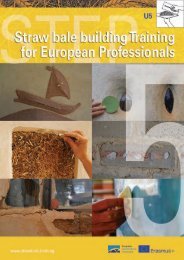

STEP U1 Handbook EN

Straw Bale Building Training for European Professionals

Straw Bale Building Training for European Professionals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1

2

U1 – INTRODUCTION

INDEX

U1

TIME

PAGE

U1 Learning Outcomes 5

U1 Session 1 : General Introduction 4 hr 6

Info-Presentation 1 : History of Straw Bale Buildings 7

Info-Presentation 2: Modern Straw Bale Buildings &Trends 8

U1 Session 2: StrawTalk 1 day 1 0

Info 1 : Straw and Bale Properties 11

Tips: Straw Bales – Quality 001 -1 2, Density 002-1 3, Measurements 003-1 4,

Expansion 004-1 5 1 2

Info 2: Storage 1 6

Info 3: Straw Bale Production 1 7

Info 4: Safety on the Building Site 1 8

Tips: Safety – Ladders & Scaffolding 005-20, Slipping 006-21 , 20

Fire Hazard 007-22, Carelessness 008-23, Protruding Tips (Pikes) 009-24,

Cables and Accus 01 0-25

U1 Session 3: Testing and Customizing Straw Bales 1 day 27

Info 1 : Handling and Adjustment of Straw Bales 28

Tip: Carry Straw Bales and save Energy 011 -29 29

Info 2: Cords and Knots 30

Tips: Tools – Belts 01 2-31 , Hammers 01 3-32, Cutting 01 4-33, Saws 01 5-34, 31

Knives 01 6-35, Hedge Saw 01 7-36, Motor Saw 01 8-37, Persuader 01 9-38,

Rakes and Bigbags 020-39, Bale Needles 021 -40, OtherTools 022-41 ,

Infill Aids (Boards) 023-42 and How to Handle them 024-43, DIY-Stuffer 025-44,

Preparing Straw Bale Walls for Plastering – Surface Shaving / Smoothing 026-45,

Stuffing Holes 027-46, Filling Gaps and Cavities 028-47

Credits and Impress 48

3

4

U1 – INTRODUCTION

LEARNING OUTCOME

U1

Level 3 (ECVET credit points: 1 5) / Level 4 (10)

Knowledge

Skills

Trainees know …

• various types of straw and their usability

• history of straw bale building

• the properties of a good construction bale

(moisture,

• direction and length of fibres, dimensions,

density, amount of weeds, type of twine)

• about the production techniques of straw

bales

• the health and safety regulations related to

straw (fire hazard, dust, slipping)

• recommendations for the farmer in the

production of good quality and good bales

• how to handle, divide, shape and store straw

bales

• appropriate tools for straw bale building

(measuring, shaping, compressing and

handling)

• the appropriate ways of shortening straw

bales

• reutilisation of remaining waste material

Trainees can …

• define the quality and properties of building

bales (dimensions, humidity, weight, density)

• define the amount of weed and the direction

of the fibres

• plan and supply of materials

• adjust the shape of the bale and cut them

accurately to size

• divide and compress the bales

• use the tools for handling and transforming

straw bales according to security rules

• keep the bales dry and well ventilated during

storage and transport

Competence

Trainees can …

• organise appropriate bales and skilfully work with bales (transport, storage, handling)

• estimate the risks connected to the use of straw and knows how to avoid these risks

• communicate with the other players on the straw bale building site about necessary safety measures

• work in teams

5

U1 – INTRODUCTION

SESSION PLAN S1

U1

Session Plan U1-S1 : General Introduction

Objectives:

Good start of training: It’s important that the trainees feel

comfortable. The trainer has to create a good atmosphere.

Introduction of participants.

The advantages of straw bales in sustainable building

Communicate with the other players

Work in team

Methods:

- Energizer to know each other better (game)

- Lecture/Talk

- Practice

- Power point

Trainer:

Place:

Classroom

Workshop

Duration:

Min. 2 hours

Equipment:

Projektor

Flip chart

50 Straw Bales

Anything else you need for

games

Theory

Practice

History of straw bale building

Examples of professional straw building

First contact with straw bales (free style)

Documents:

Trainer Sheet:

Tr1 Games

Tr2 Sheet Trainee

Tr3Training programme

Tr4 Free style

Tr5Why Straw?

