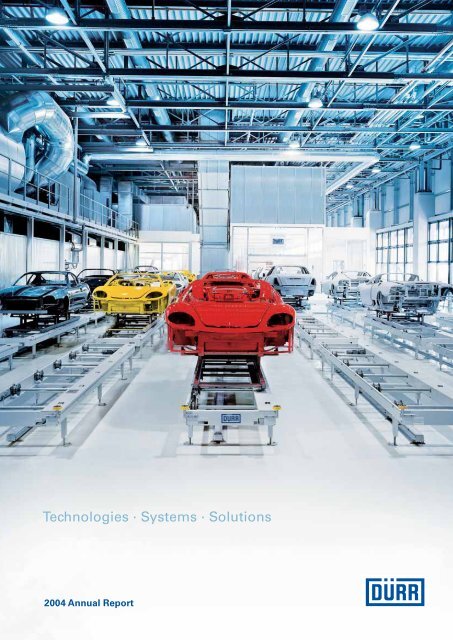

Technologies · Systems · Solutions - Dürr

Technologies · Systems · Solutions - Dürr

Technologies · Systems · Solutions - Dürr

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technologies</strong> <strong>·</strong> <strong>Systems</strong> <strong>·</strong> <strong>Solutions</strong><br />

2004 Annual Report

Key figures for the <strong>Dürr</strong> Group (IFRS)<br />

Order situation<br />

2004 2003 Change<br />

Consolidated incoming orders in €m 1,841.3 2,356.2 –21.9%<br />

Consolidated orders on hand as of December 31 in €m 1,052.7 1,364.1 –22.8%<br />

Key personnel figures<br />

Employees on annual average 13,079 12,957 0.9%<br />

Employees as of December 31 13,295 12,747 4.3%<br />

of which in continuing operations 7,280 7,642 –4.7%<br />

Key figures of the income statement<br />

Consolidated sales revenues in €m 2,271.9 –6.0%<br />

of which continuing operations in €m 2,044.9 –6.9%<br />

Cost of sales in €m 1,906.2 –6.4%<br />

Gross profit on sales in €m 365.6 –3.7%<br />

Personnel expenses in €m 608.7 –6.2%<br />

Amortization and depreciation in €m 31.0 10.0%<br />

Restructuring expenses and impairment losses in €m 26.1 –48.3%<br />

EBITDA1 in €m 45.9 51.9%<br />

of which continuing operations in €m 46.5 41.1%<br />

EBIT2 in €m 14.9 138.9%<br />

of which continuing operations in €m 19.8 114.6%<br />

EBT3 2,136.4<br />

1,903.3<br />

1,784.2<br />

352.1<br />

570.9<br />

34.1<br />

13.5<br />

69.7<br />

65.6<br />

35.6<br />

42.5<br />

in €m 11.8 –5.7 307.0%<br />

of which continuing operations in €m 18.6 –0.9 2,166.7%<br />

Net income/loss in €m 4.7 –30.3 115.5%<br />

of which continuing operations in €m 11.6 –22.0 152.7%<br />

Earnings per share in € 0.40 –2.14 118.7%<br />

Dividend per share in € – – –<br />

4<br />

Key figures of the balance sheet<br />

Non-current assets in €m 624.2 633.7 –1.5%<br />

Current assets in €m 810.8 1,031.9 –21.4%<br />

Balance sheet total in €m 1,435.0 1,665.6 –13.8%<br />

of which continuing operations in €m 1,288.5 1,509.9 –14.7%<br />

Equity without minority interests in €m 222.4 218.9 1.6%<br />

Equity ratio in % 15.5 13.1<br />

Liabilities<br />

Capital expenditures on property, plant and equipment<br />

in €m 1,210.8 1,441.4 –16.0%<br />

and intangible assets in €m 47.3 30.8 53.6%<br />

of which goodwill in €m 14.1<br />

4.4 220.5%<br />

Financial ratios<br />

Gross margin in % 16.5 16.1<br />

EBITDA margin in % 3.3<br />

2.0<br />

EBIT margin in % 1.7<br />

0.7<br />

EBT margin in % 0.6 –0.3<br />

Financial structure<br />

Bond in €m 186.5<br />

– –<br />

Liabilities to banks in €m 102.9 296.8 –65.3%<br />

Net financial debt average in €m 248.0 221.5 12.0%<br />

Net working capital average in €m 184.9 164.6 12.3%<br />

Statement of cash flows<br />

Cash flow from operating activities in €m –103.5 81.0 –227.8%<br />

Cash flow from investing activities in €m –27.6 –37.7 12.9%<br />

Cash flow from financing activities in €m –23.1 –69.8 66.9%<br />

1 EBITDA: Earnings before interest, taxes, depreciation and amortization<br />

2 EBIT: Earnings before interest and taxes<br />

3 EBT: Earnings before taxes<br />

4 Dividend proposed to the annual shareholders’ meeting<br />

Immaterial variances may occur in this report<br />

due to roundings in the computation of sums<br />

and percentages.

Continuing<br />

operations<br />

Paint <strong>Systems</strong><br />

Final Assembly<br />

<strong>Systems</strong><br />

Ecoclean<br />

Measuring<br />

<strong>Systems</strong><br />

(without DTS)<br />

Discontinued<br />

operations<br />

Services, DTS<br />

2,500<br />

2,000<br />

1,500<br />

1,000<br />

500<br />

0<br />

2004 2003 Change<br />

Total incoming orders1 in €m 1,400.1 –42.2%<br />

Total sales2 809.2<br />

in €m 1,154.5 1,250.2 –7.7%<br />

EBITDA in €m 39.6 41.3 –4.1%<br />

EBT in €m 28.3 29.3 –3.4%<br />

Employees as of December 31 2,690 2,808 –4.2%<br />

Total incoming orders in €m 345.7 405.4 –14.7%<br />

Total sales in €m 374.0 445.0 –16.0%<br />

EBITDA in €m 6.0 11.3 –46.9%<br />

EBT in €m 2.0<br />

7.5 –73.3%<br />

Employees as of December 31 1,546 1,593 –3.0%<br />

Total incoming orders in €m 183.6 176.9 3.8%<br />

Total sales in €m 186.1 208.1 –10.6%<br />

EBITDA in €m –2.0<br />

9.4 –121.3%<br />

EBT in €m –5.1<br />

5.7 –189.5%<br />

Employees as of December 31 909<br />

932 –2.5%<br />

Total incoming orders in €m 320.2 286.2 11.9%<br />

Total sales in €m 307.2 283.7 8.3%<br />

EBITDA in €m 18.6 –4.0 565.0%<br />

EBT in €m 10.9 –14.5 175.2%<br />

Employees as of December 31 2,084 2,255 –7.6%<br />

Total incoming orders in €m 257.0 230.0 11.7%<br />

Total sales in €m 233.4 227.8 2.5%<br />

EBITDA in €m 4.1 –0.6 783.3%<br />

EBT in €m –6.8 –4.8 –41.7%<br />

Employees as of December 31 6,015 5,105 17.8%<br />

The Corporate Center had 51 employees as of December 31, 2004 (2003: 54); its EBITDA amounted to € 3.4 million<br />

(2003: € –11.5 million), and its EBT € –17.5 million (2003: € –28.9 million).<br />

1 Total incoming orders: Incoming orders of a business unit including intragroup orders from other business units.<br />

2 Total sales: Sales of a business unit including intragroup transactions with other business units.<br />

Sales revenues in €m<br />

2,042 2,196<br />

2,082<br />

2000 2001 2002<br />

Consolidated group<br />

Continuing operations<br />

Discontinued operations<br />

2,271.9<br />

2003<br />

2,136.4<br />

2004<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

–20<br />

Group EBITDA in €m<br />

115.3 127.8<br />

2000 2001<br />

Figures through 2002 according to US GAAP and from 2003 onward according to IFRS<br />

