ABW Sept 2020

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

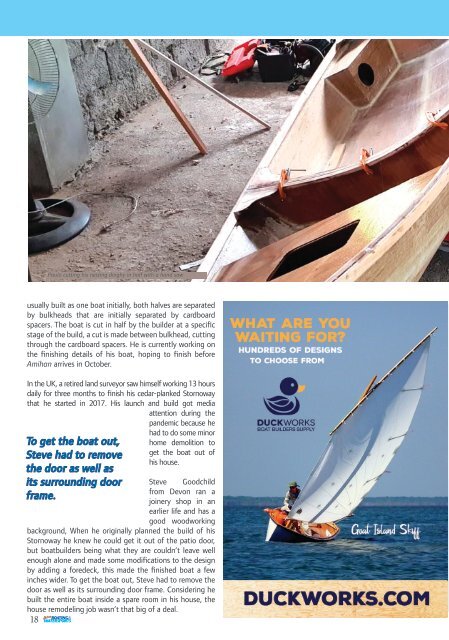

Paulo cutting his nesting dinghy in half with a hand saw<br />

usually built as one boat initially, both halves are separated<br />

by bulkheads that are initially separated by cardboard<br />

spacers. The boat is cut in half by the builder at a specific<br />

stage of the build, a cut is made between bulkhead, cutting<br />

through the cardboard spacers. He is currently working on<br />

the finishing details of his boat, hoping to finish before<br />

Amihan arrives in October.<br />

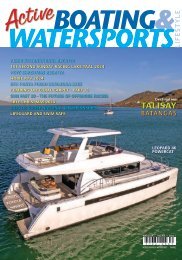

In the UK, a retired land surveyor saw himself working 13 hours<br />

daily for three months to finish his cedar-planked Stornoway<br />

that he started in 2017. His launch and build got media<br />

attention during the<br />

pandemic because he<br />

To get the boat out,<br />

Steve had to remove<br />

the door as well as<br />

its surrounding door<br />

frame.<br />

had to do some minor<br />

home demolition to<br />

get the boat out of<br />

his house.<br />

Steve Goodchild<br />

from Devon ran a<br />

joinery shop in an<br />

earlier life and has a<br />

good woodworking<br />

background, When he originally planned the build of his<br />

Stornoway he knew he could get it out of the patio door,<br />

but boatbuilders being what they are couldn’t leave well<br />

enough alone and made some modifications to the design<br />

by adding a foredeck, this made the finished boat a few<br />

inches wider. To get the boat out, Steve had to remove the<br />

door as well as its surrounding door frame. Considering he<br />

built the entire boat inside a spare room in his house, the<br />

house remodeling job wasn’t that big of a deal.<br />

18