Text sheet:

Tx1 Ecological Advantages

Powerpoint:

Ppt1 : History of Straw Bale

Buildings

Ppt2: New Buildings

Evaluation:

Multiple Choice

Organisation:

One month before order 50 bales

6

U1 – INTRODUCTION SESSION PLAN S1 – INFO-PRESENTATION 1

History of Straw Bale Building

U1

7

U1 – INTRODUCTION SESSION PLAN S1 – INFO-PRESENTATION 2

Modern Straw Bale Buildings & Trends

U1

8

9

U1 – INTRODUCTION

SESSION PLAN S2

U1

Session Plan U1-S2: Straw Talk

Objectives:

Know various types of straw and how it differs from hay

The properties of a good construction bale (moisture, direction of

fibres, dimensions, density, content of cereal, type of string,

shape)

About the production techniques of straw bales

The health and safety regulations (fire hazard, dust, slipping)

Recommendations for the farmer in the production of good quality

and good bales

Keep the bales dry and well ventilated during storage

Health / allergy

Methods:

Lecture / talk

Practice

Power point

Trainer:

Place:

Class

Duration:

Min. 2 hours

Equipment:

Projector

Flip chart

Straw bales in different

conditions

Different grains

Simulated working place

Theory

Practice

Quality control (e.g. impurity: other plants or stones inside?)

Handling the bales preserving the good shape

Properties in different directions

Insulation value / vapour resistance

Requirements for good building straw bales

Baling machines

Maintenance of machine / different kinds of harvesting and bailing

machines / good use of regulation of machine / different twines

Before the straw talk:

talks about different types of cereal (length, colour, strength, see

the wax protecting the straw, discover that the stalks are empty,

etc.)

Prepare two bales, one ideal construction bale, another in bad

condition (increasing the bad conditions). The trainees discuss and

discover the differences before the straw talk.

Documents:

Info sheet:

i1 straw (bale) properties

i2 storage

i3 straw bale production /

baling machines

i4 health & safety

Text sheet:

Tx1 manual baling machine

Tx2 the best bale (ASBN)

Tx3 list of humidity measure

Powerpoint:

Ppt1 : the best bale

Evaluation:

Multiple choice

Organisation:

Prepare classroom. Have different types grains talks. Two bales, prepare one in a bad condition (bad

shape, high humidity, bad colour, low density, strings removed, with cereal, with herbs, short straw,

etc.) and another ideal bale.

10

U1 – INTRODUCTION SESSION PLAN S2 – INFO 1

Properties of Straw and Bales

U1

11

U1 – INTRODUCTION

TIPS S2 STRAW BALE – QUALITY

U1

001

To check the Quality

of Straw Bales

If you want to use your own bales locally and you do not want to use certified bales

(specified as a building material, ETA), you have to check the quality of the bales and

therefore the suitability as building bales. The ideal bale is 1 ) yellow (and not gray,

brown or black), 2) form stable (similar to a cuboid rather than a ball), 3) dry (content

of moisture not over 1 4%, if a bale is yellow, it has never been in contact with moist

for long periods), 4) from hard cereal cultivars (winter or summer wheat, rye or

spelt), 5). free from green grains (less than 2% by weight), 6) sufficiently dense (85-

1 20 kg / m3, which gives a weight between 1 2 and 1 7 kg for a standard small bale

(80 x 47 x 36)). If the material is from organic cereals or conventional cultivation is

far less relevant in comparison with the residual content of pollutants (pesticides) in

the constructional bales, as e.g. from stalk shorteners (in rainy areas almost already

standard). Biologically cultivated grain often has the disadvantage that the amount

of greens is higher. And with moisture (imagine the moisture-content of the plaster

on the straw), the weed acts as a catalyst for mold grow.

1 2

U1 – INTRODUCTION

TIPS S2 STRAW BALE – DENSITY

U2

002

To check the Density

of Straw Bales

In order to determine the density of the bales, and thus their suitability as building

bales, the weight can of course be measured (hanging scale, put on bathroom scale

with and without bales...). We know from tests that the bale's best insulation values

are between 90 and 1 40 kg / m3. Below and above, it decreases slightly (too much air

in the bale means convection, too little air means less insulation, because the stationary

air between the stems provides the good insulation value). Now you can

calculate: approx. 7.5 bales fit in 1 m3, the measured weight x 7.5 = the specific

density (kg / m3). It is easier and quicker to try to press the two cords together. If this

is easy the bale is badly compressed, if it is hard, the bale has its ideal weight and if

it doesn't go at all ... usually it is not possible to bale higher densities with the small

standard baling machines.

Higher densities are not necessary, when we have to cover/plank (boards) the straw

bale wall on both sides. For this kind of construction, lighter bales (85-90 kg / m3) are

more suitable, as it is easier to work with it. But it is important to have an

appropriate density of min. 1 00 kg / m3 (with 36 x 47 x 80 cm bales, ie 1 3.5 kg / bale),

when the wall is directly plastered.