89.1<br />

2002<br />

45.9<br />

2003<br />

69.7<br />

2004

<strong>Dürr</strong> Group<br />

Old structure – 2004 Annual Report<br />

Paint <strong>Systems</strong><br />

Final Assembly<br />

<strong>Systems</strong><br />

Ecoclean<br />

Measuring<br />

<strong>Systems</strong><br />

Product line DTS<br />

Services<br />

New structure – since March 1, 2005<br />

Paint and Assembly<br />

<strong>Systems</strong> division<br />

Measuring and Process<br />

<strong>Systems</strong> division<br />

Our new Group structure with two divisions (for details, see<br />

p. 51) has been in effect since March 1, 2005. We have based<br />

this annual report on the old group structure. We are thus<br />

complying with International Financial Reporting Standards<br />

(IFRS), according to which the divisional structure in effect<br />

in the year reported on must be presented in the annual<br />

financial statements.<br />

Continuing operations<br />

Discontinued operations

<strong>Technologies</strong> <strong>·</strong> <strong>Systems</strong> <strong>·</strong> <strong>Solutions</strong><br />

The <strong>Dürr</strong> Group is one of the world’s leading suppliers of production<br />

systems and of modules as well as components for measuring and<br />

process systems. Our focus is on the automotive and aviation industries<br />

as well as the mining and basic materials industries.<br />

We offer innovative, environmentally friendly solutions that contribute<br />

decisively to lower costs, higher quality, and greater flexibility in<br />

manufacturing and processing operations. We thus help make our<br />

customers more competitive.<br />

Motivated, customer-oriented employees, global presence, and a strong<br />

culture of innovation are our main value drivers. On this basis, we<br />

intend to substantially increase our company’s earning power and value.<br />

1

66<br />

59<br />

Cost situation<br />

improved by<br />

“Paint <strong>Systems</strong> lowered production costs across<br />

all painting technology products by another 6%<br />

on average in 2004.”<br />

Added value for our customers<br />

“Our innovation management aspires to develop solutions that offer<br />

customers added value, whether in the form of greater flexibility,<br />

higher quality, and better environmental compatibility or greater<br />

efficiency in production.”

Contents<br />

4 Letter from the Chairman of the Board of Management<br />

7 Board of Management of <strong>Dürr</strong> AG<br />

8 Report of the Supervisory Board<br />

12 <strong>Dürr</strong> on the capital market<br />

Reports from the business units<br />

18 Paint <strong>Systems</strong><br />

24 Final Assembly <strong>Systems</strong><br />

30 Ecoclean<br />

36 Measuring <strong>Systems</strong><br />

42 Discontinued operations<br />

48 2004 at a glance<br />

Consolidated management report<br />

50 Economic environment<br />

51 Organization and strategy<br />

53<br />

59<br />

Business developments<br />

61 Financial position<br />

65 Squeeze-out<br />

Consolidated financial statements<br />

75 Independent auditors’ report<br />

76 Consolidated income statements<br />

77 Consolidated balance sheets<br />

78 Consolidated statements<br />

of equity<br />

79 Consolidated statements<br />

of cash flows<br />

66 Research and development<br />

67 Purchasing management<br />

67 Employees<br />

69 Risk management<br />

71 Events subsequent to the<br />

reporting date<br />

72 Outlook<br />

80 Notes to the consolidated<br />

financial statements<br />

134 <strong>Dürr</strong> worldwide<br />

136 Glossary

Letter from the Chairman<br />

of the Board of Management<br />

Stephan Rojahn<br />

Ladies and gentlemen,<br />

The <strong>Dürr</strong> Group achieved earnings before taxes of € 11.8 million in 2004. With this<br />

improvement of about € 18 million compared with the previous year, we managed to<br />

make the turnaround that we sought, but did not meet our substantially higher earnings<br />

target, which would have supported a dividend payout. The critical factor involved<br />

was that we had to absorb unscheduled expenditures that arose from the handling of<br />

particular orders in the Final Assembly <strong>Systems</strong> and Ecoclean business units.<br />

We nevertheless made further progress in the reorientation of the company. The<br />

earnings enhancement program enabled us to improve our cost position<br />

again. We also advanced the integration of the Group by means of the successful<br />

squeeze-out of minority shareholders at Carl Schenck AG. Finally, the corporate bond<br />

placed in July 2004 and a new syndicated loan have put our financing on a long-term<br />

foundation.<br />

More efficiency with a lean Group structure<br />

To increase our competitiveness and earning power, we have introduced a more<br />

streamlined and strongly customer-oriented corporate structure as of March 1, 2005. It<br />

enables us to accelerate and improve processes within the Group and simultaneously<br />

increase our market muscle. Our activities are now bundled in two divisions: Paint<br />

and Assembly <strong>Systems</strong>, which represents the systems and plant engineering business<br />

particularly with the automotive industry, and Measuring and Process <strong>Systems</strong>,<br />

which comprises our activities in mechanical engineering with the Schenck and <strong>Dürr</strong><br />

Ecoclean brands.<br />

In a second step, we are parting with business areas that are outside our core portfolio.<br />

We will put the Development Test <strong>Systems</strong> product line, which supplies high-end testing<br />

technology for vehicle development, into a minority shareholding or sell it. For the<br />

Services business unit, represented by the Premier Group, we have already found

Letter from the Chairman of the Board of Management<br />

a buyer, the Voith Group. Ultimately, the synergies that were expected in 1999, at the<br />

time this business area was acquired, have not been realizable. It has emerged that,<br />

as a rule, our customers award contracts for production plants and for manufacturing<br />

support services separately. Also, truly large pay-on-production models, for which<br />

we had equipped ourselves with the Services unit, have not become established in<br />

the automotive industry.<br />

Concentration on strengths<br />

With the new Group structure, we are concentrating fully on our strengths in plant<br />

and mechanical engineering. By combining and selling firms, we are reducing the<br />

number of our individual companies by about one-third. That will promote a cohesive<br />

and clear-cut market presence and enable us to provide even more intensive customer<br />

service. The leaner and more efficient organization will lead to annual savings<br />

of about € 10 million beginning next year.<br />

Expansion of high-margin business areas<br />

Targeted expansion of fast-growing, high-margin business areas in the general<br />

industrial sector, outside automotive engineering, is another strategic element of our<br />

reorientation. The Schenck Group plays an important role in this connection as a<br />

leading globaly supplier of sectors such as the mining and basic materials industries<br />

and mechanical engineering. For example, with process technology solutions for the<br />

mining industry, Schenck is benefiting from the rising demand for raw materials and<br />

energy and is utilizing continuing market opportunities in major economic regions<br />

like China and North America. We will also continue to grow profitably in the aircraft<br />

industry, whether in balancing technology or with assembly and painting systems<br />

such as those we recently supplied for the Airbus A380.<br />

Our target for the current year is to achieve about 20% of Group sales in general industrial<br />

business. Nevertheless, the automotive sector is and will remain our principal<br />

market. The <strong>Dürr</strong> and Schenck brands have been standing for innovativeness, proximity<br />

to customers, and reliability there for decades. We will also expand our leading<br />

positions in business with this sector in the future, despite high competitive pressure.<br />

We are strategically well equipped for that thanks to the new Group structure, expansion<br />

of our capacities in Eastern Europe and Asia, and strengthening of our business<br />

with automobile component suppliers. We are systematically supplementing our<br />

range of products with simpler and more cost-cutting solutions to improve our competitive<br />

position for bids and tenders where price is the critical factor. We are furthermore<br />

supporting our customers in such urgent endeavors as improving quality, reducing<br />

production costs, and complying with environmental standards. Consumption<br />

of paint and energy, as well as wage costs, can be reduced considerably, for example,<br />

by retrofitting and modernizing existing plants.<br />

Competitiveness improved by<br />

The earnings enhancement program continues to be an important element in<br />

improving our performance. It has enabled us to save a total of about € 105 million in<br />

the years 2003 and 2004. By the end of 2005, the savings will reach about € 170 million.<br />

The cost reductions are of enormous importance for securing our competitiveness<br />

in a tough price environment.<br />

5

6<br />

Avoidance or better control of risks is one of the essential goals that we are pursuing<br />

with . Following the motto of “total risk management,” we are supplementing<br />

our existing processes with further tools, for example, in the technical approval<br />

process for projects and in project controlling. We are thus improving observance of<br />

cost targets associated with order handling.<br />

The measures taken to improve our profitability and competitive power are accompanied<br />

by our consistent pursuit of innovation. We again invested about 6% of our sales<br />

in new products and technologies in 2004, including development expenditures in the<br />

framework of customer projects. Information about the most important innovations<br />

may be found in the reports from the business units and in the management report.<br />

