You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

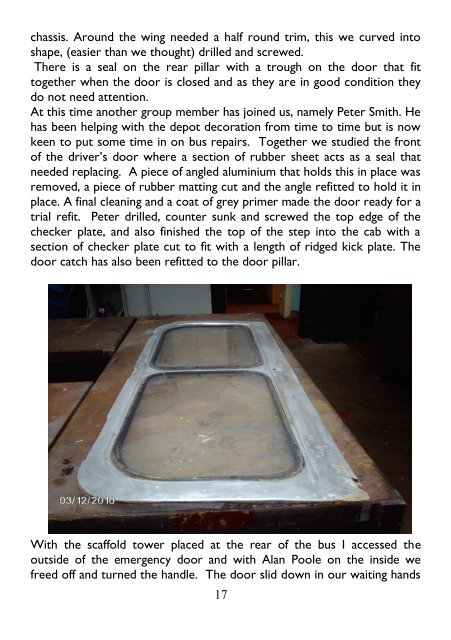

chassis. Around the wing needed a half round trim, this we curved into<br />

shape, (easier than we thought) drilled and screwed.<br />

There is a seal on the rear pillar with a trough on the door that fit<br />

together when the door is closed and as they are in good condition they<br />

do not need attention.<br />

At this time another group member has joined us, namely Peter Smith. He<br />

has been helping with the depot decoration from time to time but is now<br />

keen to put some time in on bus repairs. Together we studied the front<br />

<strong>of</strong> the driver’s door where a section <strong>of</strong> rubber sheet acts as a seal that<br />

needed replacing. A piece <strong>of</strong> angled aluminium that holds this in place was<br />

removed, a piece <strong>of</strong> rubber matting cut and the angle refitted to hold it in<br />

place. A final cleaning and a coat <strong>of</strong> grey primer made the door ready for a<br />

trial refit. Peter drilled, counter sunk and screwed the top edge <strong>of</strong> the<br />

checker plate, and also finished the top <strong>of</strong> the step into the cab with a<br />

section <strong>of</strong> checker plate cut to fit with a length <strong>of</strong> ridged kick plate. The<br />

door catch has also been refitted to the door pillar.<br />

With the scaffold tower placed at the rear <strong>of</strong> the bus I accessed the<br />

outside <strong>of</strong> the emergency door and with Alan Poole on the inside we<br />

freed <strong>of</strong>f and turned the handle. The door slid down in our waiting hands<br />

17