1 3

U1 – INTRODUCTION

TIPS S2 STRAW BALE – MEASURING

U2

003

Measuring Straw Bales

It sounds simple, but often leads to confusion or at least to communication

difficulties. How long is a bale really? Where do you measure exactly? Because of

rounded edges or bulged side surfaces, one person comes to 87 and the next to 80

cm. And why is it so important at all? Well, in the ideal case (if we have a wall

without windows and doors), we assemble the posts naturally in a distance according

to the length of the bales. Since the lengths vary slightly, we take the measurement

from the longer bales and fill too short bales with flakes (01 6). The easiest and

most reliable method of measurement is to flatten the sides of the bales. If the bales

are now semi-rectangular, we hold 2 boards or plates on the side of the bale and

measure the distance between them. If measuring this way, a 87 cm long bale will fit

between a 85 cm post spacing. The measure of the thickness is usually 36 cm (but

also worth checking). We have already had to extend roof rafters of 35 cm, because

the roof plate could not be mounted on the protruding bales. And the width is in

most cases 47 cm (and not 50, as often published). Again, it helps to measure

between two boards. We can at least be sure that the thickness and width once

measured in a charge is the same for all other bales (if it comes from the same baling

machine). And one more thing: the boards must of course be kept parallel for

exact dimensions.

1 4

U1 – INTRODUCTION

TIPS S2 STRAW BALE – EXPANSION

U2

004

Straw Bales expand only

in press-direction (of bale canal)

Straw bales always (and only) expand in the longitudinal direction, ie, in the

direction in which they have been compressed in the bale channel to so-called (8-1 4

cm thick) "flakes" (layers). These pressure-forces in the bale should be used: if you

cut the cords after filling them in post and beam constructions, good compressed

bales close the gaps to the construction (and you have less to stuff). That is why we

always cut the strings in wooden p&b constructions. However, the bales will not expand

more than 2-3 cm. For larger cavities, we fill flakes into the spaces (tip 01 6-01 7).

Only in the load bearing straw bale construction the cords remain in the

construction, otherwise the walls would fall apart after removal of the temporary

construction.

1 5

U1 – INTRODUCTION SESSION PLAN S2 – INFO 2

Storage of Straw Bales

U1

1 6

U1 – INTRODUCTION SESSION PLAN S2 – INFO 3

Production of Straw Bales (Baling)

U1

17

U1 – INTRODUCTION UNIT S2 – INFO 4

Health and Safety at the Straw Bale Building Site

U1

Objective:

To observe safe working practices at all times - and to have fun!

Good practices

In general, there are fewer accidents and errors on the site if everyone is happy and well motivated. It is

good practice for the entire team to get to know each other, and how each separate action is part of the final

realization. It is very useful for everybody to meet at the beginning and at the end of each day, to share

thoughts and reflections on the work to be done or the way to do this, and to discuss potential problems.

If we can recognize our interdependence with each other rather than be in competition, which will help to

generate a staff attentive and helpful, or each individual is responsible for his own person, but also takes

into account the well-being of others. This is particularly necessary at a site self-construction or the people

have different levels of knowledge or skill.

Encourage the questions concerning a task or a tool, until everyone feels comfortable and safe in their use.

The construction sites in bales of straw are renowned for their ethics to work together, share the knowledge

and skills, equality for women, the learning enjoyable and fun. And there is no reason that these qualities

cannot be encouraged on all construction sites.

Security on the site

These are the basic guidelines that will help to ensure that no person suffers an accident:

1 8

• Each construction site, even if it is your own home, should have a first aid kit available and everyone

must know where it is!

• Never use defective tools! !

• It is forbidden to smoke anywhere on the site or around the straw stored.

• Make sure that you know where is the nearest water point.

• Always keep the site clean. The scaffolding and working areas must be swept and tidied up each evening.

It is useful to store materials and waste etc in specific locations to maintain the order on the yard.

• Keep a central place for tools so that all those who are not used can be delivered, and can be found in

case of need.

• Never leave the tools lying around. Each person should be responsible for the tools he or she uses,

must know where they are and where to store them when they are not used.

• Unplug all electrical tools when they are not used!

• Don’t let electrical wires become trip hazards on the site!

• Fuel for the chainsaw or the brushcutter must be stored in a locked space far from the straw.

• All scaffoldings must be firmly attached.

• Step ladders and work platforms must always have a solid foundation.

•The helmets should always be worn. Especially so when somebody works above oneself.

• Extra precautions should be taken in the use of heat or open flame. Never use anything like that in the

vicinity of exposed straw.

U1 – INTRODUCTION UNIT S2 – INFO 4

Health and Safety at the Straw Bale Building Site

U1

Tools for the construction with straw bales

The construction in bales of straw requires almost no specialized tools.

As with most things, there are different grades of tools on the market. Generally speaking, it is better to

buy tools of good quality, even if they cost a little more, because the tools of poor quality may be inaccurate

and wear quickly. They will certainly frustrate you and make you feel incompetent. Remember, the

tools are the means by which you are able to do a good job. You will use them for a long period, therefore

take care of it, sharpen it, oil it, whatever is necessary to have it in good shape. They must resist the normal

wear on a building site, therefore need to be robust.

The right tools, if they are properly maintained, can last a lifetime, not only for the time you build your first

home. The right tools make the job easier, faster, and more secure.

Watch the security notice for each tool!