The Board of Management and the Supervisory Board have decided to propose to the<br />

annual shareholders’ meeting that no dividend be paid for 2004. Instead, we intend<br />

to use <strong>Dürr</strong> AG’s unappropriated profit to strengthen the Group’s equity base.<br />

Outlook<br />

In view of excess capacities and restrained capital spending in the automotive industry,<br />

the market is not going to make it easy for us this year. We are nevertheless striving<br />

to improve our margin by reducing costs further, and in continuing operations we are<br />

planning better figures for earnings before taxes and EBITDA than in 2004. On the<br />

other hand, sale will probably not reach the level achieved in 2004.<br />

On behalf of my colleagues and myself, I wish to thank all our employees for the great<br />

work they did in the past year. We are also grateful to our customers and business<br />

associates for their good cooperation and to our shareholders and investors for their<br />

confidence in us.<br />

Stuttgart, April 2005<br />

Stephan Rojahn<br />

Chairman of the Board of Management

Board of Management of <strong>Dürr</strong> AG<br />

Stephan Rojahn (56),<br />

Chairman<br />

Paint and Assembly <strong>Systems</strong><br />

, Corporate Communications<br />

& Investor Relations, Internal Audit,<br />

Corporate Senior Executives<br />

Martin Hollenhorst (46)<br />

(since April 20, 2005)<br />

Finance/Tax,<br />

Controlling,<br />

Legal/Insurance,<br />

Human Resources<br />

Kay Bönisch (44)<br />

(until April 20, 2005)<br />

Finance/Tax,<br />

Controlling,<br />

Legal/Insurance,<br />

Human Resources<br />

Ralf Dieter (44)<br />

(since January 1, 2005)<br />

Measuring and Process <strong>Systems</strong><br />

R&D, Information Technology<br />

Dr. Norbert Klapper (42)<br />

(until September 30, 2005)<br />

Sales & Marketing<br />

Paint and Assembly <strong>Systems</strong><br />

Quality Management, Patents,<br />

Sales & Marketing

Report of the Supervisory Board<br />

Dr.-Ing. E. h. Heinz <strong>Dürr</strong><br />

In 2004, the Supervisory Board performed the duties assigned to it by law and the<br />

articles of incorporation. It advised the Board of Management, and regularly and diligently<br />

monitored that body’s management of the company. The Supervisory Board<br />

was involved in all decisions of fundamental importance for the <strong>Dürr</strong> Group. The Board<br />

of Management informed the Supervisory Board in a timely and comprehensive<br />

manner about the economic situation and development of the company, about company<br />

planning, including financial, investment and personnel planning, and about<br />

transactions requiring Supervisory Board consent, substantial business occurrences,<br />

and risk management. The Supervisory Board adopted its resolutions after thorough<br />

review on the basis of detailed written and oral reports.<br />

The Supervisory Board came together at five regular meetings in 2004. No member<br />

of the Supervisory Board attended less than three meetings. Also outside the meetings,<br />

the Chairman of the Supervisory Board maintained close contact with the Board<br />

of Management and obtained timely reports on current developments and important<br />

events, primarily from the Chairman of the Board of Management. He furthermore<br />

discussed the company’s business policy, strategic orientation, and financial situation<br />

with the Chairman of the Board of Management and reported the results of these<br />

discussions to the entire Supervisory Board, either immediately or at its next meeting.<br />

The Supervisory Board formed three committees to prepare resolutions and issues to<br />

be dealt with in the full session. The Personnel Committee met three times in fiscal<br />

2004, while the Mediation Committee did not convene. The Audit Committee met on<br />

April 18, 2005, to discuss the 2004 financial statements.<br />

Harald Rüber joined the Supervisory Board as representative of the executive<br />

employees as of January 1, 2004. He succeeded Peter Krüger, who vacated his seat<br />

for reasons of age effective at the end of December 31, 2003. Dr. Heinz-Gerd Stein,<br />

representative of our shareholders, left the Supervisory Board effective at the end of<br />

the 15th ordinary annual shareholders’ meeting. The annual shareholders’ meeting<br />

elected Dr. Hans Michael Schmidt-Dencker to replace him. The Supervisory Board<br />

thanks Mr. Krüger and Dr. Stein for their constructive cooperation and dedicated<br />

efforts on behalf of the company.

Report of the Supervisory Board<br />

The Board of Management and the Supervisory Board regularly discussed the orders,<br />

sales, and earnings situation as well as the financial position of the Group and the<br />

individual divisions. Among the main topics of the deliberations were debt reduction<br />

and the need to improve profitability. In that connection, the Supervisory Board<br />

regularly obtained comprehensive information on the status of the earnings<br />

enhancement program and discussed important individual measures of the program<br />

with the Board of Management.<br />

After being informed in detail by the Board of Management, the Supervisory Board<br />

consented to the issuance of a corporate bond and negotiation of a new syndicated<br />

loan. Both transactions ensure <strong>Dürr</strong>’s long-term financing. To enable streamlining of the<br />

Group’s organization, the Supervisory Board approved the initiation of a squeezeout<br />

process at Carl Schenck AG and a cash settlement of € 157 per share for Schenck’s<br />

minority shareholders.<br />

At its meeting on December 17, 2004, the Supervisory Board appointed Ralf Dieter<br />

as a regular member of <strong>Dürr</strong> AG’s Board of Management effective January 1, 2005.<br />

Under the new rules of procedure for the Board of Management approved by the<br />

Supervisory Board, Mr. Dieter has assumed responsibility for the Measuring and<br />

Process <strong>Systems</strong> division. The Chairman of the Board of Management, Mr. Stephan<br />

Rojahn, has taken over management of the Paint and Assembly <strong>Systems</strong> division.<br />

Dr. Reinhold Grau, who joined the Board of Management in 2001, left the company at<br />

his own request at the end of October 2004. The Supervisory Board wishes to thank<br />

Dr. Grau for years of dedicated service that contributed substantially to the <strong>Dürr</strong> Group’s<br />

evolution.<br />

At the meeting on April 20, 2005, Martin Hollenhorst was named a regular member of<br />

<strong>Dürr</strong> AG’s Board of Management effective immediately. Mr. Hollenhorst assumes<br />

responsibility for the areas Finance/Tax, Controlling, and Law/Insurance as well as<br />

Human Resources, Organization, and Risk Management. He succeeds Kay Bönisch,<br />

who is leaving <strong>Dürr</strong> by mutual agreement. The Supervisory Board thanks Mr. Bönisch<br />

for his great personal dedication.<br />

In December 2004, the Board of Management and the Supervisory Board jointly issued<br />

an updated declaration of compliance – pursuant to Sec. 161 of the German Stock<br />

Corporation Law – to the effect that <strong>Dürr</strong> is largely following the recommendations of<br />

the Government Commission German Corporate Governance Code. Please refer to<br />

pages 15 to 17 for details concerning corporate governance at <strong>Dürr</strong> AG.<br />

The Board of Management reported regularly and in a timely manner to the Supervisory<br />

Board about existing risks. The Supervisory Board advised the Board of<br />

Management regarding the expansion of risk control and monitoring systems.<br />

The annual financial statements and management report prepared by the Board of<br />

Management as of December 31, 2004, together with the consolidated financial<br />

statements and consolidated management report of <strong>Dürr</strong> AG, were examined by the<br />

auditors engaged by the Supervisory Board after their appointment by the annual<br />

shareholders’ meeting. The auditor issued an unqualified auditor’s report. The annual<br />

financial statements and consolidated financial statements, the management report<br />

and consolidated management report, the proposal for the use of unappropriated profit<br />

of <strong>Dürr</strong> AG, and the auditors’ reports concerning the auditing of the annual financial<br />

statements and of the consolidated financial statements were submitted to all mem-<br />

9

10<br />

bers of the Supervisory Board in good time before the meeting held to approve the<br />

financial statements, and were discussed in detail with the Board of Management at<br />

that meeting of the Supervisory Board on April 20, 2005. The auditors signing the<br />

audit reports for the annual financial statements and the consolidated financial statements<br />

of <strong>Dürr</strong> AG also participated in that meeting with regard to the relevant points<br />

on the agenda, and reported concerning their audit. The Supervisory Board took<br />

approving note of the audit result.<br />

The Supervisory Board examined the annual financial statements, the consolidated<br />

financial statements, the management report and the consolidated management<br />

report. This examination by the Supervisory Board revealed no cause for objection.<br />

