and relaying. The crew also operates and maintains <strong>Loup</strong>’s SCADA<br />

(Supervisory Control and Data Acquisition) system and irrigation Load Control.<br />

Ramaekers joined <strong>Loup</strong> in 2001 as a Lineman. He was promoted to Journeyman<br />

Lineman in 2006 and was promoted to Meter Relay & Equipment Technician in 2008.<br />

Ramaekers is a graduate of Norfolk Catholic High School and earned an Associate of<br />

Applied Science Degree in Utility Line from Northeast Community College.<br />

He and his wife, Michelle, are the parents of a daughter, Garyn, and a son, Kai.<br />

Employees help raise funds for flood relief<br />

Nikki Brunken saw photo after<br />

photo of the devastation caused by<br />

flooding in mid-March.<br />

She wanted to do something for<br />

the victims, but wasn’t sure exactly<br />

how to help.<br />

The answer ended up coming to<br />

her when she was asked to volunteer<br />

for a flood relief event in Columbus.<br />

“I decided it was something I<br />

was interested in,” Brunken said. “I<br />

couldn’t just sit at home and see my<br />

house that was perfectly fine and not<br />

do something.”<br />

Brunken was tasked with<br />

organizing a silent auction just three<br />

weeks before the event.<br />

“I knew there was absolutely<br />

no way that I could go around and<br />

solicit enough on my own,” she said.<br />

“I knew I was going to need a team<br />

to help me out.”<br />

She asked three fellow coworkers<br />

for help along with some other<br />

friends. They agreed to help for the<br />

same reason she did.<br />

“We all felt we wanted to do<br />

something but didn’t know what we<br />

could do,” said Shari Cromwell.<br />

The team reached out to local<br />

businesses and asked if they would<br />

consider donating to the event. The<br />

response was amazing — especially<br />

since there were several recent<br />

fundraisers for other causes.<br />

<strong>Loup</strong> Power District employees (left to right) Lynette June, Nikki Brunken, Shari<br />

Cromwell and Rhonda Rogers volunteered with a flood relief event in April. They are<br />

pictured with Julie Oppliger, who also volunteered time for the event along with Sue<br />