Clothing and safety equipment

When you work with straw, it is advisable to wear a long-sleeved shirt and long pants, because the stalks

of straw can be thorny.

Gloves are also a must, at least for some aspects of the work.

Eye protection, ear protection and dust masks may be necessary for some work.

The helmets must be worn if someone workes above yourself.

Safety shoes are necessary for protecting the feet from falling objects.

Identify the responders qualified on the site, and attach a list of emergency phone numbers.

1 9

U1 – INTRODUCTION

TIPS S2 SAFETY – FALLING

U1

005

Safety on Straw Building Sites:

Falling (from) Ladders

When filling from a stepladder, always place the steps parallel to the wall, otherwise

there is the danger that you will fall over from the ladder when filling with high

pressure. The distance of the ladder to the wall is also important for the pressure and

your power. The more the you use your own weight as pressure, the less efforts and

muscles are required for the filling process. So, try to place the ladder a little further

from the wall, and lean your body in an angle to the wall. Do the same with auxiliary

scaffoldings (scaffoldings with planks) and the façade scaffolding (you will nedd a

space between also for stuffing and plastering). Finally, leaned ladders should be fixed

with a cord or a wire at the upper end, if there is a risk of slipping (especially on

straw) as well as falling danger.

20

U1 – INTRODUCTION

TIPS S2 SAFETY – SLIPPING

U1

006

Safety on Straw Building Sites:

Slipping

Where work is done, chips fall. In our case, it is straw. Summerized - scaffoldings,

floors, ladders and stairways on our construction site are soon covered by a (thin)

layer of loose straw. As romantic as this may be: loose straw is quite slippery

(especially when wet, ie while plastered). Cables disappear under this straw blanket,

as well as tools and, of course, holes (e.g., between provisional planks or boards).

The most important danger, however, is represented by our hardboards for filling

(023). Loose straw in combination with (the slippery) filling aids laid flat on the

ground will let you slip even with the best shoes. The first requirement on a straw

site (also for reasons of fire protection) is therefore cleaning: collect the loose straw

in BigBags. Tools should never be placed on the ground (always collect them centered

on tables - easy available for all employees. Place the cut bales on the narrow

side and lean against a wall so that the layers do not fall apart. And before the shaving,

all the straw is collected again. Because the short straw which is falling from

the walls when shaving is ideal as a fiber reinforcement for our plaster.

21

U1 – INTRODUCTION

TIPS S2 SAFETY – FIRE

U1

007

Safety on Straw Building Sites:

Fire

The handling with open fire on a straw site is, of course, forbidden. This applies both

to smoking and especially to welding and hot-tacking (whether it is gluing roofing

paper or welding rainwater gutters). Here, great caution is necessary, because most

of the fires were caused by the flames or heat of roofing works or improper - non insulated

- chimneys through straw bale walls. Finally, waxed or oil-impregnated

cloths must be kept in sheet metal (danger of self-ignition).

Nevertheless: Well compressed straw bales form a coal layer in the event of fire,

which strongly hinders the propagation of the fire (see fire test below). The problem

is loose straw, which literally burns like tinder ("straw fire").

22

U1 – INTRODUCTION

TIPS S2 SAFETY – CARELESSNESS

U1

008

Safety on Straw Building Sites:

Carelessness

Everyone who works on a straw bale building site should be aware that one can

barely see the ground with one or two straw bales in their hands. The ground on

which we move, - whether it is the loamy excavation pit, a foamed glass fleece

covered with straw (which perhaps is folded), the unfinished floor, 2 laid boards for a

ramp (always the same thickness), a temporarily planked (interleaving) floor or terrace

(no holes, planks fixed with screws) or the scaffolding (well anchored), - should

be blindly accessible without being seriously injured. Often we work with large

weights (wheelbarrow full of clay). We should be at least able to rely on the safe

ground under our feet. Laying planks without temporarily fixing them (nailing,

screwing) is negligent. To remove a scaffolding plank somewhere without an

arrangement, because youI need it somewhere else, is actually a murder attempt. It

is also negligent not to anchor a scaffolding to the wall. And finally, anyone who

runs or jumps on a construction site should get the red card, no matter how fast he /

she wants to finish the work.

23

U1 – INTRODUCTION

TIPS S2 SAFETY – PROTRUDING TIPS

U1

009

Safety on Straw Building Sites:

protruding Tips

Especially when nailing or shooting brackets you will not always hit the wood-construction

behind. The tips of the brackets / nails / screws extending in the insulation

area are difficult to see when filling, so always check and remove or flatten them

before you strat the infill. They are a serious risk of injury. When naileg / screwed

planks are removed, remove the nails / screws immediately (if necessary with the

grinding machine). Even with steel caps on the shoes the kick on a screw tip is

dangerous (and hurts badly). Even building irons (rebars), which extend the

foundations, should always be made more visible with a cup or bottle. Summarized

it can be said that most of the subsequent accidents occur under time pressure /

during busy work. It should be self-evident that we can rely on the correct execution

of the work of our partners and those, who worked before us, that everybody corrects

his/her own mistakes.