The Supervisory Board concurs with the assessment of the economic situation and<br />

future development of the Group as presented in the consolidated management report.<br />

The Supervisory Board approves the annual financial statements prepared by the<br />

Board of Management, which are hereby ratified. The Supervisory Board approves<br />

the Board of Management’s proposal for the use of the unappropriated profit of<br />

<strong>Dürr</strong> AG. The Supervisory Board also approves the consolidated financial statements.<br />

The Supervisory Board has examined the report prepared by the Board of Management<br />

pursuant to Sec. 312 of the German Stock Corporation Law concerning relationships<br />

with associated enterprises for the period from January 1 to December 31, 2004<br />

(dependent company report). The dependent company report was also examined<br />

by the auditors appointed by the annual shareholders’ meeting and has been affixed<br />

with the following unqualified auditor’s report pursuant to Sec. 313 (3) of the German<br />

Stock Corporation Law:<br />

“After examination and assessment in accordance with our professional duties,<br />

we confirm that:<br />

1. the factual information given in the report is correct,<br />

2. the performance rendered by the company in connection with the transactions<br />

mentioned in the report was not unduly high,<br />

3. regarding the measures mentioned in the report, no circumstances argue in favor<br />

of a materially different judgment than that made by the Board of Management.”<br />

The examination of the dependent company report by the Supervisory Board revealed<br />

no cause for objection. The Supervisory Board concurs with the results of the examination<br />

of the dependent company report by the auditors. According to the final results<br />

of the examination by the Supervisory Board, there are no objections to be raised<br />

against the declaration by the Board of Management at the end of the dependent<br />

company report.<br />

The Supervisory Board thanks the Board of Management, all members of staff, and<br />

their representatives for their dedication in the past fiscal year, as well as the shareholders<br />

for the confidence they have placed in the company.<br />

Stuttgart, April 20, 2005<br />

The Chairman<br />

Dr.-Ing. E. h. Heinz <strong>Dürr</strong>

Report of the Supervisory Board<br />

Members of the Supervisory Board<br />

Dr.-Ing. E. h. Heinz <strong>Dürr</strong> 1<br />

Entrepreneur, Berlin<br />

Chairman<br />

1, 3<br />

Peter Weingart<br />

Chairman of the Group Works<br />

Council of <strong>Dürr</strong> AG, Stuttgart<br />

Deputy Chairman<br />

1, 2<br />

Prof. Dr. Norbert Loos<br />

Managing Partner of Loos<br />

Beteiligungs-GmbH, Stuttgart<br />

Deputy Chairman<br />

Lieselotte Dedek-Fried2, 3<br />

Member of the Works Council of<br />

Schenck RoTec GmbH, Darmstadt<br />

2, 3<br />

Benno Eberl<br />

Trade Union Secretary of IG Metall<br />

administrative offices, Stuttgart<br />

Prof. Dipl.-Ing. Jörg Menno Harms<br />

Managing Director of<br />

Menno Harms GmbH, Stuttgart<br />

Until October 31, 2004 Chairman of<br />

the Managing Board of Hewlett-<br />

Packard GmbH and Hewlett-Packard<br />

Holding GmbH, Böblingen<br />

Dr.Tessen von Heydebreck<br />

Member of the Board of Management<br />

of Deutsche Bank AG, Frankfurt am<br />

Main<br />

1 Member of the Mediation Committee and Personnel Committee<br />

2 Member of the Audit Committee<br />

3 Representative of the employees<br />

4 Application has been filed for court appointment of a successor.<br />

Werner Kramp3 Chairman of the Works Council of<br />

Schenck Final Assembly Products<br />

GmbH, Püttlingen<br />

Günter Lorenz1, 3<br />

Principal Authorized Representative<br />

of IG Metall administrative offices,<br />

Darmstadt<br />

3, 4<br />

Harald Rüber<br />

(until February 28, 2005)<br />

President of <strong>Dürr</strong> <strong>Systems</strong> GmbH,<br />

Stuttgart<br />

Until February 28, 2005 Head of<br />

Project Development at <strong>Dürr</strong> <strong>Systems</strong><br />

GmbH, Stuttgart<br />

Joachim Schielke2 Member of the Board of Management<br />

of Landesbank Baden-Württemberg,<br />

Stuttgart<br />

Chairman of the Board of Management<br />

of Baden-Württembergische Bank AG,<br />

Stuttgart<br />

Dr. Hans Michael Schmidt-Dencker<br />

(since June 9, 2004)<br />

Spokesman for the Managing Board<br />

of BWK GmbH Unternehmensbeteiligungsgesellschaft,<br />

Stuttgart<br />

Dr. Heinz-Gerd Stein2 (until June 9, 2004)<br />

Business consultant, Duisburg<br />

11

<strong>Dürr</strong> on the capital market<br />

Financing secured for the long term<br />

Corporate bond successfully placed<br />

Circle of investors and analysts widened by bond issue<br />

After a variable year in 2003, development on the stock markets was comparatively<br />

calm in 2004. The DAX index registered a plus of 7%. The MDAX and SDAX sideline<br />

indexes each gained about 16% last year. Many smaller stocks managed to make up<br />

their reduction in stock valuation compared with large-cap blue chips. Among the<br />

important reference indexes, only the TecDAX finished the year down, with a minus<br />

of 4%. The bond markets developed positively in the course of the year. With continuing<br />

low interest rates and low inflation expectations, yields on 10-year government<br />

bonds declined from about 4.3% to about 3.5% at the end of 2004.<br />

<strong>Dürr</strong> stock began last year quoting at € 19.39 on the XETRA electronic exchange.<br />

Its price steadily advanced until mid-year and reached its high for the year in June at<br />

€ 21.10. The stock then declined significantly in the subsequent weeks, parallel to<br />

the comparison indexes. At the end of October, it reached the year’s low at € 14.50.<br />

After revising our earnings forecast at the beginning of November, the stock moved<br />

largely sideways with slight fluctuations. Trading of <strong>Dürr</strong> stock closed the year at<br />

€ 15.11, which meant a price decline of 22% for 2004 as a whole.<br />

<strong>Dürr</strong> stock is listed in Deutsche Börse’s Prime Standard segment and is traded on<br />

all German stock exchanges. Since March 2003, <strong>Dürr</strong> has been represented in the<br />

SDAX, the index that comprises the top 50 German small caps as measured by the

Bond<br />

ISIN (Reg S): XS0195957658<br />

ISIN (144a): XS0195957815<br />

ISIN DE0005565204<br />

Reuters symbol DUEG<br />

Bloomberg code DUE GY<br />

120<br />

110<br />

100<br />

90<br />

80<br />

<strong>Dürr</strong> on the capital market<br />

trading volume and market capitalization of free float. A designated sponsor, who<br />

regularly makes prices in our stock, ensures that it has adequate liquidity at all times<br />

in trading.<br />

2004: Debut on the bond market<br />

13<br />

We put our financing on a new foundation and restructured the liabilities side of our<br />

balance sheet in 2004. The aim was to reduce short-term debt and convert it into longterm<br />

financial liabilities. A corporate bond in the nominal amount of € 200 million<br />

and a syndicated loan in the amount of € 400 million now provide long-term financing<br />

security and greater financial leeway to develop the operating business. The fixedinterest<br />

bond matures in 2011 and has a coupon of 9.75%.<br />

With the two interconnected transactions, we have settled our short-term liabilities<br />

to banks to a very large extent and have diversified our financing structure. At the<br />

same time, we have attracted a new group of investors, primarily in the institutional<br />

segment. The corporate bond is subordinated to the syndicated loan. In that respect,<br />

it explains, among other things, the higher interest rate on the bond compared with<br />

a bank loan.<br />

Our bond started trading at a price of 96.40 at the beginning of July 2004 and rose<br />

until September 20 to 107.10. After the price declined to a level of just over 100 by<br />

mid-October, it advanced again and reached the year’s high at 108.60 on December<br />