Hoge, wife of <strong>Loup</strong> employee Jim Hoge, and many others.<br />

“The community was quite<br />

generous,” Brunken said. “A lot of<br />

people donated on their own for the<br />

flood and yet they were still willing to<br />

donate to the silent auction.”<br />

In the end, the event, held on April<br />

27, raised $86,374.77. The total does<br />

not count businesses or individuals<br />

who donated directly to the fund.<br />

Donations are still being<br />

accepted. To learn more,<br />

visit floodreliefne.org.<br />

16 GENERATOR

AC tune up water heater heat pump<br />

$<br />

40<br />

Tune-ups on cooling<br />

systems that have been<br />

neglected for a few years<br />

will improve efficiency<br />

and provide energy<br />

savings of 15% or more.<br />

QUALIFYING SYSTEMS:<br />

Residential central air<br />

conditioners, air-source and<br />

water-source heat pumps.<br />

$<br />

400–600<br />

A heat pump water heater<br />

is more efficient than a<br />

standard unit. While it<br />

costs more upfront, the<br />

savings will pay back the<br />

difference in two years.<br />

QUALIFYING SYSTEMS:<br />

Air source HP water<br />

heaters ($400), and wateror<br />

ground-source heat pump<br />

water heaters ($600).<br />

$<br />

400–3,300<br />

Heating and cooling your<br />

home is probably one of<br />

your largest energy<br />

expenses. High-efficiency<br />

heat pumps can help<br />

reduce that cost.<br />

QUALIFYING SYSTEMS:<br />

Minimum 15 SEER,<br />

12.5 EER, and 8.5 HSPF;<br />

or a variable capacity<br />

heat pump.<br />

ENERGYWISE ℠ INCENTIVES<br />

increased to aid flood victims<br />

<strong>Loup</strong> Power District, in partnership with Nebraska<br />

Public Power District (NPPD), is increasing three<br />

residential EnergyWiseSM incentives to help those<br />

affected by the recent historic and devastating<br />

flooding.<br />

The incentive amounts for the High-Efficiency<br />

Heat Pump, Cooling System Tune Up and Heat Pump<br />

Water Heater programs have increased approximately<br />

33 percent.<br />

The temporary incentive increases end December<br />

31, 2019. They are available to all customers — not<br />

just those with flood damage.<br />

All projects must be installed and operational<br />

during the calendar year to be eligible for the<br />

corresponding EnergyWiseSM program year<br />

incentives.<br />

LEARN MORE AT LOUP.COM<br />

SUMMER 2019 17

MICHAEL ZIOLA<br />

Doane University<br />

—<br />

Master’s Degree<br />

in Educational Leadership<br />

MORGAN TROFHOLZ<br />

University of Nebraska-Lincoln<br />

—<br />

Bachelor’s Degree<br />

in Business<br />

BRIANNA PRATER<br />

University of Nebraska-Lincoln<br />

—<br />

Bachelor’s Degree<br />

in Psychology<br />

JACEY OLMER<br />

University of Nebraska-Lincoln<br />

—<br />

Bachelor’s Degree<br />

in Graphic Design<br />

Plans: Continue to teach<br />

and coach at Waverly High School<br />

Son of Peg and Ron Ziola,<br />

Vice President of Engineering<br />

Granddaughter of Gary<br />

and Sharon Trofholz,<br />

Columbus Service Center<br />

Coordinator (Columbus)<br />

Plans: Master’s Degree in Clinical<br />

and Mental Health Counseling<br />

Daughter of Sue and Rick Prater,<br />

Supervisor of Safety and Training<br />

Daughter of Tom and<br />

Ann Olmer, Humphrey<br />

Customer Service<br />

Representative<br />

AUSTAN KORUS<br />

Twin River High School<br />

AIDEN CROMWELL<br />

Columbus High School<br />

BRADY SOKOL<br />

Newman Grove High School<br />

GRIFFIN BABB<br />

Boone Central High School<br />

Son of Brenda Korus and Neil<br />

Korus, Chief Mechanic<br />

Plans: Study mechatronics<br />

at Central Community<br />

College-Columbus<br />

Son of John and Shari Cromwell,<br />

Lead Customer Service<br />

Representative<br />

Plans: Ag Business<br />

at Northeast Community College<br />

Son of Joan and Scott Sokol,<br />

Newman Grove Local<br />

Superintendent<br />

Plans: Lineman Program at<br />

Northeast Community College<br />

Son of Shelly and Roy Babb,<br />

St. Edward Local Superintendent<br />

18 GENERATOR

Area students earn scholarships<br />

LINKAGES SCHOLARSHIPS<br />

Linkages Scholarships were awarded to 11 students in the 2019<br />

graduating class at Columbus High School.<br />

The Linkages Program is a nationally recognized program that supports<br />

high schools offering a quality program of engineering and technology<br />

courses. The Columbus Economic Council, <strong>Loup</strong> Power District, and local<br />

businesses provide support for the program.<br />

The students qualified for the Linkages Scholarship by taking engineering<br />

and technical courses. The scholarship can be used at each student’s college<br />

of choice.<br />

The 2019 Linkages Scholarships were awarded to the following students:<br />

Gold Level —Logan Garbers, Edwin Ortiz-Morales, Eduardo Lares, and Ethan<br />

Gaston; Silver Level — Avery McMeekin, Pedro Zayas-Vargas, Mitchell<br />

Thelen, and Heriberto Huerta-Zayas; Bronze Level — Jan Gomez, Treyton<br />

Mead, and Eduardo Loredo-Luevano.<br />

The following local sponsors provided important financial support to this<br />

year’s program: BD Medical, Behlen Mfg., Cargill Protein, Columbus Bank,<br />

Columbus Community Hospital, Duo Lift Manufacturing, Pinnacle Bank, and<br />

TORIN Products.<br />

Since its beginning in 2004, the Linkages Program has awarded 192<br />

scholarships totaling $57,775.<br />

LOUP POWER DISTRICT SCHOLARSHIPS<br />

<strong>Loup</strong> Power District has awarded scholarships to nine area students who<br />

are attending Central Community College-Columbus this fall.<br />

<strong>Loup</strong> Power District scholarships are awarded to high school seniors<br />

living in Boone, Colfax, Nance, and Platte Counties and portions of Madison<br />

County. Selection is based on academic achievement, employment and<br />

school activities, quality of the personal statement, application completeness<br />

and recommendations.<br />

Scholarships were awarded to: Boone Central High School — Haley Buck;<br />

Columbus High School — Juliette Caballero, Aiden Cromwell, Hailey Wagner,<br />

and Nadine Hernandez; Howells-Dodge High School — Dylan Horejsi;<br />

Lakeview High School — Emma Williams; St. Edward High School — Keean<br />

Cruise; Twin River High School — Logan Dickey.<br />

Lease payments<br />

total more than<br />

$1.2 million<br />

<strong>Loup</strong> Power District officials recently<br />

presented lease payment checks<br />

totaling more than $1.2 million to<br />

area communities.<br />

Each of these communities owns<br />

their electric distribution systems.<br />

These payments compensate them<br />

for the use of those systems for the<br />

first quarter of 2019.<br />

Communities use the funds for a<br />

variety of public projects.<br />

The payments were:<br />

Columbus — $1,099,536.66<br />

Genoa — $30,863.46<br />

Creston — $9,053.75<br />

Lindsay — $53,710.91<br />

Leigh — $18,945.55<br />

Newman Grove — $23,287.06<br />

ELECTRICITY<br />

REMAINS A<br />

GOOD VALUE<br />

The cost of powering your home<br />

rises slowly compared to other<br />

common expenses. Looking<br />

at price increases over the last<br />

five years, it’s easy to see that<br />

electricity remains a good value!<br />

Average Annual Price Increase 2013-2018<br />

Percent<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

3.6%<br />

3%<br />

2.8%<br />

1.1%<br />

Sources: U.S. Bureau of Labor Statistics<br />

Consumer Price Index<br />

0<br />

Rent<br />

Cable/<br />

Satellite TV<br />

Education<br />

Electricity<br />

SUMMER 2019 19

2404 15th Street | PO Box 988<br />

Columbus, NE 68602-0988<br />

Employees added 2×4s to the diversion wall at the Genoa Headworks on June 19.<br />

The wall diverts water into the settling basin and must be repaired every year.