24

U1 – INTRODUCTION

TIPS S2 SAFETY – CABLES & ACCUS

U1

010

Safety on Straw Building Sites:

Cables and Accus (Batteries)

The cable-free construction site will remain a dream, despite batteries (accus).

Compressors and many other tools have electric cables. Cable drums and their feeds

usually run crosswise through construction sites and where barriers are piling up

(wooden stacks, straw bales) also cross these piles on top. And even batteries are

charged via chargers with cables. Cables, hidden under the straw on the ground or

on scaffolding, can easily become a tripping trap. If you are in a hurry on a

construction site, you are more exposed to the risk of serious injury. In case of shaving

the bales with hedge saws or cutting with the alligator (electrical saw) you can -

if you are not careful and wear the cable for example over the shoulder - also

slightly cut the cable and cause a short circuit (or ruin the tool).

25

26

U1 – INTRODUCTION

SESSION PLAN S3

U1

Session Plan U1-S3: Customizing Straw Bales

Objectives:

How to handle, divide and shape straw bales

Appropriate tools

The advantages and disadvantages of different types of strings

The appropriate ways of tying straw bales (knots)

Check the quality and usability of straw bales

Methods:

Presentation

Testing and customizing straw bales

Trainer:

Place:

Workshop

Duration:

Min. 3.5 hours

Equipment:

Tools and straw bales

Theory

Practice

Overview about the tools on a typical straw bale building site

Methods of measuring and manipulating straw bales (tools,

machines)

Plan the supply of straw bales

Use the bale in the correct orientation

Measure the bales

Adjust the shape of the bale and square off the ends

Divide and restring the bale

Cut the bale

Calculate the density of bale

Check/measure moisture in the bale

Use tools for handling and transforming bales

Documents:

Trainer sheet:

Tr1 Health/ Safety game

Info sheet:

i1 Control sheet

i2 handle and shape bales

i3 twine and knots

i4 straw bale measuring

Evaluation:

Multiple choice

Organisation:

prepare the work shop (tools, bales, safety recommendations)

27

U1 – INTRODUCTION SESSION PLAN S3 – INFO 1

Shaping Straw Bales

U1

28

U1 – INTRODUCTION

TIPS S3 HANDLING STRAW BALES

U1

011

Carry Straw Bales

and save Energy

Small standard straw bales (36 x 47 x 80-1 00 cm) are usually tied with 2 strings in

the longitudinal direction (formerly sisal, now mostly polyethylene). In order to carry

the straw bales, these cords are of course very suitable. However, always put the

hand around both strings when carrying, so that a cord does not slip from the bale

(which - at least if the bale is not perfectly compressed - causes it to fall apart). Keep

the weight of the bales (approx. 1 2-1 4 kg) as close to the body as possible, it reduces

the force required. Another possibility is to embrace the bales and to carry them

close to the body. This can be a relieve for our fingers, because the cords cut with time

quite nicely into the hands. In addition, you should quickly learn to see the raw

material bales as a valuable material and not as a favorable waste material in grain

harvesting. Watch out for the mountains of loose straw, which can occur if you do

not care about this building material. It is quite elaborate to dispose, even if it can

finally be composted and it is always in the way on a construction site.

29

U1 – INTRODUCTION SESSION PLAN S3 – INFO 2

Cords and Knots

U1

30

U1 – INTRODUCTION

TIPS S3 TOOLS – BELT & BAGS

U1

01 2

Straw Bale-Tools:

The practical Belt

I personally have in my (carpenter-)belt bags (left and right) always my two stuffers

(like colts), for me the most important professional tool in straw bale building, next

to a knife to cut the strings. In the bags I have a few galvanized 6 cm nails, various

screws, a meter measure and a carpenter's pencil. Also gloves which are thin

enough not to prevent the feeling in your fingers, but protect you against the many

small chips from the construction wood. Actually, the bags should have top tabs, as

they are constantly filling with straw. Or I would have to turn the bags to the backside,

but I find that not practical looking for right screws or bits.

31

U1 – INTRODUCTION

TIPS S3 TOOLS – HAMMERING

U1

01 3

Straw Bale-Tools:

Hammering Nails

The Carpenter-Hammer must not be missing. With it, you simply (no, that is actually

a lie) pull out nails. There are two different models available on the market: those

with the flat tips, which are also ribbed so that they have better grip on the nail head.

And a model (claw hammer) that often meets me in other countries, which I personally

can not handle. It is so bent and has such a round head that it is almost

impossible to get a nail straight in. What I want to say is, that everyone is used to the

tool with which he has learned. That is why you should always take it with you to

your building sites. Even with hammers without grip on the cap, it can be hard to

strike a nail straight. No wonder, that nailing seems to be the biggest challenge for

many in straw bale building. Therefore, here are a few tips: 1 ) Holding the hand at

the bottom of the stem, helps to save energy. It is about the momentum, and the

less often a nail is hit, the less chance of bending it. Well, practice makes perfect. 2)

Look at the hammer head and align it before impact so that it does not strike

obliquely on the nail head, avoiding the distorted bending and pulling out again. The

same technique also leads to the goal (hole) with tennis or Minigolf.