16. At year’s end, the price was little changed at 108.20. The bond quoted at 101.91<br />

on March 31, 2005.<br />

<strong>Dürr</strong> stock price development in the XETRA from January to December 2004<br />

compared with development of the DAX, MDAX, SDAX, and Prime Industrial Index (indexed values)<br />

in %<br />

J F M A M J J A S O N D<br />

<strong>Dürr</strong> stock in the XETRA DAX MDAX SDAX Prime Industrial Index

14<br />

Key figures for <strong>Dürr</strong> stock<br />

2004 2003<br />

Earnings per share in € 0.40 –2.14<br />

Cash flow per share in € 2.82 0.06<br />

1<br />

Dividend per share in € – –<br />

Price-earnings ratio 2 37.8 –<br />

Price-cash flow ratio 2 5.4 321.7<br />

High in € 21.10 19.30<br />

Low in € 14.50 13.15<br />

Close in € 15.11 19.30<br />

Market capitalization 2 in €m 216 276<br />

Number of shares in k 14,298 14,298<br />

1 Dividend proposed to the annual shareholders’ meeting<br />

2 Based on the closing price at year’s end<br />

Before placing the bond, <strong>Dürr</strong> was reviewed by rating agencies Standard & Poor’s<br />

(S&P) and Moody’s. We received a credit rating of “BB–” from S&P and “Ba3” from<br />

Moody’s. The bond was rated “B” and “B2” by the respective agencies. The outlook<br />

for all first ratings was stable.<br />

In mid-March 2005, S&P downgraded <strong>Dürr</strong> AG’s previous credit rating from “BB–” to<br />

“B+.” The credit rating’s outlook is stable. In explaining its decision, the rating agency<br />

cited the earnings performance in 2004 and the currently difficult environment in the<br />

automotive industry. S&P also compared <strong>Dürr</strong> with companies in the same rating and<br />

business sector categories. The issue rating of the corporate bond has been lowered<br />

by S&P from “B” to “B–.” The outlook is stable.<br />

The Board of Management and the Supervisory Board have decided to propose to<br />

the annual shareholders’ meeting that no dividend be paid for 2004. Instead, <strong>Dürr</strong> AG’s<br />

unappropriated profit is to be used to strengthen the Group’s equity base.<br />

Shareholder structure<br />

15.0%<br />

5.6%<br />

7.0%<br />

11.0%<br />

<strong>Dürr</strong> AG has 29.4% free float.<br />

9.9%<br />

47.0%<br />

4.5%<br />

Heinz <strong>Dürr</strong> GmbH<br />

Heinz und Heide <strong>Dürr</strong>-Stiftung GmbH<br />

Süd-Kapitalbeteiligungs-Gesellschaft mbH<br />

BWK GmbH Unternehmensbeteiligungsgesellschaft<br />

Kreissparkasse Biberach<br />

Institutional investors<br />

Private investors<br />

According to the latest data available to the company, March 2005

<strong>Dürr</strong> on the capital market<br />

15<br />

With efficiency gains from the ongoing earnings enhancement program and<br />

increased market muscle from the new corporate structure implemented at the beginning<br />

of March 2005, the Board of Management not only intends to improve the rating<br />

as soon as possible, but also to increase earning power, to reduce financial liabilities<br />

and furthermore to pay a dividend again.<br />

Intensive capital market communication<br />

Our entry into the corporate bond market has significantly widened the circle of<br />

investors and analysts with whom we communicate. In 2004, 17 banks and analyst<br />

firms wrote a total of 63 analyses and flash reports about <strong>Dürr</strong>, 20 analyses more<br />

than in the previous year. <strong>Dürr</strong> AG thus attracted far more attention in the financial<br />

community.<br />

The central concern of <strong>Dürr</strong>’s communication policy is to inform all shareholders about<br />

developments in the company in a way that is as transparent, timely, and regular as<br />

possible. The Board of Management has presented the company, its strategy, and the<br />

business trend at investor conferences and road shows in Europe and the United<br />

States. Furthermore, we have also assisted many private investors extensively with<br />

information – by telephone, on the internet (www.durr.com), and with regular reports<br />

and investor fact books.<br />

We have invited members of the financial community to analyst meetings and conference<br />

calls upon the release of new business figures and other important events.<br />

The response to the <strong>Dürr</strong> Capital Markets Day, which was held for the third consecutive<br />

year, was very positive. The management invited analysts, bank representatives, and<br />

investors to Carl Schenck AG’s Darmstadt facility in October to talk with the Board of<br />

Management and experience <strong>Dürr</strong>’s measuring technology business on site.<br />

<strong>Dürr</strong> complies with the German Corporate Governance Code<br />

<strong>Dürr</strong> sees the German Corporate Governance Code as an important guide for transparent<br />

and responsible corporate management and control. We firmly believe that<br />

the initiative will contribute to better protecting shareholder rights and boosting confidence<br />

in German companies, both in their home market and abroad.<br />

According to Sec. 161 of the German Stock Corporation Law, the board of management<br />

and the supervisory board of a listed stock corporation are obliged to declare<br />

once every year that the recommendations of the Government Commission German<br />

Corporate Governance Code were and are being complied with, or which recommendations<br />

were or are not being applied. <strong>Dürr</strong> AG fulfills most of the mandatory provisions<br />

of the code, while planning on implementing further provisions. The deviations<br />

from the code are specified below with the corresponding reasons.

16<br />

In accordance with Sec. 161 of the German Stock Corporation Law, the Board of<br />

Management and the Supervisory Board of <strong>Dürr</strong> AG declare:<br />

“<strong>Dürr</strong> AG complies with the recommendations of the Government Commission<br />

German Corporate Governance Code with the following exceptions:<br />

Item 3.8, Paragraph 2<br />

If the company takes out a D&O (directors and officers’ liability insurance) policy<br />

for the Management Board and Supervisory Board, a suitable deductible shall<br />

be agreed.<br />

A D&O insurance policy with no deductibles exists for the members of the Board<br />

of Management and the Supervisory Board. This is a group insurance policy for<br />

executives at home and abroad, although a differentiation between members of<br />

the executive body and employees does not appear appropriate. In addition, a<br />

deductible is not usual abroad and would therefore make it difficult to recruit executives<br />

from abroad.<br />

Item 4.2.4<br />

Compensation of the members of the Management Board shall be reported in the<br />

Notes of the Consolidated Financial Statements subdivided according to fixed,<br />

performance-related and long-term incentive components. The figures should be<br />

individualized.<br />

We report the sum of salaries of the members of our Board of Management in the<br />

Notes to our consolidated financial statements. In our view a special, individualized<br />

item broken down into fixed salary and success-related components would not<br />

provide any additional benefit for the shareholders. Moreover, individualized reporting<br />

brings with it the risk of leveling out performance and task-related differences<br />

in compensation.<br />

Item 5.4.1, Sentence 2<br />

Furthermore, ... an age limit to be specified for the members of its Supervisory<br />

Board shall be taken into account<br />

<strong>Dürr</strong> sees no necessity for defining an age limit for members of its Supervisory<br />

Board.<br />

Item 5.4.5, Paragraph 1, Sentence 3<br />

Also to be considered [for specifying the compensation of the members of the<br />

Supervisory Board] ... shall be … the chair and memberships in committees.<br />

Because of the success-related compensation of the members of our Supervisory<br />

Board there is no separate remuneration for the chair or for membership in<br />

committees.<br />

Item 5.4.5, Paragraph 3<br />

The compensation of the members of the Supervisory Board should be reported<br />

in the Notes of the Consolidated Financial Statements individualized, subdivided<br />

according to components. Also payments made by the enterprise to the members<br />

of the Supervisory Board or advantages extended for services provided individually,<br />

in particular, advisory or agency services shall be listed separately in the<br />

Notes to the Consolidated Financial Statements.

<strong>Dürr</strong> on the capital market<br />

We report the sum of compensation of the members of our Supervisory Board<br />

in the Notes to our consolidated financial statements. In our view a special,<br />

individualized by components would not provide any additional benefit for the<br />

shareholders.<br />

17<br />

The possibility of obtaining the expertise of individual members of our Supervisory<br />

Board for special topics at any time represents a special advantage for <strong>Dürr</strong>.<br />

Cooperation is based on the conditions that are usual in the industry, which are<br />

also maintained in comparable transactions with third parties. Hence, we see no<br />

necessity for individualized publication.<br />

Item 7.1.2, Sentence 2<br />

The Consolidated Financial Statements shall be publicly accessible within 90 days<br />

of the end of the financial year…<br />

We cannot yet make the Consolidated Financial Statements for 2004 publicly<br />

accessible within 90 days of the end of the financial year. However, this is planned<br />

for the Consolidated Financial Statements for 2005. The Consolidated Financial<br />

Statements for 2004 will be published within four months of the end of the financial<br />

year.<br />

Item 7.1.4, Sentences 1 and 3<br />

The company shall publish a list of third party companies in which it has a shareholding<br />

that is not of minor importance for the enterprise. … The following shall<br />

be provided: name and headquarters of the company, the amount of the shareholding,<br />

the amount of equity, and the operating result of the past financial year.<br />

We publish a list of the significant third party companies, indicating the company’s<br />

headquarters. We do not make public additional information for reasons relating<br />

to competition.”

Paint <strong>Systems</strong><br />

When it comes to automotive painting, the name <strong>Dürr</strong> stands for quality, top technology,<br />

efficiency, and environmental compatibility worldwide. We can set up turnkey paint shops<br />

for our customers anywhere in the world, whether in Europe, the Americas, or the grow-<br />

ing markets of Asia. Our innovative power, proximity to customers, reliability, and many<br />

years of experience in executing large-scale projects have made us the market and tech-<br />

nology leader. Effective March 1, 2005, the Paint <strong>Systems</strong> business unit belongs to the new<br />

Paint and Assembly <strong>Systems</strong> division.

Application of powder paint base<br />

coat: The EcoBell 2 Powder highrotation<br />

atomizer is used to spray the<br />

paint powder on the car body surface.<br />

The EcoBell 2 Powder can operate at<br />

speeds of up to 15,000 rpm ensuring<br />

uniform distribution of the paint on<br />

the surface.<br />

Paint <strong>Systems</strong> business unit<br />

Good business development in<br />

a tough market environment<br />

EBT margin improved<br />

Success with powder painting systems<br />

Computational Fluid Dynamics simulation developed further<br />

Amounts in €m<br />

2004 2003 Change<br />

Total incoming orders 809.2 1,400.1 –42.2%<br />

Total sales 1,154.5 1,250.2 –7.7%<br />

EBITDA 39.6 41.3 –4.1%<br />

EBT 28.3 29.3 –3.4%<br />

Employees at year’s end 2,690 2,808 –4.2%<br />

21<br />

Fiscal 2004 went well for Paint <strong>Systems</strong> despite declining capital spending in the automotive<br />

industry. Based on earnings before taxes, our return on sales increased from<br />

2.3% to 2.5%. As expected, incoming orders returned to their normal level, after having<br />

been far above average in 2003 due to a large order.<br />

Brisk demand in Asia<br />

We registered continuing strong demand in the growth markets of Asia. In China,<br />

we were able to consolidate our leading position with an order from the SGM joint<br />

venture for a turnkey paint shop. Business with the expanding Korean automotive<br />

industry also developed well. KIA Motors and its Russian licensee Izmash placed two<br />

orders together as a package. We are erecting a complete paint shop including the<br />

building at KIA’s new plant in ˇZilina, Slovakia, and we are converting Izmash’s paint<br />

shop in Izhevsk, Russia. In addition, we were able to acquire projects in newly emerging<br />

automotive markets like India and Iran. For example, we supplied a body pretreatment<br />

and dip-painting line for Iranian vehicle manufacturer Khodro.<br />

RoDip process well established<br />

Demand in North America was subdued. In Western Europe, our market volume<br />

declined temporarily following a strong trend in the automotive industry toward modernizing<br />

painting capacities for passenger vehicles that lasted through 2002. We won<br />

major contracts in the truck segment, including a package order from DaimlerChrysler<br />

for the construction of a paint shop in Ludwigsfelde and a top-coat application line<br />

in Düsseldorf, both in Germany. We will also be supplying extensive systems for the<br />

DaimlerChrysler plant in Wörth, Germany, including our innovative RoDip dippainting<br />

process, which will be used for priming truck cabs. In another marketing<br />

success for RoDip, Karmann became the first contract manufacturer to choose the

22<br />

Paint <strong>Systems</strong><br />

Product lines<br />

Paint <strong>Systems</strong> Automotive<br />

Complete automotive paint<br />

shops, including buildings,<br />

materials flow and process<br />

systems, and control and<br />

supervisory control systems<br />

Paint <strong>Systems</strong> Industrial<br />

Complete paint shops for automobile<br />

component suppliers<br />

and other industrial sectors<br />

Application Technology<br />

<strong>Systems</strong> for automated<br />

application of paint and highviscosity<br />

materials<br />

Environmental <strong>Systems</strong><br />

Exhaust-air purification<br />

systems for paint shops and<br />

other areas of industrial<br />

production<br />

process. Karmann’s decision is a tribute to RoDip’s flexibility since contract manufacturing<br />

generally involves production of smaller batches and frequent model changes.<br />

With a total of 27 systems sold to date, RoDip has become very well established<br />

since its market launch in 2001.<br />

Powder painting continues to gain ground<br />

We successfully completed several demanding projects in 2004, further cementing our<br />

position as market and technology leader. We started up several fully automated<br />

robotic painting lines for BMW in Regensburg and Leipzig, both in Germany. We supplied<br />

Ferrari with a complete paint shop in Maranello, Italy, for whose “high technological<br />

quality” the sports car maker has honored us with its President’s Award for top<br />

suppliers. A turnkey paint shop including the building went into operation at General<br />

Motors in Oshawa, Canada.<br />

All these paint shops use solvent-free powder paints, which shows that we took the<br />

right path when we decided some four years ago to develop a complete range of<br />

products for powder painting. In 2004, we continued on this path with several innovations,<br />

particularly in application and spray booth technology.<br />

Computational Fluid Dynamics (CFD) simulation brings product improvements<br />

Oven technology was a key area of our innovation work in 2004. We developed a<br />

process that allows more intensive chemical cross-linking of the surface when working<br />

with UV-cured paints, which increases scratch resistance. We also developed<br />

new areas of application for CFD simulation. For example, using computers we can<br />

now simulate the process with such precision that an increase in heat at any point<br />

on the vehicle body parts in the oven can be predicted and this means we no longer<br />

have to rely on laborious experiments. For cathodic dip-painting, we can now simulate<br />

paint deposition on the computer. The result is improved system design, which<br />

ensures a more even paint build-up on the body surface.<br />

We have also broken new ground in concepts for process flow in the painting process<br />

itself. In development collaboration with one of our customers, we tested a “wet-onwet”<br />

application process, in which the fresh paint is not dried, but merely passes through<br />

an intermediate flash-off area, before the next layer of paint is applied. This cuts energy<br />

consumption and speeds up the entire process.<br />

The future goals of our innovation management include further expanding our powder<br />

painting product range, refining our process and CFD simulations, and developing<br />

concepts for paint recycling and energy-saving operation of spray booths. Our focus<br />

in this connection is on reducing painting costs for our customers.<br />

Application Technology: Market leadership bolstered by new products<br />

We registered continued good business development in Application Technology<br />

despite the difficult situation in the automotive industry. Our leading position is based<br />

on fully automated solutions that give customers higher quality and environmental<br />

compatibility at a lower cost. An important pillar of our market success was once again<br />

the <strong>Dürr</strong> Ecopaint painting robot, of which we have sold around 500 units. The new<br />

EcoBell 2 generation of high-rotation atomizers for electrostatic paint application also

RoDip dip-painting process:<br />

In the dip tank, each car body is<br />

rotated one full turn around its<br />

own axis. This means excellent<br />

application of primer and ensures<br />

lasting corrosion protection.<br />

Paint <strong>Systems</strong> business unit<br />

23<br />

met with great response. We were even able to sell this product in Japan, a market<br />

that is very difficult for foreign suppliers to break into. We made other successful market<br />

launches with products for direct electrostatic charging of water-based paints and for<br />

sealing weld seams on vehicle bodies.<br />

Growing market potential among suppliers<br />

The trend toward outsourcing and modularization in vehicle production<br />

has parts and module suppliers doing more and more<br />

painting work. The Paint <strong>Systems</strong> Industrial product line, which is<br />

positioning itself in the market as a partner for sophisticated<br />

paint technology and turnkey systems, is benefiting from this<br />

trend. To best exploit the growing market volume, we improved<br />

our internal cooperation in 2004 and established centers of competence<br />

for various applications in France, Germany, and the<br />

United States. We also brought more products to market that are<br />

specifically geared toward the needs of suppliers in the automotive<br />

industry.<br />

We completed an important showcase project in Mexico, where<br />

we supplied a complete paint shop for truck beds. In Germany,<br />

we installed a system for painting vehicle roofs for the first time.<br />

Exhaust-air purification: Good business development, also in new markets<br />

The Environmental <strong>Systems</strong> product line registered good business development. A<br />

key contributor was the expansion of our activities in China. In addition to business<br />

with the automotive industry, we focused increasingly on the pharmaceutical, chemical,<br />

and printing industries, using our expertise to build systems precisely tailored to our<br />

customers’ needs on the basis of standardized modular products.