32

U1 – INTRODUCTION

TIPS S3 TOOLS – CUTTING

U1

01 4

Straw Bale-Tools:

Cutting Straw Bales

II tried pretty much everything that has blades. But the only tool that really cuts

straw like butter is the electric saw (in German Elektro-Fuchsschwanz). I use the

Bosch ® Professional with 35 cm sword, which also cuts at the top. There are

alligators with comparatively long swords. But if the first 5 cm of the tip do not cut

(see drawing below), it becomes tedious. It is not always a question of dividing or

cutting a bale in the longitudinal direction, but sometimes also of forming a wedge

or an opening (niche) into the bale. The two blades are, by the way, easily

interchangeable and there are different ones for wood (and straw), metal and plastic.

33

U1 – INTRODUCTION

TIPS S3 TOOLS – SAWS

U1

01 5

Straw Bale-Tools:

other Saws

In addition to this all-purpose device, a simple (sharp) hand saw (without electrics),

e.g. for the cutting of our CUT-battens should of course be available. Also a jigsaw is

a nice addition to our tools, especially for all round cuts. But this is more for wood

construction, as it usually don't cut a straw bale. A crosscut saw is, of course, also

worth the gold on a construction site, for all exact cuts in the wood (joining). And

finally we need a table circular saw, if we e.g. cut the battens lengthwise from the

raw planks.

34

U1 – INTRODUCTION

TIPS S3 TOOLS – KNIFES

U1

01 6

Straw Bale-Tools:

Knives (Cutters)

The advantage of cut-off blades is that they are always sharp. As we soon get

muscles when working on building sites we start to cut with more pressure, so the

more sturdy 3 cm blades are more convenient to us. The 1 cm toy blades are good

enough for paper, but even do hard when cutting the polyethylene cords. By chance,

cutting straw bales on a construction site (actually more sawing) with a new, ribbed

bread knife works wonderful. The result was so positively convincing that I always

have one with me (or ask the cook for it). For all other knives applies: it's about the

sharpness, halms/stalks are quite brittle and it's boring to sharpen your knife

constantly.

35

U1 – INTRODUCTION

TIPS S3 TOOLS – HEDGE SAW

U1

017

Straw Bale-Tools: Shaving

Surfaces with Hedge Saws

We do not only want to squeeze a few protruding stalks with hedge saws, in most

cases we want a plane surface to save plaster and to avoid different drying times,

even if bales are slightly differently thick or bulged or not exactly installed plane.

Even if there are customers who prefer a more organic-hunched surface, in most

cases they mean slight bumps in the (hand-) plaster and not simply covering uneven

bales with the plaster. The cutting of the hunches of straw bales is a long-term work,

but it really becomes hard work with not really sharp hedge saws. Unfortunately

sharpening is often as expensive as a new one. A tip to save energy is to pick hedge

saws with a rather shorter sword (about 50-60 cm). The longer the sword, the more

pressure we need to push to the bale surface, and the harder it is to shave a round

wall or vault inside. In terms of strength: from 450 W, hedge trimmers are robust and

strong enough. The sharpness of the knives is much more important. Hedge saws

are among the very safe machines (since they cut only between the knives).

Nevertheless, you can tweak neatly with hedge saws (a small cut with painful

bruising is the result). It can happen when you sit on the scaffolding shaving the

walls. More often, if you don't take care, you will cut the cable and cause a short

circuit. Therefore, it is best to carry the cable over the shoulder. Or choose a model

with battery.

36

U1 – INTRODUCTION

TIPS S3 TOOLS – CHAIN SAW

U1

01 8

Straw Bale-Tools: Cutting Bales

with a Chain Saw

Some can do it, I have never managed to cut a straw bale with a chainsaw, it almost

always leads to smoking straw halms under the chain cover in short time. The

mixture with the chain saw oil is quite inflammable. The trick is to use a chain saw

with rather long sword and cut only (mainly) with the tip so that the stalks fly

tangentially away and do not get under the protective cover of the chain. Gasoline

powered chainsaws are also noisy and stinking, electrical usually not so strong. For

structural wood ideal, I cannot recommend it for straw bales from my point of view.

37

U1 – INTRODUCTION

TIPS S3 TOOLS – PERSUADER

U1

01 9

Straw Bale-Tools: the Straw Bale

Hammer or Persuader

This wooden hammer "persuades" each bale (at least as long as it is not fixed by

battens). It is a must on each straw building site and also easy to manufacture in the

DIY process from residues of construction wood. Only the handle should be sturdy

(typically hardwood). Do not screw the handle to the wooden plates too often (2

times should be enough), otherwise it will break more easily at this point. The

Persuader should be heavy, but it is used with a swing to move the bales back into

the row, or to connect the upper bale with the underlying ones well.