Final Assembly <strong>Systems</strong><br />

The Final Assembly <strong>Systems</strong> business unit plans and realizes intelligent solutions for<br />

the final stage of vehicle assembly – from individual solutions to complete plants.<br />

Automobile manufacturers can thus assemble variously equipped automobiles quickly,<br />

at low cost, and with high quality on one and the same line. We are the second-largest<br />

supplier in systems business involving complete assembly lines. We also intend to continue<br />

expanding the business in production technology for the aircraft industry. Effective<br />

March 1, 2005, the Final Assembly <strong>Systems</strong> business unit belongs to the new Paint and<br />

Assembly <strong>Systems</strong> division.

<strong>Dürr</strong> designs and supplies perfectly<br />

matched systems for vehicle final<br />

assembly. The range includes flexible<br />

conveyor systems designed to transport<br />

add-on components and bodies<br />

exactly in accordance with sequence<br />

timing requirements.<br />

Final Assembly <strong>Systems</strong> business unit<br />

Innovative solutions<br />

strengthen market position<br />

Large order received for final assembly plant in Slovakia<br />

New FAStplant factory concept<br />

Production technology supplied for Airbus A380<br />

Amounts in €m<br />

2004 2003 Change<br />

Total incoming orders 345.7 405.4 –14.7%<br />

Total sales 374.0 445.0 –16.0%<br />

EBITDA 6.0 11.3 –46.9%<br />

EBT 2.0 7.5 –73.3%<br />

Employees at year’s end 1,546 1,593 –3.0%<br />

27<br />

As a full-range supplier for the final stage of vehicle assembly, the Final Assembly<br />

<strong>Systems</strong> business unit, established at the beginning of 2002, has rapidly advanced to<br />

a top position. It is our goal to expand this business further.<br />

To lower its manufacturing costs, the automobile industry needs efficient assembly<br />

lines with flexible possibilities of use. We meet that need with the widest range of products<br />

in the competitive field. We can ourselves supply about 70% of the equipment<br />

needed for a final assembly facility – whether it is a matter of assembly, filling, testing,<br />

or conveyor technologies. Also, as a systems partner, we are able not only to supply<br />

individual equipment, but also to plan and realize complete turnkey assembly lines.<br />

New orders: Demand primarily for conversion and modernization<br />

A very large contract we won at the end of 2004 underscores that we are one of the<br />

top suppliers in systems business. For KIA’s new factory in ˇZilina, Slovakia, we are<br />

planning and realizing a complete final assembly facility worth more than € 40 million.<br />

This contract is a success for <strong>Dürr</strong> in two respects: It is another showcase project in<br />

final assembly technology and it is extraordinary proof of confidence after KIA had<br />

earlier awarded the Paint <strong>Systems</strong> business unit the contract for the construction of<br />

a paint shop in ˇZilina.<br />

In general, the automobile industry’s reluctance to invest in the past year led to<br />

noticeably fewer large orders for new final assembly plants throughout the sector.<br />

Instead, our customers awarded more projects for the conversion or modernization<br />

of existing facilities. We received the largest conversion order from Volkswagen<br />

in Mosel, Germany, where we are retooling the final assembly facility to the new<br />

Passat B6. This contract was largely the result of Volkswagen’s satisfaction with the<br />

earlier final assembly retooling we did at the same plant for the Golf A5.<br />

Among the most important operational startups were a complete assembly line in<br />

DaimlerChrysler’s plant in Tuscaloosa, Alabama (USA), conveyor systems and a<br />

marriage station for Land Rover in Solihull near Birmingham, Great Britain, and<br />

a renewed assembly line for the Ford Motor Company in Turkey.

28<br />

<strong>Dürr</strong> conveyor systems transport<br />

bodies through the various process<br />

stations in the body-in-white, paint<br />

and final assembly shops.<br />

The French auto manufacturer PSA Group placed an order for us to deliver the equipment<br />

for end-of-line vehicle adjustment and testing, including conveyor systems, in<br />

Trnava, Slovakia. Indian vehicle manufacturer Tata had us supply conveyor technology<br />

for the final stage of vehicle assembly, filling technology, and a marriage station for<br />

joining power trains and bodies. Both contracts show that we are in a position to<br />

complete demanding projects reliably and on time even in the emerging markets of<br />

the automotive industry.<br />

FAStplant: More functionality with simpler technology<br />

We are taking an entirely new path with our FAStplant factory concept for the highly<br />

flexible final stage of vehicle assembly. FAStplant uses pre-manufactured conveyor<br />

modules that can be placed freely in any shop, since they do not require ceiling suspension<br />

or foundation pits. The modules come with all of the interfaces needed for<br />

the integration of assembly and testing facilities. Since FAStplant is designed as a<br />

modular system, the main line of a final assembly facility can be set up within just a<br />

few days and can easily be modified or retooled, extended, divided, or shortened to<br />

suit new vehicle models. The marketing of our new factory concept is off to a promising<br />

start, as we have already built a test line for a German automobile manufacturer<br />

with convincing results.<br />

Combination products for final assembly<br />

We primarily use technically standardized modules that can be<br />

combined into customer-specific yet cost-effective package solutions.<br />

A current example of this is the combination of our marriage<br />

stations with the freely guidable FASmatic conveyor system.<br />

This solution allows more flexibility and greater availability when<br />

joining power trains and bodies – convincing advantages, as orders<br />

from Germany, China, and the United States demonstrate.<br />

In terms of filling technology, we are rounding off our range of<br />

products by offering more systems with a low level of automation,<br />

which are especially well suited for production sites in lowcost<br />

countries. We see strong sales potential for these systems,<br />

for example, on the Chinese market.<br />

Conveyor technology: MOVITRANS used throughout<br />

In conveyor technology, we were able to demonstrate our expertise<br />

in completing projects with tight schedules. We converted the<br />

complete conveyor system for the paint shop at Hyundai’s plant<br />

in Chennai, India, in just eight months. At the start of 2005, we finished<br />

the new conveyor system for the paint shop at Volkswagen’s<br />

plant in Bratislava, Slovakia, after just six months’ conversion time.<br />

Both projects presented a significant logistical challenge, since<br />

they had to be done under ongoing production.

Final Assembly <strong>Systems</strong><br />

Product lines<br />

Automation and Conveyor<br />

Techniques<br />

Turnkey final assembly plants<br />

Conveyor systems for body-inwhite,<br />

paint shop, and final<br />

assembly stages of automobile<br />

production<br />

Planning of final assembly<br />

plants and test centers<br />

for vehicle and component<br />

development<br />

Final Assembly Products<br />

Fitting and assembly equipment,<br />

filling systems, and<br />

testing technology for final<br />

vehicle inspection<br />

Final Assembly <strong>Systems</strong> business unit<br />

In product development, we focused on expanding the range of application for<br />

MOVITRANS, our system for contactless power and data transmission. In the coming<br />

months, we will adapt all our floor and overhead conveyors to MOVITRANS to distinguish<br />

ourselves technologically even more from the competition.<br />

29<br />

Production technology for aircraft construction<br />

We further expanded our activities in aircraft construction. For example, we delivered<br />

to the Airbus plant in Stade, Germany, a major part of the assembly line for the tail<br />

fin of the A380. At the Airbus plant in Broughton, Great Britain, we put into operation<br />

a paint shop for wings as well as a complete assembly line for wing components.<br />

<strong>Dürr</strong> technology is also being used to produce the new A400M, for which Airbus ordered<br />

a complete line for the production of the rudder units and assembly equipment for<br />

the production of the wing skins.<br />

Relocating parts of the value chain<br />

One way in which we are dealing with high cost pressure is to shift parts of the value<br />

chain to our Polish subsidiary <strong>Dürr</strong>pol. We have already finished setting up the design<br />

and assembly of skid conveyors there. We are preparing to transfer further steps in<br />

the value chain to Poland and are pursuing similar concepts for the North American<br />

and Asian markets.

Ecoclean<br />

<strong>Dürr</strong> Ecoclean stands out for high-tech workpiece cleaning systems. The most important<br />

area of use for these systems is engine and transmission manufacturing in the auto-<br />

motive industry. To ensure quality, it is essential that all components are absolutely clean<br />

prior to assembly, since even tiny amounts of residue can cause damage. Ecoclean is<br />

the world’s market and technological leader and the only provider that operates world-<br />

wide. Since March 1, 2005, Ecoclean operations have been a part of the new Measuring<br />

and Process <strong>Systems</strong> division.

Cylinder head cleaning: A highpressure<br />

lance, working with an<br />

operating pressure of approximately<br />

400 bar, removes residues of contamination<br />

originating from the manufacturing<br />

process. The lance is mounted<br />

on a robotic arm that makes sure the<br />

high pressure water jet is directed just<br />

where it is needed. Final cleaning<br />

is carried out with multi-nozzle spray<br />

systems.<br />

Ecoclean business unit<br />

Course set for<br />

earnings improvement<br />

Difficult market environment in Germany<br />

Earnings enhancement measures under way<br />

New cleaning systems for diesel fuel injection systems<br />

Amounts in €m<br />

2004 2003 Change<br />

Total incoming orders 183.6 176.9 3.8%<br />

Total sales 186.1 208.1 –10.6%<br />

EBITDA –2.0 9.4 –121.3%<br />

EBT –5.1 5.7 –189.5%<br />

Employees at year’s end 909 932 –2.5%<br />

For the Ecoclean business unit, 2004 was marked by very weak demand in the important<br />

German market, which we were only partly able to offset with an increase in<br />

business in the United States, where capital spending restraint in the automotive<br />

industry was slowly beginning to ease. A gratifying development came out of the<br />

newly tapped Chinese market, where we smoothly completed a showcase project<br />

involving 19 cleaning systems for an automotive joint venture through our local<br />

unit established there in 2003.<br />

33<br />

Earnings enhancement measures introduced without delay<br />

A difficult overall market environment, insufficient capacity utilization in Germany and<br />

Spain, and unscheduled expenditures in the Coolant Filtration product line resulted<br />

in considerable reductions in profit. In response, we immediately launched a series of<br />

short and medium-term measures as part of the JUMP restructuring program. These<br />

measures will increase our profitability and strengthen our market position, especially<br />

since some of our smaller competitors have been unable to withstand the price and<br />

cost pressures and have withdrawn from the market.<br />

We are cutting production costs by simplifying the concepts and designs of our cleaning<br />

systems without compromising on functionality and quality.<br />

To further utilize the potential of the international Ecoclean network, we are installing<br />

a process-oriented organization based on international centers of competence.<br />

The interfaces between sales, purchasing, design, and assembly are being optimized<br />

to accelerate product development and order processing times and to reduce costs<br />

and capital tie-up. Strengthening project management as a key overarching process is<br />

playing a vital role.

34<br />

Ecoclean<br />

Product lines<br />

Cleaning Automotive<br />

Cleaning technology used in<br />

the production of engine and<br />

transmission components<br />

by the automobile industry<br />

Cleaning Industrial<br />

Cleaning technology used in<br />

the production of small parts<br />

and components by automobile<br />

component suppliers<br />

and other industrial enterprises<br />

Coolant Filtration<br />

Coolant recycling systems<br />

Automation<br />

Automation systems<br />

for workpiece transport<br />

and handling<br />

In the medium term, we will pursue a global platform strategy for our products, which<br />

will allow us to use more common parts and reduce costs.<br />

We are also organizing our production activities more cost-effectively. For example,<br />

we have completely stopped production at our Spanish plant in Barcelona and relocated<br />

it to the Czech Republic. The reduction of manufacturing capacities in the United<br />

States that we completed in 2003 has already begun to pay off. When the North<br />

American market picked up, we benefited from our significantly reduced fixed costs.<br />

Innovations for diesel fuel injection systems<br />

The focus of our development work in 2004 was on cleaning systems for diesel fuel<br />

injection systems. Driven by the brisk demand for fuel-efficient diesel engines, the<br />

automotive industry is setting a fast pace for innovation in this area. Parallel to that,<br />

we are developing matching systems that are capable of cleaning even tiny bores –<br />

like those in common-rail injector nozzles – with utmost precision. Our most important<br />

innovation in this area is a cleaning system for a new type of diesel fuel injection<br />

pump, with which we won a leading automotive supplier’s design competition.<br />

As the technological leader, we were also called upon by a fellow automobile components<br />

supplier for the automotive industry. We delivered cleaning equipment for<br />

diesel fuel injection systems that use the so-called piezo technology. Instead of conventional<br />

solenoid valves, the nozzle openings in piezo systems are fitted with crystal<br />

layers that expand, and thus close the opening, when electrical voltage is applied.<br />

Piezo technology makes it possible to use extremely small nozzle openings, a special<br />

challenge for us as a cleaning technology supplier.<br />

Proving our systems expertise<br />

<strong>Dürr</strong> Ecoclean is the only provider to combine cleaning technology, coolant recycling,<br />

and automation technology under a single roof. This puts us in the position of<br />

being able to process complex systems orders for engine and transmission plants.<br />

For example, we were able in 2004 to provide a US automaker with cleaning and<br />

filtration systems for the production of a new engine model plus the conveyor systems<br />

linking the individual cleaning and production process centers. Another customer<br />

ordered automation and cleaning technology in a single package from Ecoclean for<br />

the first time for its engine and six-speed transmission manufacturing facilities in<br />

the United States and Great Britain. A major factor that won us the contract was our<br />

ability to complete large-scale international projects. This expertise sets us apart<br />

from the competition and secures us a strong position in the acquisition of orders for<br />

“common products” projects, in which automakers order identical production facilities<br />

for different plants to ensure a consistent standard of production quality.

<strong>Dürr</strong> Ecoclean systems ensure optimum<br />

cleaning results coupled with environmental<br />

compatibility.<br />

Ecoclean business unit<br />

Automation systems: Solid business development<br />

Business development was strong in automation systems in 2004, both in North<br />

America and in France, the product line’s primary European market. In France, we<br />

delivered a comprehensive package of cleaning and automation technology to an<br />

automotive joint venture for the production of a new diesel engine.<br />

Coolant Filtration: Unscheduled charge against earnings<br />

Coolant Filtration also benefited from the revival of the North American market.<br />

Activity in Europe, on the other hand, declined. In addition, unscheduled expenses<br />

associated with particular orders weighed heavily on results.<br />

35<br />

Suppliers market: New vacuum cleaning system unveiled<br />

The Cleaning Industrial product line, which delivers to automotive<br />

suppliers and machinery builders, benefited from the recovering<br />

machinery business. Incoming orders, sales, and earnings all<br />

improved.<br />

Our Ecocell 79W inline cleaning system once again testified to<br />

our innovative power in this area. Workpieces such as pump housings<br />

and valve blocks are automatically placed in vacuum-sealed<br />

cells, pre-cleaned in a submersion bath, further treated with ultrasound,<br />

and finally dried in a vacuum. This process achieves far<br />

higher quality of cleaning than other processes, in which the workpieces<br />

are merely sprayed clean. Another advantage is that the<br />

cleaning cells move in a circular path as opposed to conventional<br />

inline systems in which the individual treatment stages are<br />

arranged one after the other. This gives the Ecocell 79W a much<br />

smaller footprint than conventional machines.

Measuring <strong>Systems</strong><br />

Measuring <strong>Systems</strong> supplies high-precision plants and systems for measuring static and<br />

dynamic forces. We occupy leading positions both in balancing and diagnostics systems<br />

as well as in measuring and process systems. We serve a wide range of customers, which<br />

extends beyond the automotive sector to the basic materials, machinery, and mining<br />