38

U1 – INTRODUCTION

TIPS S3 TOOLS – RAKE AND BIGBAGS

U1

020

Cleaning the Building Site:

Rakes and Bigbags

Keeping your construction site always clean is not only practical, it's also a matter of

safety. With a broom you will work mainly on floors, natural subsoils need flat rakes

for cleaning and removing straw, as we often cleaning grassy or gravel surfaces. The

elastic leaf rakes work best for this. And because of the quantities that are caused by

building bales due to destroyed bales and loose straw, the purchase of BigBags is

worthwhile (or you take your used clay or sand bags).

39

U1 – INTRODUCTION

TIPS S3 TOOLS – BALE NEEDLES

U1

021

Dividing Straw Bales with

Bale Needles

Bale Needles may be useful or even indispensable for load-bearing straw bale walls

(in this case each new row of bales needs half-bales). In the infill-technique, the bales

are compressed more easily with adding flakes between two plates (023). Bales

can also be compressed to a certain density by simply rebinding it with strings,

depending on the strength you tear, or with screw clamps. But as bale needles are

connected to straw bale building like the halms to the bale, let's look at these tools.

Actually a pointed wooden stick with two holes at the top is enough for their

function (since there are 2 new cords needed - one for the right, one for the left bale

part). There are also combined bale needles (which are connected to a bar / handle,

which pull all 4 cords through the bale at the same time (2 upper and 2 lower -

instead of the 2 existing cords). After you pulled your strings through the bale, the

cords are knotted to each half-bale. There are special knots, as they are known from

sailing. After you rebound your halfs, the original two cords are removed, thereby

maintaining the density of the bale. If you took the right strings on the right half bale

you can divide your bale (otherwise, if strings are crossed, you have two connected

half-bales). So you can definitely say that some straw balers make a science out of a

simple thing.

40

U1 – INTRODUCTION

TIPS S3 TOOLS – MORE TOOLS

U1

022

More Tools on

Straw Bale Building Sites

A cordless screwdriver (per worker) must not be missing on straw sites. We will not

screw straw bales to the wall, but often enough we need to do smaller woodwork

and fixtures, just for safety reasons. We also need a spirit level. But that's it for now.

With these tools you are already equipped as a straw bale builder. Except for the

crosscut saw (which is brought by the carpenter) and the table circular saw (let's

assume, it is anyway on a good construction site) our tools fit playfully into a small

car, even with 3 employees and luggage.

Especially in the case of workshops, it is a good idea to put the tools in different

labeled boxes so that they can be found by every participant. Paying attention to

your collection of tools saves a lot of searching-time.

41

U1 – INTRODUCTION

TIPS S3 TOOLS – INFILL AIDS

U1

023

Straw Bale-Tools:

The essential Infill-Aids (Boards)

For infilling flakes, we use thin (6 mm) plates (baords) of plywood, hard fiber, plastic

or metal, usually with a handle (hole) or with metal flaps with a bent folding handle,

so that they can be pulled out more easily. The smooth surface shows to the flake,

the rough to the existing bale or the construction. The boards should be available in

different sizes (approx. 47 x 47 cm for filling from the front, 36 x 57 cm for filling

from above, or half-sizes for smaller cavities).

42

U1 – INTRODUCTION

TIPS S3 TOOLS – INFILL AIDS

U1

024

Straw Bale-Tools:

How to handle Infill-Aids

When infilling bales or flakes (best with a helper), the boards are held like a funnel to

create the largest opening possible for the position (see picture). As soon as the bale

or flake is half filled into the wall, the helper pushes the plate to the bale (so that the

funnel becomes a tunnel with parallel sideboards and the straw is not squeezed on

the backside). Insert the flake only until the surface of the wall (same level as the

adjacent bales around). Another tip: usually more flakes fit into cavities than

assumed. If you fill too little, you must repeat the process. Therefore, use a little

more straw (several - still cohesive - layers at a time), then the surface becomes

even more even.

When removing the boards, lateral wobbling helps (much easier than just pulling). If

enough layers are infilled (high density) the boards are difficult to pull out: this is the

guarantee for a really good plaster surface.

43

U1 – INTRODUCTION

TIPS S3 TOOLS – STUFFER

U1

025

Straw Bale-Tools:

DIY-Stuffer in two Sizes

No one can fill straw bales between posts / rafters (or stack them over one another in

the load bearing straw bale building) without leaving any holes at all. This is due to

the fact that bales on the edges are often rounded (and not sharp-edged); on the

other hand, cavities can also develop when filling (densifying) with layers. And

finally it happens again and again that, for structural reasons, there is a (diagonal)

squared or round wood in the insulation area, such as the planks of an intermediate

vault. In order to fill these cavities with (loose) straw and prevent convection in the

thermal insulation layer or simply a cold bridge, we use homemade, simple (DIY)

stuffing tools. Of course, you can also stuff with the hands (fingers), but I wouldn't

recommend that for larger areas. After some days you cannot move your fingers any

more. Especially if the wall is to be plastered, it is important to stuff the straw in the

same density as the bales nearby, so that the weight of the plaster does not pull it

out again. For these purpose we need 2 tools, made of strips of 25 x 25 mm (1 x 1 ")

for the small and 25 x 50 mm for the large stuffer. So we are building a "T", which we

screw together 1 -2 times (6-8 cm screw, 5-6 mm hole pre-drill). The smaller handle

has a length of 1 5 cm, the larger handle has a length of 25-30 cm, which we slant at

the top like a screwdriver (with a jigsaw or crosscut saw). Finally, we put a small

notch in the middle of the "cutting edge" so we can later better collect the straw to

be stuffed. Finally we take sandpaper (or a rasp) and round off all edges easily.

44

U1 – INTRODUCTION

TIPS S3 TOOLS – SHAVING AND SMOOTHING

U1

026

Preparing Straw Bale Surfaces

for Plasters

Straw bales provide a pretty good plaster ground when the surface is prepared (and

will not be planked). To achieve the best possible and long lasting connection with

the plaster, the surface of the bales is cut with a (sharp) hedge trimmer. Since this

can be a lot of work (especially with well compressed bales), short hedge saws

(about 60 cm of sword) are usually better than long ones. This also makes it easier to

cut curved surfaces (as in the case of a round house or vault). It is not just about removing

protruding stalks, but of smoothing all the unevenness, ie shortening the

whole stalks one to two centimeters. On these many stalk ends, the plaster adheres

much better than on the untrimmed stalks covered with a wax layer. This method of

plaster preparation is much more useful than depositing the bales (so that the wax

layer disappears). Earth- and lime plasters have mainly mechanically based connections

to the plaster-ground through rough surfaces.

45

U1 – INTRODUCTION

TIPS S3 – STUFFING HOLES

U1

46

027

Customizing Straw Bales:

Stuffing Holes

Now go to the stuffing: by the rule of thumb, the loose straw is to be stuffed to the

middle of the bales (about 1 8 cm deep). For preparation the surface is shaved with a

hedge trimmer, then we see the holes much better. Take as many stalks as possible

from a straw bale (in the beginning always twice as much as you think that fits in the

hole), put this amount centrally over the hole and form a heart: with the small stuffer

you insert the stalks to the centre of the bale so they are deep in the hole and only

about 5 to 1 0 cm is exceeding. This should be done with power, and if it goes too easy,

you took too little straw. The protruding stalks are then bent and put back into the

cavity, this time with the larger stuffer. If we do this on both sides of the wall, a heart

shape is created. It is very important that in the end the triple bent stalks neither

protrude nor form a new cavity (because we have stuffed the straw too deep). The

visible crease should lie exactly on the surface. We can easily remove any protruding

stalks with a second hedge-trimmers (or push them by hand into the bale), but if we

cut the crease, the short stalks fall out again. Why the trick with the crease? Again,

we use the material's own power (the strong tendency of the stalks to expand after

buckling or compression) to fix the straw well in the bale. If you do not believe, try it

differently, but then you should also plaster at this place. I have often experienced

that suddenly plugs of plaster fall from the wall because the straw was not well fixed

in these places. This may sound a bit complicated, but it is really simple - and guarantees

a perfect straw surface, which is also a good plaster-ground.

U1 – INTRODUCTION

TIPS S3 – FILLING GAPS

U1

028

Customizing Straw Bales:

Filling Gaps

Larger holes and cavities can be stuffed in the same way, if necessary. In principle,

we fill the gaps as good as possible with bunches of loose straw and compress the

straw with the stuffer. This may seem hopeless in the beginning, but there is always

the moment when everything suddenly becomes stable (and dense). One of the

basic principles of straw construction is that compressed straw tends to expand and

at a certain density it begins to form a stable building body no matter what shape.

Straw figures or straw sculptures can also be built in this way, as hollow spaces can

be filled and compressed. The only exception are oblique or very shallow cavities

which have a larger opening to the exterior. Here you need to build a cage for the

straw: close the surface with plates, sturdy mats (for example, bamboo) or with

strips / boards, then you can stuff the straw in the cavity, without falling out again.

47

STEP – Straw Bale Training for European Professionals

UNIT 1 – Introduction/Einführung (201 7)

Editing/Tips: Herbert Gruber, Helmuth Santler (ASBN)

Cooperation: BuildStrawPro-Team (Erasmus+ Project)

Design & Fotos: Herbert Gruber (ASBN, StrohNatur),

More Fotos: RFCP, provided by Architects & companies.

Illustrations/Icons: Michael Howlett (SBUK)

This Handbook is based on

the Handbook from Leonardo-

Group STEP (201 5)

48